$37

Sakai CR271 Shop Manual 3498-65634-0 – PDF DOWNLOAD

Sakai CR271 Shop Manual 3498-65634-0 – PDF DOWNLOAD

FILE DETAILS:

Sakai CR271 Shop Manual 3498-65634-0 – PDF DOWNLOAD

Language : English

Pages :170

Downloadable : Yes

File Type : PDF

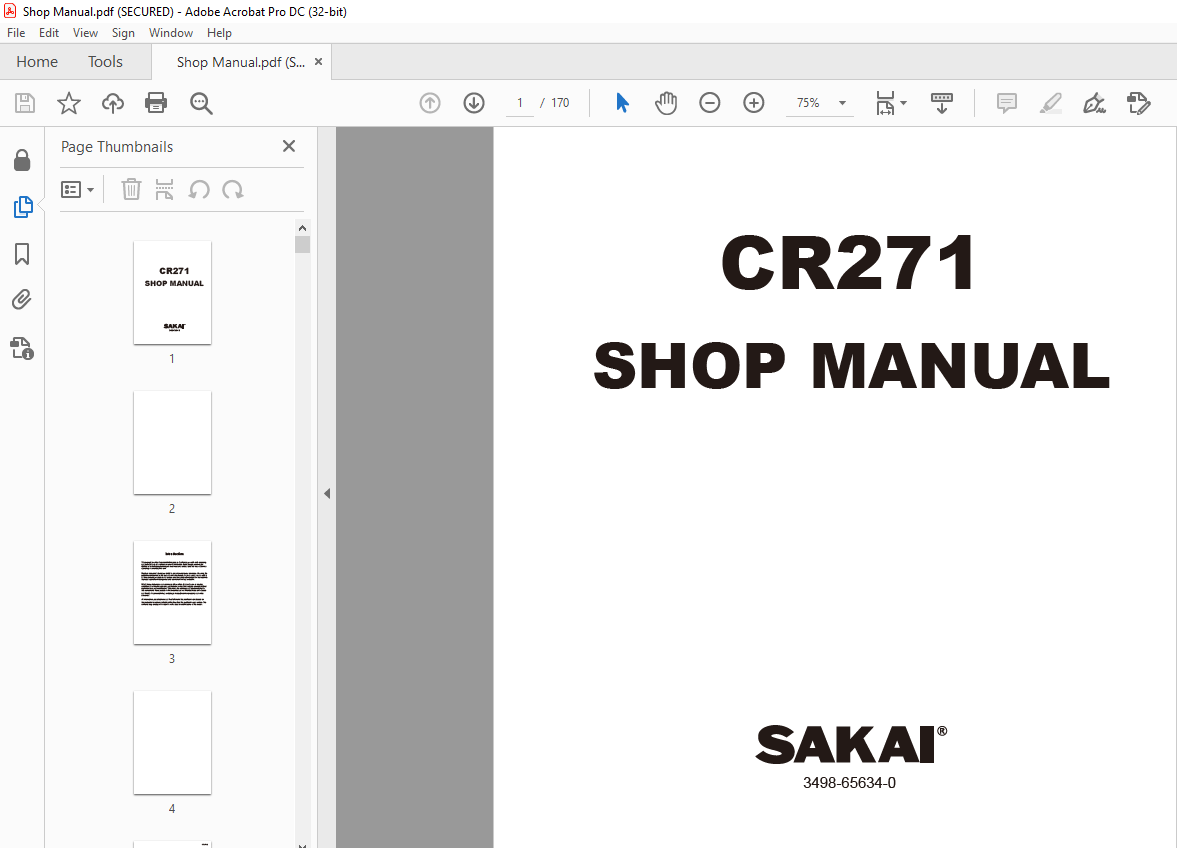

TABLE OF CONTENTS:

Sakai CR271 Shop Manual 3498-65634-0 – PDF DOWNLOAD

1. SAFETY

1. GENERAL SAFETY

1-1. Understanding the Safety Symbols and Words 1-001

1-2. General 1-001

1-3. Qualifications of Operators and Maintenance Personnel 1-002

1-4. Safety Practices and Policies 1-002

1-5. Pre Start Inspection 1-003

1-6. Safety Instructions 1-003

1-7. Starting 1-004

1-8. Operating 1-004

1-9. Stopping 1-004

1-10. Maintenance 1-005

1-11. Transporting the Machine 1-007

2. SPECIFICATIONS

1. SPECIFICATION DATA

1-1. CR271 2-001

2. TABLE OF STANDARD VALUES

2-1. Engine 2-003

2-2. Propulsion 2-003

2-3. Hydraulic Systems 2-003

2-4. Steering 2-004

2-5. Capacities 2-004

3. FUEL AND LUBRICANTS SPECIFICATION

3-1. Rating 2-005

3-2. Recommended Lubricants 2-005

4. TIGHTENING TORQUE CHART 2-006

3. ENGINE AND CONTROLS

1. ENGINE

1-1. Engine Mount 3-001

2. CONTROL SYSTEM

2-1. Throttle Control 3-002

2-2. Forward-reverse Control 3-003

3. PUMP MOUNT

3-1. Pump Mount 3-004

3-1-1. Installation of pump 3-005

4. HYDRAULIC SYSTEMS

1. SYSTEM CIRCUIT DIAGRAM

1-1. Graphic Symbols for Hydraulic Circuits 4-001

1-2. Hydraulic Circuit Diagram 4-003

2. PROPULSION HYDRAULIC SYSTEM

2-1. Propulsion Hydraulic Piping 4-004

2-1-1. Propulsion hydraulic piping (1) 4-004

2-1-2. Propulsion hydraulic piping (2) 4-005

2-2. Hydraulic Component Specifications 4-006

2-2-1. Hydraulic pump assembly (propulsion + vibrator + steering) 4-006

2-2-2. Propulsion hydraulic motor 4-008

2-2-3. Valve block 4-009

2-2-4. Valve 4-010

3. VIBRATOR HYDRAULIC SYSTEM

3-1. Vibrator Hydraulic Piping 4-011

3-2. Hydraulic Component Specification 4-012

3-2-1. Vibrator hydraulic motor 4-012

4. STEERING SYSTEM

4-1. Steering Hydraulic Piping 4-013

4-2. Hydraulic Component Specifications 4-014

4-2-1. Orbitrol 4-014

4-3. Frame (Center Pin) 4-015

CR271 ○0

5. ELECTRICAL SYSTEM

1. Precautions for wor k

1-1. W ire Numbers, Wire Sizes, Wire Colors and Connectors Shown in

Electrical Circuit Diagrams, Wiring Harness Layout and Wiring Harnesses 5-001

2. SYSTEM CIRCUIT DIAGRAM

2-1. Electrical Circuit Diagram 5-003

3. ELECTRICAL COMPONENTS

3-1. Electrical component Layout 5-004

4. WIRING HARNESSES

4-1. Harness (1) 5-005

4-2. Harness (2) 5-007

6. DRUMS

1. PRECAUTIONS FOR DISASSEMBLY AND REASSEMBLY 6-001

2. REMOVAL AND INSTALLATION OF DRUMS

2-1. Removal of Drums 6-003

2-1-1. Front drum 6-003

2-1-2. Rear drum 6-006

2-2. Installation of Drums 6-008

3. DRUM ASSEMBLY

3-1. Front Drum 6-009

3-2. Rear Drum 6-010

4. DISASSEMBLY AND REASSEMBLY OF DRUMS

4-1. Disassembly of Drums 6-011

4-1-1. Front drum 6-011

4-1-2. Rear drum 6-018

4-2. Reassembly of Drums 6-024

4-2-1. Front drum 6-024

4-2-2. Rear drum 6-034

7. PARKING BRAKE

1. PARKING BRAKE

1-1. Brake 7-001

8. WATER SPRAY SYSTEM

1. WATER SPRAY SYSTEM

1-1. Water spray 8-001

9. INSPECTION AND ADJUSTMENT

1. INSPECTION AND ADJUSTMENT

1-1. Safety Precautions for Inspection and Adjustment 9-001

1-2. Preparation for Inspection and Adjustment 9-001

1-3. Precautions for Inspection and Adjustment 9-001

1-4. Warm-up 9-001

1-5. Inspection and Adjustment of Engine Related Items 9-001

2. MEASUREMENT AND INSPECTION OF PROPULSION CIRCUIT PRESSURE

2-1. Measurement 9-002

2-2. Adjustment 9-003

3. MEASUREMENT AND INSPECTION OF PROPULSION CHARGE CIRCUIT

PRESSURE 9-004

3-1. Measurement 9-004

3-2. Adjustment 9-005

4. MEASUREMENT AND ADJUSTMENT OF STEERING CIRCUIT PRESSURE

4-1. Measurement 9-006

4-2. Adjustment 9-007

5. MEASUREMENT OF HYDRAULIC PUMP CASE PRESSURE

5-1. Measurement 9-008

6. MEASUREMENT OF PROPULSION MOTOR CASE PRESSURE

6-1. Measurement 9-009

7. ADJUSTMENT OF THROTTLE LEVER LINKAGE

7-1. Adjustment 9-010

8. ADJUSTMENT OF F-R LEVER LINKAGE

8-1. Adjustment 9-012

10. TROUBLESHOOTING

1. TROUBLESHOOTING

1-1. Safety Precautions for Troubleshooting 10-001

1-2. Important Information for Troubleshooting 10-001

1-3. Before Starting 10-002

1-4. Wire Number and Color Code 10-002

2. ELECTRICAL SYSTEM TROUBLESHOOTING

2-1. When Performing Electrical System Fault Diagnosis 10-003

2-1-1. Precautions to take during electrical circuit fault diagnosis 10-003

2-1-2. Inspection procedures using a tester 10-004

2-1-3. Inspection of electrical system 10-009

2-2. Engine 10-012

CR271 ○0

2-2-1. Engine will not start (Starter motor does not run) 10-012

2-2-2. Engine will not start (But starter motor runs) 10-014

2-2-3. No charging 10-016

2-2-4. Starter motor runs even when F-R lever is not at “N” applied 10-016

2-3. Propulsion 10-018

2-3-1. Hour meter is abnormal 10-018

2-3-2. Horn does not sound 10-018

2-4. Vibration 10-020

2-4-1. No vibration occurs 10-020

3. HYDRAULIC SYSTEM TROUBLESHOOTING

3-1. When Performing Hydraulic System Troubleshooting 10-021

3-2. Propulsion System 10-022

3-2-1. Machine moves neither forward nor backward 10-022

3-2-2. Machine moves in one direction only (forward or backward) 10-023

3-2-3. Slow machine speed or small drive force 10-023

3-2-4. Machine does not stop completely with F-R lever in “N” 10-024

3-2-5. Propulsion system is overheating 10-024

3-2-6. Abnormal noise from propulsion system 10-024

3-3. Steering System 10-025

3-3-1. Steering wheel is hard to turn 10-025

3-3-2. Steering response is slow 10-025

3-3-3. Steering wheel backlash or play is large 10-026

3-3-4. Steering system is overheating 10-026

3-3-5. Abnormal noise from steering system 10-026

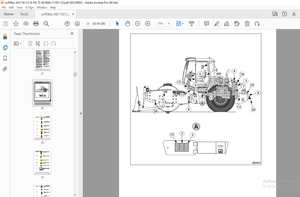

IMAGES PREVIEW OF THE MANUAL: