$33.95

Sakai Asphalt Roller SW800-II/850-II Service Manual PDF

Sakai Asphalt Roller SW800-II/850-II Service Manual – PDF DOWNLOAD

The Sakai Asphalt Roller SW800-II/850-II Service Manual is a comprehensive guide for maintenance and repair of Sakai SW800-II/850-II asphalt rollers. It includes detailed procedures, diagrams, and troubleshooting tips in a downloadable PDF format.

FILE DETAILS:

Sakai Asphalt Roller SW800-II/850-II Service Manual – PDF DOWNLOAD

Language : English

Pages : 258

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Sakai Asphalt Roller SW800-II/850-II Service Manual – PDF DOWNLOAD

- This manual provides important information to familiarize you with safe operating and maintenance procedures for your SAKAI roller. Even though you may be familiar with similar equipment you must read and understand this manual before operating or servicing this unit.

- Safety is everyone’s business and it is one of your primary concerns. Knowing the guidelines presented in this manual will help provide for your safety, for the safety of those around you and for the proper operation and maintenance of the machine. Improper operation is dangerous and can result in injury or death.

- Sakai Heavy Industries cannot foresee all possible circumstances or varying conditions to which the operator, serviceman or machine may be exposed to that might lead to a potential hazard. Therefore, the warnings and cautions listed in this manual and those placed on the machine are not intended to be all inclusive and liability for personal injury or damage to equipment or property cannot be assumed.

- All information, specifications and illustrations in this publication are based on the product information available at the time that the publication was written. The contents may change without prior notice due to modifications of the model.

TABLE OF CONTENTS:

Sakai Asphalt Roller SW800-II/850-II Service Manual – PDF DOWNLOAD

1. SAFETY

1. GENERAL SAFETY

1-1. Understanding the Safety Symbols and Words 1-001

1-2. General 1-001

1-3. Qualifications of Operators and Maintenance Personnel 1-002

1-4. Safety Practices and Policies 1-002

1-5. Pre Start Inspection 1-003

1-6. Safety Instructions 1-003

1-7. Starting 1-004

1-8. Operating 1-004

1-9. Stopping 1-004

1-10. Maintenance 1-005

1-11. Transporting the Machine 1-007

2. SPECIFICATIONS

1. SPECIFICATION DATA

1-1. SW800- 2-001

1-2. SW850- 2-003

2. TABLE OF STANDARD VALUES

2-1. Engine 2-005

2-2. Propulsion 2-005

2-3. Hydraulic System 2-005

2-4. Steering 2-006

2-5. Brakes 2-006

2-6. Water System 2-006

2-7. Oil and Grease Capacity 2-006

3. FUEL AND LUBRICANTS SPECIFICATION

3-1. Rating 2-007

3-2. Recommended Lubricants 2-007

4. TIGHTENING TORQUE CHART 2-008

3. ENGINE AND CONTROLS

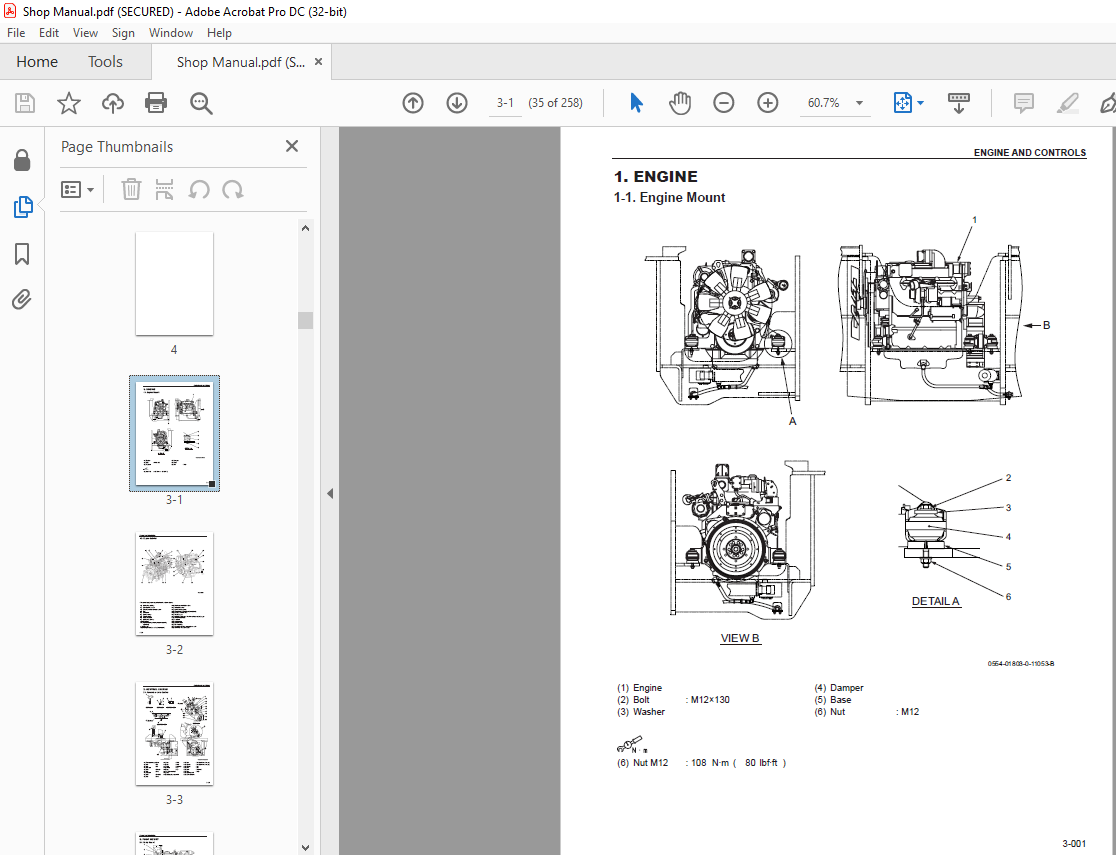

1. ENGINE

1-1. Engine Mount 3-001

1-2. Engine Exterior 3-002

SW800- /850- ○0

2. CONTROL SYSTEM

2-1. Forward-reverse Control 3-003

3. PUMP MOUNT

3-1. Pump Mount 3-004

3-1-1. Installation of pump 3-005

4. HYDRAULIC SYSTEMS

1. SYSTEM CIRCUIT DIAGRAM

1-1. Graphic Symbols for Hydraulic Circuits 4-001

1-2. Hydraulic Circuit Diagram (SW800- ) 4-003

1-3. Hydraulic Circuit Diagram (SW850- ) 4-004

2. PROPULSION HYDRAULIC SYSTEM

2-1. Propulsion Hydraulic Piping 4-005

2-1-1. Propulsion hydraulic piping (1) 4-005

2-1-2. Propulsion hydraulic piping (2) 4-006

2-2. Hydraulic Component Specifications 4-007

2-2-1. Hydraulic pump assembly (propulsion + vibrator) 4-007

2-2-2. Propulsion hydraulic motor (front) (SW800- ) 4-009

2-2-3. Propulsion hydraulic motor (front) (SW850- ) 4-011

2-2-4. Propulsion hydraulic motor (rear) (SW800- ) 4-013

2-2-5. Propulsion hydraulic motor (rear) (SW850- ) 4-015

3. VIBRATOR HYDRAULIC SYSTEM

3-1. Vibrator Hydraulic Piping 4-017

3-1-1. Vibrator hydraulic piping (1) 4-017

3-1-2. Vibrator hydraulic piping (2) 4-018

3-2. Hydraulic Component Specifications 4-019

3-2-1. Vibrator hydraulic motor 4-019

3-2-2. Vibration solenoid valve 4-020

4. STEERING SYSTEM

4-1. Steering Hydraulic Piping 4-021

4-1-1. Steering hydraulic piping 4-021

4-2. Hydraulic Component Specifications 4-022

4-2-1. Orbitrol 4-022

4-2-2. Steering pump 4-023

4-3. Frame (Center Pin) 4-024

5. ELECTRICAL SYSTEM

1. ELECTRICAL CIRCUIT

1-1. Electrical Circuit Diagram 5-001

2. ELECTRICAL COMPONENTS

2-1. Electrical Component Layout (1) 5-002

2-2. Electrical Component Layout (2) 5-003

3. ELECTRICAL COMPONENT SPECIFICATIONS

3-1. Fuse Box 5-004

3-2. Control Box (EMR3) 5-005

3-3. Resistor 5-006

3-4. Combination Meter 5-007

3-5. Diode Unit 5-008

6. VIBRATORY DRUM

1. PRECAUTIONS FOR DISASSEMBLY AND REASSEMBLY 6-001

2. REMOVAL AND INSTALLATION OF VIBRATORY DRUM

2-1. Removal of Vibratory Drum 6-003

2-2. Installation of Vibratory Drum 6-006

3. VIBRATORY DRUM ASSEMBLY

3-1. Vibratory Drum Assembly (SW800- ) 6-007

3-1-1. Vibratory drum exploded diagram 6-008

3-2. Vibratory Drum Assembly (SW850- ) 6-009

3-2-1. Vibratory drum exploded diagram 6-010

4. DISASSEMBLY AND REASSEMBLY OF VIBRATORY DRUM

4-1. Disassembly of Vibratory Drum 6-011

4-2. Reassembly of Vibratory Drum 6-025

7. BRAKE

1. BRAKE PEDAL 7-001

2. BRAKE CIRCUIT CONFIGURATION 7-002

3. HYDRAULIC COMPONENT SPECIFICATIONS

3-1. Valve 7-003

8. WATER SPRAY SYSTEM

1. WATER SPRAY PIPING 8-001

2. WATER SPRAY COMPONENT SPECIFICATION

2-1. Water Spray Pump 8-002

9. INSPECTION AND ADJUSTMENT

1. INSPECTION AND ADJUSTMENT

1-1. Safety Precautions for Inspection and Adjustment 9-001

1-2. Preparation for Inspection and Adjustment 9-001

1-3. Precautions for Inspection and Adjustment 9-001

1-4. Warm-up 9-001

1-5. Inspection and Adjustment of Engine Related Items 9-001

2. MEASUREMENT AND ADJUSTMENT OF PROPULSION CIRCUIT PRESSURE

2-1. Measurement 9-002

2-2. Adjustment 9-003

2-2-1. If the pressures on both the forward and reverse sides deviate

from the maximum circuit pressure range by the same value 9-003

2-2-2. If the pressure on either the forward or reverse side deviates from

the maximum circuit pressure range 9-004

3. MEASUREMENT AND ADJUSTMENT OF PROPULSION CHARGE CIRCUIT

PRESSURE

3-1. Measurement 9-005

3-2. Adjustment 9-006

4. MEASUREMENT OF PROPULSION SERVO CIRCUIT PRESSURE

4-1. Measurement 9-007

5. MEASUREMENT OF PARKING BRAKE RELEASE PRESSURE

5-1. Measurement 9-008

6. MEASUREMENT AND ADJUSTMENT OF VIBRATOR CIRCUIT PRESSURE

6-1. Measurement 9-009

6-1-1. Measurement of main relief pressure 9-009

6-1-2. Measurement of port relief pressure 9-010

6-2. Adjustment 9-011

6-2-1. Adjustment of the main relief valves 9-011

6-2-2. Adjustment of the port relief valves 9-012

7. MEASUREMENT AND INSPECTION OF STEERING CIRCUIT PRESSURE

7-1. Measurement 9-013

7-2. Inspection 9-014

8. ADJUSTMENT OF FORWARD-REVERSE LEVER LINKAGE

8-1. Adjustment 9-015

10. TROUBLESHOOTING

1. TROUBLESHOOTING

1-1. Safety Precautions for Troubleshooting 10-001

1-2. Important Information for Troubleshooting 10-001

1-3. Before Starting 10-002

1-4. Wire Color Code and Number 10-002

2. ELECTRICAL SYSTEM TROUBLESHOOTING

2-1. When Performing Electrical System Fault Diagnosis 10-003

2-1-1. Precautions to take during electrical circuit fault diagnosis 10-003

2-1-2. Inspection procedures using a tester 10-004

2-1-3. Inspection of electrical system 10-009

2-2. Blink Codes 10-011

2-2-1. Description of blink codes 10-011

2-2-2. Blink code list 10-012

2-3. Engine 10-017

2-3-1. Engine will not start (starter motor does not run) 1/2 10-017

2-3-1. Engine will not start (starter motor does not run) 2/2 10-019

2-3-2. Engine will not start (But starter motor runs) 10-021

2-3-3. No charging 10-023

2-3-4. Engine speed cannot be switched 10-023

2-3-5. Glow plug is not heated (Engine starting performance is bad

in cold weather) 10-025

2-3-6. Starter motor runs even when F-R lever is not at neutral position 10-025

2-4. Propulsion 10-027

2-4-1. Vehicle moves neither forward nor backward 10-027

2-4-2. Brake cannot be released 10-029

2-4-3. Brake does not operate 10-031

2-5. Vibrator 10-033

2-5-1. No vibration occurs 10-033

2-5-2. Amplitude does not change (Remains either Low or High) 10-035

2-5-3. Vibration frequency does not change 1/4 10-037

2-5-3. Vibration frequency does not change 2/4 10-039

2-5-3. Vibration frequency does not change 3/4 10-041

2-5-3. Vibration frequency does not change 4/4 10-043

2-5-4. Continuous/automatic-vibration mode does not change 10-045

2-5-5. Automatic-vibration mode does not work 1/2 10-047

2-5-5. Automatic-vibration mode does not work 2/2 10-049

2-6. Water Spray 10-051

2-6-1. Continuous water spray does not operate 1/2 10-051

2-6-1. Continuous water spray does not operate 2/2 10-053

2-6-2. Continuous water spray works, but intermittent water spray

does not operate 10-055

2-7. Lighting 10-057

2-7-1. Headlamps or flood lamps do not light 10-057

2-7-2. Illumination of combination meter does not turn on 10-059

2-7-3. Combination meter warning lamp or indicator lamp is abnormal 10-059

2-7-4. Tachometer reading is abnormal 10-061

2-7-5. Hour meter is abnormal 10-063

2-7-6. Temperature gauge is abnormal 10-063

2-7-7. Fuel gauge is abnormal 10-065

2-7-8. Hydraulic oil filter warning lamp remains ON 10-065

2-7-9. Charge warning lamp remains ON 10-067

2-7-10. Vibrator indicator lamp does not light 1/2 10-067

2-7-10. Vibrator indicator lamp does not light 2/2 10-069

2-7-11. Parking brake indicator lamp does not light 10-069

2-7-12 Water spray indicator lamp does not light 10-071

2-7-13. Flood lamp indicator lamp does not light 10-071

2-7-14. Horn does not sound 10-073

2-7-15. Backup buzzer does not sound 10-073

3. HYDRAULIC SYSTEM TROUBLESHOOTING

3-1. When Performing Hydraulic System Troubleshooting 10-074

3-2. Propulsion 10-075

3-2-1. Vehicle moves neither forward nor backward 1/2 10-075

3-2-1. Vehicle moves neither forward nor backward 2/2 10-076

3-2-2. Vehicle moves in one direction only (forward or backward) 10-076

3-2-3. Slow vehicle speed or small drive force 10-076

3-2-4. Vehicle does not stop completely with forward-reverse lever

in neutral position 10-077

3-2-5. Propulsion system is overheating 10-077

3-2-6. Abnormal noise from propulsion system 10-077

3-3. Vibrator System 10-078

3-3-1. No vibration 10-078

3-3-2. Vibrator frequency does not change 10-078

3-3-3. Vibrator frequency is too low 10-079

3-3-4. Amplitude does not switch between high and low 10-079

3-3-5. Vibrator does not stop 10-079

3-3-6. Vibrator system is overheating 10-080

3-3-7. Abnormal noise from vibrator system 10-080

3-4. Steering 10-081

3-4-1. Steering wheel is hard to turn 10-081

3-4-2. Steering response is slow 10-081

3-4-3. Steering wheel backlash or play is large 10-082

3-4-4. Steering system is overheating 10-082

3-4-5. Abnormal noise from steering system 10-082