$45

New Holland TD5.65, TD5.75, TD5.85, TD5.95, TD5.105, TD5.115 Tractor Service Repair Manual

New Holland TD5.65, TD5.75, TD5.85, TD5.95, TD5.105, TD5.115 Tractor Service Repair Manual

FILE DETAILS:

New Holland TD5.65, TD5.75, TD5.85, TD5.95, TD5.105, TD5.115 Tractor Service Repair Manual

Size: 88.9 MB

Format: PDF

Language: English

Number of Pages : 1207 pages

Brand: New Holland

Type of document: Service Manual

Model: TD5.105, TD5.115, TD5.65, TD5.75, TD5.85, TD5.95

Part No: 47445474

DESCRIPTION:

New Holland TD5.65, TD5.75, TD5.85, TD5.95, TD5.105, TD5.115 Tractor Service Repair Manual

Note to the Owner:

General instructions

Important notice

All maintenance and repair operations described in this manual should be carried out exclusively by the NEW HOLLAND authorised workshops. All instructions detailed should be carefully observed and special equipment indicated should be used if necessary. Everyone who carries out service operations described without carefully observing these prescriptions will be directly responsible of deriving damages.

Shimming:

At each adjustment, select adjusting shims, measure them individually using a micrometer and then sum up recorded values. Do not rely on measuring the whole shimming set, which may be incorrect, or on rated value indicated for each shim.

Rotating shaft seals:

To correctly install rotating shaft seals, observe the following instructions:

• Let the seal soak into the same oil as it will seal for at least half an hour before mounting.

• Thoroughly clean the shaft and ensure that the shaft working surface is not damaged.

• Place the sealing lip towards the fluid. In case of a hydrodynamic lip, consider the shaft rotation direction and orient grooves in order that they deviate the fluid towards the inner side of the seal.

• Coat the sealing lip with a thin layer of lubricant (oil rather than grease) and fill with grease the gap between the sealing lip and the dust lip of double lip seals.

• Insert the seal into its seat and press it down using a flat punch. Do no tap the seal with a hammer or a drift.

• Take care to insert the seal perpendicularly to its seat while you are pressing it. Once the seal is settled, ensure that it contacts the thrust element if required.

• To prevent damaging the sealing lip against the shaft, place a suitable protection during installation.

O-rings:

Lubricate the O-rings before inserting them into their seats. This will prevent the O-rings from rolling over and twine during mounting which will jeopardise sealing.

Sealers:

Apply one of the following sealers: RTV SILMATE, RHODORSIL CAF 1, or LOCTITE PLASTIC GASKET over the mating surfaces marked with an X.

Before applying the sealer, prepare the surface as follows:

• Remove possible scales using a metal brush.

• Thoroughly degrease the surfaces using one of the following cleaning agent: trichlorethylene, petrol or a water and soda solution.

Bearings:

It is advisable to heat the bearings to 80 – 90 °C (176 – 194 °F) before mounting them on their shafts and cool them down before inserting them into their seats with external tapping.

TABLE OF CONTENTS:

New Holland TD5.65, TD5.75, TD5.85, TD5.95, TD5.105, TD5.115 Tractor Service Repair Manual

INTRODUCTION

Engine 10

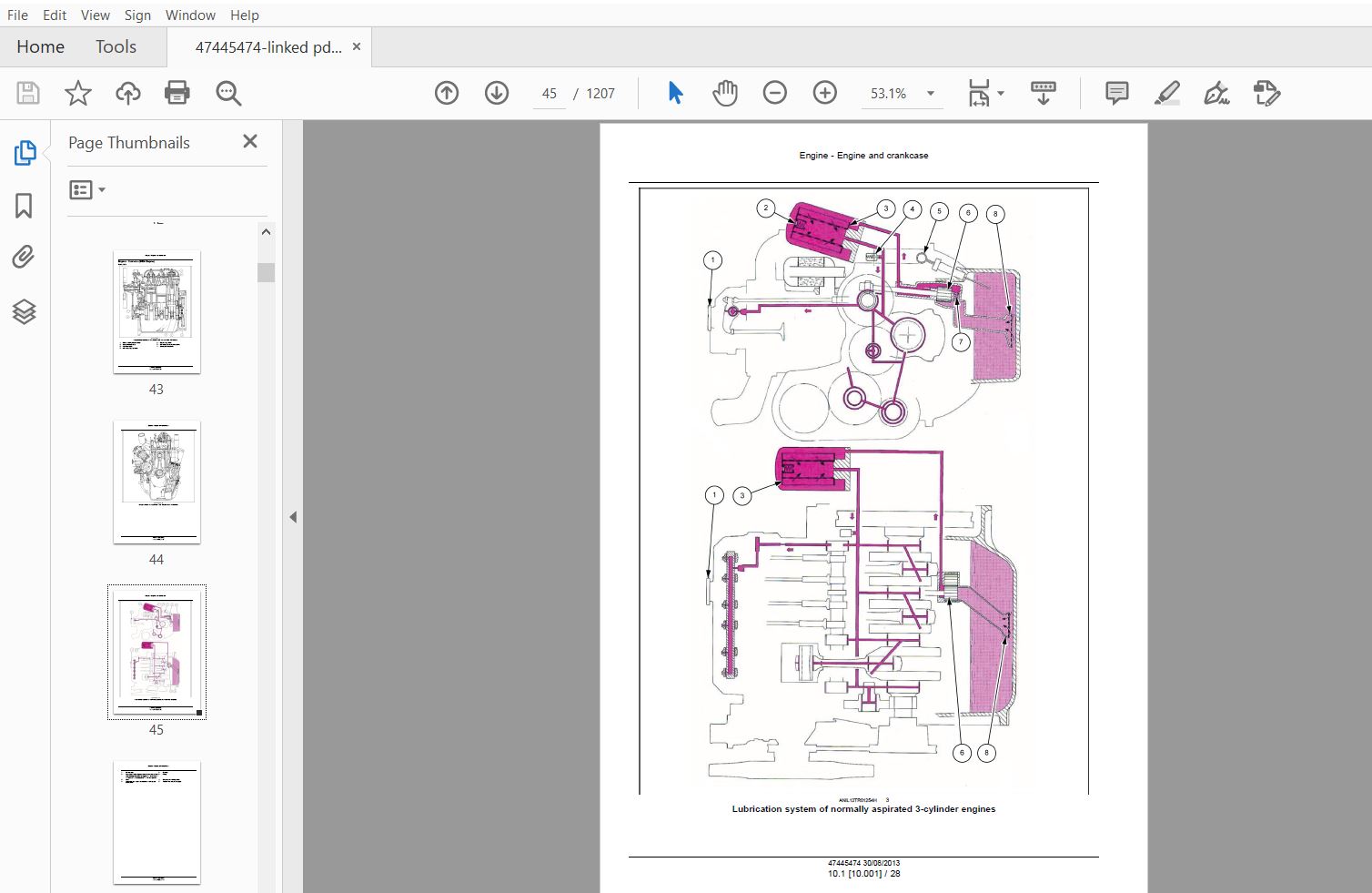

[10001] Engine and crankcase 101

[10106] Valve drive and gears102

[10103] Crankshaft and flywheel 103

[10218] Fuel injection system104

[10400] Engine cooling system 105

[10414] Fan and drive 106

Clutch 18

[18104] Clutch hydraulic release control 181

[18110] Clutch and components 182

Transmission 21

[21114] Mechanical transmission 211

[21140] Mechanical transmission internal components 212

[21112] Power shuttle transmission 213

[21120] Gearbox214

[21154] Power shuttle transmission internal components215

[21160] Creeper216

[21162] Reverser 217

Four-Wheel Drive (4WD) system 23

[23304] Four-Wheel Drive (4WD) gearbox 231

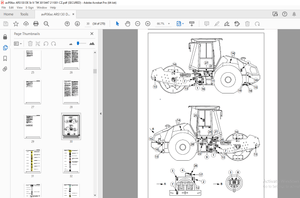

Front axle system 25

[25100] Powered front axle 251

[25102] Front bevel gear set and differential 252

[25108] Final drive hub, steering knuckles, and shafts 253

Rear axle system 27

47445474 30/08/2013

[27100] Powered rear axle 271

[27106] Rear bevel gear set and differential272

[27124] Final drive hub, steering knuckles, and shafts 273

Power Take-Off (PTO) 31

[31101] Rear mechanical control 311

Brakes and controls 33

[33AAA] Brakes and controls generic sub-group 331

[33202] Hydraulic service brakes 332

[33110] Parking brake or parking lock 333

[33220] Trailer brake hydraulic control 334

Hydraulic systems 35

[35000] Hydraulic systems 351

[35350] Safety and main relief valves 352

[35525] Auxiliary hydraulic valves and lines353

Steering 41

[41200] Hydraulic control components 411

[41206] Pump 412

[41216] Cylinders 413

Wheels 44

[44511] Front wheels 441

Cab climate control 50

[50100] Heating 501

[50200] Air conditioning 502

Electrical systems 55

[55000] Electrical system 551

[55100] Harnesses and connectors 552

[55201] Engine starting system 553

[55301] Alternator 554

47445474 30/08/2013

[55302] Battery 555

[55512] Cab controls 556

[55518] Wiper and washer system 557

[55408] Warning indicators, alarms, and instruments 558

Platform, cab, bodywork, and decals 90

[90150] Cab 901

[90151] Cab interior 902

[90154] Cab doors and hatches 903

[90105] Machine shields and guards904

IMAGES PREVIEW OF THE MANUAL: