$35

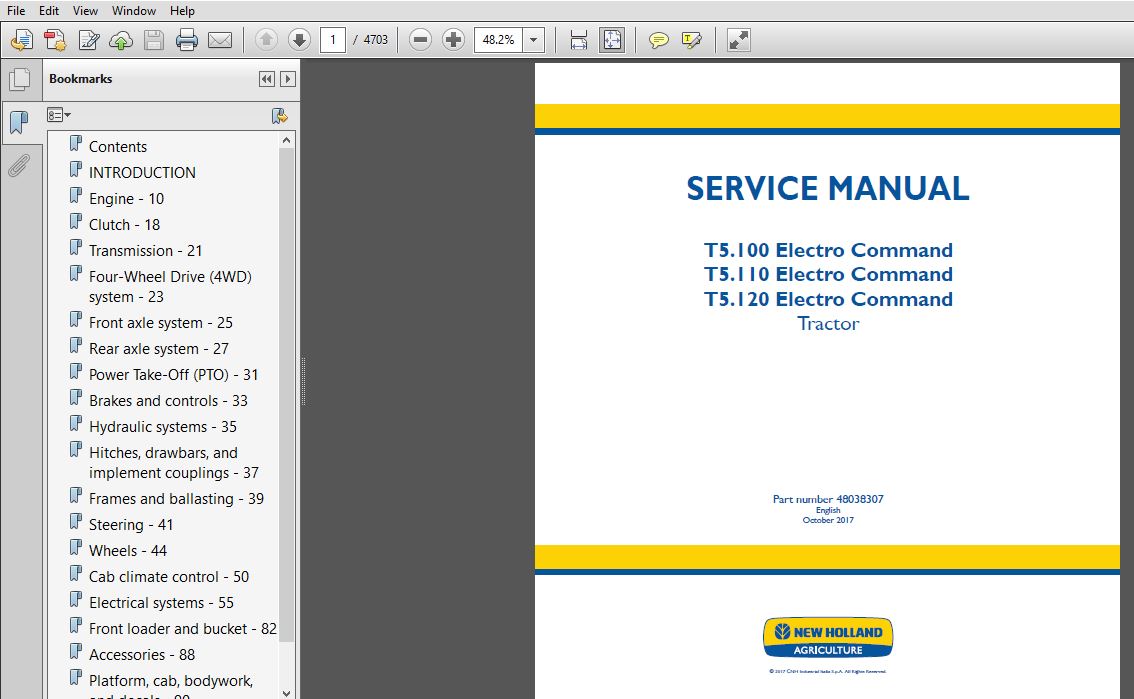

New Holland Tractor T5.100, T5.110, T5.120 Electro Command Service Manual 48038307 – PDF DOWNLOAD

New Holland Tractor T5.100, T5.110, T5.120 Electro Command Service Manual

FILE DETAILS:

New Holland Tractor T5.100, T5.110, T5.120 Electro Command Service Manual

Size: 416 MB

Format: PDF

Language: English

Number of Pages : 4703 pages

Brand: New Holland

Type of document: Service Manual

Model: T5.100 Electro Command, T5.110 Electro Command, T5.120 Electro Command Stage IV Tractor

Part No: 48038307

DESCRIPTION:

New Holland Tractor T5.100, T5.110, T5.120 Electro Command Service Manual

FOREWORD:

All repair and maintenance work listed in this manual must be carried out only by qualified dealership personnel, strictly complying with the instructions given, and using, whenever possible, the special tools. Anyone who performs repair and maintenance operations without complying with the procedures provided herein shall be responsible for any subsequent damages.

- The manufacturer and all the organizations of its distribution chain, including – without limitation – national, regional, or local dealers, reject any responsibility for damages caused by parts and/or components not approved by the manufacturer, including those used for the servicing or repair of the product manufactured or marketed by the manufacturer.

- In any case, no warranty is given or attributed on the product manufactured or marketed by the manufacturer in case of damages caused by parts and/or components not approved by the manufacturer.

- The manufacturer reserves the right to make improvements in design and changes in specifications at any time without notice and without incurring any obligation to install them on units previously sold. Specifications, descriptions, and illustrative material herein are as accurate as known at time of publication but are subject to change without notice. In case of questions, refer to your NEW HOLLAND Sales and Service Networks.

TO PREVENT ACCIDENTS:

Most accidents and personal injuries taking place in workshops are due from non-observance of some essential rules and safety precautions. The possibility that an accident might occur with any type of machines should not be disregarded, no matter how well the machine in question was designed and built. A wise and careful service technician is the best precautions against accidents. Careful observance of this basic precaution would be enough to avoid many severe accidents.

SAFETY RULES:

Generalities

• Carefully follow specified repair and maintenance procedures.

• Do not wear rings, wristwatches, jewels, unbuttoned or flapping clothing such as ties, torn clothes, scarves, open jackets or shirts with open zips which could get caught on moving parts. Use approved safety clothing such as anti-slipping footwear, gloves, safety goggles, helmets, etc.

• Wear safety glasses with side guards when cleaning parts using compressed air.

• Damaged or frayed wires and chains are unreliable. Do not use them for lifting or towing.

• Wear suitable protection such as approved eye protection, helmets, special clothing, gloves and footwear whenever welding. All persons standing in the vicinity of the welding process should wear approved eye protection. NEVER LOOK AT THE WELDING ARC IF YOUR EYES ARE NOT SUITABLY PROTECTED.

• Never carry out any repair on the machine if someone is sitting on the operator’s seat, except if they are qualified operators assisting in the operation to be carried out.

• Never operate the machine or use attachments from a place other than sitting at the operator’s seat or at the side of the machine when operating the fender switches.

• Never carry out any operation on the machine when the engine is running, except when specifically indicated. Stop the engine and ensure that all pressure is relieved from hydraulic circuits before removing caps, covers, valves, etc.

• All repair and maintenance operations should be carried out with the greatest care and attention.

• Disconnect the batteries and label all controls to warn that the tractor is being serviced. Block the machine and all equipment which should be raised.

• Never check or fill fuel tanks or batteries, nor use starting liquid if you are smoking or near open flames as such fluids are flammable.

• The fuel filling gun should always remain in contact with the filler neck. Maintain this contact until the fuel stops flowing into the tank to avoid possible sparks due to static electricity build-up.

• To transfer a failed tractor, use a trailer or a low loading platform trolley if available.

• To load and unload the machine from the transportation means, select a flat area providing a firm support to the trailer or truck wheels. Firmly tie the machine to the truck or trailer platform and block wheels as required by the transporter.

• Always use lifting equipment of appropriate capacity to lift or move heavy components.

• Chains should always be safely fastened. Ensure that fastening device is strong enough to hold the load foreseen. No persons should stand near the fastening point.

• The working area should be always kept CLEAN and DRY. Immediately clean any spillage of water or oil.

• Never use gasoline, diesel oil or other flammable liquids as cleaning agents. Use non-flammable non-toxic proprietary solvents.

• Do not pile up grease or oil soaked rags, as they constitute a great fire hazard. Always place them into a metal container.

TABLE OF CONTENTS:

New Holland Tractor T5.100, T5.110, T5.120 Electro Command Service Manual

INTRODUCTION

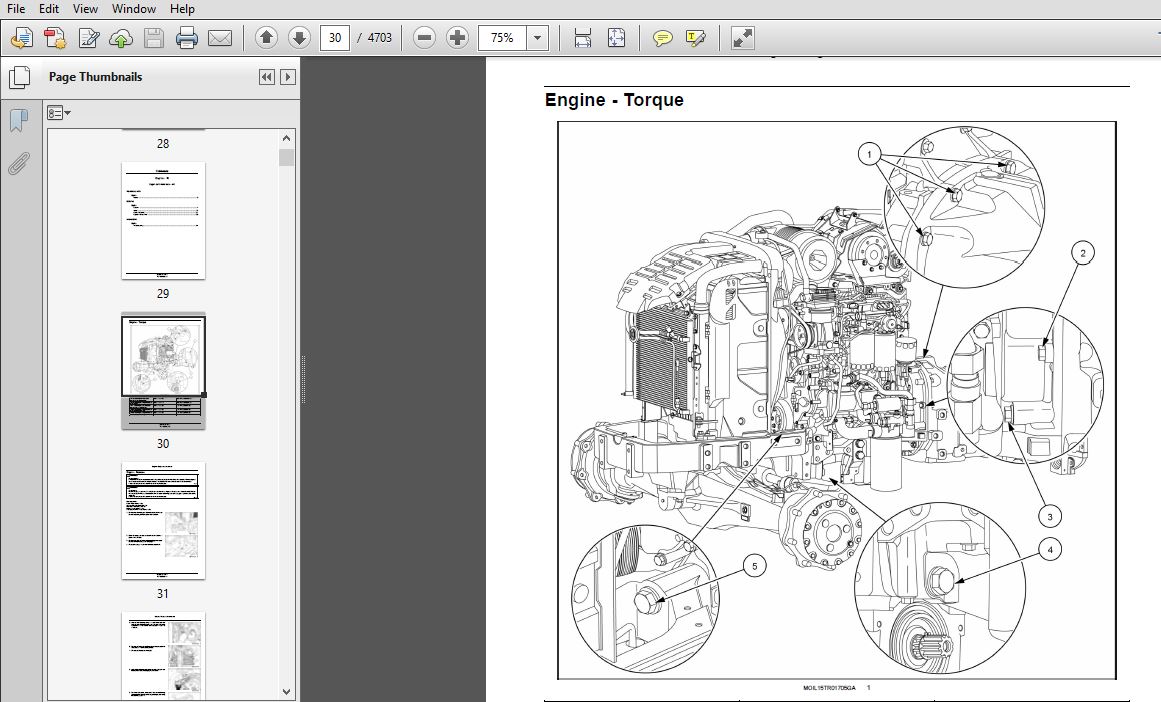

Engine 10

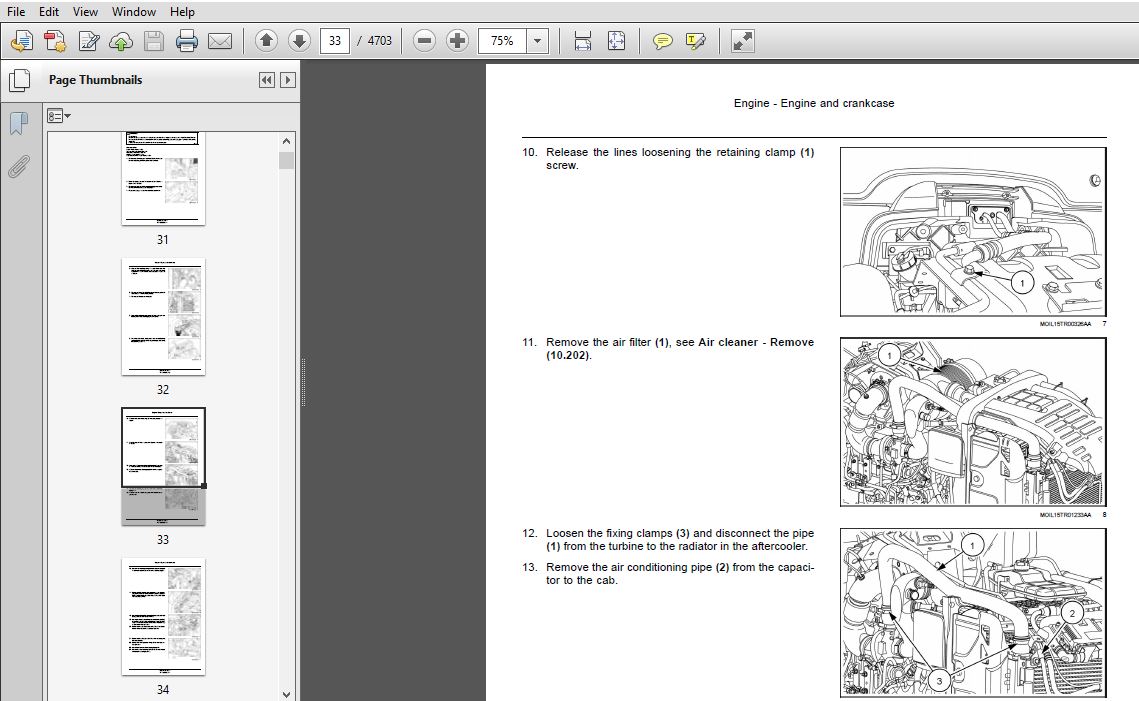

[10001] Engine and crankcase 101

[10216] Fuel tanks 102

[10206] Fuel filters 103

[10202] Air cleaners and lines 104

[10254] Intake and exhaust manifolds and muffler 105

[10500] Selective Catalytic Reduction (SCR) exhaust treatment106

[10501] Exhaust Gas Recirculation (EGR) exhaust treatment 107

[10400] Engine cooling system 108

[10414] Fan and drive 109

[10310] Aftercooler1010

[10304] Engine lubrication system 1011

[10218] Fuel injection system 1012

Clutch 18

[18100] Clutch mechanical release control 181

[18112] Slip clutch or flywheel damper 182

Transmission 21

[21111] Semi-Powershift transmission 211

[21133] Semi-Powershift transmission external controls212

[21103] Semi-Powershift transmission hydraulic components 213

[21152] Semi-Powershift transmission internal components214

[21160] Creeper 215

[21109] Transmission cooler and lines 216

Four-Wheel Drive (4WD) system 23

[23202] Electro-hydraulic control231

48038307 02/10/2017

[23314] Drive shaft 232

Front axle system 25

[25100] Powered front axle 251

[25102] Front bevel gear set and differential252

[25108] Final drive hub, steering knuckles, and shafts 253

[25122] Axle suspension control 254

Rear axle system 27

[27100] Powered rear axle 271

[27106] Rear bevel gear set and differential 272

[27120] Planetary and final drives 273

Power Take-Off (PTO) 31

[31104] Rear electro-hydraulic control 311

[31114] Two-speed rear Power Take-Off (PTO) 312

[31116] Three-speed rear Power Take-Off (PTO) 313

[31142] Front Power Take-Off (PTO) control314

[31146] Front Power Take-Off (PTO)315

Brakes and controls 33

[33202] Hydraulic service brakes331

[33110] Parking brake or parking lock 332

[33220] Trailer brake hydraulic control 333

[33224] Trailer brake pneumatic control 334

[33204] Front axle brake 335

Hydraulic systems 35

[35000] Hydraulic systems 351

[35204] Remote control valves 352

[35100] Main lift system 353

[35160] Front hitch controls and lines 354

[35162] Front hitch cylinders and lines 355

48038307 02/10/2017

[35116] Three-point hitch cylinder 356

[35304] Combination pump units357

Hitches, drawbars, and implement couplings 37

[37100] Drawbars and towing hitches 371

[37106] Automatic pickup hitch 372

[37110] Rear three-point hitch 373

[37120] Rear three-point hitch linkage 374

[37162] Front hitch 375

[37166] Front hitch linkage 376

Frames and ballasting 39

[39140] Ballasts and supports 391

Steering 41

[41101] Steering control 411

[41106] Tie rods 412

[41200] Hydraulic control components 413

[41216] Cylinders414

Wheels 44

[44511] Front wheels441

[44520] Rear wheels 442

Cab climate control 50

[50100] Heating 501

[50104] Ventilation 502

[50200] Air conditioning 503

Electrical systems 55

[55100] Harnesses and connectors 551

[55525] Cab engine controls 552

[55015] Engine control system 553

48038307 02/10/2017

[55201] Engine starting system 554

[55301] Alternator 555

[55302] Battery 556

[55011] Fuel tank system557

[55010] Fuel injection system 558

[55014] Engine intake and exhaust system 559

[55988] Selective Catalytic Reduction (SCR) electrical system 5510

[55989] Exhaust Gas Recirculation (EGR) electrical system 5511

[55640] Electronic modules5512

[55513] Cab transmission controls5513

[55024] Transmission control system 5514

[55020] Transmission speed sensors 5515

[55022] Transmission temperature sensors 5516

[55045] Front axle control system 5517

[55048] Rear Power Take-Off (PTO) control system 5518

[55031] Parking brake electrical system 5519

[55512] Cab controls 5520

[55035] Remote control valve electric control 5521

[55051] Cab Heating, Ventilation, and Air-Conditioning (HVAC) controls 5522

[55050] Heating, Ventilation, and Air-Conditioning (HVAC) control system 5523

[55523] Cab hitch controls 5524

[55130] Rear three-point hitch electronic control system 5525

[55202] Cold start aid 5526

[55785] Precision farming system 5527

[55905] ISOBUS components 5528

[55911] Satellite navigation systems 5529

[55680] Autopilot/Autoguidance 5530

[55518] Wiper and washer system5531

[55404] External lighting 5532

48038307 02/10/2017

[55405] External lighting switches and relays 5533

[55408] Warning indicators, alarms, and instruments 5534

[55988] Selective Catalytic Reduction (SCR) electrical system 5535

[55DTC] FAULT CODES 5536

Front loader and bucket 82

[82100] Arm 821

Accessories 88

[88100] Accessories 881

Platform, cab, bodywork, and decals 90

[90118] Protections and footboards 901

[90150] Cab 902

[90151] Cab interior 903

[90160] Cab interior trim and panels904

[90154] Cab doors and hatches 905

[90156] Cab windshield and windows 906

[90120] Mechanically-adjusted operator seat 907

[90124] Pneumatically-adjusted operator seat 908

[90100] Engine hood and panels909

[90102] Engine shields, hood latches, and trims 9010

[90116] Fenders and guards 9011

IMAGES PREVIEW OF THE MANUAL:

PLEASE NOTE:

- This is the SAME manual used by the dealers to troubleshoot any faults in your vehicle. This can be yours in 2 minutes after the payment is made.

- Contact us at heydownloadss@gmail.com should you have any queries before your purchase or that you need any other service / repair / parts operators manual.