$45

New Holland Tractor T4_75 PowerStar Tier 4B (final) Service Manual_47711469

New Holland Tractor T4.75 Power Star Tier 4B (final) Service Manual

FILE DETAILS:

New Holland Tractor T4.75 Power Star Tier 4B (final) Service Manual

Size: 95.1 MB

Format: PDF

Language: English

Number of Pages: 1938 pages

Brand: New Holland

Type of document: Service Manual

Model: T4_75 PowerStar Tier 4B

Part No: 47711469

DESCRIPTION:

New Holland Tractor T4.75 Power Star Tier 4B (final) Service Manual

Safety rules SAFETY REGULATIONS:

TO PREVENT ACCIDENTS:

Most accidents or injuries that occur in workshops are the result of non–observance of simple and fundamental safety regulations. For this reason, IN MOST CASES THESE ACCIDENTS CAN BE AVOIDED: by foreseeing possible causes and consequently acting with the necessary caution and care. Accidents may occur with all types of vehicle, regardless of how well it was designed and built. A careful and judicious service technician is the best guarantee against accidents. Precise observance of the most basic safety rule is normally sufficient to avoid many serious accidents.

GENERAL:

• Carefully follow specified repair and maintenance procedures.

• Do not wear rings, wristwatches, jewellery, unbuttoned or loose articles of clothing such as: ties, torn clothing, scarves, open jackets or shirts with open zips that may remain entangled in moving parts. It is advised to wear approved safety clothing, e.g: non–slip footwear, gloves, safety goggles, helmets, etc.

• Do not carry out repair operations with someone sitting in the driver’s seat, unless the person is a trained technician who is assisting with the operation in question.

• Operate the vehicle and use the implements exclusively from the driver’s seat.

• Do not carry out operations on the vehicle with the engine running, unless specifically indicated.

• Stop the engine and ensure that all pressure is relieved from hydraulic circuits before removing caps, covers, valves, etc.

• All repair and maintenance operations must be carried out using extreme care and attention.

• Service steps and platforms used in a workshop or in the field should be built in compliance with the safety rules in force.

• Disconnect the batteries and label all controls to indicate that the vehicle is being serviced. Block the machine and all equipment which should be raised.

• Do not check or fill fuel tanks, accumulator batteries, nor use starting liquid when smoking or near naked flames, as these fluids are inflammable.

• Brakes are inoperative if manually released for repair or maintenance purposes. In such cases, the machine should be kept constantly under control using blocks or similar devices.

• The fuel nozzle should always be in contact with the filling aperture. Maintain this position until filling operations are completed in order to avoid possible sparks caused by the accumulation of static electricity.

• Only use specified towing points for towing the tractor, connect parts carefully.Make sure that all pins and/or locks are secured in position before applying traction. Never remain near the towing bars, cables or chains that are operating under load

• Transport vehicles that cannot be driven using a trailer or a low–loading platform trolley, if available.

• When loading or unloading the vehicle from the trailer (or other means of transport), select a flat area capable of sustaining the trailer or truck wheels, firmly secure the tractor to the truck or trailer and lock the wheels in the position.

• Electric heaters, battery–chargers and similar equipment must only be powered by auxiliary power supplies with efficient ground insulation to avoid electrical shock hazards.

• Always use suitable hoisting or lifting devices when raising or moving heavy parts.

• Take extra care if bystanders are present.

• Never pour gasoline or diesel oil into open, wide and low containers.

• Never use gasoline, diesel oil or other inflammable liquids as cleaning agents. Use non-flammable non-toxic proprietary solvents.

• Wear safety goggles with side guards when cleaning parts with compressed air.

• Limit the air pressure to a maximum of 2.1 bar (30.5 psi), according to local regulations.

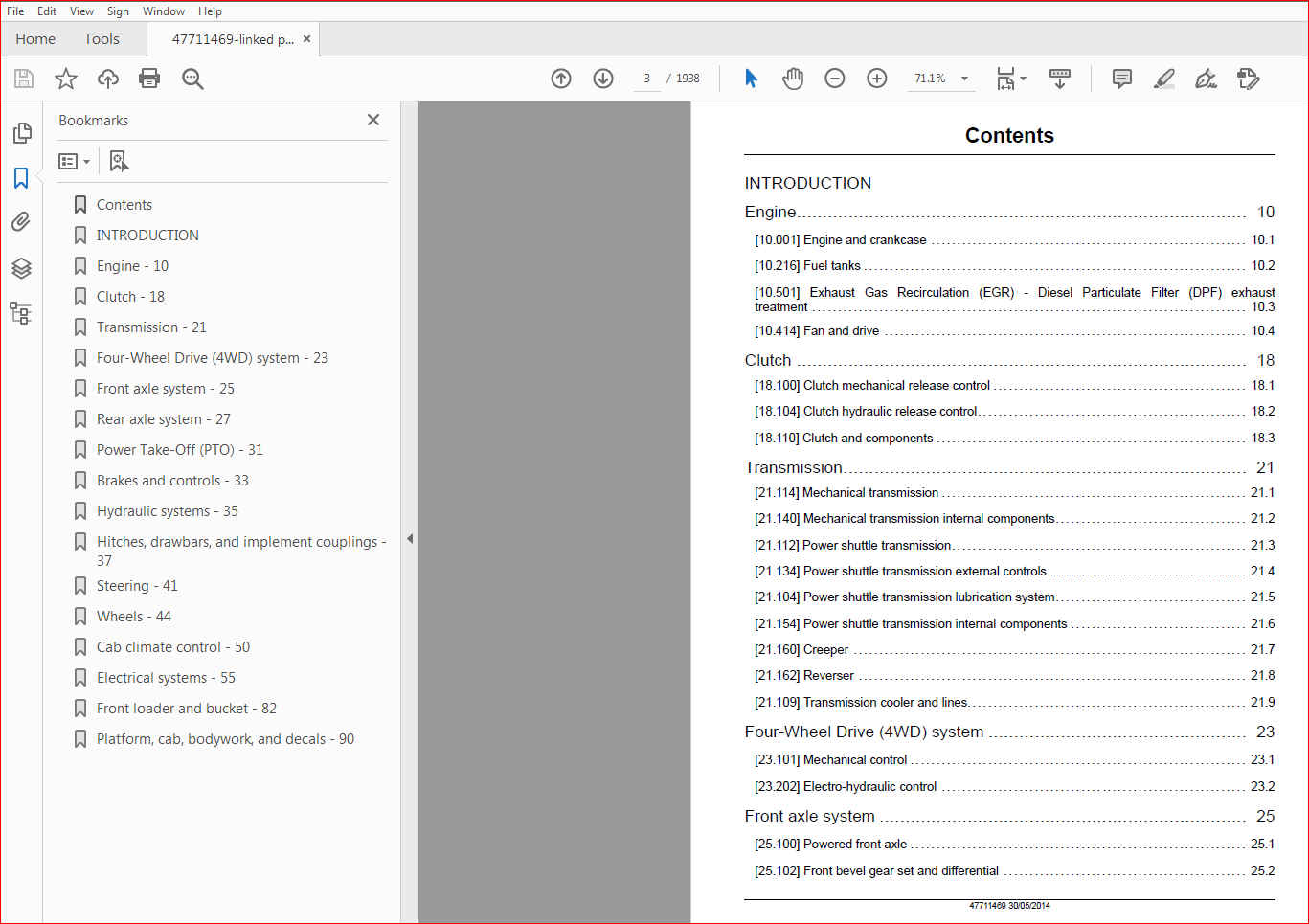

TABLE OF CONTENTS:

New Holland Tractor T4.75 Power Star Tier 4B (final) Service Manual

INTRODUCTION

Engine 10

[10001] Engine and crankcase 101

[10216] Fuel tanks 102

[10501] Exhaust Gas Recirculation (EGR) – Diesel Particulate Filter (DPF) exhaust

treatment 103

[10414] Fan and drive 104

Clutch 18

[18100] Clutch mechanical release control 181

[18104] Clutch hydraulic release control 182

[18110] Clutch and components 183

Transmission 21

[21114] Mechanical transmission211

[21140] Mechanical transmission internal components 212

[21112] Power shuttle transmission 213

[21134] Power shuttle transmission external controls 214

[21104] Power shuttle transmission lubrication system 215

[21154] Power shuttle transmission internal components 216

[21160] Creeper 217

[21162] Reverser 218

[21109] Transmission cooler and lines219

Four-Wheel Drive (4WD) system 23

[23101] Mechanical control231

[23202] Electro-hydraulic control232

Front axle system 25

[25100] Powered front axle251

[25102] Front bevel gear set and differential252

47711469 30/05/2014

[25108] Final drive hub, steering knuckles, and shafts 253

[25400] Non-powered front axle 254

Rear axle system 27

[27100] Powered rear axle271

[27106] Rear bevel gear set and differential 272

[27120] Planetary and final drives 273

Power Take-Off (PTO) 31

[31101] Rear mechanical control311

[31104] Rear electro-hydraulic control 312

[31110] One-speed rear Power Take-Off (PTO) 313

[31114] Two-speed rear Power Take-Off (PTO) 314

Brakes and controls 33

[33202] Hydraulic service brakes331

[33110] Parking brake or parking lock 332

Hydraulic systems 35

[35104] Fixed displacement pump 351

[35204] Remote control valves 352

[35114] Three-point hitch control valve353

[35723] Front loader bucket hydraulic system 354

Hitches, drawbars, and implement couplings 37

[37100] Drawbars and towing hitches 371

[37110] Rear three-point hitch 372

Steering 41

[41106] Tie rods 411

[41206] Pump 412

[41101] Steering control 413

[41200] Hydraulic control components414

47711469 30/05/2014

[41216] Cylinders 415

Wheels 44

[44511] Front wheels441

[44520] Rear wheels 442

Cab climate control 50

[50100] Heating501

[50104] Ventilation 502

[50200] Air conditioning 503

Electrical systems 55

[55100] Harnesses and connectors 551

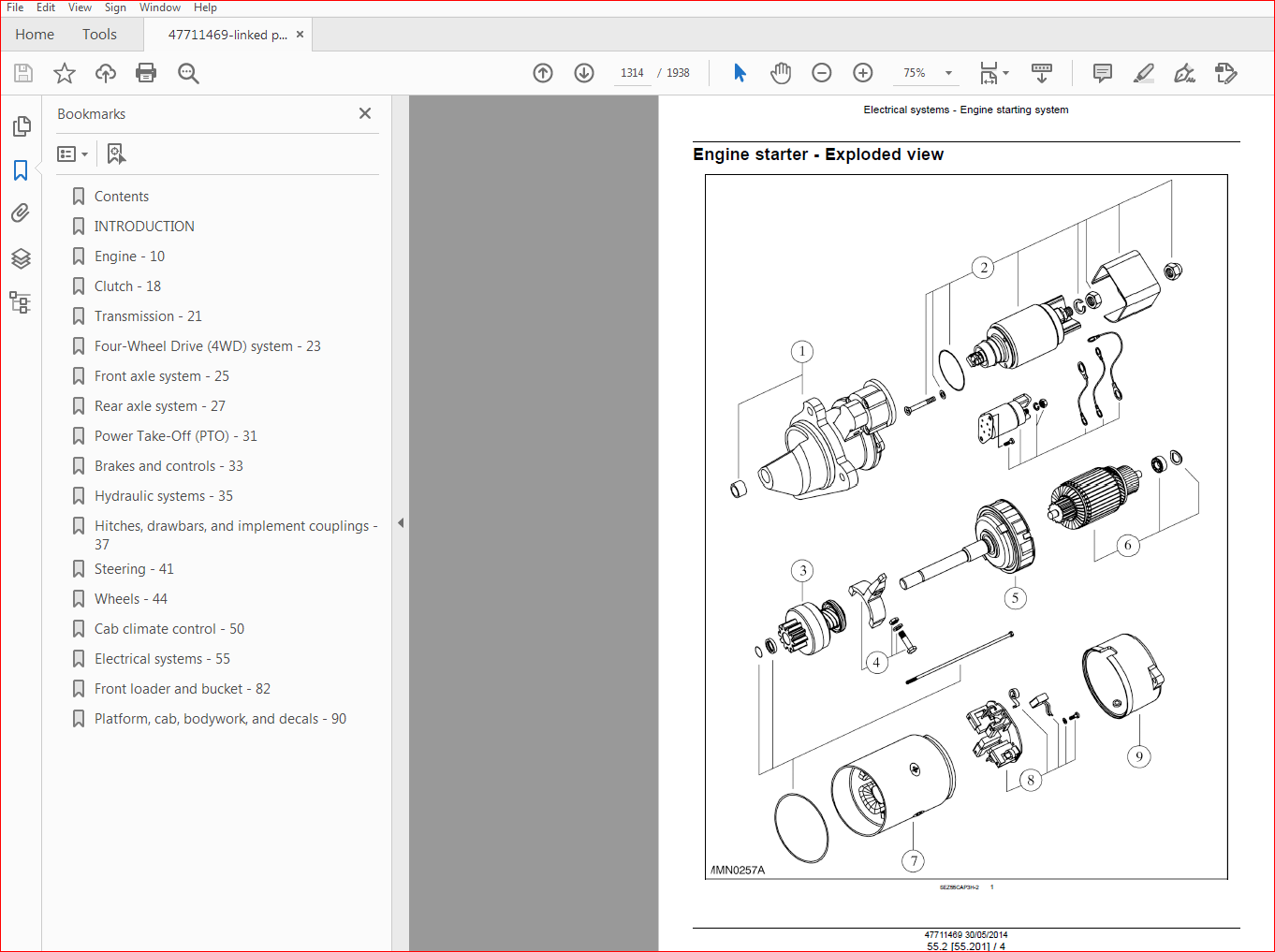

[55201] Engine starting system 552

[55301] Alternator 553

[55302] Battery554

[55640] Electronic modules555

[55048] Rear Power Take-Off (PTO) control system 556

[55408] Warning indicators, alarms, and instruments 557

[55DTC] FAULT CODES 558

Front loader and bucket 82

[82300] Bucket 821

Platform, cab, bodywork, and decals 90

[90150] Cab 901

[90151] Cab interior 902

[90160] Cab interior trim and panels 903

[90154] Cab doors and hatches 904

[90110] Operator platform less cab 905

[90100] Engine hood and panels906

IMAGES PREVIEW OF THE MANUAL: