$21.95

Sakai SW800-II SW850-II SW850ND-II Operation & Maintenance Manual PDF

Sakai Asphalt Roller SW800-II SW850-II SW850ND-II Operation & Maintenance Manual – PDF DOWNLOAD

The Sakai Asphalt Roller SW800-II, SW850-II, SW850ND-II Operation & Maintenance Manual offers comprehensive guidance for efficient operation and upkeep of these models. Download the PDF for detailed instructions on operating procedures and maintenance tasks to ensure optimal performance and longevity.

FILE DETAILS:

Sakai Asphalt Roller SW800-II SW850-II SW850ND-II Operation & Maintenance Manual – PDF DOWNLOAD

Language : English

Pages : 84

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Sakai Asphalt Roller SW800-II SW850-II SW850ND-II Operation & Maintenance Manual – PDF DOWNLOAD

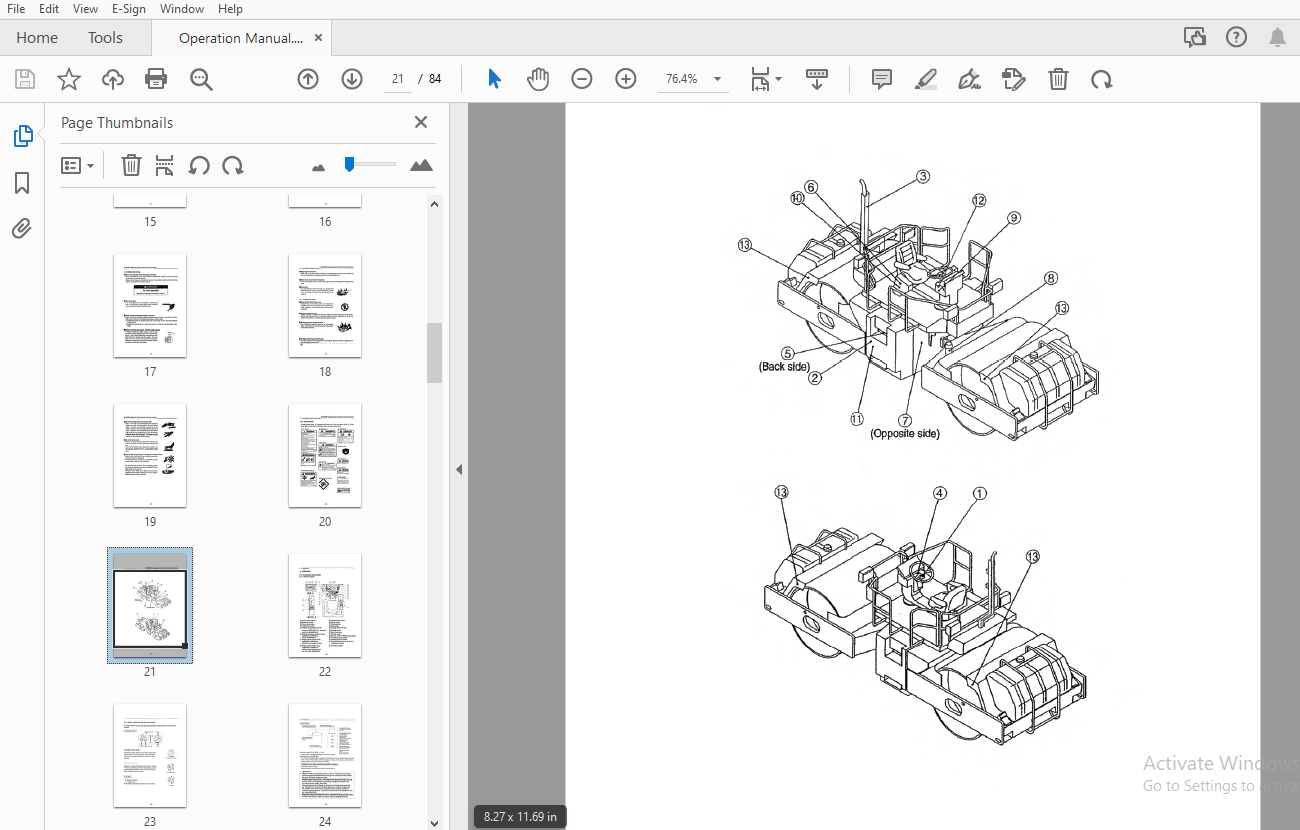

- This operator’s manual serves as a guide for the use of your Sakai SWS00-11, SW850-II and SW850ND-II Vibrating Roller for those who are new to the machine, and also for the people who have experience in using the Machine and want to refresh their knowledge for the machine.

- Read this manual thoroughly and try to fully understand the information before operating your machine. Keep this handbook at hand whenever you do your work.

The main subjects of this manual are:

(1) Basic precautions for safety, (2) Operation, (3) Daily maintenance and (4) Specifications. - For operation and maintenance of the engine, refer to the Engine Instruction Manual furnished separately. Descriptions in this manual can differ from the machine instructions of your machine due to the results of the investigation and improvement in its design. If you have any inquiry regarding your Machine or this manual, contact our distributors.

TABLE OF CONTENTS:

Sakai Asphalt Roller SW800-II SW850-II SW850ND-II Operation & Maintenance Manual – PDF DOWNLOAD

PREFACE

MACHINE AND ENGINE IDENTIFICATION NUMBERS 1

SAFETY NOTICES 2

1.BASIC PRECAUTIONS FOR SAFETY .4

1.1 General Precautions 4

1.2 Preparation for Safe Operation 6

1.3 Before Starting the Engine 7

1.4 After Starting the Engine 8

1.5 During Operation 8

1.6 Loading and Unloading 10

1.7 Transportation 11

1.8 Handling the Battery 11

1.9 Towing 12

1.1 O Before Servicing 13

1.11 During Servicing 14

1.12 Safety Decals 16

2.OPERATION 18

2.1 Instruments and Controls 18

2.1.1 Operator’s station 18

2.1.2 Gauges, indicator lamps and warning lamps 19

2.1.3 Engine Check Lamp 21

2.1.4 Switches 22

2.1 .5 Operating Levers/ Pedals 26

2.1.6 Fuse Box 29

2.2 Handling and Adjustments 29

2.2.1 Seat adjustment 29

2.2.2 Scraper adjustment or replacement 29

2.2.3 Disengaging the brake when towing 30

2.2.4 Steering wheel position adjustment 31

2.2.5 Dashboard position adjustment 31

2.3 Operation 32

2.3.1 Before-starting inspection 32

2.3.2 Starting the engine 33

2.3.3 After starting the engine 34

2.3.4 Traveling 35

2.3.5 Stopping/ Parking 36

2.3.6 Stopping the engine 36

2.3.7 Check after stopping the engine 37

2.4 Vibratory Operation 37

2.5 Sprinkler 39

2.6 Precautions for Work .42

2.6.1 Compaction operation 42

2.6.2 When going downhill .42

2.6.3 On a slope 42

2.7 Applicable jobs 43

2.8 After Operation 44

2.9 Loading and Unloading .44

2.9.1 Use of a trailer equipped with a winch .44

2.9.2 Self-propelling .45

2.10 After Loading the Machine .46

2.11 Transportation 46

2.12 Operation in Cold Weather .46

2.12.1 Fuel oil and grease 46

2.12.2 Coolant .4 6

2.12.3 Battery 47

2.13 When the Cold Season is Over 48

2.14 For a Long Storage Period .48

2.15 During the Storage Period .48

2.16 When the Battery has Discharged .49

2.16.1 Connection and disconnection of booster cables .49

2 .17 Exact Compact Operation 51

3 PERIODICAL MAINTENANCE 53

3.1 Precautions 53

3.1.1 In using the crane 55

3.2 Walk-Around Checking 56

3.3 Periodical Maintenance Points 57

3.4 Maintenance Procedure 59

(1) Every 10 hours or daily 59

(2) Every 50 hours 59

(3) Every 250 hours 61

(4) Every 500 hours 62

(5) Every 1000 hours 64

(6)As required 69

3.5 Filling Water and Lubricants 71

3.6 Electric Wiring Diagram 73

4 SPECIFICATIONS 76