$40

New Holland Tractor T9.390 T9.450 T9.505 T9.560 T9.615 T9.670 Service Manual

New Holland Tractor T9.390 T9.450 T9.505 T9.560 T9.615 T9.670 Service Manual

FILE DETAILS:

New Holland Tractor T9.390 T9.450 T9.505 T9.560 T9.615 T9.670 Service Manual

Size: 259 MB

Format: PDF

Language: English

Number of Pages : 4015 pages

Brand: New Holland

Type of document: Service Manual

Model: T9_390, T9_450, T9_505, T9_560, T9_615, T9_670

Part No: 47488219

DESCRIPTION:

New Holland Tractor T9.390 T9.450 T9.505 T9.560 T9.615 T9.670 Service Manual

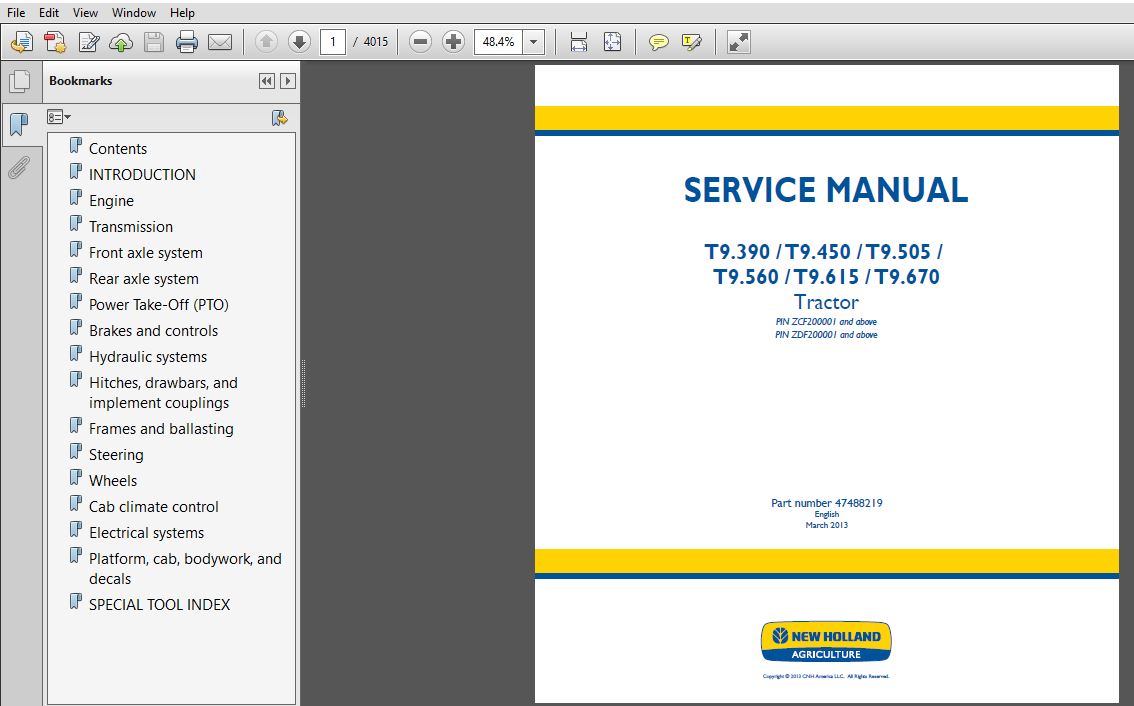

INTRODUCTION

Engine 10

[10 001] Engine and crankcase 10 1

[10 202] Air cleaners and lines 10 2

[10 400] Engine cooling system 10 3

[10 414] Fan and drive 10 4

[10 500] Selective Catalytic Reduction (SCR) exhaust treatment 10 5

Transmission 21

[21 113] Powershift transmission 21 1

[21 135] Powershift transmission external controls 21 2

[21 145] Gearbox internal components 21 3

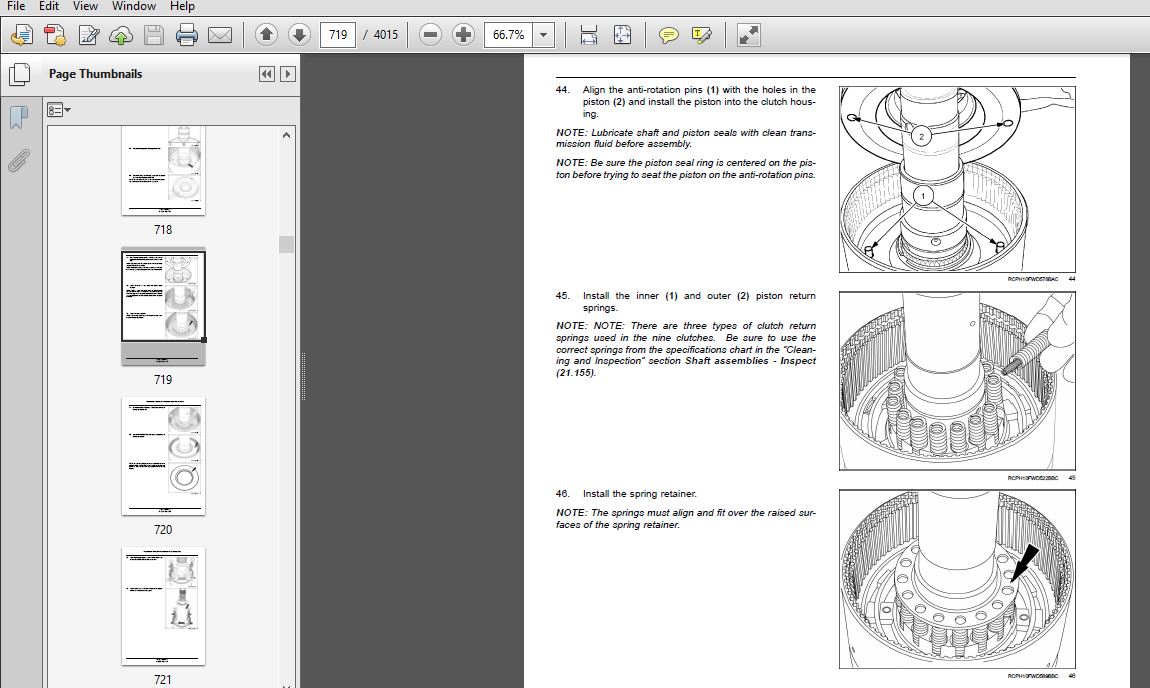

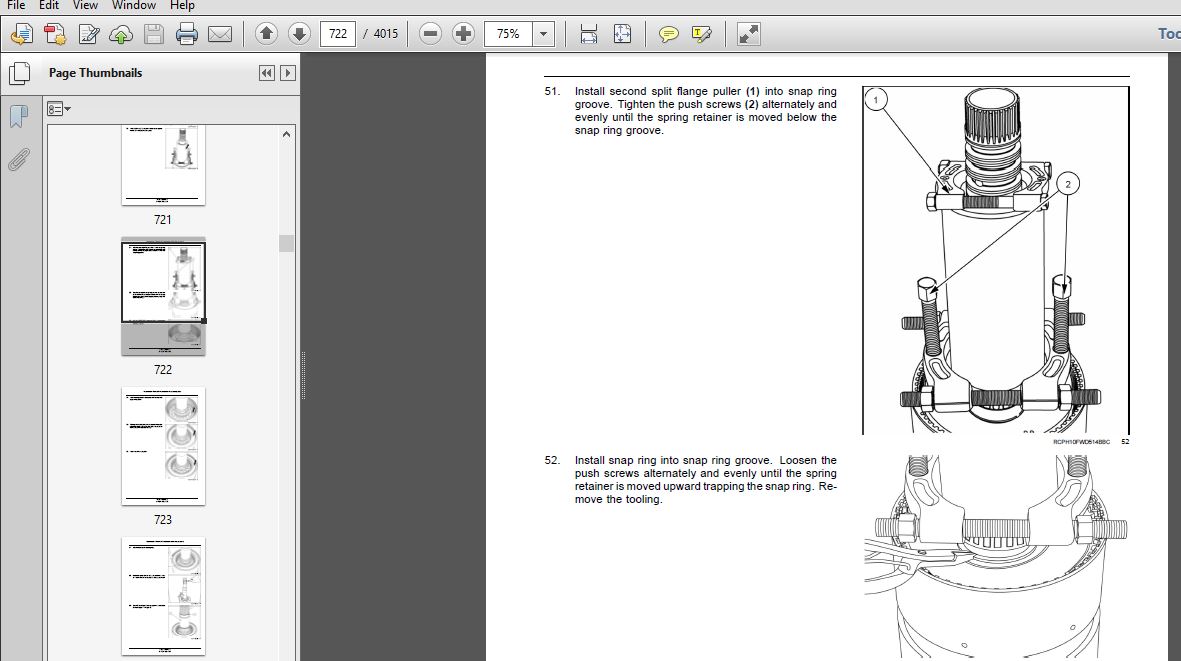

[21 155] Powershift transmission internal components 21 4

Front axle system 25

[25 100] Powered front axle 25 1

[25 102] Front bevel gear set and differential 25 2

[25 310] Final drives 25 3

Rear axle system 27

[27 100] Powered rear axle 27 1

[27 106] Rear bevel gear set and differential 27 2

[27 120] Planetary and final drives 27 3

Power Take-Off (PTO) 31

[31 104] Rear electro-hydraulic control 31 1

[31 110] One-speed rear Power Take-Off (PTO) 31 2

[31 220] Gearbox 31 3

Brakes and controls 33

[33 110] Parking brake or parking lock 33 1

47488219 26/02/2013

[33 202] Hydraulic service brakes 33 2

Hydraulic systems 35

[35 000] Hydraulic systems 35 1

[35 102] Pump control valves 35 2

[35 105] Charge pump 35 3

[35 106] Variable displacement pump 35 4

[35 204] Remote control valves 35 5

[35 220] Auxiliary hydraulic pump and lines 35 6

[35 300] Reservoir cooler and filters 35 7

[35 304] Combination pump units 35 8

[35 600] High flow hydraulics 35 9

Hitches drawbars and implement couplings 37

[37 100] Drawbars and towing hitches 37 1

Frames and ballasting 39

[39 100] Frame 39 1

[39 110] Drawbar and hitch assembly 39 2

Steering 41

[41 101] Steering control 41 1

[41 200] Hydraulic control components 41 2

[41 206] Pump 41 3

[41 910] Auxiliary steering 41 4

Wheels 44

[44 511] Front wheels 44 1

[44 520] Rear wheels 44 2

Cab climate control 50

[50 104] Ventilation 50 1

[50 200] Air conditioning 50 2

[50 300] Cab pressurizing system 50 3

47488219 26/02/2013

Electrical systems 55

[55 010] Fuel injection system 55 1

[55 014] Engine intake and exhaust system 55 2

[55 024] Transmission control system 55 3

[55 035] Remote control valve electric control 55 4

[55 045] Front axle control system 55 5

[55 046] Rear axle control system 55 6

[55 048] Rear Power Take-Off (PTO) control system 55 7

[55 050] Heating Ventilation and Air-Conditioning (HVAC) control system 55 8

[55 051] Cab Heating Ventilation and Air-Conditioning (HVAC) controls 55 9

[55 100] Harnesses and connectors 55 10

[55 130] Rear three-point hitch electronic control system 55 11

[55 301] Alternator 55 12

[55 302] Battery 55 13

[55 404] External lighting 55 14

[55 522] Cab Power Take-Off (PTO) controls 55 15

[55 640] Electronic modules 55 16

[55 988] Selective Catalytic Reduction (SCR) electrical system 55 17

[55 DTC] FAULT CODES 55 18

Platform cab bodywork and decals 90

[90 100] Engine hood and panels 90 1

[90 102] Engine shields hood latches and trims 90 2

[90 124] Pneumatically-adjusted operator seat 90 3

[90 150] Cab 90 4

[90 151] Cab interior

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

New Holland Tractor T9.390 T9.450 T9.505 T9.560 T9.615 T9.670 Service Manual

SAFETY RULES:

- Use caution when operating the machine on slopes. Raised equipment, full tanks and other loads will change the center of gravity of the machine. The machine can tip or roll over when near ditches and embankments or uneven surfaces.

- Never permit anyone other than the operator to ride on the machine. Never operate the machine under the influence of alcohol, drugs, or while otherwise impaired. While driving on the road, the seat swivel position must always be straight forward and locked in position with no rotation.

- The seat swivel should only be rotated for in field operation. Stay off slopes too steep for safe operation. Shift down before you start up or down a hill with a heavy load. Avoid “free wheeling.” Do not drive on roads, or at high speed anywhere, with the differential lock engaged. Difficult steering will occur, and can result in an accident. In field operation, use the differential lock for traction improvement, but release for turning at row ends.

- Do not exceed implement transport speed or the speed rating on the implement tires. Review the implements Operator’s Manual for specifications. Failure to comply could result in death or serious injury. For speeds up to 16 km/h (10 mph), make sure that the weight of a trailed vehicle that is not equipped with brakes does NOT EXCEED 1.5 times the Tractor weight.

- For speeds up to 40 km/h (25 mph), make sure that the weight of the trailed vehicle that is not equipped with brakes, does NOT EXCEED the weight of the Tractor. Stopping distance increases with increasing speed as the weight of the towed load increases, especially on hills and slopes. Rear upset can result if pulling from wrong location on tractor. Hitch only to the drawbar.

- Use three point hitch only with the implements designed for its use – not as a drawbar. Do not look directly into the front or rear HID (high intensity discharge) lamps. Eye damage can occur. Do not tamper with the ballast on the front or rear high intensity discharge (HID) lamp since it uses high voltage. Personal injury or death can occur.

- To avoid possible eye damage from microwave signals emitted by the radar sensor, do not look directly into the sensor face. When digging or using ground engaging attachments be aware of buried cables. Contact local utilities to determine the locations of services. Pay attention to overhead power lines and hanging obstacles. High voltage lines may require significant clearance for safety. Hydraulic oil or diesel fuel leaking under pressure can penetrate the skin, causing serious injury or infection. DO NOT use your hand to check for leaks.

- Use a piece of cardboard or paper. Stop engine, remove key and relieve the pressure before connecting or disconnecting fluid lines. Make sure all components are in good condition and tighten all connections before starting the engine or pressurizing the system. If hydraulic fluid or diesel fuel penetrates the skin, seek medical attention immediately. Continuous long term contact with hydraulic fluid may cause skin cancer. Avoid long term contact and wash the skin promptly with soap and water. Keep clear of moving parts. Loose clothing, jewelry, watches, long hair, and other loose or hanging items can become entangled in moving parts. Wear protective equipment when appropriate.