$22

OM Pimespo ELECTRIC TRACTOR SERVICE MANUAL – PDF DOWNLOAD

OM Pimespo ELECTRIC TRACTOR SERVICE MANUAL – PDF DOWNLOAD

FILE DETAILS:

OM Pimespo ELECTRIC TRACTOR SERVICE MANUAL – PDF DOWNLOAD

Language : English

Pages : 62

Downloadable : Yes

File Type : PDF

DESCRIPTION:

OM Pimespo ELECTRIC TRACTOR SERVICE MANUAL – PDF DOWNLOAD

INTRODUCTION

This is a guide to those responsible for the repair and maintenace of the 127 towtractor. A full inspection and maintenance procedure for up to 10000 hours, together with all necessary checks and adjustments can be found in the Operating Instructions publication 127 804 2531 E. The TABLE OF CONTENT gives the various sections into which this manual is divided. Due to the ever increasing higher standard of production methods, materials used, and the company policy of continuous improvement, various servicing procedures will have changed.

IMAGES PREVIEW OF THE MANUAL:

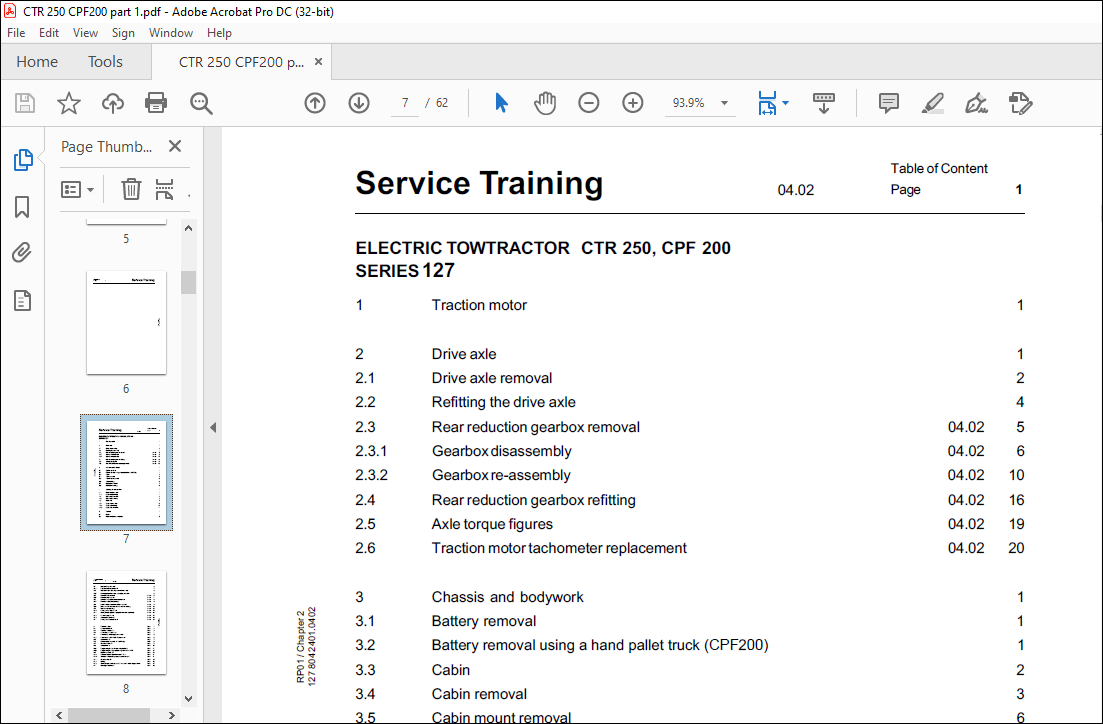

TABLE OF CONTENTS:

OM Pimespo ELECTRIC TRACTOR SERVICE MANUAL – PDF DOWNLOAD

Service TrainingTable of ContentELECTRIC TOWTRACTOR CTR 250, CPF 200

SERIES 127Traction motorDrive axleDrive axle removalRefitting the drive axleRear reduction gearbox removal

Gearbox disassemblyGearbox re-assemblyRear reduction gearbox refittingAxle torque figuresTraction motor tachometer replacementChassis and bodyworkBattery removalBattery removal using a hand pallet truck (CPF200)

CabinCabin removalCabin mount removalCabin refittingDashboard removalDashboard refittingSteering, wheels and tyres

Front wheel removalFront wheel refittingRear wheel removalRear wheel refittingFront axleFront axle removalFront axle refittingFront axle assemblyControls

Brakes

Front disc brake examination

54 Front brake pad removal 6

5.4.1 Front brake pad replacement 7

55 Front brake disc and caliper assembly removal 8

5.5.1 Refitting of front brake disc and caliper assembly 9

5.6 Rear brake disassembly 04.02 10

5.6.1 Rear brake reassembly 04.02 11

5.7 Rear disc brake piston seals repacement 04.02 16

5.7.1 Rear disc brake piston refitting 04.02 18

5.8 Master cylinder and servo cylinder – removal 04.02 19

5.8.1 Brake master cylinder and servo cylinder – refitting 04.02 23

5.9 Brake system bleeding 04.02 23

5.10 Parking brake – adjustment 04.02 25

5.11 Inching cylinder pushrod and proximity switch adjustment 04.02 26

5.12 Footbrake adjustment 04.02 27

5.13 Accelerator adjustment 04.02 28

5.14 Parking brake cable removal 04.02 29

6 Electrical system 09.01 1

6.1 Control unit layout 09.01 12

6.2 Traction controller 1A1 09.01 13

6.3 Contactor 1K1a and 1K1b 09.01 14

6.4 Keyswitch S1 (Steering Power circuit) 09.01 15

6.4.1 Keyswitch S1 (TRACTION Power circuit) 09.01 16

6.5 Seat switch 151 09.01 17

6.6 Battery door lock switch 1812 (CPF200) 09.01 18

6.7 Direction switch S11 09.01 19

6.8 Accelerator 1A4 09.01 20

6.8.1 Programming the Accelerator using LINDIAG 09.01 21

6.8.2 Programming the Accelerator using TRUCK DOCTOR 09.01 22

6.9 Footbrake switch 157 09.01 23

6.10 Traction motor Temperature sensor 1B12 09.01 24

6.10.1 Traction controller temperature sensor (internal) 09.01 24

6.11 Speed sensor 1B1 09.01 25

6.12 Inching 09.01 26

6.13 Axle brake proximity sensor 1B11 (on trucks with inching controls) 09.01 27

6.14 Steering controller 3A1 09.01 286.15 Steering pressure switch 1522 09.01

6.16 Steering pump motor temperature sensor 3B11 09.01

6.17 Driver’s display 09.01

6.18 Diagnostics 09.01

6.19 LINDIAG menu map 09.01

6.20 TRUCK DOCTOR navigational structure 09.01

6.21 Traction controller parameters 09.01

6.21.1 Traction controller options 09.01

6.21.2 Traction controller test values (controller inputs) 09.01

6.21.3 Traction controller alarms 09.01

6.22 Steering controller parameters 09.01

6.22.1 Steering controller options 09.01

6.22.2 Steering controller test values (controller inputs) 09.01

6.22.3 Steering controller alarms 09.01

6.23 Display parameters 09.01

6.23.1 Display options 09.01

6.23.2 Display test values (inputs) 09.01

6.23.3 display alarms 09.01

7 Hydraulic system7.1 Introduction7.2 Hydraulic schematic7.3 Filter renewal74 Hydraulic tank breather renewal7.5 Hydraulic fluid level check7.6 Hydraulic pump motor7.6.1 Pump and motor removal7.6.2 Pump and motor refitting7.6.3 Removing the hydraulic pump from the motor

10 Miscelaneous 1

10.1 AMP-SAAB connectors 1

10.2 Standard torques 2

10.3 Non standard torques 3

10.4 Special tools, sealants and compounds 04.02 4

10.5 Recommend lubricants 09.01 5