$45

New Holland TL80A TL90A TL100A Tractor Service Repair Manual - PDF DOWNLOAD

New Holland TL80A TL90A TL100A Tractor Service Repair Manual

FILE DETAILS:

New Holland TL80A TL90A TL100A Tractor Service Repair Manual

Language : English

Pages : 1582

Downloadable : YES

Format : PDF

Part No : 87580875

DESCRIPTION:

New Holland TL80A TL90A TL100A Tractor Service Repair Manual

GENERAL INSTRUCTIONS:

IMPORTANT NOTICE:

All maintenance and repair work described in this manual must be performed exclusively by NEW HOLLAND service technicians, in strict accordance with the instructions given and using any specific tools necessary. Anyone performing the operations described herein without strictly following the instructions is personally responsible for any eventual injury or damage to property.

BATTERY:

Before carrying out any kind of service operations, disconnect and isolate the battery negative lead, unless other- wise requested for specific operations (e.g.: operations that require the engine running). Once the specific operation has been completed, disconnect the lead in order to complete the operation.

SHIMMING:

For each adjustment operation, select adjusting shims and measure individually using a micrometer, then add up the recorder values. Do not rely on measuring the entire shimming set, which may be incorrect, or the rated value indicated for each on shim.

ROTATING SHAFT SEALS:

For correct rotating shaft seal installation, proceed as follows:

— before assembly, allow the seal to soak in the oil it will be sealing for at least thirty minutes;

— thoroughly clean the shaft and check that the working surface on the shaft is not damaged;

— position the sealing lip facing the fluid; with hydrodynamic lips, take into consideration the shaft rotation direction and position the grooves so that they will deviate the fluid towards the inner side of the seal;

— coat the sealing lip with a thin layer of lubricant (use oil rather than grease) and fill the gap between the sealing lip and the dust lip on double lip seals with grease;

— insert the seal in its seat and press down using a flat punch, do not tap the seal with a hammer or mallet;

— whilst inserting the seal, check that the it is perpendicular to the seat; once settled, make sure that it makes contact with the thrust element, if required;

— to prevent damaging the seal lip on the shaft, position a protective guard during installation operations.

O–RING SEALS:

Lubricate the O–RING seals before inserting them in the seats, this will prevent them from overturning and twist-

ing, which would jeopardise sealing efficiency.

TABLE OF CONTENTS:

New Holland TL80A TL90A TL100A Tractor Service Repair Manual

Chapter 1 – General

CONTENTS

Section Description Page

General Instructions 3

Health and Safety 5

Precautionary Statements 15

Safety 16

Ecology and the Environment 19

Minimum Hardware Tightening Torques 20

Federal Emissions Warranty 22

Consumables 25

SECTION 10 — ENGINE

BOOK 1 – 87580876

Chapter 1 — Engine

CONTENTS

Operation Description Page

Specifications 3

Tightening Torques 9

Special Tools 11

Description and Operation 12

Sectional Views 12

Troubleshooting 17

Overhaul 21

10 001 10 Engine 21

Removal 21

Installation 39

Compression Test 41

Considerations 41

Uniform Compression 41

Low Compression Readings 41

3

SECTION 10 — ENGINE

BOOK 1 – 87580876

Chapter 1 — Engine (Continued)

CONTENTS

Operation Description Page

Disassembly 42

Crankshaft Front Seal Removal 45

Crankshaft Rear Seal Removal 47

Assembly 53

Bushings 53

Tappet 54

Camshaft 54

Oil Nozzle 55

Crankshaft 55

Connecting Rod and Piston 58

Installing the Piston Connecting Rod Assemblies in the Cylinder 59

Big End Cap Assembly 60

Thermostat Valve 61

Cylinder Head 61

Fuel Injectors 63

Rocker Arm Assembly 63

Timing Gear 64

Injection Pump 66

Counterweight and Balancer 66

Hydraulic Pump Drive Gear 67

Timing Gear Casing 68

Crankshaft Rear Seal 68

Flywheel 69

Oil Pump 70

Oil Sump 70

Crankshaft Front Seal 70

Crankshaft Front Pulley 70

Cooling System Union 71

Coolant Pump 71

Fan–Alternator Pulley 71

Auxiliary Drive Belt 73

4

SECTION 10 — ENGINE

BOOK 1 – 87580876

Chapter 1 — Engine (Continued)

CONTENTS

Operation Description Page

Exhaust Manifold — Turbocharger 73

Injector Feed Pipe 73

Priming Pump — Feed Pipe 73

Installing The Pipes Between The Fuel Supply and Injection Pumps,

Pre-Heating System and Tappet Cover 74

Starter Motor 75

Checks, Measurements and Repairs 76

Cylinder Block 76

Crankshaft 79

Main Crankshaft Tolerances 80

Connecting Rods 81

Pistons 83

Measuring the Piston Diameter 84

Piston Pins 84

Conditions for Correct Pin-piston Coupling 85

Piston Rings 85

Camshaft and Valves 87

Decarbonizing and grinding valves 87

Checking Valve Spring Flexibility 89

Tappets 89

Camshaft 90

Cylinder Head 91

Crankshaft Front Seal 92

Crankshaft Rear Seal 95

Valve Tappet and Rocker Arm 98

5

SECTION 10 — ENGINE

BOOK 1 – 87580876

Chapter 2 — Cooling System

CONTENTS

Operation Description Page

Specifications 2

Description of Operation 3

Radiator 3

Coolant Thermometer 3

Thermostat Valve 3

Sectional Views 4

Overhaul 5

10 402 10 Coolant Pump 5

Removal 5

Installation 6

10 402 30 Thermostat Valve 7

Removal 7

Installation 8

10 406 10 Radiator 9

Removal 9

Installation 14

10 414 10 Coolant Pump and Alternator Belts 15

Tension Adjustment 15

Polyvee Belt 15

SECTION 10 — ENGINE

BOOK 1 – 87580876

Chapter 3 — Lubrication System

CONTENTS

Operation Description Page

Specifications 2

Lubrication System Components 4

Oil Pressure Indicator 5

Oil Filter 6

Oil Pump 6

6

SECTION 10 — ENGINE

BOOK 1 – 87580876

Chapter 4 — Fuel System

CONTENTS

Operation Description Page

Specifications 2

Special Tools 4

Description and Operation 6

Turbocharged Engine 6

Manifold Pressure Compensator (LDA) 6

Description 6

Operation 7

All Models 8

Electrical Cold-start Accelerator (KKSB) 8

Overhaul 10

10 218 30 Fuel Injectors 10

Removal 10

Installation 12

10 246 14 BOSCH Fuel Injection Pump 13

Removal 13

Locking the Injection Pump 16

Timing the Fuel Injection Pump on a Workbench 18

Installation 21

Timing the Pump on the Tractor 21

7

SECTION 18 — CLUTCH

BOOK 1 – 87580876

Chapter 1 — Clutch

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 3

Special Tools 3

Description and Operation 4

Cross Sectional Views 4

Troubleshooting 5

Overhaul 6

Inspection and Adjustment 6

12″/12″ Dual Clutch 6

18 100 40 Clutch Pedal 8

18 110 10 12″/12″ Dual Clutch 9

Removal 9

Installation 10

Disassembly 12

Assembly 15

Adjust Release Levers 16

Single Disk Clutch 17

Inspection 17

8

SECTION 21 — TRANSMISSIONS

BOOK 2 – 87053392

Chapter 1 — 12 x 12 Synchro Command Mechanical

Shuttle Transmission

(TL80A, TL90A, TL100A Standard Models)

CONTENTS

Operation Description Page

12 x 12 Synchro Command Mechanical Shuttle Transmission 3

SECTION 21 — TRANSMISSIONS

BOOK 2 – 87053392

Chapter 2 — Reverser

(12 x 12 Mechanical Shuttle Transmissions)

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 3

Special Tools 4

Description and Operation 4

Cross-Sectional Views 4

Troubleshooting 6

Overhaul 7

21 110 85 Clutch-Reverser Casing 7

Removal 7

Disassembly 7

Assembly 10

Installation 10

9

SECTION 21 — TRANSMISSIONS

BOOK 2 – 87053392

Chapter 3 — Reverser and Creeper Unit for 20 x 12

Mechanical Shuttle Transmission

(Optional for TL80A, TL90A Standard and all Deluxe Models)

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 3

Special Tools 4

Description and Operation 6

Cross-Sectional Views 6

Troubleshooting 8

Overhaul 9

21 110 87 Reverser-Clutch Casing and Creeper Unit 9

Removal 9

Disassembly 9

Assembly 13

Installation 14

10

SECTION 21 — TRANSMISSIONS

BOOK 2 – 87053392

Chapter 4 — 24 x 24 Dual Command Power Shuttle

(TL80A, TL90A, TL100A Deluxe Models)

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 4

Special Tools 6

Description and Operation 8

Cross-Sectional Views 8

Overhaul 18

21 110 88 Clutch Casing with Power Shuttle and Dual Command 18

Removal 18

Disassembly 18

Assembly 24

Installation 24

21 154 60 Clutch (A) 25

Disassembly 25

Assembly 27

Installing on Clutch Casing 28

21 154 60 Clutch (B) 30

Disassembly — Assembly 30

11

SECTION 23 — FWD TRANSFER BOX

BOOK 2 – 87053392

Chapter 1 — FWD Transfer Box

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 3

Special Tools 4

Description and Operation 5

Cross-Sectional Views 5

Electro-Hydraulic Four Wheel Drive (FWD) 7

Troubleshooting 8

Overhaul 9

23 202 20 Services Control Valve 9

Removal 9

Installation 11

Disassembly 12

Assembly 13

23 202 50 Drive Gear 14

Removal 14

Installation 18

23 202 52 Drive Gear Housing 19

Removal 19

Installation 22

12

SECTION 25 — FRONT AXLE MECHANICAL TRANSMISSION

BOOK 2 – 87053392

Chapter 1 — Front Axle Mechanical Transmission

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 4

Special Tools 6

Description and Operation 9

Cross-Sectional Views 9

Limited-Slip Self-Locking Differential 12

Front Differential Lock 13

Troubleshooting 14

Overhaul 15

25 100 30 Front Axle 15

Removal 15

Installation 18

Correctly Installing Axle Support to the Engine 19

Disassembly 20

Assembly 28

25 102 24 Front Axle Differential 29

Backlash Between Side and Planetary Pinion Teeth 29

25 102 27 Front Axle Differential with Limited-Slip Unit 30

Removal 30

Disassembly 31

Assembly 31

Installation 31

25 104 34 Front Differential Lock Clutch Assembly 32

Disassembly 32

Assembly 33

25 108 30 Front Epicyclic Final Drive 34

Removal 34

Installation 35

Wheel Hub Seal Replacement 37

25 108 46 Steering Knuckle Pins and Bearings Replacement 38

Adjustments 39

Stub Axle 39

Pinion 41

Differential 45

13

SECTION 27 — REAR AXLE MECHANICAL TRANSMISSION

BOOK 2 – 87053392

Chapter 1 — Rear Axle Mechanical Transmission

CONTENTS

Operation Description Page

Specifications 2

Drive and Differential Data 2

Final Drive Data 3

Tightening Torques 3

Special Tools 5

Description and Operation 10

Sectional Views 10

Hydraulically Controlled Rear Differential Lock 14

Troubleshooting 15

Drive and Differential 15

Final Drive 15

Differential Lock 16

Overhaul 17

21 118 12 Rear Gearbox — Transmission Casing 17

Removal 17

Installation 36

Disassembly 39

Assembly, Adjustment, Installation 47

Final Drive Casing 59

Removal 59

Installation 61

Epicyclic Final Drive 62

Disassembly 62

Assembly 62

27 120 34 Drive Wheel Shaft 63

Disassembly 63

Assembly 64

14

SECTION 31 — POWER TAKE-OFF

BOOK 3 – 87580877

Chapter 1 — Mechanical Power Take-Off

CONTENTS

Operation Description Page

Specifications 2

Special Tools 4

Tightening Torques 5

Description and Operation 6

Sectional Views 6

Mechanically Operated PTO 8

Troubleshooting 10

Overhaul 11

31 112 20 Power Take-Off Housing 11

Removal 11

Installation 13

31 112 45 Power Take-Off Shafts 14

Disassembly 14

Assembly 16

15

SECTION 31 — POWER TAKE-OFF

BOOK 3 – 87580877

Chapter 2 — Electro-Hydraulic Power Take-Off

CONTENTS

Operation Description Page

Specification 2

Special Tools 4

Tightening Torques 5

Description and Operation 6

Sectional Views 6

Electro-Hydraulic PTO 10

PTO Engagement 11

Troubleshooting 18

Overhaul 19

31 114 64 PTO Clutch Brake 19

Removal 19

Installation 21

31 116 21 PTO Housing 22

Removal 22

Installation 25

Disassembly 26

Assembly 32

16

SECTION 33 — BRAKES

BOOK 3 – 87580877

Chapter 1 — Brakes

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 3

Description of Operation 4

Sectional Views 4

Troubleshooting 7

Overhaul 8

33 110 08 Handbrake Lever 8

Adjustment 8

Parking Brake Housing 9

Removal 9

Disassembly 9

Assembly 11

Installation 11

33 202 04 Brake System Bleeding 12

33 202 46 Brake Pump 13

Removal 13

Installation 14

Adjustment of Pedal Travel 14

33 202 60 Brake Units 15

Removal 15

Installation 18

17

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 1 — Hydraulic System Description

CONTENTS

Operation Description Page

Specifications 2

Precautionary Statements 3

Description and Operation 4

Power Steering and Lift Pump Components 4

Hydraulic System Configurations 5

Hydraulic System — General Description 6

Hydraulic Power Lift (HPL) Control 7

Rear Auxiliary (Remote) Control Valves 11

Rear Remote Valve Arrangement 12

Mid-Mount Control Remote Control Valves 13

Auxiliary Control Valve Oil Flow 14

18

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 2 — Mechanically Operated Hydraulic Power Lift (HPL)

CONTENTS

Operation Description Page

Specifications 2

Torque Valves 4

Sectional Views 7

Special Tools 6

Troubleshooting 9

Description and Operation 10

Hydraulic Power Lift (HPL) Control Valve Oil Flow 10

Lower Phase 10

Neutral Phase 12

Lift Phase 14

Overhaul 16

HPL Cover 16

Removal 16

Disassembly 20

Assembly 24

Adjusting the HPL on a Workbench 26

Adjusting the HPL on the Tractor 39

Fast Raise/Lower Control Upper Stroke Limit 42

HPL Control Valve 43

Removal 43

Disassembly 45

Assembly 49

Installation 50

HPL Pump Seals 51

Lift Pressure Relief Valve 52

19

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 3 — KONTAK Auxiliary Control Valves

(TLA Standard Models)

CONTENTS

Operation Description Page

Sectional Views 2

Description and Operation 4

Kontak Remote Valve Oil Flow 5

Double-Acting Raise Position 5

Double-Acting Lower Position 5

Single-Acting Raise Position 6

Single-Acting Lower Position 6

Kontak Remote Valve With Detent Release and Float Oil Flow 7

Double-Acting Raise Position 7

Double-Acting Lower Position 7

Double-Acting Float Position 8

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 4 — BOSCH Auxiliary Control Valves

(TLA Deluxe Models)

CONTENTS

Operation Description Page

Sectional Views 2

Description and Operation 5

Bosch Closed-Center Remote Control Valves With Open-Center Pump 5

Bosch Remote Valve With Detent (Non-Adjustable), Float, and Flow Control Oil Flow 6

Neutral Position 7

Raise Position 7

Lower Position 8

Float Position 8

35 204 40 BOSCH Remote Valves 9

Removal 9

Disassembly 11

Assembly 15

Installation 17

20

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 5 — Kontak Mid-Mount Auxiliary Control Valves

CONTENTS

Operation Description Page

Sectional Views 2

Torque Values 4

Description and Operation 5

Kontak Mid-Mount Remote Valve Oil Flow 5

35 204 46 Flow Control Valve 7

Disassembly 7

Assembly 9

35 204 46 Mid-Mount Remote Valves 11

Disassembly 11

Assembly 11

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 6 — Low Pressure Hydraulic System

CONTENTS

Operation Description Page

Low-Pressure, Steering and Lubrication Circuit 2

Description and Operation 2

Low Pressure Circuit Hydraulic Pump 2

Power Shuttle Transmissions with Dual Command 3

Services Control Valve (Models with Power Shuttle Transmission) 4

Services Control Valve (Models with Mechanical Shuttle Transmission) 4

Lubrication Oil Flow on TLA Models with Power Shuttle Transmission

and Dual Command 5

Oil Flow 6

12×12 Synchro Command Mechanical Shuttle Transmission on TL80A,

TL90A and TL100A Standard Models 6

24×24 Dual Command Power Shuttle Transmission on TL80A,

TL90A and TL100A Deluxe Models 7

Rear Differential Lock (Hydraulic Control) on all TL80A, TL90A and TL100A

Deluxe Models and on Standard Models with FWD 8

Front Differential Lock (Hydraulic Control) on TL80A, TL90A and TL100A

Deluxe Models with FWD 10

Electro-Hydraulically Disengaged Four-Wheel Drive (FWD) — All Models 11

Power Take-Off [Electro-Hydraulic Engagement] (TLA Deluxe models) 12

21

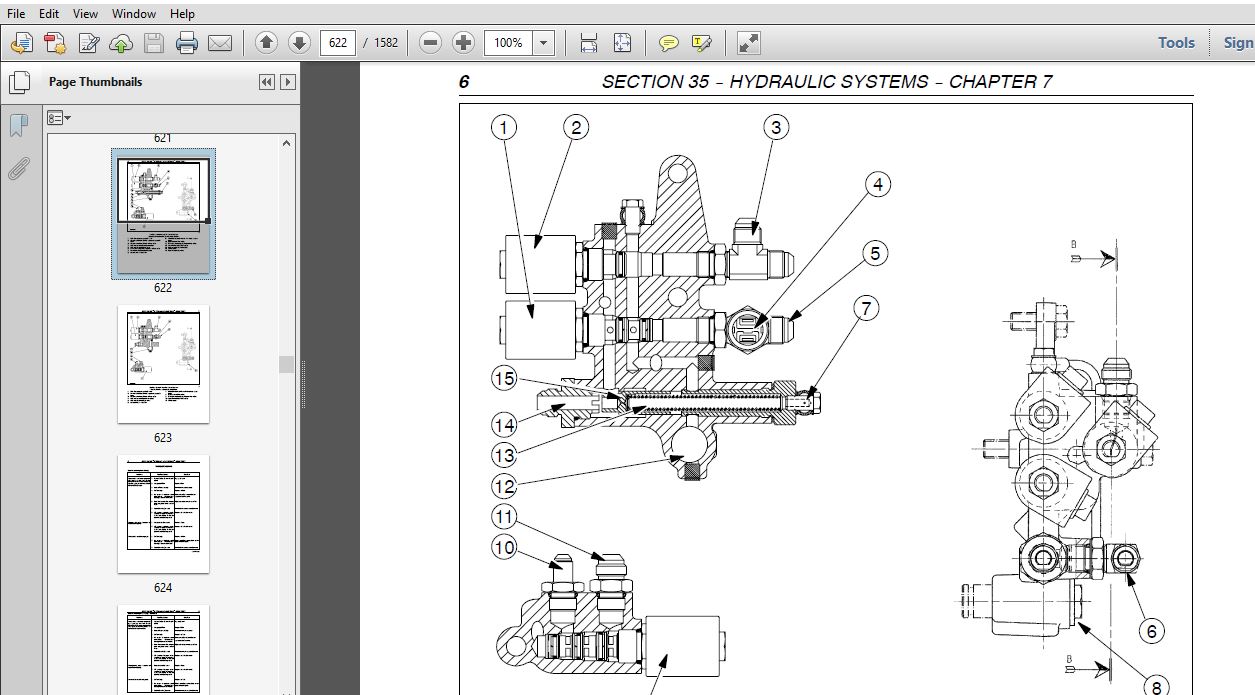

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 7 — Low-Pressure Hydraulic System Overhaul

CONTENTS

Operation Description Page

Specifications 2

Sectional Views 5

Troubleshooting 8

Overhaul 12

23 202 20 Services Control Valve 12

Removal 12

Disassembly 14

Assembly 16

Installation 16

22

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 8 — Hydraulic System Testing

CONTENTS

Operation Description Page

Precautionary Statements 2

Special Tools 3

Test Procedures 6

Dual Command Clutch Pack Operating Pressure (Power Shuttle Transmission) 6

Low-pressure System Relief Valve Setting (Power Shuttle Transmission) 6

Low-pressure System Relief Valve Setting (Mechanical Shuttle Transmission) 7

Transmission Lubrication Relief Valve Setting (Power Shuttle Transmission) 8

Transmission Lubrication Relief Valve Setting (Mechanical Shuttle Transmission) 9

Steering System Relief Valve Setting (FWD or 2WD) 10

Steering System Pump Oil Flow 11

High-pressure System Relief Valve Setting 11

High-Pressure System Pump Oil Flow 12

PTO Clutch Pack Operating Pressure 13

PTO Clutch Brake Operating Pressure 14

PTO Clutch Lubrication Relief Valve Setting (Power Shuttle Transmission) 15

PTO Clutch Lubrication Relief Valve Setting (Mechanical Shuttle Transmission) 16

FWD Disengagement Pressure (Power Shuttle Transmission) 17

FWD Disengagement Pressure (Mechanical Shuttle Transmission) 17

Differential Lock Engagement Pressure (Power Shuttle Transmission) 18

Differential Lock Engagement Pressure (Mechanical Shuttle Transmission) 18

23

SECTION 35 — HYDRAULIC SYSTEMS

BOOK 3 – 87580877

Chapter 9 — Walvoil Open-Center Mid-Mount Control Valves

(For Models with Serial Number HJS026057 and Above)

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 3

Sectional Views 4

Walvoil Mid-mount Valve Stack 4

Walvoil Mid-mount Components 5

Description of Operation 6

Joystick Control 6

Regenerative Lock-out Function 8

Control Valve Circuit 9

Hydraulic Diagram 10

2nd Control Valve 11

Operation in the Neutral Phase (Figure 11) 12

1st Control Valve 13

Operation in the Neutral Phase (Figure 12) 14

1st and 2nd Control Valves 15

Operation in the Neutral Phase (Figure 13) 16

1st Control Valve Operation 17

Lowering Phase 17

Float Phase 17

Lifting Phase 17

2nd Control Valve Operation 18

Lifting Phase 18

Regenerative Phase 18

Lowering Phase 18

1st and 2nd Control Valve Operation 19

24

SECTION 41 — STEERING

BOOK 4 – 87580878

Chapter 1 — Hydrostatic Power Steering

CONTENTS

Operation Description Page

Specifications 2

Tightening Torques 4

Troubleshooting 5

Special Tools 6

Component List 7

Description and Operation 8

Hydrostatic Power Steering (2WD) 8

Hydrostatic Power Steering (FWD) 10

Operation 12

Steering Right 12

Steering Left 12

Manual Steering to Right 12

Manual Steering to Left 12

Overhaul 13

41 204 30 Power Steering Control Valve 13

Removal 13

Installation 17

41 204 34 Disassembly 18

Assembly 23

41 216 10 Power Steering Cylinder(s) (FWD) 32

Removal 32

Installation 32

41 216 20 Power Steering Cylinder (2WD) 33

Removal 33

Installation 34

41 206 10 Power Steering Pump 35

Disassembly 35

Assembly 35

Testing the Steering System 36

Steering Control Valve 36

Checking Rotating Valve Wear 36

Checking Control Valve Return to Neutral 37

Checking the Seals for Leaks 37

Pressure Relief Valve 37

25

SECTION 44 — AXLES AND WHEELS

BOOK 4 – 87580878

Chapter 1 — Axles and Wheels

CONTENTS

Operation Description Page

Specifications 2

Description and Operation 4

Cross-Sectional Views 4

Tightening Torques 5

Special Tools 6

Troubleshooting 6

Overhaul 7

44 101 22 Front Axle Hub 7

Removal 7

Installation 9

44 101 30 Front Axle 10

Removal 10

Installation 12

44 101 46 Stub Axle 13

Removal 13

Installation 15

44 511 80 Adjustments 16

Checking Front Wheel Toe-In 16

Checking FWD Front Wheel Toe-In 17

26

SECTION 50 — AUXILIARY UNITS

BOOK 4 – 87580878

Chapter 1 — Auxiliary Units

CONTENTS

Operation Description Page

Safety Precautions 3

Specifications 4

Special Tools 5

Description and Operation 6

Main Components 8

Sanden SD 7H15 Model Compressor 8

Condenser 9

Filter/Dryer 9

Thermostatic Expansion Valve 10

Electronic Thermostatic Switch (Antifrost) 11

Evaporator 12

Warnings for Air Conditioning System Repair Operations 12

Cab Heating and Ventilation Controls 13

Ventilation 13

Electric Fan 13

Air Filter 13

Temperature Control Knob 14

Ignition Switch 14

Cab Air Conditioning Controls 15

Temperature Control Knob 15

Electric Fan Control Knob 15

Operation 16

Recovery, Recycling, Evacuation, Charging Station (380000315) 16

Description 16

Leak Detector (380000314) 17

Description and Operation 17

Maintenance 17

Air Conditioning System Maintenance 18

Compressor 18

Condenser 18

Filter/Dryer 18

Expansion Valve 18

27

SECTION 50 — AUXILIARY UNITS

BOOK 4 – 87580878

Chapter 1 — Auxiliary Units (Continued)

CONTENTS

Operation Description Page

Troubleshooting 19

Visual Inspection of Components 19

Problems and Possible Causes 20

Functional Tests 24

Checking Air Temperature 24

Checking for Gas Leaks (with Detector 38000314) 25

50 200 10 Compressor Drive Belt 26

Compressor Drive Belt Tension 26

Inspecting the Belt 26

Overhaul 27

50 200 26 Air Conditioner Compressor 27

Removal 27

Installation 29

Compressor Oil — Type and Quantity 29

50 200 40 Heating Pipes 30

Removal 30

Installation 31

50 200 60 Air Conditioner Pipes 32

Removal 32

Installation 37

50 200 72 Air Conditioner Condenser 38

Removal 38

Installation 38

50 200 74 Filter/Dryer 39

Removal 39

Installation 40

50 206 50 Cab Heating Unit 41

Removal 41

Installation 43

50 206 56 Air Conditioner Evaporator 44

Removal 44

Installation 46

50 206 66 Electric Fan 47

Removal 47

Installation 48

28

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 4 – 87580878

Chapter 1 — Instruments

CONTENTS

Section Description Page

55418 Control panel 2

Indicator Lights 2

Analog/Digital Instruments 4

Instruments 4

Liquid Crystal Displays 5

Central Display 6

Advanced Keypad 10

Transmitters, Sensors and Switches 12

Maintenance 20

29

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 4 – 87580878

Chapter 2 — Components

CONTENTS

Section Description Page

General Information 2

Description and Operation 2

Dashboard Controls 2

Lights/horn Switch 3

Direction Indicators 3

Tail/Side Lights, Full Beam, Dipped Beam And Front Headlight Flash 3

Horn 3

Flashing Hazard Warning Lights Switch 4

Swivel Work Lights Switch 4

Differential Lock Switch 4

Four-wheel Drive Switch (version without cab) 5

Starter Switch 5

Advanced Keypad 6

Instrument Calibration Switch (version without advanced keypad) 8

Front Windscreen Washer/Wiper Control Lever (models without cab) 8

Right-hand Mudguard Controls (With Cab) 9

LIFT-O-MATIC Control Button 9

Gear Lever with Dual Command Push-buttons 9

Right-hand Mudguard Controls (Without Cab) 10

Controls on Right-hand Cab Upright 10

Lighting Control Switches 10

Rear Work Lights Control Switch 10

Windscreen Wiper/Washer Switch 11

Electrohydraulic PTO Control Switch (version with cab) 11

Rotating Beacon Light ON/OFF Switch 11

Front Work Lights Control Switch 11

Air Conditioning and Temperature Control 12

Air Conditioning Control Knob 12

Temperature Control Knob 12

Electric Fan Control Knob 12

Bulb Replacement 13

Front Work Lights Lamp 13

Front Sidelight and Direction Indicator Lamp 13

Work Lights Lamp Bulb 14

Front Side Light, Brake and Direction Indicator Lamp 14

30

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 4 – 87580878

Chapter 3 — Starting System

CONTENTS

Section Description Page

Specifications 2

Tightening Torques 2

Description and Operation 2

Fault Diagnosis 6

System Testing 7

Starting System Circuit Resistance (Voltage Drop) 8

Overhaul 9

Starter Motor 9

Removal 9

Installation 9

Disassembly 10

Assembly 11

Testing 12

31

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 4 – 87580878

Chapter 4 — Charging System

CONTENTS

Section Description Page

Specifications 2

Tightening Torques 2

Description and Operation 2

Charging System Testing 4

Precautions 4

Preliminary Checks 4

Battery Check 4

Driving Belt Check 5

Checking the Warning Lights on the Control Panel 5

Tests 5

Alternator Wire Connection 6

Charging Current and Regulated Voltage 6

Charging Circuit Voltage Drop 7

Maximum Alternator Output 8

Alternator Component Tests 9

Overhaul 10

Alternator 10

Removal 10

Disassembly 15

Assembly 17

Installation 18

32

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 4 – 87580878

Chapter 5 — Battery

CONTENTS

Section Description Page

Specifications 2

Description and operation 2

Overhaul 3

Battery 3

Removal 3

Installation 4

Battery Testing 5

Relative Density 5

Battery Maintenance 5

Dry-Charged Batteries 6

Charging the Battery 6

Tests 7

Battery Problems — Causes 9

33

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 5 – 87053395

Chapter 6 — Electrical Circuits

CONTENTS

Section Description Page

Description and Operation 3

Fuse and Relay Layout 3

Standard Deluxe with Mechanical Shuttle Transmission/Without Cab 3

Deluxe with Power Shuttle Transmission/Without Cab 11

Standard/Deluxe with Mechanical Shuttle Transmission/With Cab 15

Deluxe with Power Shuttle Transmission/With Cab 19

Power Sockets 23

Operator Safety Circuit 24

Grid Heater Relay 25

Grid Heater Control Module 25

Electronic Flasher Module 25

Ground Location Points 26

Symbols Used In Electrical Circuits 28

Wire Color Coding 29

Electrical Circuits 30

34

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 5 – 87053395

Chapter 7 — Components Testing

CONTENTS

Operation Description Page

Components 2

Differential Lock Indicator Switch (66) 2

Brake Fluid Level Switch (18) 3

Low Transmission Oil Pressure Switch (83) 3

Air Filter Clogged Switch (12) 3

Lift Status Switch (127) 3

Fuel Sediment Filter Switch (4) 4

Engine Coolant Temperature Sensor (2) 5

Brake Light Switch (16) 5

Safety Pressure Switches / Italia Trailer Brake Valve Circuit Indicator (54) 5

Handbrake Status Switch (25) 6

Dual Command (2 Speed Power Shift) Switches (76) 7

Gear/Range Lever Position Sensors (139–140–141) 8

Alternator (87) 9

Engine Oil Pressure Sensor (82) 10

Speed Sensors (68–162) 10

Speed Sensor for Electronic Lift (162) 10

Power Shuttle Control Unit Ground Speed Sensor (68) 10

Switch (126) and Clutch Pedal Potentiometer (129) 11

Power Shuttle A/B Clutch Pressure Switches (132–133) and Oil Temperature

Sensor (138) 12

Power Shuttle Lever (130) 13

Radar (123) 14

Fuel Level Indicator (67) 14

4WD Pressure Switch (70) 14

PTO Speed Sensor (62) 15

Seat Safety Switch (97) 16

Electronic Lift Arm Position Potentiometer (145) 16

Draft Pin Sensors (119–120) 16

Overhaul 17

55 518 52 Front Wiper Motor 17

Removal 17

Installation 17

35

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 6 – 87053396

Chapter 8 — Fault Codes

CONTENTS

Operation Description Page

Introduction 2

Special Tools 3

Wiring Harness Repairs 3

Temporary Wiring Harness Repair 3

Harness Wire Replacement 5

Testing 6

Digital Multi-Meter 6

Electrical Tests 9

Continuity Test – Short to Ground 9

Voltage Measurement or Short to Positive Supply Volts 10

Resistance Test for Electrical Parts 10

Continuity Test – Check for Open Circuits 11

Circuit Components 12

Circuit Protection Devices 12

Fuses 12

Fuse Links 12

Circuit Control Devices 13

Switches 13

Flashers 14

Diodes 14

Resistance Devices 14

Potentiometers 14

Electromagnetic Devices 15

Relays 15

Solenoids 16

PWM Solenoid Valves 17

Sensors 19

Electronic Modules 21

Controller Area Network (CAN) System 22

Controller Locations 22

Fault Code Displays 23

H-Menu Diagnostic Mode 25

36

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 6 – 87053396

Chapter 8 — Fault Codes (Continued)

CONTENTS

Operation Description Page

Error Code Listing 26

Transmission 26

Rear Power Take-Off (PTO) 28

Four Wheel Drive (FWD) 29

Differential Lock 30

Analogue Digital Instrument Cluster (ADIC) 31

Electronic Draft Control (EDC) not in North America 32

Calibration U-Codes 33

Transmission Error Code Listing 37

Rear Power Take-Off (PTO) Error Code Listing 239

Four Wheel Drive Error Code Listing 257

Differential Lock Error Code Listing 267

Analogue Digital Instrument Cluster (ADIC) Error Code Listing 281

Electronic Draft Control (EDC) Error Code Listing 349

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 7 – 87053397

Chapter 9 — HH Menu and Calibrations

CONTENTS

Section Description Page

Description and Operation 2

Instrument Panel Display 2

Calibrations 2

HH MENU Access 3

HH MENU of the Instrument Panel 4

HH MENU of the Dual Command Power Shuttle Transmission (PA) 11

HH MENU of the Advanced Keypad (JB) 24

37

SECTION 55 — ELECTRICAL SYSTEMS

BOOK 7 – 87053397

Chapter 10 — CAN Bus Network

CONTENTS

Section Description Page

Description and Operation 2

Terminology 2

Troubleshooting 6

Testing 7

Repair 12

SECTION 90 — CAB, PLATFORM, AND BODYWORK

BOOK 7 – 87053397

Chapter 1 — Removal of Components

CONTENTS

Operation Description Page

Special Tools 3

Overhaul 4

90 100 22 Engine Hood 4

Removal 4

Installation 5

90 110 36 Platform 6

Removal 6

Installation 13

90 120 10 Operators Seat 14

Removal 14

Installation 14

90 150 10 Cab 15

Removal 15

Installation 26

90 154 10 Cab Doors 28

Removal 28

Installation 28

38

SECTION 90 — CAB, PLATFORM, AND BODYWORK

BOOK 7 – 87053397

Chapter 1 — Removal of Components (Continued)

CONTENTS

Operation Description Page

90 156 10 Cab Windows (Glued) 29

Removal 29

Installation 30

90 156 52 Cab Rear Window 31

Removal 31

Installation 33

90 160 16 Left-Hand Pillar Seal 34

Removal 34

Installation 34

90 160 16 Right-Hand Pillar Seal 35

Removal 35

Installation 36

90 160 42 Right-Hand Wall Padding 37

Removal 37

Installation 39

90 160 43 Left-Hand Wall Padding 40

Removal 40

Installation 41

90 160 50 Hydraulic Control Lever Guard 42

Removal 42

Installation 43

90 160 60 Cab Ceiling Trim 44

Removal 44

VIDEO PREVIEW OF THE MANUAL:

IMAGES PREVIEW OF THE MANUAL: