$45

Pinguely Haulotte SELF PROPELLED LIFT HA20 PX - HA26PX REPAIR MANUAL - PDF DOWNLOAD

Pinguely Haulotte SELF PROPELLED LIFT HA20 PX - HA26PX REPAIR MANUAL - PDF DOWNLOAD

FILE DETAILS:

Pinguely Haulotte SELF PROPELLED LIFT HA20 PX - HA26PX REPAIR MANUAL - PDF DOWNLOAD

Language :English

Pages :282

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Pinguely Haulotte SELF PROPELLED LIFT HA20 PX - HA26PX REPAIR MANUAL - PDF DOWNLOAD

GENERAL

- This manual gives the information required for you to perform servicing and repair operations on certain pieces of equipment yourself

- However, we would like to bring your attention to the importance of:

• respecting the safety instructions concerning the machine itself, its use and

its environment,

• use within the limits of its performance,

• correct servicing to ensure long service life - During and after the guarantee period, our After-Sales service is available to perform any servicing operations you may require. In this case, contact our local agency or our Plant After-Sales service, specifying the exact type of machine and its serial number. To order consumables or spare parts, use the "Instructions for use and maintenace" manual and the "Spare parts" catalogue to order original parts, the only guarantee of interchangability and perfect operation

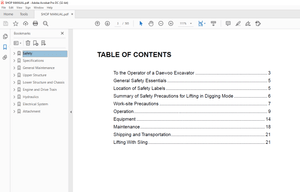

TABLE OF CONTENTS:

Pinguely Haulotte SELF PROPELLED LIFT HA20 PX - HA26PX REPAIR MANUAL - PDF DOWNLOAD

general 3

1 - general recommendations - safety 11

11 - general warning 11

111 - Manual 11

112 - Labels 11

113 - Safety 11

12 - general safety recommendations 12

121 - Operators 12

122 - Environment 12

123 - Using the machine 12

13 - RESIDUAL RISKS 14

131 - Risks of jerky movements and tipping over 14

132 - Electrical risk 14

133 - Risk of explosion or burning 14

134 - Risks of collision 14

14 - INSPECTIONS 15

141 - Periodic inspections 15

142 - Examination of machine suitability 15

143 - State of conservation 15

15 - REPAIRS AND ADJUSTMENTS 16

16 - Verifications When Returning To Service 16

17 - Beaufort Scale 16

2 - SPECIFICATIONS 17

21 - TECHNICAL CHARACTERISTICS 17

211 - HA 20PX technical characteristics 17

212 - HA 26PX technical characteristics 18

22 - OVERALL DIMENSIONS 20

221 - HA 20PX overall dimensions 20

222 - HA 26PX overall dimensions 21

23 - tightening torque 22

231 - Tightening torque for large thread 22

232 - Tightening torque for fine thread 22

233 - Tightening torque for hydraulic hoses 23

234 - Pressure values (in bar) 24

235 - Adjustment time 25

3 - SAFETY SYSTEM 27

31 - FUNCTIONS OF THE TURRET CABINET FUSES AND RELAYS 27

32 - FUNCTION OF THE SAFETY SWITCHES 27

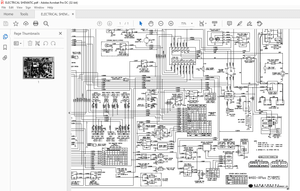

4 - WIRING DIAGRAM 29

41 - WIRING DIAGRAM E 448 - Folio 01/05 29

42 - WIRING DIAGRAM E 448 - Folio 02/05 30

43 - WIRING DIAGRAM E 448 - Folio 03/05 31

44 - WIRING DIAGRAM E 448 - Folio 04/05 32

45 - WIRING DIAGRAM E 448 - Folio 05/05 33

46 - PART LIST 34

5 - MACHINES ELEMENTS 37

51 - MOTOR 37

52 - FUSES 37

53 - Input 37

531 - Control inputs : 37

532 - Safety inputs : 39

54 - Output 39

541 - Relay 39

542 - "On/Off" electrovalves 39

543 - Proportional electrovalves 40

544 - Buzzer and light indicators 40

6 - operating equations 41

61 - start 41

62 - Stop moteur 41

63 - accelerator 41

64 - Compensation 41

65 - Rotation 41

66 - jib 42

67 - rotation 42

68 - arm lifting 42

69 - boom lifting 43

610 - telescoping 43

611 - travel 43

612 - steering 43

613 - differential blocking 44

614 - horn - buzzer 44

615 - indicators 44

616 - OTHER FUNCTIONS : OVERLOAD, DEAD MAN, SLOPE 45

6161 - Overload 45

6162 - Dead man 45

6163 - Slope 45

617 - HA26P REACH LIMIT 45

7 - SAFETY LOCATION 47

8 - POSITIONs of electric components 49

81 - mother board 49

811 - Description 49

812 - Positions of screws, connectors and relays 50

813 - Positions of fuses 51

814 - Positions of diagnosis help LEDs 52

9 - HYDRAULIC DIAGRAMS 53

91 - hydraulic diagram for ha20/26px AND ha61/80jrt MODELS (B1539)0 53

10 - HYDRAULICS COMPONENTS DESCRIPTION 55

101 - tRAVEL BLOCK 55

1011 - Location 55

1012 - Input and output 57

102 - PVG 32 DANFOSS BLOCK 58

1021 - Location 58

1022 - Input and output 59

103 - CETOP 3 AUXOLIARY BLOCK 60

1031 - Location 60

104 - Emergency pump unit 61

1041 - Location 61

105 - telecoping block 62

1051 - Location 62

106 - steering block control 63

1061 - Location 63

1062 - Input and output 63

11 - HYDRAULIC EQUATIONS 65

111 - TRAVEL 65

112 - Turntable rotation 65

113 - arm lifting 65

114 - boom lifting 65

115 - Telescoping 65

116 - Other movement 65

12 - MAINTENANCE 67

121 - GENERAL RECOMMENDATIONS 67

122 - PARTICULAR RECOMMENDATIONS 67

1221 - Specific tools 67

1222 - Replacing an element 68

1223 - Locating the breakdown 68

123 - maintenance system 68

124 - electric power supply 69

125 - MAINTENANCE PLAN 70

126 - OPERATIONS 72

1261 - Summary table 72

127 - presence of labels 73

1271 - Common "yellow" label 73

1272 - Commom "orange" label 74

1273 - Common "red" label 75

1274 - Other common label 76

1275 - Model-specific labels 77

1276 - Description 78

1277 - Label positioning 79

128 - presence of manuals 80

13 - PREVENTIVE MAINTENANCE SHEET 81

14 - OPERATING INCIDENTS 89

141 - INCIDENT TABLE 89

1411 - General operation 90

1412 - Lifting system 92

1413 - Travel system 93

1414 - Steering system 94

1415 - Turntable rotation system 94

142 - breakdown detection flow chart 94

15 - CORRECTIVE MAINTENANCE PROCEDURES183

S.M 24/2/2025