$40

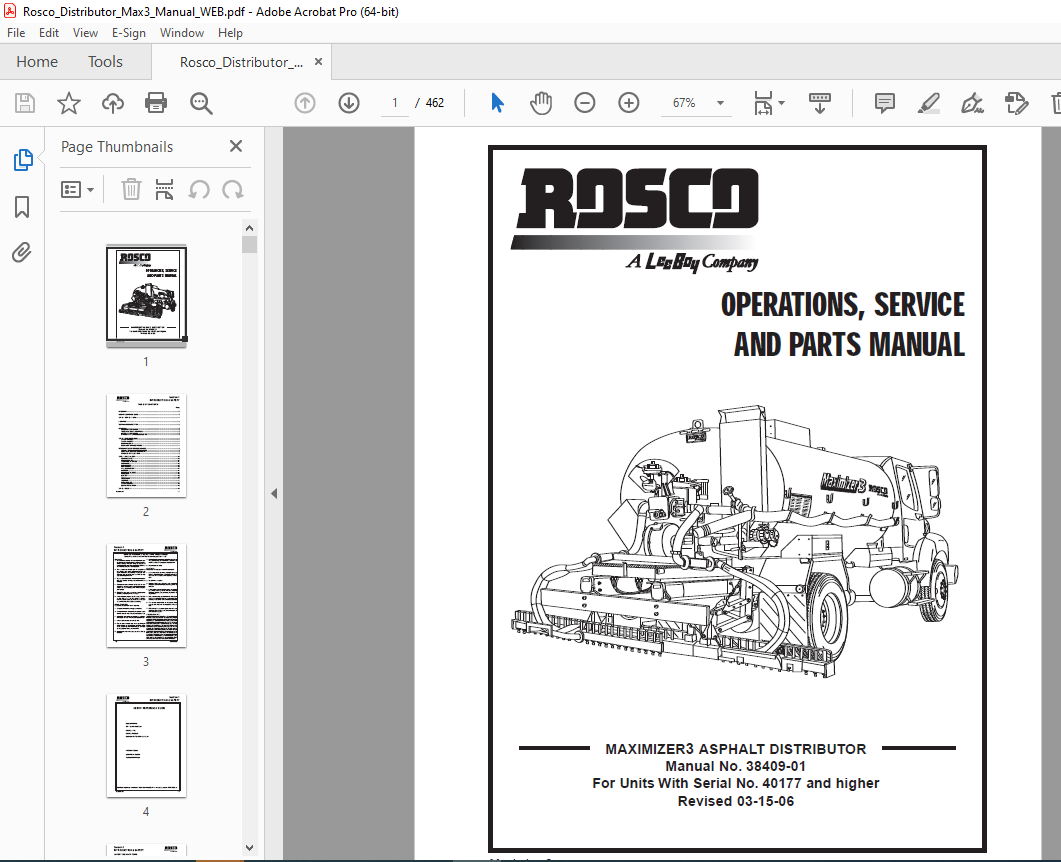

ROSCO MAXIMIZER3 ASPHALT DISTRIBUTOR Operation, Service & Parts Manual SN 40177 PDF DOWNLOAD

ROSCO MAXIMIZER3 ASPHALT DISTRIBUTOR Operation, Service & Parts Manual SN 40177 PDF DOWNLOAD

FILE DETAILS:

ROSCO MAXIMIZER3 ASPHALT DISTRIBUTOR Operation, Service & Parts Manual SN 40177 PDF DOWNLOAD

Language : English

Pages : 462

Downloadable :Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

VIDEO PREVIEW:

DESCRIPTION:

ROSCO MAXIMIZER3 ASPHALT DISTRIBUTOR Operation, Service & Parts Manual SN 40177 PDF DOWNLOAD

FORWARD

- The ROSCO Maximizer3 is used for the transportation and distribution of asphalt-based products for road maintenance and repair. The machine can spray asphalt emulsions, asphalt cements and cutback asphalts. ROSCO Manufacturing Company strongly recommends the use of asphalt emulsions.

- Water based emulsions reduce the risk of fire and explosion. The Maximizer3 should not be used to distribute water, calcium chloride or other de-icing liquids.

- These materials can corrode the pump and valves and dangerously contaminate the tank. If these materials are used in a Maximizer3, the warranty is voided on those components affected by the material. This manual contains the correct operation and routine maintenance procedures needed by the owner/ operator for the safe and efficient use of the ROSCO Maximizer3 Asphalt Distributor.

- In order to maximize the performance and efficiency of the Maximizer3, it is VERY IMPORTANT that the owner/ operator and maintenance personnel read this manual thoroughly before operating or servicing the distributor.

- You must know to handle asphalt products and should be trained and licensed per state requirements before operating this equipment. Always keep this manual in a convenient place for instant reference and never attempt to make repairs or adjustments that you do not fully understand.

- If you require additional information or service, contact your authorized ROSCO Dealer. The technical information found in this manual was correct at the time it was approved for publication.

- However, due to a continuous program of research and development, some procedures, specifications and parts may be altered in a constant effort to update and improve our products.

- ROSCO Manufacturing Company reserves the right to make design or specification changes without prior notification and to make improvements without incurring an obligation to add them to any machine in existence. Please contact your local authorized ROSCO Dealer if you require further assistance.

TABLE OF CONTENTS:

ROSCO MAXIMIZER3 ASPHALT DISTRIBUTOR Operation, Service & Parts Manual SN 40177 PDF DOWNLOAD

ROSCO A LeeBoy Company MAXIMIZER3 ASPHALT DISTRIBUTOR

Manual No. 38409-01 For Units With Serial No. 40177 and higher

Revised 03-15-06

WARRANTY 1-2

USERS’ REFERENCE GUIDE 1-3

SAFETY SIGN-OFF FORM 1-4

FORWARD 1-5

SERIAL NUMBER LOCATION 1-5

OVERVIEW 1-6

GENERAL INFORMATION 1-6

SPECIFICATIONS & CONTROLS 1-6

MATERIAL & OPERATION 1-6

MAINTENANCE & TROUBLESHOOTING 1-6

SAFETY CONSIDERATIONS 1-7

SAFETY SYMBOL 1-7

SAFETY WORDS 1-7

MACHINE SAFETY 1-7

EQUIPMENT DAMAGE SYMBOL 1-7

OPERATOR SAFETY CONSIDERATIONS 1-8

ASPHALT DISTRIBUTOR OPERATORS 1-8

QUALIFICATIONS FOR OPERATORS 1-8

CONDUCT OF OPERATORS 1-9

SAFETY PRECAUTIONS 1-10

GENERAL SAFETY 1-10

PRE-OPERATING 1-11

STARTING & STOPPING 1-11

OPERATING 1-12

MAINTENANCE 1-12

HOT MATERIAL 1-13

FIRE & EXPLOSION 1-14

BURNERS 1-14

HYDRAULIC SYSTEMS 1-14

REFUELING 1-15

BATTERY 1-16

TIRES 1-16

TRANSPORT 1-17

STORAGE 1-17

PTO DRIVELINE 1-17

SAFETY DECALS 1-18

DECAL INSTALLATION 1-18

SAFETY DECALS 1-19

MACHINE SPECIFICATIONS 2-2

COMPONENTS 2-4

EZ-3S CONTROLLER 2-6

REAR CONTROLLER 2-9

MATERIAL CONSIDERATIONS 3-4

MATERIAL TYPES AND GRADES 3-4

Asphalt Cement 3-4

Emulsified Asphalt 3-4

Cutback Asphalt 3-4

VISCOSITY 3-5

CONTAMINATION 3-5

GUIDELINE TEMPERATURES FOR LIQUID ASPHALT 3-6

GUIDE FOR LOADING ASPHALT PRODUCTS 3-7

SYSTEM OVERVIEW 3-8

CIRCULATING SYSTEM 3-8

BURNER SYSTEM 3-8

MACHINE BREAK-IN 3-10

BEFORE STARTING 3-10

AFTER 2 HOURS OF OPERATION 3-10

AFTER 8 & 20 HOURS OF OPERATION 3-10

PRE-OPERATING CHECK LIST 3-10

VISUAL INSPECTION 3-10

SERVICE & MAINTENANCE 3-10

SPRAYBAR INSPECTION 3-10

FUNCTIONAL CHECK 3-11

HYDRAULIC CIRCUIT 3-11

HYDROSTATIC CIRCUIT 3-11

AUTOMATIC VALVE SYSTEM 3-14

Tank Valve 3-14

2-Way Valve 3-14

3-Way Valve 3-14

ASPHALT SPRAYBAR 3-16

SPRAY PATTERN 3-16

SPRAYBAR HEIGHT 3-16

PREVENTING SPRAYBAR FAILURE 3-17

VALVES AND NOZZLES 3-17

ADJUSTMENT 3-17

NOZZLE SELECTION 3-18

BURNERS AND TORCH OPERATION 3-19

DIESEL BURNERS 3-19

Diesel Burner Ignition 3-19

Diesel Burner Extinguishing 3-21

LPG BURNERS 3-22

LPG Burner Manual Ignition 3-22

LPG Burner Manual Extinguishing 3-24

LPG Burner Auto Ignition 3-24

LPG Burner Auto Extinguishing 3-26

PORTABLE LPG TORCH 3-27

Portable LPG Torch Ignition 3-27

Portable LPG Torch Extinguishing 3-27

EZ-3S CONTROLLER OPERATION 3-29

OPERATING SCREENS 3-30

PRE-SETTING AND USING MEMORY FEATURE 3-32

SET-UP DISPLAY 3-33

Spraybar Rate Screen 3-33

Flow Calibration Screen 3-33

Speed Calibration Screen 3-34

Unit Of Measure Screen 3-34

Bar Retract Offset Screen 3-35

Bar Extend Offset Screen 3-35

Spraybar Stagger Screen 3-35

Spraybar Maximum Delay Screen 3-35

Bar Width Screen 3-35

Saving Data 3-36

MANUAL MODE 3-36

ERROR MESSAGES 3-37

ELECTRO MOTIVE RADIATION INTERFERENCE 3-37

MODES OF OPERATION 3-39

LOAD MODE 3-40

Bottom Tank Loading 3-41

Top Tank Loading 3-42

TANK CIRCULATE MODE 3-44

SPRAY / BAR CIRCULATE MODE 3-46

SPRAY MODE 3-48

HANDSPRAY MODE 3-50

Using Tank Circulate Mode 3-50

Using Unload Mode 3-51

Using Spray / Bar Circulate Mode 3-52

REVERSE SUCTION MODE 3-54

CLEANOUT MODE 3-56

Removing Solvent 3-58

Enviroflush 3-60

Remote Solvent Tank 3-62

TRANSFER MODE 3-66

UNLOAD MODE 3-70

WASHDOWN 3-72

COMBATING POOR VISIBILTY 3-73

MANUAL CALIBRATION 3-74

CALCULATIONS 3-74

RUN SIMULATION 3-75

TRIAL RUN 3-76