$38

Sakai SW770 Shop Manual 3498-6431 A-0 – PDF DOWNLOAD

Sakai SW770 Shop Manual 3498-6431 A-0 – PDF DOWNLOAD

FILE DETAILS:

Sakai SW770 Shop Manual 3498-6431 A-0 – PDF DOWNLOAD

Language : English

Pages :400

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Sakai SW770 Shop Manual 3498-6431 A-0 – PDF DOWNLOAD

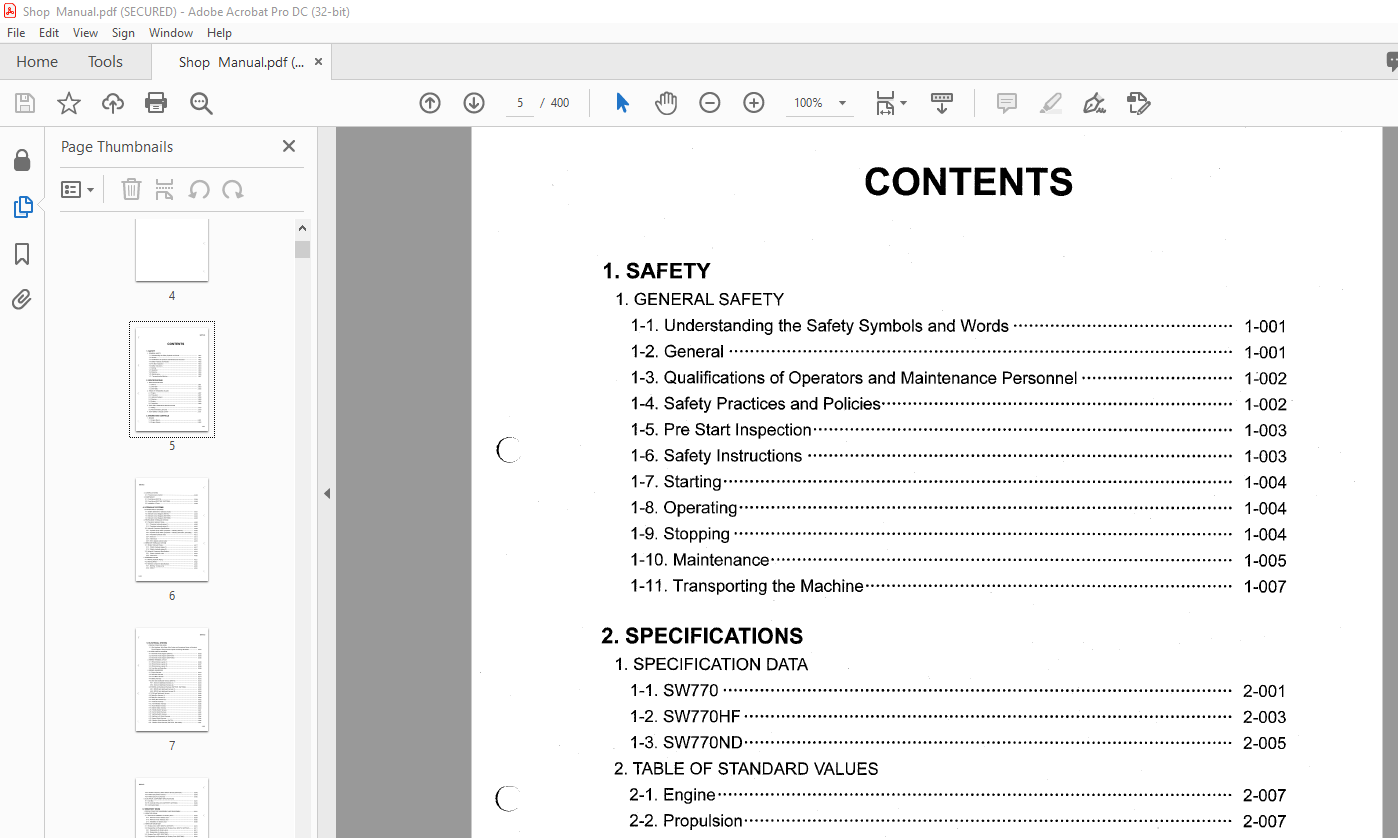

1 SAFETY

1 GENERAL SAFETY

1-1 Understanding the Safety Symbols and Words 1-001

1-2 General 1-001

1-3 Qualifications of Operators and Maintenance Personnel 1:002

1-4 Safety Practices and Policies 1-002

1-5 Pre Start Inspection 1-003

1-6 Safety Instructions 1-003

1-7 Starting 1-004

1-8 Operating 1-004

1-9 Stopping 1-004

1-10 Maintenance 1-005

1-11 Transporting the Machine 1-007

2 SPECIFICATIONS

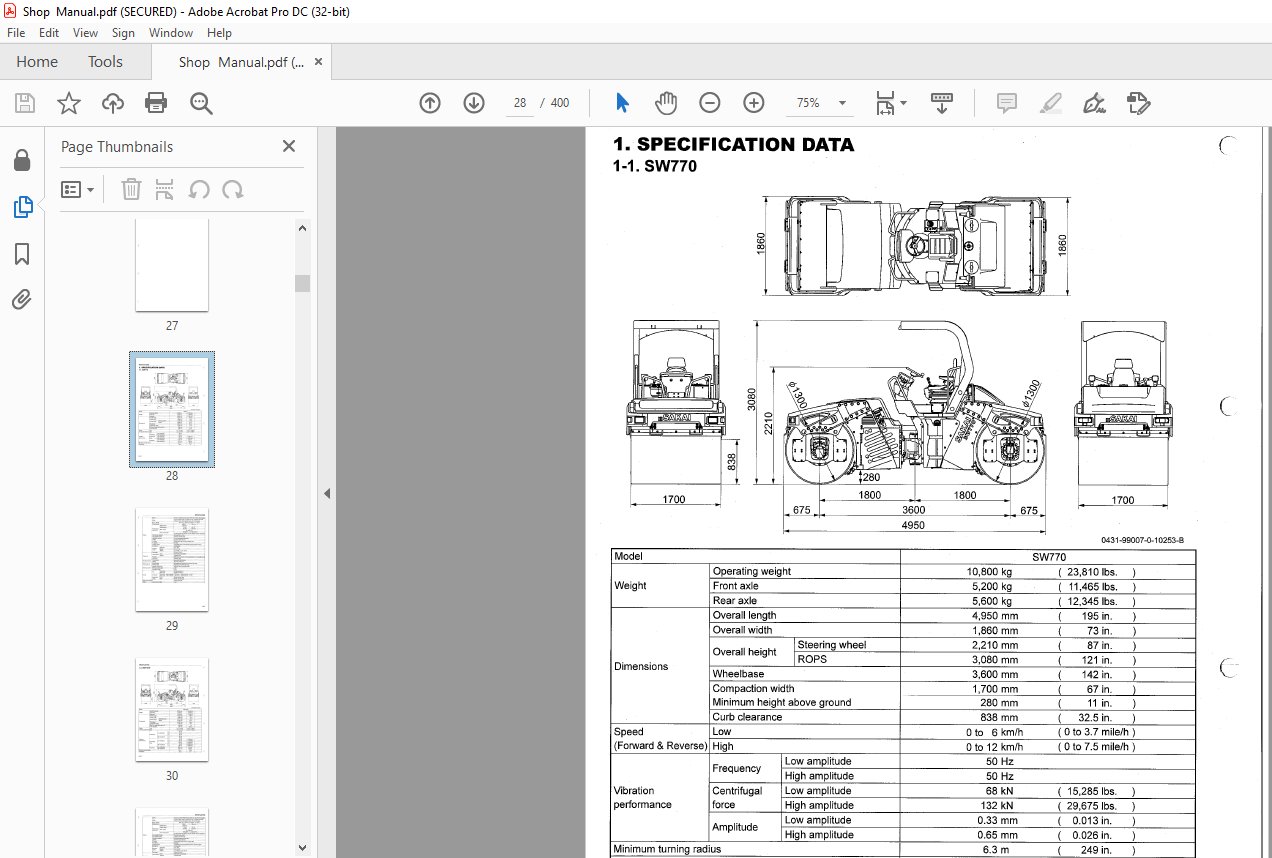

1 SPECIFICATION DATA

1-1 SW770 2-001

1-2 SW770HF 2-003

1-3 SW770ND 2-005

2 TABLE OF STANDARD VALUES

2-1 Engine 2-007

2-2 Propulsion 2-007

2-3 Hydraulic Systems 2-008

2-4 Steering 2-008

2-5 Brakes 2-009

2-6 Capacities 2-009

3 FUELAND LUBRICANTS SPECIFICATION

3-1 Rating 2-01 O

3-2 Recommended Lubricants 2-01 O

4 TIGHTENING TORQUE CHART– 2-011

3 ENGINE AND CONTROLS

1 ENGINE

1-1 Engine Mount 3-001

1-2 Engine Exterior 3-002

2 CONTROL SYSTEM

2-1 Forward-reverse Control 3-003

3 PUMP MOUNT

3-1 Pump Mount (SW770) 3-004

3-2 Pump Mount (SW770HF, SW770ND) 3-005

3-3 Installation of Pump 3-006

4 HYDRAULIC SYSTEMS

1 SYSTEM CIRCUIT DIAGRAM

1-1 Graphic Symbols for Hydraulic Circuits 4-001

1-2 Hydraulic Circuit Diagram (SW770) 4-003

1-3 Hydraulic Circuit Diagram (SW770HF) 4-004 C

1-4 Hydraulic Circuit Diagram (SW770ND) 4-005

2 PROPULSION HYDRAULIC SYSTEM

2-1 Propulsion Hydraulic Piping 4-006

2-1-1 Propulsion hydraulic piping (1) 4-006

2-1-2 Propulsion hydraulic piping (2) 4-007

2-2 Hydraulic Component Specifications 4-008

2-2-1 Hydraulic pump ASSY (propulsion + vibrator) (SW770) 4-008

2-2-2 Hydraulic pump ASSY (propulsion+ vibrator) (SW770HF, SW770ND) 4-010

2-2-3 Propulsion hydraulic motor 4-012

2-2-4 Gear box 4-013

2-2-5 Valve block 4-014

2-2-6 Servo bypass solenoid valve 4-016

3 VIBRATOR HYDRAULIC SYSTEM (

3-1 Vibrator Hydraulic Piping 4-017

3-1-1 Vibrator hydraulic piping (1) 4-017

3-1-2 Vibrator hydraulic piping (2) 4-018

3-2 Hydraulic Component Specifications 4-019

3-2-1 Vibrator hydraulic motor 4-019

3-2-2 Valve block 4-020

4 STEERING SYSTEM

4-1 Steering Hydraulic Piping 4-021

4-2 Steering Wheel 4-022

4-3 Hydraulic Component Specifications 4-023

4-3-1 Steering• charge pump 4-023

4-3-2 Orbitrol 4-024

5 ELECTRICAL SYSTEM

1 PRECAUTIONS FOR WORK

1-1 Wire Numbers, Wire Sizes, Wire Colors and Connectors Shown in Electrical

Circuit Diagram, Wiring Harness Layout and Wiring Harnesses 5-001

2 SYSTEM CIRCUIT DIAGRAM

2-1 Electrical Circuit Diagram (SW770) 5-003

2-2 Electrical Circuit Diagram (SW770HF) 5-004

2-3 Electrical Circuit Diagram (SW770ND) 5-005

3 WIRING HARNESS LAYOUT

3-1 Wiring Harness Layout (1 ) 5-006

3-2 Wiring Harness Layout (2) 5-007

3-3 Wiring Harness Layout (3) 5-008

3-4 Fuse Box and Relay Box 5-009

4 WIRING HARNESSES

4-1 Engine Harness 5-01 O

4-2 Rear Main Harness 5-012

4-3 Front Main Harness 5-014

4-4 Battery Harness 5-016

4-5 Deck and Dashboard Harness (SW770) 5-018

4-5-1 Deck and dashboard harness (1) 5-018

4-5-2 Deck and dashboard harness (2) 5-020

4-6 SODAS and Dashboard Harness (SW770HF, SW770ND) 5-022

4-6-1 BO DAS and dashboard harness (1 ) 5-022

4-6-2 SODAS and dashboard harness (2) 5-024

4-7 ECM and Dashboard Harness 5-026

4-8 Relay Box Harness (1 ) 5-028

4-9 Relay Box Harness (2) 5-030

4-10 Relay Box Harness (3) 5-032

4-11 Fuse Box Harness 5-034

4-12 Front Member Harness 5-036

4-13 Rear Member Harness 5-038

4-14 Starter Switch Harness 5-040

4-15 Throttle Switch Harness 5-041

4-16 Control Switch Harness 5-042

4-17 Lighting Switch Harness 5-043

4-18 Lighting Lo-Hi Switch Harness 5-044

4-19 Hazard Switch Harness 5-045

4-20 Vibration Switch Harness (SW770) 5-046

4-21 Vibration Switch Harness (SW770HF, SW770ND) 5-047

4-22 Vibration Frequency Select Switch Harness (SW770HF) 5-048

4-23 Water Spray Switch Harness 5-049

4-24 Water Spray Pump Harness 5-050

5 ELECTRICAL COMPONENT SPECIFICATIONS

5-1 Fuse Box 5-051

5-2 RC Controller (RC2-2/21) (SW770HF, SW770ND) 5-052

5-3 Combination Meter5-054

6 VIBRATORY DRUM

1 PRECAUTIONS FOR DISASSEMBLY AND REASSEMBLY6-001

2 VIBRATORY DRUM

2-1 Removal and Installation of Vibratory Drum

2-1-1 Removal of front vibratory drum

2-1-2 Removal of rear vibratory drum

2-1-3 Installation of vibratory drum

3 VIBRATORY DRUM ASSY

3-1 Vibratory Drum ASSY (SW770, SW770HF)

3-2 Disassembly and Reassembly of Vibratory Drum (SW770, SW770HF)

3-2-1 Disassembly of vibratory drum

3-2-2 Reassembly of vibratory drum

3-3 Vibratory Drum ASSY (SW770ND)

3-4 Disassembly and Reassembly of Vibratory Drum (SW770ND)

3-4-1 Disassembly of vibratory drum

3-4-2 Reassembly of vibratory drum

1 BRAKE PEDAL 7-001

2 BRAKE SYSTEM?-002

8 WATER SPRAY SYSTEM

1 WATER SPRAY SYSTEM

1-1 Water Spray Piping (1 )8-001

1-2 Water Spray Piping (2) 8-002

9 INSPECTION AND ADJUSTMENT

1 INSPECTION AND ADJUSTMENT

1-1 Safety Precautions for Inspection and Adjustment 9-001

1-2 Preparation for Inspection and Adjustment 9-001

1-3 Precautions for Inspection and Adjustment 9-001

1-4 Warm-up 9-001

1-5 Inspection and Adjustment of Engine Related Items 9-001

2 MEASUREMENT AND ADJUSTMENT OF PROPULSION CIRCUIT PRESSURE

(SW770)

2-1 Measurement 9-002

2-2 Adjustment 9-003

2-2-1 If pressures on both forward and reverse sides deviate from maximum circuit

pressure range by same value 9-003

2-2-2 If pressure on either forward or reverse side deviates from maximum circuit

pressure range 9-004

3 MEASUREMENT AND ADJUSTMENT OF PROPULSION CIRCUIT PRESSURE

(SW770HF, SW770ND)

3-1 Measurement 9-005

3-2 Adjustment 9-006

3-2-1 If pressures on both forward and reverse sides deviate from maximum circuit

pressure range by same value 9-006

3-2-2 If pressure on either forward or reverse side deviates from maximum circuit

pressure range 9-007

4 MEASUREMENT AND ADJUSTMENT OF PROPULSION/ VIBRATOR CHARGE

CIRCUIT PRESSURE (SW770)

4-1 Measurement 9-008

4-2 Adjustment 9-009

5 MEASUREMENT AND ADJUSTMENT OF PROPULSION/ VIBRATOR CHARGE

CIRCUIT PRESSURE (SW770HF, SW770ND)

5-1 Measurement 9-01 O

5-2 Adjustment 9-011

6 MEASUREMENT OF MACHINE HIGH/LOW SPEED CHANGE CIRCUIT PRESSURE

6-1 Measurement 9-012

7 MEASUREMENT OF PROPULSION SERVO CIRCUIT PRESSURE

(SW770)

7 -1 Measurement 9-013

8 MEASUREMENT OF PROPULSION SERVO CIRCUIT PRESSURE

(SW770HF, SW770ND)

8-1 Measurement 9-014

9 MEASUREMENT OF PARKING BRAKE RELEASE PRESSURE

9-1 Measurement 9-015

0-005

SW770®

10 MEASUREMENT AND ADJUSTMENT OF VIBRATOR CIRCUIT PRESSURE

(SW770)

10-1 Measurement 9-016

10-2 Adjustment 9-017

10-2-1 If pressures on both Low amplitude and High amplitude sides deviate from

maximum circuit pressure range by same value 9-017

10-2-2 If pressure on either Low amplitude or High amplitude side deviates from

maximum circuit pressure range 9-018

11 MEASUREMENT AND ADJUSTMENT OF VIBRATOR CIRCUIT PRESSURE

(SW770HF, SW770ND)

11-1 Measurement 9-019

11-2 Adjustment 9-020 (_

11-2-1 If pressures on both Low amplitude/Normal and High amplitude/

Horizontal sides deviate from maximum circuit pressure range by

same value 9-020

11-2-2 If pressure on either Low amplitude/Normal or High amplitude/

Horizontal side deviates from maximum circuit pressure range 9-021

12 MEASUREMENT AND INSPECTION OF STEERING CIRCUIT PRESSURE

12-1 Measurement 9-022

12-2 Inspection 9-023

13 MEASUREMENT OF HYDRAULIC PUMP CASE PRESSURE (SW770)

13-1 Measurement of Propulsion Pump Case Pressure 9-024

13-2 Measurement of Vibrator Pump Case Pressure 9-025

14 MEASUREMENT OF HYDRAULIC PUMP CASE PRESSURE (SW770HF, SW770ND)

14-1 Measurement of Propulsion Pump Case Pressure 9-026

14-2 Measurement of Vibrator Pump Case Pressure 9-027

15 MEASUREMENT OF PROPULSION MOTOR CASE PRESSURE

15-1 Measurement 9-028

16 MEASUREMENT OF VIBRATOR MOTOR CASE PRESSURE (SW770, SW770HF)

16-1 Measurement 9-029

17 MEASUREMENT OF VIBRATOR MOTOR CASE PRESSURE (SW770ND)

17-1 Measurement • 9-030

18 ADJUSTMENT OF F-R LEVER LINKAGE

18-1 Adjustment 9-031

10 TROUBLESHOOTING

1 TROUBLESHOOTING

1-1 Safety Precautions for Troubleshooting 10-001

1-2 Important Information for Troubleshooting 10-001

1-3 Before Starting 10-002

2 ELECTRICAL SYSTEM TROUBLESHOOTING

2-1 When Performing Electrical System Fault Diagnosis 10-003

2-1-1 Precautions to take during electrical circuit fault diagnosis 10-003

2-1-2 Inspection procedures using a tester 10-004

2-1-3 Inspection of electrical system 10-009

2-2 Engine Diagnosis Trouble Code 10-011

2-2-1 Description of diagnostic trouble code (OTC) 10-011

2-2-2 Table of the diagnostic trouble code (DTC) 10-013

2-3 Vibration Error Lamp (SW770HF, SW770ND) 10-016

2-4 Engine 10-018

2-4-1 Engine will not start (Starter motor does not run) 1/3 10-018

2-4-1 Engine will not start (Starter motor does not run) 2/3 10-020

2-4-1 Engine will not start (Starter motor does not run) 3/3 10-022

2-4-2 Engine will not start (But starter motor runs) 10-024

2-4-3 No charging 10-026

2-4-4 Glow plug is not heated

(Engine starting performance is bad in cold weather) 10-026

2-4-5 Engine speed cannot be switched 10-028

2-4-6 Starter motor runs even when F-R lever is not at “N” and

parking brake is not applied 10-028

2-5 Propulsion 10-030

2-5-1 Machine moves neither forward nor backward 1/3 10-030

2-5-1 Machine moves neither forward nor backward 2/3 10-032

2-5-1 Machine moves neither forward nor backward 3/3 10-034

2-5-2 Machine speed cannot be changed 10-034

2-5-3 Brake does not work 10-036

2-6 Vibration 10-038

2-6-1 No vibration occurs 1/4 10-038

2-6-1 No vibration occurs 2/4 10-040

2-6-1 No vibration occurs 3/4 10-042

2-6-1 No vibration occurs 4/4 10-044

2-6-2 Amplitude does not change

(Remains either low/horizontal or high/normal) 1/3 10-046

2-6-2 Amplitude does not change

(Remains either low/horizontal or high/normal) 2/3 10-048

2-6-2 Amplitude does not change

(Remains either low/horizontal or high/normal) 3/3 10-050

2-6-3 Frequency does not change (Remains either frequency)

(SW770HF) 1/2 ••••10-052

2-6-3 Frequency does not change (Remains either frequency)

(SW770HF) 2/2 10-054

2-6-4 Vibration mode cannot be switched

C’

(F-R lever vibration switch does not work) 10-056 (

2-6-5 Vibratory drum cannot be switched 10-058

2-7 Water Spray 10-060

2-7-1 Continuous water spray does not operate 1/2 10-060

2-7-1 Continuous water spray does not operate 2/2 10-062

2-7-2 Continuous water spray works, but auto water spray does not operate 10-064

2-7-3 Continuous water spray works,

but intermittent water spray does not operate 10-066

2-8 Lighting 10-068

2-8-1 Head lamp, side marker lamp and tail lamp do not light 10-068

2-8-2 Flood lamp does not light 10-070

2-8-3 High-beam of head lamp does not light 10-070

2-8-4 Turn signal lamp does not blink 10-072

2-8-5 Hazard lamp does not light (Turn signal blinks) 10-074 (

2-8-6 Backup lamp does not light10-074

2-8-7 Stop lamp does not light 10-076

2-8-8 Illumination of combination meter does not turn on 10-078

2-8-9 Combination meter warning lamp or indicator lamp is abnormal 10-080

2-8-10 Tachometer reading is abnormal 10-082

2-8-11 Hour meter is abnormal 10-082

2-8-12 Temperature meter is abnormal 10-084

2-8-13 Fuel meter is abnormal 10-084

2-8-14 Hydraulic oil filter warning lamp remains ON 10-086

2-8-15 Engine oil pressure warning lamp remains ON 10-086

2-8-16 Vibration indicator lamp does not light (SW770) 10-088

2-8-17 Vibration indicator lamp does not light (SW770HF, SW770ND) 10-090

2-8-18 Parking brake indicator lamp does not light 10-092

2-8-19 Water spray indicator lamp does not light 10-094

2-8-20 Flood lamp indicator lamp does not light 10-096

2-8-21 Side marker lamp indicator lamp does not light 10-096

2-8-22 Turn signal indicator lamp does not light 10-098

2-8-23 Preheating indicator lamp does not light 10-100

2-8-24 Horn does not sound 10-102

2-8-25 Backup buzzer does not sound 10-102

3 HYDRAULIC SYSTEM TROUBLESHOOTING

3-1 When Performing Hydraulic System Troubleshooting 10-103

3-2 Propulsion System 10-104

3-2-1 Machine moves neither forward nor backward 1/2 10-104

3-2-1 Machine moves neither forward nor backward 2/2 10-105

3-2-2 Machine moves in one direction only (forward or backward) 10-105

3-2-3 Slow machine speed or small drive force 1/2 10-105

3-2-3 Slow machine speed or small drive force 2/2 10-106

3-2-4 Machine speed cannot be switched 10-106

3-2-5 Machine does not stop completely with F-R lever in “N” 10-106

3-2-6 Propulsion system is overheating 10-107

3-2-7 Abnormal noise from propulsion system 10-107

3-3 Vibrator System 10-108

3-3-1 No vibration 1 /2 10-108

3-3-1 No vibration 2/2 10-109

3-3-2 Vibrator frequency is too low 10-109

3-3-3 Vibrator amplitude does not change 10-11 O

3-3-4 Vibratory drum does not changeover vibrating • 10-11 O

3-3-5 Vibrator does not stop 10-11 O

3-3-6 Vibrator system is overheating 10-11 O

3-3-7 Abnormal noise from vibrator system 10-11 O

3-4 Steering System 10-111

3-4-1 Steering wheel is hard to turn 10-111

3-4-2 Steering response is slow 10-111

3-4-3 Steering wheel backlash or play is large 10-112

3-4-4 Steering system is overheating 10-112

3-4-5 Abnormal noise from steering system 10-112

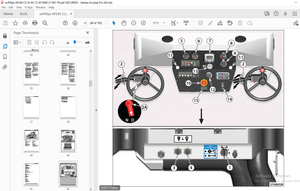

IMAGES PREVIEW OF THE MANUAL: