$36

Sandvik Crusher QH441 Operators Manual_140415 – PDF DOWNLOAD

Sandvik Crusher QH441 Operators Manual_140415 – PDF DOWNLOAD

FILE DETAILS:

Sandvik Crusher QH441 Operators Manual_140415 – PDF DOWNLOAD

Language : English

Pages :176

Downloadable : Yes

File Type : PDF

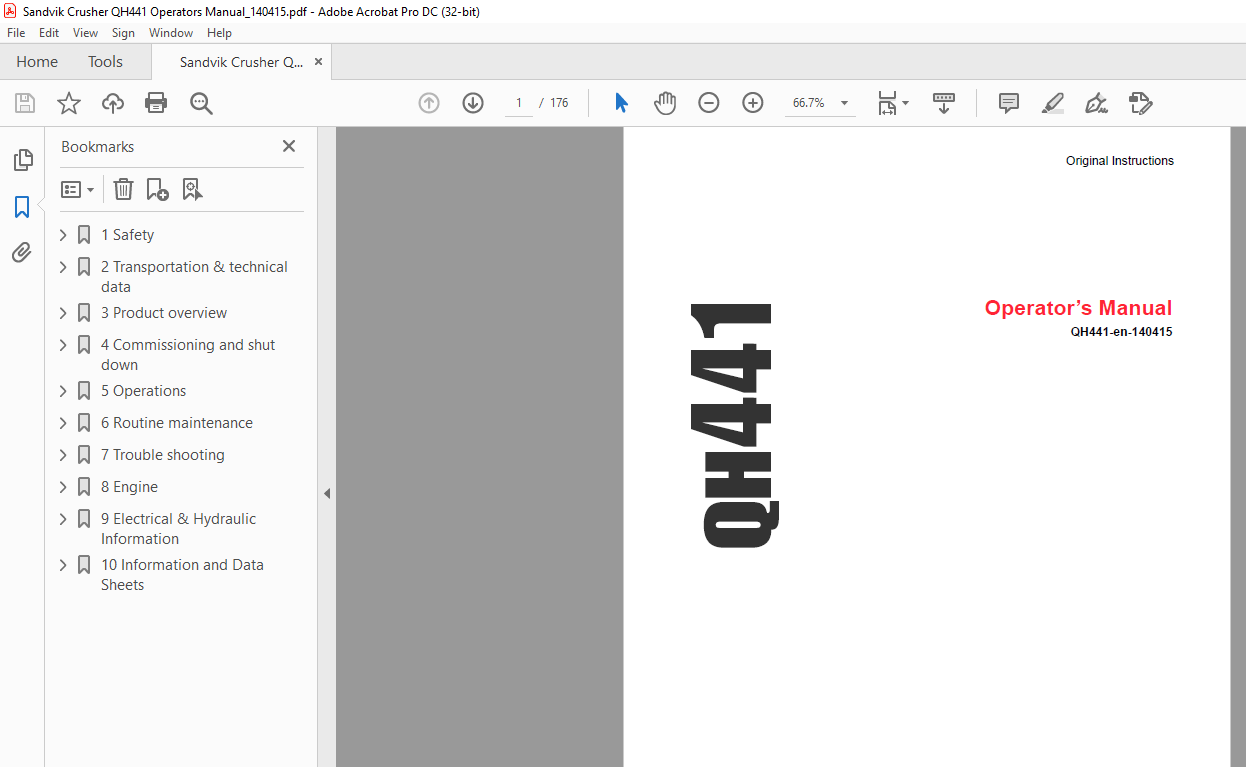

TABLE OF CONTENTS:

Sandvik Crusher QH441 Operators Manual_140415 – PDF DOWNLOAD

1 Safety……………………………………………………………………. 9

1.1 Safety principles…………………………………………………….. 10

1.1.1 Signal words……………………………………………………. 10

1.1.2 General hazard symbol……………………………………………. 10

1.1.3 Essentials……………………………………………………… 11

1.1.4 Safety hazards pertaining to the equipment…………………………. 11

1.1.5 Colour coded safety signs………………………………………… 12

1.1.6 Symbols for prohibited actions……………………………………. 12

1.1.7 Symbols for mandatory actions…………………………………….. 13

1.1.8 Symbols for hazards……………………………………………… 14

1.2 Features for operator safety…………………………………………… 15

1.3 Environmental safety………………………………………………….. 16

1.3.1 Hazardous materials……………………………………………… 16

1.3.2 Battery disposal………………………………………………… 17

1.3.3 Machine disposal………………………………………………… 17

1.4 Personal protective equipment (PPE)…………………………………….. 18

1.5 Organisational safety measures…………………………………………. 19

1.5.1 Fire risk control measures……………………………………….. 19

1.6 Personnel qualifications, requirements and responsibilities……………….. 20

1.7 Safety advice regarding specific operational phases………………………. 21

1.7.1 Standard Operation………………………………………………. 21

1.7.2 Blockage or malfunction………………………………………….. 21

1.7.3 Unguarded areas…………………………………………………. 21

1.7.4 Fire risk control measures……………………………………….. 22

1.8 Special work, including maintenance, parts disposal and hazardous materials…. 23

1.8.1 Securing equipment before performing maintenance……………………. 23

1.8.2 Maintenance site conditions………………………………………. 24

1.8.3 Replacement & removal of components……………………………….. 24

1.8.4 Climbing and falling…………………………………………….. 24

1.8.5 Safety considerations during maintenance…………………………… 26

1.8.6 Safety considerations during cleaning……………………………… 26

1.8.7 Removal of safety devices, guards and decals……………………….. 26

1.8.8 Surrounding structures…………………………………………… 27

1.8.9 Safety when refuelling…………………………………………… 27

1.9 Specific hazards……………………………………………………… 28

1.9.1 Electrical energy……………………………………………….. 28

1.9.2 Automotive batteries…………………………………………….. 29

1.9.3 Gas, dust, steam, smoke and noise…………………………………. 29

1.9.4 Welding or Naked Flames………………………………………….. 31

1.9.5 Hydraulic equipment……………………………………………… 31

1.9.6 Hazardous substances…………………………………………….. 32

1.10 Vibration levels…………………………………………………….. 33

1.11 Hazard exclusion zones……………………………………………….. 35

1.12 Measured noise levels………………………………………………… 36

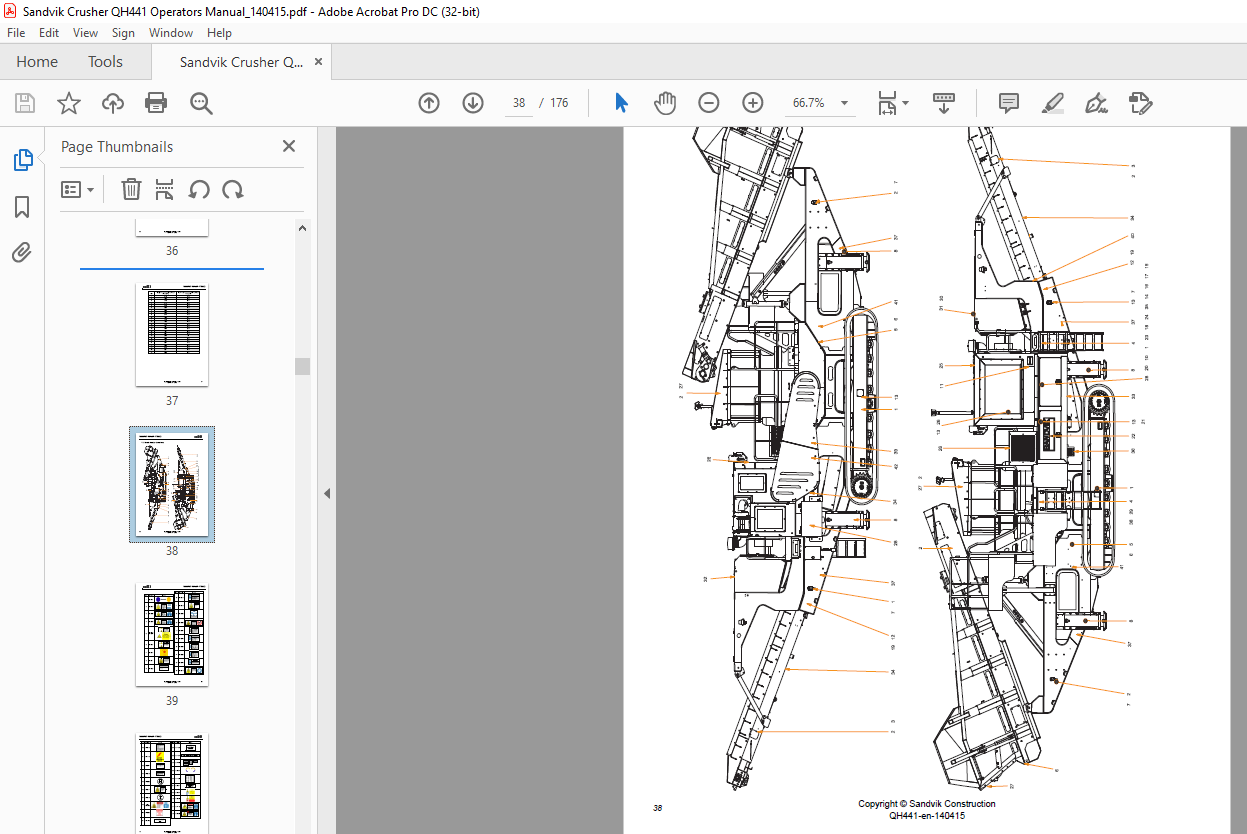

1.13 Safety decals – Locations…………………………………………….. 38

2 Transportation & technical data……………………………………………… 41

2.1 Special considerations for transport……………………………………. 42

2.1.1 Machine preparation for transport…………………………………. 42

2.1.2 Tracking machine on or off transport vehicle……………………….. 49

2.1.3 Securing……………………………………………………….. 49

2.2 Application & limitations……………………………………………… 50

2.2.1 Common applications……………………………………………… 50

2.3 Technical specification……………………………………………….. 51

2.3.1 Feed hopper…………………………………………………….. 51

2.3.2 Feed Conveyor Belt………………………………………………. 51

2.3.3 Main Conveyor…………………………………………………… 51

2.3.4 Lubrication Tank………………………………………………… 51

2.3.5 Power Pack……………………………………………………… 52

2.3.6 Electrical system……………………………………………….. 52

2.3.7 Tracks…………………………………………………………. 52

2.3.8 Dimensions……………………………………………………… 52

2.3.9 Weight…………………………………………………………. 52

2.3.10 Machine Transportation Dimensions………………………………… 53

3 Product overview…………………………………………………………… 55

3.1 Features…………………………………………………………….. 56

3.1.1 Standard……………………………………………………….. 56

3.1.2 Machine Models, Variations And Options…………………………….. 56

3.1.3 Optional items………………………………………………….. 56

3.2 Main Components – Overview…………………………………………….. 57

3.3 Main control devices………………………………………………….. 58

3.3.1 Electrical controls……………………………………………… 58

3.3.2 Display screen and soft keys……………………………………… 59

3.3.3 Icon highlighting……………………………………………….. 59

3.3.4 Stopping machine in an emergency………………………………….. 60

3.3.5 Emergency stop locations…………………………………………. 60

3.3.6 Operation of an emergency stop……………………………………. 62

3.3.7 To reset an emergency stop……………………………………….. 62

3.3.8 Set language, date and time………………………………………. 63

3.3.9 Radio remote control…………………………………………….. 64

3.3.10 Remote control battery recharging………………………………… 65

3.3.11 Wired umbilical track control……………………………………. 66

3.4 Machine Working Dimensions…………………………………………….. 67

4 Commissioning and shut down…………………………………………………. 69

4.1 General Safety……………………………………………………….. 70

4.2 Pre-Commissioning…………………………………………………….. 71

4.2.1 Pre-Start Instructions…………………………………………… 71

4.3 Engine starting procedure……………………………………………… 73

4.3.1 Before starting engine…………………………………………… 73

4.3.2 Engine start……………………………………………………. 73

4.4 Initial screen display………………………………………………… 75

4.5 Moving the machine using the tracks…………………………………….. 76

4.5.1 Before moving the machine………………………………………… 76

4.5.2 Moving the machine………………………………………………. 77

4.5.3 Coloured direction indicators…………………………………….. 78

4.5.4 Moving using the radio remote control……………………………… 78

4.5.5 Moving using wired umbilical control………………………………. 79

4.6 Preparing the crusher for operation…………………………………….. 81

4.7 Legs set-up procedure…………………………………………………. 86

4.7.1 Lowering the legs……………………………………………….. 86

4.7.2 Raising the legs………………………………………………… 88

4.8 Shut down the machine…………………………………………………. 90

4.8.1 Automatic mode shut down…………………………………………. 90

4.8.2 Manual mode shut down……………………………………………. 90

4.9 Lockout and tag procedure……………………………………………… 92

4.9.1 How to fit a single tag………………………………………….. 92

4.9.2 To remove a single tag…………………………………………… 92

4.9.3 How to fit a gang tag……………………………………………. 93

4.9.4 To remove a gang tag…………………………………………….. 93

5 Operations………………………………………………………………… 95

5.1 Operations – minimum safety requirements………………………………… 96

5.2 Machine crushing modes………………………………………………… 97

5.3 Methods of operation………………………………………………….. 99

5.4 Automatic mode………………………………………………………..100

5.4.1 Feeder start and stop…………………………………………….100

5.4.2 Automatic operation – additional control screens…………………….100

5.4.3 Automatic mode screen 2…………………………………………..101

5.4.4 To stop the crusher in automatic mode………………………………101

5.5 Manual mode…………………………………………………………..102

5.5.1 Feeder start and stop…………………………………………….102

5.5.2 To stop the crusher in manual mode…………………………………102

5.5.3 Feed conveyor manual speed adjustment………………………………103

5.5.4 Feed conveyor automatic speed control………………………………103

5.6 Daily calibration of crusher wear parts………………………………….105

5.7 Close side setting gap [CSS]……………………………………………106

5.8 Feeding material into machine…………………………………………..107

5.8.1 Before starting………………………………………………….107

5.8.2 Loading hopper with material………………………………………107

5.8.3 Cone crusher…………………………………………………….107

5.9 Feed conveyor metal detector……………………………………………108

5.10 Blocked crusher………………………………………………………109

6 Routine maintenance…………………………………………………………113

6.1 Maintenance – minimum safety requirements………………………………..114

6.2 Reference information………………………………………………….116

6.3 Maintenance Schedules………………………………………………….117

6.3.1 First 50 to 80 Hours maintenance schedule…………………………..117

6.3.2 Daily maintenance schedule………………………………………..117

6.3.3 Weekly maintenance schedule……………………………………….118

6.3.4 Monthly maintenance schedule………………………………………119

6.3.5 250 Hours maintenance – C13 Tier 3a engine only……………………..119

6.3.6 500 Hours maintenance schedule…………………………………….119

6.3.7 1000 Hours maintenance schedule……………………………………120

6.3.8 2000 Hours or 1 year maintenance schedule…………………………..120

6.4 Maintenance procedures…………………………………………………121

6.4.1 Location of compartments for maintenance……………………………121

6.4.2 Fluid drain points……………………………………………….122

6.4.3 Track gearbox oil – check top up…………………………………..123

6.4.4 Track gearbox oil – replace……………………………………….124

6.4.5 Fuel tank – check top up………………………………………….125

6.4.6 Hydraulic tank – check top up……………………………………..125

6.4.7 Crusher lubrication tank – check top up…………………………….126

6.4.8 Clutch lubrication tank – check top up……………………………..127

6.4.9 Air cleaner – servicing…………………………………………..128

6.4.10 Hydraulic tank air vent filter element…………………………….130

6.4.11 Hydraulic return filters…………………………………………131

6.4.12 Hydraulic strainers, filters and fluid renewal……………………..132

6.4.13 Hydraulic pressure filters……………………………………….133

6.4.14 Clutch lubrication oil and filter…………………………………134

6.4.15 Cone lubrication in-line filter…………………………………..135

6.4.16 Strainer and filters inside cone lubrication tank…………………..136

6.4.17 Air fan filter………………………………………………….137

6.4.18 Crushing chamber – inspect……………………………………….138

6.4.19 Crusher belt drive tension system – Inspect/adjust………………….139

6.4.20 Replacing the crusher drive belts…………………………………140

6.4.21 Replacing the turnbuckle polyurethane bushes……………………….142

6.4.22 Bearings – grease……………………………………………….146

6.4.23 Belt scraper – adjust……………………………………………147

6.4.24 Tracks – inspect………………………………………………..148

6.4.25 Track tension – check……………………………………………148

6.4.26 Track tension – increase…………………………………………149

6.4.27 Track tension – reduce…………………………………………..150

6.4.28 Crusher liners – replace…………………………………………150

6.4.29 New crusher liners – Reset datum………………………………….151

6.5 Lubricants and fluids………………………………………………….152

6.5.1 Machine Lubricants and fluids used in manufacture……………………152

6.5.2 Clutch fluid renewal……………………………………………..153

6.5.3 Engine lubricants and fluids………………………………………153

6.5.4 Hazardous fluids…………………………………………………153

6.6 Maintenance display screens…………………………………………….154

6.6.1 Access to maintenance display screens………………………………154

6.6.2 To exit maintenance display screens………………………………..155

6.6.3 Maintenance display screen 1………………………………………155

6.6.4 Maintenance display screen 2………………………………………156

6.6.5 Maintenance display screen 3………………………………………157

6.6.6 Maintenance display screen 4………………………………………158

6.7 Diagnostic display screens……………………………………………..159

6.7.1 Access to diagnostic display screens……………………………….159

6.7.2 Diagnostic main display screen:……………………………………159

6.7.3 To exit diagnostic display screens…………………………………160

6.7.4 Outputs diagnostic display screens…………………………………160

6.7.5 Speeds diagnostic display screen…………………………………..161

6.7.6 Tracks diagnostic display screen…………………………………..161

6.7.7 Inputs diagnostic display screens………………………………….162

6.7.8 Clutch diagnostic display screen…………………………………..162

7 Trouble shooting……………………………………………………………163

7.1 Common problems……………………………………………………….164

7.1.1 Machine fault codes………………………………………………164

8 Engine…………………………………………………………………….165

8.1 Engine information…………………………………………………….166

8.1.1 Engine manual……………………………………………………166

8.1.2 Alternative Caterpillar engines……………………………………166

8.2 Maintenance schedules………………………………………………….167

8.2.1 250 Hours engine maintenance schedule – C13 Tier 3a only……………..167

8.2.2 500 Hours engine maintenance schedule………………………………167

8.2.3 1000 Hours engine maintenance schedule……………………………..167

8.2.4 2000 Hours or 1 year engine maintenance schedule…………………….167

8.3 Engine lubrication and fluids…………………………………………..169

8.3.1 Lubricants and fluids used in manufacture…………………………..169

8.3.2 Engine oil renewal……………………………………………….169

9 Electrical & Hydraulic Information……………………………………………171

9.1 Schematic diagrams…………………………………………………….172

9.1.1 Electrical information……………………………………………172

9.1.2 Hydraulic information…………………………………………….172

10 Information and Data Sheets…………………………………………………173

10.1 Original equipment manufacturer information……………………………..174

10.1.1 Tracks – Strickland……………………………………………..174

10.1.2 Hydraulic power take-off (clutch) – PT Tech (HPTO14)………………..174

10.1.3 JMG display fault codes………………………………………….174

10.1.4 Engine manual (supplied separately)……………………………….174

10.1.5 Sandvik cone crusher manuals……………………………………..174

10.1.6 Optional auto grease lubrication………………………………….174

10.1.7 Electrical schematic diagrams…………………………………….174

10.1.8 Hydraulic schematic diagrams……………………………………..174

10.2 Hazardous substances………………………………………………….175

IMAGES PREVIEW OF THE MANUAL:

S.M 5/24