$45

New Holland Tractor TK4030V, TK4050, TK4050M, TK4060 Service Manual

New Holland Tractor TK4030V, TK4050, TK4050M, TK4060 Service Manual

FILE DETAILS:

New Holland Tractor TK4030V, TK4050, TK4050M, TK4060 Service Manual

Size: 56.3 MB

Format: PDF

Language: English

Number of Pages : 915 pages

Brand: New Holland

Type of document: Service Manual

Model: TK4030V, TK4050, TK4050M, TK4060

Part No: 47830956

DESCRIPTION:

New Holland Tractor TK4030V, TK4050, TK4050M, TK4060 Service Manual

To prevent accidents:

Most accidents or injuries that occur in workshops are the result of non-observance of simple and fundamental safety regulations. For this reason, in most cases these accidents can be avoided: by foreseeing possible causes and consequently acting with the necessary caution and care. Accidents may occur with all types of vehicle, regardless of how well it was designed and built. A careful and judicious service technician is the best guarantee against accidents. Precise observance of the most basic safety rule is normally sufficient to avoid many serious accidents. “DANGER” – Never carry out any cleaning, lubrication or maintenance operations when the engine is running.

Safety regulations:

General guidelines:

• Carefully follow specified repair and maintenance procedures.

• Do not wear rings, wristwatches, jewellery, unbuttoned or loose articles of clothing such as: ties, torn clothing, scarves, open jackets or shirts with open zips that may remain entangled in moving parts. It is advised to wear approved safety clothing, e.g: non-slip footwear, gloves, safety goggles, helmets, etc.

• Do not carry out repair operations with someone sitting in the driver’s seat, unless the person is a trained technician who is assisting with the operation in question.

• Do not operate the vehicle or use any of the implements from different positions, other than the driver’s seat.

• Do not carry out operations on the vehicle with the engine running, unless specifically indicated.

• Stop the engine and ensure that all pressure is relieved from hydraulic circuits before removing caps, covers, valves, etc.

• All repair and maintenance operations must be carried out using extreme care and attention.

• Service steps and platforms used in a workshop or in the field should be built in compliance with the safety rules in force.

• Disconnect the batteries and label all controls to indicate that the vehicle is being serviced. Block the machine and all equipment which should be raised.

• Do not check or fill fuel tanks, accumulator batteries, nor use starting liquid when smoking or near naked flames, as these fluids are inflammable.

• Brakes are inoperative when manually released for repair or maintenance purposes: use blocks or similar devices to control the machine in these conditions.

• The fuel nozzle should always be in contact with the filling aperture: maintain this contact until the fuel stops flowing into the tank to avoid possible sparks due to static electricity build-up.

• Only use specified towing points for towing the vehicle. Connect parts carefully: make sure that all pins and/or locks are secured in position before applying traction. Never remain near the towing bars, cables or chains that are operating under load.

• Transport vehicles that cannot be driven using a trailer or a low-loading platform trolley, if available.

• When loading or unloading the vehicle from the trailer (or other means of transport), select a flat area capable of sustaining the trailer or truck wheels. Firmly secure the vehicle to the truck or trailer and lock the wheels in the position used by the carrier.

• Electric heaters, battery-chargers and similar equipment must only be powered by auxiliary power supplies with efficient ground insulation to avoid electrical shock hazards.

• Always use suitable hoisting or lifting devices when raising or moving heavy parts.

• Take extra care if bystanders are present.

• Never pour petrol or diesel oil into open, wide or low containers.

• Never use gasoline, diesel oil or other inflammable liquids as cleaning agents: use non-inflammable, non toxic commercially available solvents.

• Wear safety goggles with side guards when cleaning parts with compressed air.

• Limit the air pressure to a maximum of 2.1 bar, according to local regulations.

• Do not run the engine in confined spaces without suitable ventilation.

• Do not smoke, use naked flames, or cause sparks in the area when fuel filling or handling highly inflammable liquids.

• Never use naked flames for lighting when working on the machine or checking for leaks.

• All movements must be carried out carefully when working under, on or near the vehicle. Wear protective equipment: helmets, goggles and special footwear.

• When carrying out checks with the engine running, request the assistance of an operator in the driver’s seat. The operator must maintain visual contact with the service technician at all times.

• If operating outside the workshop, position the vehicle on a flat surface and lock in position. If working on a slope, lock the vehicle in position. Move to a flat area as soon as is safely possible.

• Damaged or bent chains or cables are unreliable: do not use them for lifting or towing. Always use suitable protective gloves when handling chains or cables.

• Chains should always be safely secured: make sure that the hitch-up point is capable of sustaining the load in question. Keep the area near the hitch-up point, chains or cables free of all bystanders.

• Maintenance and repair operations must be carried out in a clean and dry area. Eliminate any water or oil spillage immediately.

• Do not create piles of oil or grease-soaked rags: as they represent a serious fire hazard. Always store rags in a closed metal container. Before starting the tractor or its attachments, check, adjust and block the operator’s seat. Also check that there are no persons within the vehicle or implement range of action.

• Empty pockets of all objects that may fall unobserved into the vehicle parts.

• In the presence of protruding metal parts, use protective goggles or goggles with side guards, helmets, special footwear and gloves.

TABLE OF CONTENTS:

New Holland Tractor TK4030V, TK4050, TK4050M, TK4060 Service Manual

INTRODUCTION

Engine 10

[10001] Engine and crankcase 101

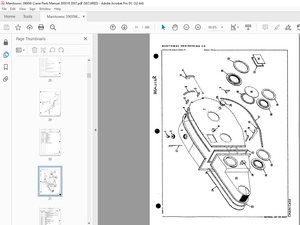

[10216] Fuel tanks 102

[10400] Engine cooling system 103

Clutch 18

[18104] Clutch hydraulic release control181

[18100] Clutch mechanical release control 182

[18110] Clutch and components 183

Transmission 21

[21114] Mechanical transmission211

[21118] Transmission/Rear drive212

[21140] Mechanical transmission internal components 213

[21148] Transmission/Rear drive internal components 214

[21160] Creeper 215

[21162] Reverser216

Rear axle system 27

[27100] Powered rear axle 271

[27126] Spur gear and final drives 272

Power Take-Off (PTO) 31

[31114] Two-speed rear Power Take-Off (PTO) 311

Brakes and controls 33

[33120] Mechanical service brakes 331

[33202] Hydraulic service brakes332

Hydraulic systems 35

[35114] Three-point hitch control valve 351

[35322] Regulated/Low pressure system352

[35204] Remote control valves 353

Steering clutches 46

[46110] Steering clutch 461

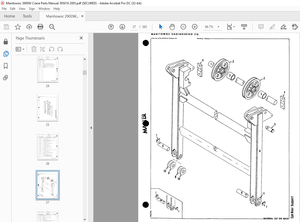

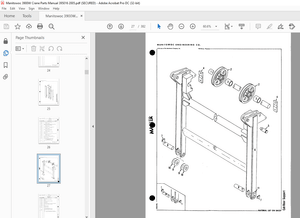

Tracks and track suspension 48

[48130] Track frame and driving wheels 481

[48100] Tracks 482

[48110] Front suspension483

[48114] Rear suspension484

[48134] Track tension units 485

[48138] Track rollers 486

Electrical systems 55

[55100] Harnesses and connectors 551

[55201] Engine starting system 552

[55301] Alternator 553

[55302] Battery 554

[55640] Electronic modules 555

[55404] External lighting 556

[55408] Warning indicators, alarms, and instruments 557

[55DTC] FAULT CODES558

Platform, cab, bodywork, and decals 90

[90150] Cab 901

IMAGES PREVIEW OF THE MANUAL: