$45

New Holland Tractor TD3.50 Service Manual - PDF DOWNLOAD

New Holland Tractor TD3.50 Service Manual

FILE DETAILS:

New Holland Tractor TD3.50 Service Manual

Size: 22.2 MB

Format: PDF

Language: English

Number of Pages : 501 pages

Brand: New Holland

Type of document: Service Manual

Model: TD3.50

Part No: 47840677

DESCRIPTION:

New Holland Tractor TD3.50 Service Manual

IMPORTANT NOTICE:

All maintenance and repair operations described in this manual should be carried out exclusively by the NEW HOLLAND authorised workshops. All instructions detailed should be carefully observed and special equipment indicated should be used if necessary. Everyone who carries out service operations described without carefully observing these prescriptions will be directly responsible of deriving damages.

SHIMS:

At each adjustment, select adjusting shims, measure them individually using a micrometer and then sum up recorded values. Do not rely on measuring the entire shimming set, which may be incorrect, or the rated value indicated on each shim.

ROTATING SHAFT SEALS:

To correctly install rotating shaft seals, observe the following instructions:

– Let the seal soak into the same oil as it will seal for at least half an hour before mounting

– Thoroughly clean the shaft and ensure that the shaft working surface is not damaged.

– Place the sealing lip towards the fluid. In case of a hydrodynamic lip, consider the shaft rotation direction and orient grooves in order that they deviate the fluid towards the inner side of the seal.

– coat the sealing lip with a thin layer of lubricant (use oil rather than grease) and fill the gap between the sealing lip and the dust lip on double lip seals with grease;

– Insert the seal into its seat and press it down using a flat punch. Do no tap the seal with a hammer or a drift;

– Take care to insert the seal perpendicularly to its seat while you are pressing it. Once the seal is settled, ensure that it contacts the thrust element if required;

To prevent damaging the sealing lip against the shaft, place a suitable protection during installation.

O RINGS:

Lubricate the O rings before inserting them into their seats. This will prevent the O rings from rolling over and

twine during mounting which will jeopardise sealing.

SEALANTS:

Apply one of the following sealers: RTV SILMATE, RHODORSIL CAF 1, or LOCTITE PLASTIC GASKET over the mating surfaces marked with an X.

Before applying the sealer, prepare the surface as follows:

– thoroughly de-grease the surfaces using one of the following cleaning agents: trichlorethylene, petrol or a

water and soda solution.

TABLE OF CONTENTS:

New Holland Tractor TD3.50 Service Manual

Notes for spare parts2

Notes for equipment 2

Safety Rules 3

Consumables 6

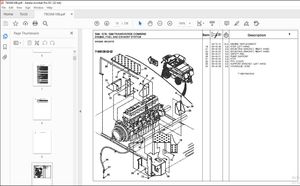

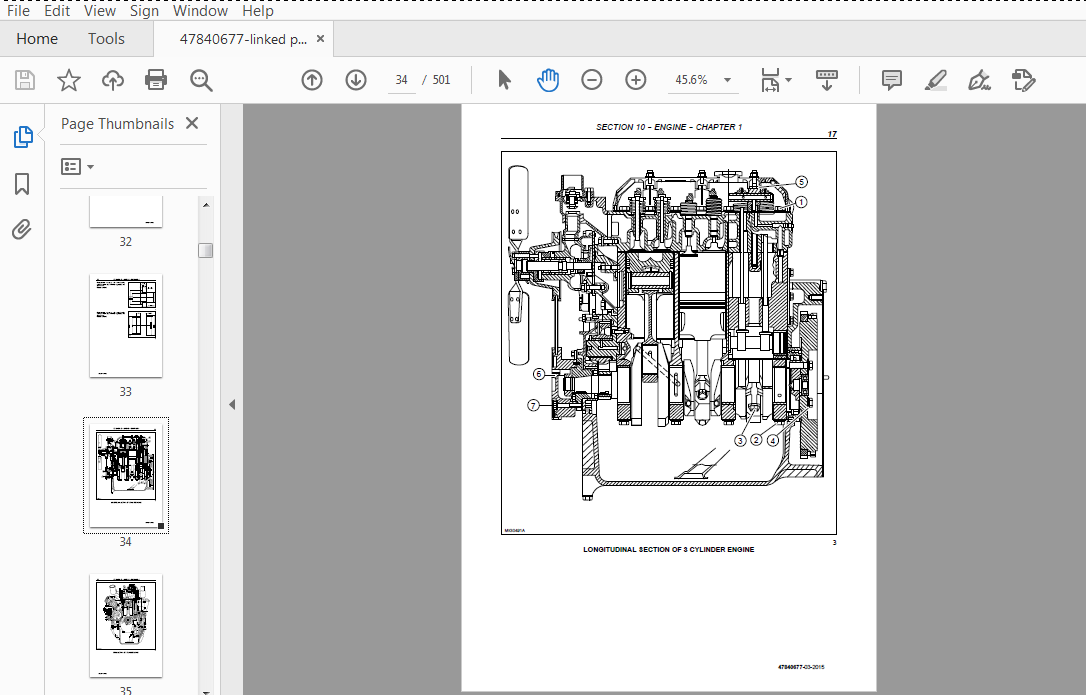

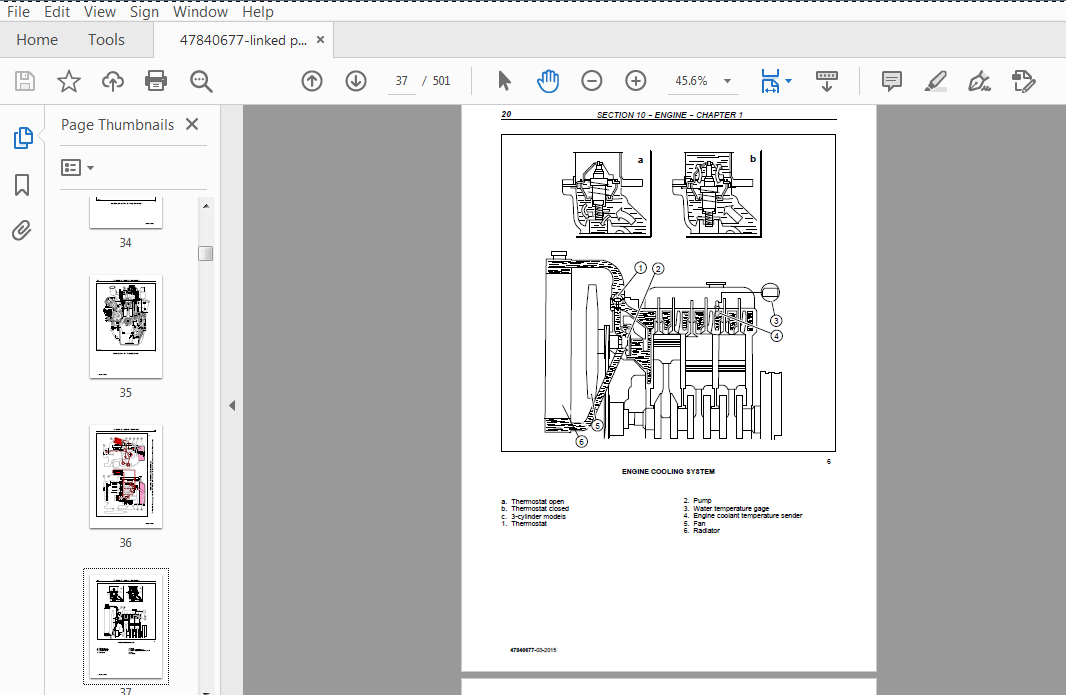

ENGINE SECTION 10

Engine System Chapter 1

Bölüm Tanım Sayfa

10 000 Specifications 2

Tightening Torques14

Special Tools15

Cross Sectional Views 17

Engine Cooling System 20

Troubleshooting 21

Engine – Remove and Install 25

Engine Removal and Overhaul37

Engine Timing Gear Cover, Timing Gears, and Cam Shaft 44

Cylinder Head 46

Valves 47

Cylinder Block 50

Pistons70

Crankshaft – Main Bearing and Thrust Washer 65

Camshaft 73

Hydraulic Oil Pump83

Description of operation – Engine Lubrication System84

Description of operation – Cooling System86

Clutches Section 18

Section Description Page

18 000 Specifications 1

TIGHTENING TORQUES 2

Special Tools 3

Cross Sectional Views 3

Troubleshooting 4

Remove – Assembly 5-13

Control, Measurement and Repair15-18

General Maintenance – Overhaul 18-19

Clutch Adjustments 20-22

TRANSMISSION SECTION 21

Mechanical Transmission Chapter 1

Section Description Page

21 000 Specifications 2

Tightening Torques

Liquid Sealants 4

Special Tools 5

Cross Sectional Views 6

Troubleshooting 8

Description and Operation8

Reverser Chapter 2

Section Description Page

General Recommendations For Overhauling Operations 2

Transmission Assembly, Removal – Installation 3

Transmission – Mechanical – Disassemble 8×8 Shuttle Transmission 18

Gear and Synchroniser – Remove Transmission Synchroniser Kit and Cluster

Gear Assembly 24

Gear and Synchroniser – Inspect Transmission Synchroniser Kit and Cluster Gear Assembly28

Gear and Synchroniser – Install Transmission Synchroniser Kit and Cluster Gear Assembly 29

DRIVE LINES SECTION 23

Drive Lines Chapter 1

Section Description Page

23 000 Specifications 1

Torque Settings and Tools2

Cross-Sectional Views 3

Transmission shafts and guard (Disassembly – Assembly) 4

Drive gear housing (Removal – Installation) 5

Drive gear housing removed (Disassembly – Assembly)6

FRONT AXLE MECHANICAL TRANSMISSION SECTION 25

Front Axle Mechanical Transmission Chapter 1

Section Description Page

25 000 Specifications 2

TIGHTENING TORQUES 3

Tools 6

Cross Sectional Views 7

Description and Operation 9

25 100 30 Complete front axle Remove – Install 10

25 100 38 Front axle Remove – Install 15

25 108 46-47 Steering knuckle bearing pins Replace 22

Stub axle adjustment 23

Wheel hub bearing adjustment25

Bevel drive adjustment 26

25 102 24 Front Axle Differential Overhaul 32

25 100 27 Front axle differential with LIM-SLIP Overhaul 33

44 511 80 Leading drive wheels toe-in check 35

REAR AXLE AND TRANSMISSION SECTION 27

Rear Axle And Transmission Chapter 1

Section Description Page

21 000 Specifications 2

Tightening Torques 3

Liquid Sealants 6

Special Tools 7

Cross Sectional Views 7

Troubleshooting 10

Description and Operation10

Low Gear Drive Line Schema 13

Reverse Gear Drive Shaft13

High Gear Drive Shaft 14

Transmission Assembly, Removal – Installation 16

Internal Components, Disassembly – Assembly 33

Diferential Chapter 2

Section Description Page

27 000 Differential Assembly 2

Differential pinion and side gear backlash 4

Repair and Inspection 5

Adjustment of bevel wheel bearings and crown pinion backlash adjustment 6

Final drive housing 8

POWER TAKE-OFF SECTION 31

Mechanical Power Take – Off Chapter 1

Section Description Page

31 000 Specifications 1

Tightening Torques 2

Liquid Sealants 3

Cross Sectional Views 4

Description and Operation 5

RemovalInstallation – Overhaul 7

BRAKING SYSTEM SECTION 33

Braking System Chapter 1

Section Description Page

33 000 Specifications 2

Tightening Torques 3

Special Tools 4

Liquid Sealants 4

Cross Sectional Views 5

Troubleshooting 6

Description and Operation7

Brake Control, Removal – Installation 8

Brake Assembly, Removal – Installation 10

Brake Pedal Free Play Setting 13

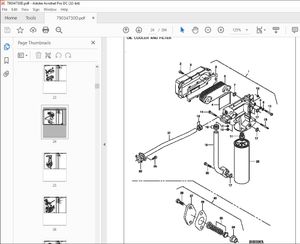

HYDRAULIC SYSTEM SECTION 35

Hydraulic System

Chapter 1

35 000 Introduction and Circuit Identification 1

Open Centre High Pressure Hydraulic Circuit 3

Hydraulic Circuit Diagram4

Sectional view5

Hydraulic Pump

Chapter 1

Specifications 1

Tightening Torques 2

Special Tools 2

Description and Operation3

Remove and Install 4

Disassembly – Assembly 5

Hydraulic Pump

Chapter 2

35 000 Specifications 2

Tightening Torques 3

Liquid Sealants 4

Special Tools 4

Cross Sectional Views 5

Troubleshooting 7

Description and Operation8

Operation of Distributor 12

Internal Three-Point Hitch15

Operation of Internal Lift-O-Matic Levers 21

Remove and Install 23

Disassembly – Assembly 25

Adjustment and Settings 38

STEERING SECTION 41

Steering Chapter 1

Section Description Page

Section Description Page

41 000 Specifications 1

Tightening Torques 3

Special Tools 3

Troubleshooting 3

Description and Operation8

Removal Installation – Overhaul12

ELECTRICAL SYSTEM SECTION 55

Instruments Section 1

Section Description Page

Semi-digital instruments Introduction 1

Transmitters, sensors and switches 3

Components Chapter 2

Section Description Page

55 500 Introduction 1

Description of the Component 2

Starting System Chapter 3

Section Description Page

55 000 Technical Information1

TIGHTENING TORQUES 1

Description and Operation 2

Starter System Circuit 3

Operation Description 5

Removal and re-installation of starter motor 7

Electrical Test 8

Bench tests 10

Charging System Chapter 4

Section Description Page

55 000 Technical Information1

TIGHTENING TORQUES 1

Description and Operation 2

Alternator – Removal and Reassembly4

Alternator component testing and inspection 10

Battery Chapter 5

Section Description Page

55 000 Technical Information1

Description and Operation 1

Removal and Re-installation 2

Battery Checking and Maintenance 3

Battery Charging 4

Battery Problems – Frequent Causes 7

IMAGES PREVIEW OF THE MANUAL:

PLEASE NOTE: