$45

New Holland TC35A – TC45DA Service Repair Manual 87618714 – PDF DOWNLOAD

New Holland TC35A – TC45DA Service Repair Manual

FILE DETAILS:

New Holland TC35A – TC45DA Service Repair Manual

Size : 41.2 MB

Format : PDF

Language : English

Number of Pages : 1478 Pages

DESCRIPTION:

New Holland TC35A – TC45DA Service Repair Manual

GENERAL :

The TC35A, TC35DA, TC40A, TC40DA, TC45A and TC45DA tractors have been built using metric hardware. NOTE: Be sure to use the hardware specified when using tapped holes, as trying to install ametric bolt in an inch thread, or an inch bolt in a metric thread, will damage the thread. Certain hardware must be tightened to specific torque specifications. If specific torque specifications are not noted, tighten the hardware to the standard torque chart specification listed in this manual.

- PLATING :Hardware used on New Holland balers is plated with zinc chromate (gold color). Gold colored hardware has different torquing requirements from unplated or zinc plated (silver color) hardware because of the difference in the coefficient of friction of the plating material. The torque charts in this manual list the correct specifications for gold, silver, and unplated bolts.

- NUT TIGHTENING :Whenever possible, the nut should be tightened, not the head of the bolt. When tightening using the bolt head, the clamp load can be lost because some of the torque applied twists the bolt instead of tensioning (stretching) it. The tension on the bolt is what holds the joint together. Approximately 90% of the torque applied during assembly goes to overcoming friction between the parts. The other 10% is used to tension (stretch) the bolt. After assembly, the frictional forces disappear, which is the basis for the saying If it does not fail during assembly, it will not fail in service. The bolt may later fail due to other factors, but not from being over tightened.

- LOCKNUTS : Most locknuts are coated with a special lubricant that is dry to the touch. Anytime a locknut is used, a lower than normal torque is required. Refer to the torque charts in this manual for specific values.

- JAM NUTS: When using a jam nut to lock a regular nut, the jam nut should be installed first and tightened to one half the recommended torque, then held in place while installing a regular nut to the recommended torque.

- THREAD LUBRICATION :The addition of antiseize compound, Molykote, oil, graphite, or any other lubricant to a bolt decreases the friction between it and a nut. This makes it necessary to reduce the recommended torque to prevent over tensioning of the bolt. When using the torque charts in this manual, decrease the value by 20% whenever a lubricant is used.

TABLE OF CONTENTS:

New Holland TC35A – TC45DA Service Repair Manual

SECTION 00 – GENERAL INFORMATION 2

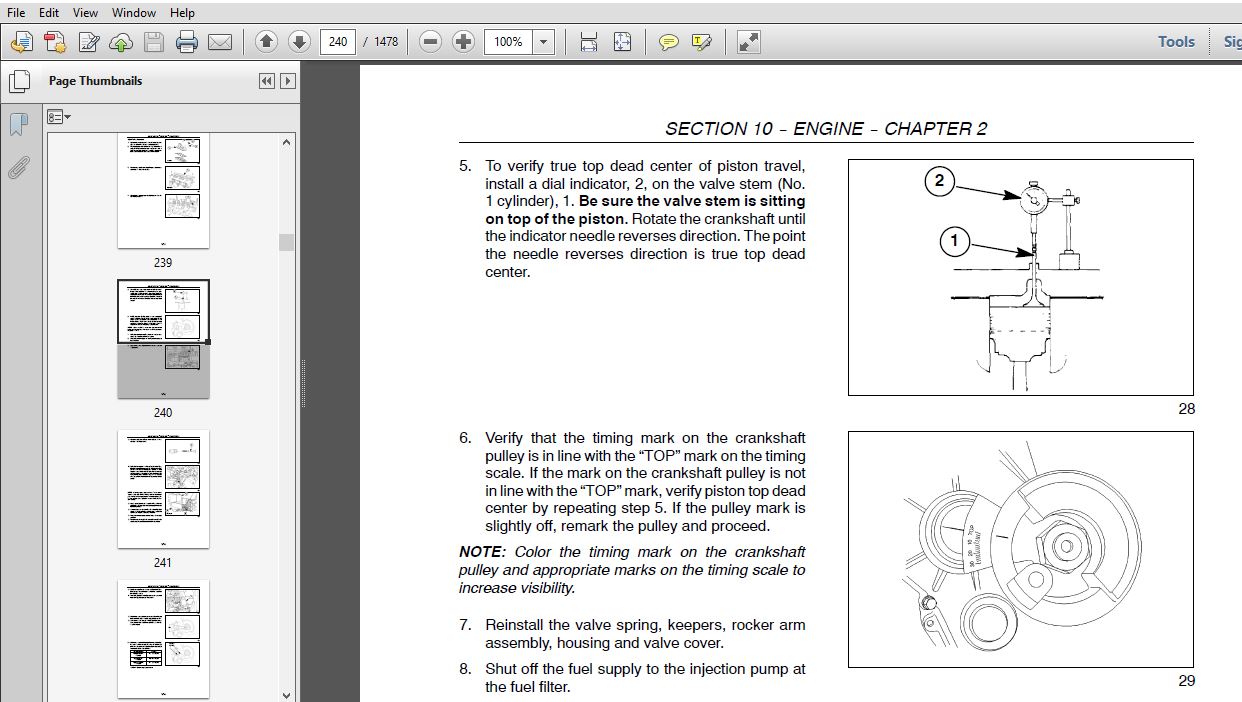

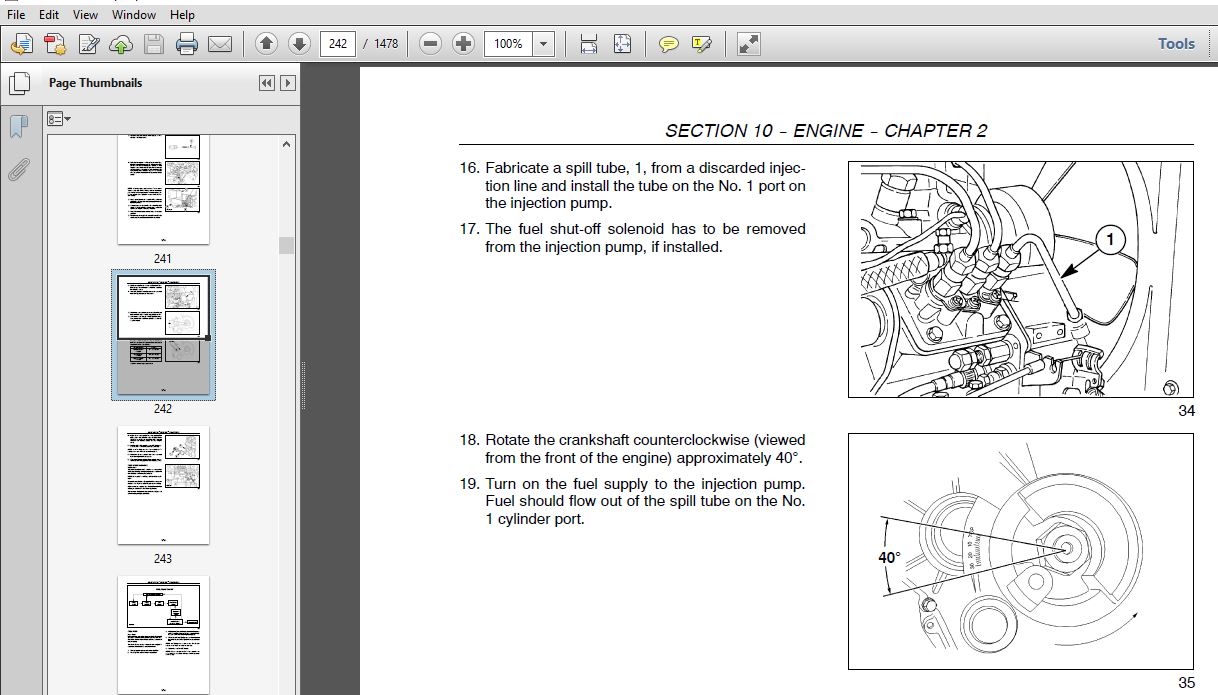

SECTION 10 – ENGINE 3

SECTION 18 – CLUTCH 10

SECTION 21 – TRANSMISSION12

SECTION 23 – DRIVELINE 14

SECTION 25 – FWD FRONT AXLE 15

SECTION 27 – DIFFERENTIAL, REAR AXLE 18

SECTION 29 – HYDROSTATIC TRANSMISSION19

SECTION 31 – POWER TAKE-OFF (PTO) SYSTEMS 22

SECTION 33 – BRAKES 25

SECTION 35 – HYDRAULIC SYSTEM25

SECTION 41 – STEERING29

SECTION 44 – 2WD FRONT AXLE 31

SECTION 50 – CLIMATE CONTROL 31

SECTION 55 – ELECTRICAL 35

SECTION 90 – PLATFORM 53

IMAGES PREVIEW OF THE MANUAL: