$38

Sandvik Mining QJ341 Operators Manual – PDF DOWNLOAD

Sandvik Mining QJ341 Operators Manual - PDF DOWNLOAD

FILE DETAILS:

Sandvik Mining QJ341 Operators Manual - PDF DOWNLOAD

Language : English,

Pages :206

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Sandvik Mining QJ341 Operators Manual - PDF DOWNLOAD

Operator’s Manual 0

Conformity Section 3

Contents 5

1 Safety Section 11

11 Safety Essentials 12

111 Safety Labels and Signals 13

112 Signal Words 13

113 General Hazard Symbol 13

114 Safety Hazards Pertaining to the Equipment 13

115 Colour Coded Safety Signs 14

116 Symbols for Prohibited Actions 14

117 Symbols for Mandatory Actions 15

118 Symbols for Hazards 16

119 Machine Serial Number Plate 17

12 Component Safety Features 17

13 Features for Operator Safety 17

14 Environmental Safety 18

141 Hazardous Materials 18

142 Machine Disposal 19

15 Personal Protective Equipment (PPE) 19

151 Entanglement Hazards 19

152 Minimum Required Personal Protective Equipment (PPE) 20

16 Hazard Zones 21

17 Measured Noise Levels 22

18 Vibration Levels 22

19 Organizational Safety Measures 22

110 Personnel Qualifications, Requirements and Responsibilities 23

111 Safety Advice Regarding Specific Operational Phases 23

1111 Standard Operation 23

1112 Blockage or Malfunction 24

1113 Unguarded Areas 25

112 Special Work, Including Equipment Maintenance, Disposal of Parts, and Hazardous Materials 25

1121 Securing Equipment Before Performing Maintenance 25

1122 Maintenance Site Conditions 26

1123 Replacement & Removal of Components 26

1124 Climbing and Falling 26

1125 Safety Considerations During Maintenance 27

1126 Safety Considerations During Cleaning 28

1127 Removal of Safety Devices, Guards and Decals 28

1128 Surrounding Structures 28

1129 Safety when Refuelling 29

113 Specific Hazards 29

1131 Electrical Energy 29

1132 Battery 30

1133 Gas, Dust, Steam, Smoke and Noise 31

1134 Welding or Naked Flames 31

1135 Hydraulic Equipment 32

1136 Hazardous Substances 33

114 Safety Decals - Locations 35

2 Transport and Technical Data 41

21 Special Considerations for Transport 42

211 Machine Preparation for Transport 42

212 Tracking Machine onto/off Transport Vehicle 48

22 Transport and Working Dimensions 48

23 Application and Limitations 49

231 Common Applications 49

24 Description 49

25 Operation Description 49

26 Key Features 49

27 Identification of Main Units 50

28 Identification of Emergency Stop Positions 51

29 Technical Information 51

291 Machine dimensions 51

292 Standard Features 51

293 Options 51

210 Specification of Main Units 52

2101 Feeder 52

2102 Crusher 52

2103 Main Conveyor 52

2104 Natural Fines Conveyor 52

2105 Tracks 52

2106 Power Unit 53

2107 Magnetic Separator 53

211 Machine Working Dimensions 54

212 Machine Transport Dimensions 55

3 Product Overview 57

31 Product Overview 58

311 Main Components: 58

312 Optional Extras: 58

313 Machine Layout Indicating Main Components 59

4 Commissioning and Shut Down 61

42 Commissioning and Shutdown - Safety 62

43 Commissioning 63

431 Preliminary Operations 63

44 Main Control Devices 66

441 Electrical Control Box 66

442 Display Panel 67

443 Setting Time and Date 68

444 Setting the Language 68

45 Engine - Starting Procedure 69

451 Engine Starting Procedure - Safety 69

452 Tracking Machine 71

453 Direction indicators 73

454 Wired umbilical track control 74

455 Main Conveyor - Manual Raise 75

456 Machine Set-up for Operation 76

457 Jacking Legs - Lower 81

458 Jacking Legs - Raise 84

46 Operating the Machine 88

461 Start-up Sequence - Running the Crusher 88

462 Manual Run Mode 89

463 Manual Run Page 1 Options - Functionality 91

464 Manual Run Page 2 Options - Functionality 93

465 Auto Run Mode 94

466 Auto Mode Display - Functionality 96

467 Feed Conveyor - Remote Adjustment 97

468 Feeder Transfer Chute 98

47 Fault Events 99

48 Machine Shut Down101

481 Machine Shut Down Safety101

482 Manual Stop Sequence102

483 Auto Stop Sequence103

484 Emergency Stop - Operation104

485 Emergency Stop - Reset104

49 Lock and Tag-out Procedure105

491 Tag Removal Procedure106

5 Operation107

51 Before Starting Up the Machine for Operation108

52 Machine Crushing Mode109

53 Methods of Operation109

54 Automatic Mode110

541 Feeder Start and Stop111

542 Feeder Speed Adjustment111

543 Natural Fines Conveyor Start and Stop111

544 Automatic Operation - Additional Control Screen111

545 To Stop the Crusher in Auto Mode112

546 Return to Initial Control Display112

55 Manual Mode113

551 Starting the machine114

552 Engine Speed Adjustment114

553 Feeder Start and Speed Control114

554 Natural Fines Conveyor Start and Stop115

555 Manual Operation Screen Display 2115

556 Crusher Chamber Level Monitor116

557 Joggle the Crusher117

558 Using Radio Remote for Machine Adjustments118

559 Control Feeder by Engine and Crusher Load119

5510 View Engine parameters120

5511 Manual Operation Screen Display 3 0

5512 Main conveyor raise and lower 0

56 Stalled or Blocked Crusher122

57 Adjust the Jaw Closed Size Setting (CSS)123

58 Operating The Machine (Crushing)125

581 Loading Material Into Machine:125

59 Reverse Jaw Operation126

510 Feeder Transfer Chute Setup127

6 Maintenance129

61 Maintenance - Safety Requirements130

62 Daily Maintenance Schedule132

63 Weekly Maintenance Schedule133

64 50-80 Hours Maintenance Schedule134

65 250 Hours Maintenance Schedule135

66 500 Hours Maintenance Schedule136

67 750 Hours Maintenance Schedule136

68 1000 Hours Maintenance Schedule137

69 2000 Hours Maintenance Schedule138

610 Maintenance Procedures139

6101 Fluid Drain Points140

6102 Engine Oil - Check Level and Top Up140

6103 Diesel Fuel - Check Level and Top Up141

6104 Diesel Water Trap - Drain142

6105 Hydraulic Fluid - Check Level and Top Up142

6106 Engine Coolant - Check Level and Top Up143

6107 Checking/ Changing Hydraulic Tank Air Breather143

6108 Air Cleaner - Servicing144

6109 Magnet Conveyor - Maintenance145

61010 To Adjust the Magnet Conveyor Belt Tension146

61011 Feeder Gearbox - Check Oil Level and Top Up147

61012 Bearings - Grease148

61013 Grease Pump Unit (Auto-lubrication system)- Fill with Grease149

61014 Inspecting/ Adjusting Belt Sealing Rubbers150

61015 Belt Scraper - Adjust151

61016 Conveyor Belts - Adjust152

61017 Hydraulic Filters - Replace153

61018 Track Gearbox Oil - Change155

61019 Track Tension156

61020 Track Tension - Check157

61021 Track Tension - Increase158

61022 Track Tension - Reduce159

611 Jaw Plates - Turning and changing160

6111 Prepare to Remove the Jaw Plates161

6112 Jaw Guards - Remove162

6113 Swing Jaw Plate - Remove163

6114 Fixed Jaw Plate - Remove167

6115 Crusher Box Liner Plates - Replace170

6116 Fixed Jaw Plate - Install172

6117 Swing Jaw Plate - Install178

6118 Jaw Guards - Install183

6119 Toggle Plate - Remove/ Replace184

612 Oils and Fluids189

613 Machine Fault Codes and Maintenance Screens191

6131 Maintenance screens191

6132 Machine Fault Codes191

6133 Red Faults191

6134 Blue Faults192

6135 Engine Faults192

7 Trouble Shooting195

71 Trouble Shooting196

711 Machine faults displayed on screen196

712 Original Equipment Manufacturer (OEM) Trouble shooting198

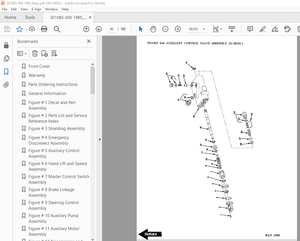

Electrical and Hydraulics199

91 Electrical Schematics200

92 Hydraulic Schematics202

Information and Data Sheets205

101 Original Equipment Manufacturer Information206

102 Hazardous Substances206

103 Variations and Options (if applicable)206

IMAGES PREVIEW OF THE MANUAL: