$42

Sandvik Mining TH540 Service and Repair Manual – PDF DOWNLOAD

Sandvik Mining TH540 Service and Repair Manual – PDF DOWNLOAD

FILE DETAILS:

Sandvik Mining TH540 Service and Repair Manual – PDF DOWNLOAD

Language : English

Pages :1457

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Sandvik Mining TH540 Service and Repair Manual – PDF DOWNLOAD

SERVICE AND REPAIR MANUAL 1

TABLE OF CONTENTS 3

1 FOR THE READER OF THIS MANUAL 15

2 GENERAL SAFETY INSTRUCTIONS 17

21 General safety precautions during operations 19

22 Warning and information symbols used in this manual 19

221 Safety Symbols Pertaining to the Machine 20

3 GENERAL REPAIR INSTRUCTIONS 25

31 Location of main switch 27

32 Hydraulics maintenance 28

33 Electric system maintenance 29

34 Battery maintenance 30

35 Welding 32

36 Blocking the machine for repair procedures 33

37 Lifting methods and lifting points 34

4 FRAME STRUCTURES 37

41 Locking devices 38

411 How to install frame locking bar 39

412 How to remove frame locking bar 40

413 How to install the box support bar 41

414 How to remove the box support bar 42

42 Middle hinge joint 43

421 Design features of upper hinge 43

422 Design features of lower hinge 44

423 Disassembly of middle hinge joints 46

424 Assembly of the middle hinge joint 51

425 Adjusting of middle hinge joint 56

43 Oscillating axle 57

431 Disassembly of oscillating axle 59

432 Assembly of oscillating axle 61

433 Oscillating cradle bushing replacement 62

44 Pins 63

441 Design features of the pins 63

442 Pin removal 64

443 Pin removal with a puller 64

444 Pin removal without special tools 65

445 Pin installation 65

45 Removing the box 66

46 Installing the box 68

47 Welding 69

471 Precautions before welding 70

472 Basic quality requirements 70

473 Frame welding 71

474 Box welding 71

475 Edge preparation 72

476 Working temperature and pre-heating 73

477 Heat-input – number of welding passes 74

478 Welding to other steels 75

479 Gas cutting 77

5 LUBRICATION SYSTEM 79

51 System description 81

511 Safety interlocks 81

512 Inputs 82

513 Outputs 82

52 Functional description of the components 83

521 Removing the lubrication unit 85

522 Installing the lubrication unit 88

53 Checking and adjusting 91

531 Forced functions (requires service password) 91

532 Diagnostics 94

533 Filling the central lube reservoir 94

534 Bleeding the pump 95

535 Main piping 95

536 Doser adjustment 96

54 General troubleshooting 97

541 VCM-System troubleshooting 98

6 FIRE SUPRESSION SYSTEM 101

61 Ansul 102

611 Main components 102

612 System description 103

613 Inputs 103

614 Outputs 103

615 Specifications 103

616 System components 104

617 Location of nozzles 105

618 Ansul system operation 106

619 Ansul Checkfire system (optional) 107

62 Sandvik FS 1000 109

621 Main components 109

622 System description 110

623 Inputs 110

624 Outputs 110

625 System components 111

626 Specifications 111

627 Location of nozzles 112

628 System operation 113

63 Checking and adjusting 115

631 Forced functions 115

632 Diagnostics 118

64 VCM-System troubleshooting 119

7 CABIN 121

71 Instrument panel 124

72 Functional description of components 125

721 Steering wheel 125

722 Box control 125

723 Combination switch 125

724 Brake pedal 126

725 Throttle pedal 126

726 Door switch 127

73 Heating and air conditioning system 128

731 System description 129

732 Component descriptions 130

74 Window washer and wiper 131

741 Inputs 131

742 Outputs 131

743 Removing the wiper motor assembly 132

744 Installing the wiper motor assembly 132

75 Removing the cabin 133

76 Installing the cabin 137

77 Removing the cabin seat 139

78 Installing the cabin seat 140

79 Removing the cabin window 140

710 Installing the cabin window 141

711 Removing the cabin door 142

712 Installing the door to the cabin 143

713 Checking and adjusting 144

7131 Testing the door switch 144

7132 Testing the buttons 144

7133 Forced functions 145

7134 Throttle pedal calibration 148

7135 Diagnostics 149

714 VCM-System troubleshooting 150

8 POWERPACK 155

81 Engine 157

811 Technical data 157

812 Technical data 159

813 System description 160

814 Explanation of concepts 161

815 Starting and shutting down the engine 162

816 Over-rev protection 164

817 Jump-starting 165

818 Restarting an Out of Fuel Engine 166

819 Check stop engine and engine codes 168

8110 Changing engine oil and filters 171

8111 Engine mounts inspection 173

8112 Removing the powerpack 175

8113 Installing the powerpack 182

82 Fuel system 186

821 System description 186

822 Fuel filters 187

823 Fuel lines 188

824 Fuel gauge 188

83 Air Cleaner system 189

831 System description 189

832 Air filter 190

833 Restriction indicator 191

84 Exhaust system 191

841 System description 191

842 Exhaust piping 192

843 Exhaust purifier 192

844 Servicing the exhaust purifier 193

845 Removing the exhaust purifier 193

846 Installing the exhaust purifier 193

85 Turbocharger 194

851 Servicing the turbocharger 194

852 Removing the turbocharger 195

853 Fitting the turbocharger 196

86 Pumps 197

87 Cooling system 198

871 Main components of the engine coolers 198

872 System description 199

873 Functional description of components 200

874 Cleaning the engine cooler cores 203

875 Engine cooler tube and sealing removal 206

876 Removing the engine radiator assembly 208

877 Installing the engine radiator assembly 211

878 Removing the engine charge air cooler assembly 214

879 Installing the engine charge air cooler assembly 218

8710 Removing the engine thermostat 221

8711 Installing the engine thermostat 223

88 Checking and adjusting 224

881 Checking of the blower pump pressures 224

882 Forced functions 229

883 Diagnostics 231

89 General troubleshooting 232

810 VCM-System troubleshooting 233

9 POWER TRAIN 237

91 System description 238

92 Transmission hydraulics 239

93 Transmission 240

931 Gearbox 240

932 Transmission filter unit 241

933 Gear selection 242

934 Transmission shaft speed sensor 243

935 Controlling manual transmission 244

936 Controlling automatic transmission 245

937 Filling instructions 246

938 Removing the transmission 248

939 Installing the transmission 252

9310 General troubleshooting 255

94 Transmission cooling 256

941 System description 257

942 Removing and installing the transmission oil heat exchanger 257

95 Torque converter 257

951 System description 258

952 Functional description of the components 259

953 Converter lock 261

954 Torque converter change 262

96 Jake brake (option) 265

961 Exhaust brake, Jake brake (option) 266

97 Retarder (option) 267

971 Electric retarder, Telma (option) 267

972 Servicing electric retarder 268

98 Wheels 269

981 Removing the wheels 270

982 Installing the wheels 276

983 Rim 278

984 Structures and functions of the off-road tyre components 279

985 Tire dismounting from rim 281

986 Rim Inspection 283

987 Tire vertical mounting on rim 284

99 Axles 285

991 Technical data 286

992 Planetary hub and differential oil change 289

993 Tightening torques of power train flanges and bolts 291

994 Removing of the rear axle 292

995 Installing the rear axle 296

996 Removing the front axle assembly 300

997 Installing the front axle assembly 304

998 Disassembling the wheel ends 307

999 Assembling wheel ends 308

910 Cardan shafts 309

9101 General Maintenance and Inspection 309

9102 Removing the cardan shaft 310

9103 Installing the cardan shaft 311

911 Checking and adjusting 312

9111 Measuring speed and travelled distance, and sensor diagnostics 312

9112 Measuring the transmission pressure 314

9113 Forced functions 315

9114 Diagnostics 318

9115 The measurement data of the modules 319

912 VCM-System troubleshooting 320

10 GENERAL HYDRAULICS 325

101 Hydraulic oil 326

102 Hydraulic diagram 327

103 General hydraulic maintenance 329

1031 General troubleshooting 330

1032 Basic causes of hydraulic system failures 331

1033 Checking hydraulic system for leaks 332

1034 Low temperature starting 332

1035 Prevent of cavitation formation 333

1036 Oil filters 333

1037 Servicing filters and strainers 333

1038 Level of oil in tank 333

1039 Oil storage and handling 334

104 Hydraulic oil tanks 335

1041 Design features 335

1042 Filter diagnostics 337

1043 Functional description of components 338

1044 Level sensors for the oil tanks 339

1045 To change filter element 340

1046 Changing oil in the hydraulic system 341

1047 Repairing the tank 345

1048 Hydraulic tank cover resealing 346

105 Suction lines 349

1051 Design features 349

1052 Bleeding the suction lines 350

106 Hydraulic pressure test points 351

107 Hoses and tubing 357

1071 Marking of hydraulic hoses 358

108 Pressure accumulators 359

1081 Recharging piston accumulators 360

1082 Disassembly and assembly of the piston accumulator 361

1083 Recharging diaphragm accumulators 363

109 Hydraulic oil cooler and return lines 365

1091 System description 366

1092 Functional description of the components 367

1093 Cleaning the hydraulic cooler cores 368

1094 Removing the hydraulic oil cooler 369

1095 Installing the hydraulic oil cooler 372

1096 Removing the hydraulic cooler fan motor 374

1097 Installing the hydraulic cooler fan motor 376

1010 Pumps 378

10101 Piston type pump 379

10102 Piston type double pump 380

10103 Starting new pumps 381

10104 Removing the pump P2112 382

10105 Installing the pump P2112 384

10106 Removing the double pump P202 386

10107 Installing the double pump P202 388

1011 Checking and adjusting 390

10111 Measuring the temperatures of the brake, hydraulic and transmission oil 391

10112 Forced functions 393

1012 VCM-System troubleshooting 396

1013 Hydraulic component symbols 400

11 STEERING 407

111 Main components 408

112 Hydraulic diagram 409

113 System description 411

1131 Safety interlocks 411

1132 Inputs 411

1133 Outputs 411

114 Functional description 412

1141 Steering main valve (automation) 412

1142 Steering main valve (manual) 412

1143 Directional valve 413

1144 Orbitrol assembly 413

1145 Steering cylinder 414

1146 Steering pump 414

1147 Steering limit switch (optional) 414

1148 Pressure relief valve 414

115 Emergency steering (option) 415

1151 System description of VCM 415

1152 Functional description of components 416

1153 Safety interlocks 416

1154 Inputs 416

1155 Outputs 417

116 Steering cylinder 418

1161 Removing the steering cylinder 420

1162 Installing the steering cylinder 423

1163 Cylinder disassembly 425

1164 Inspection and repair 426

1165 Reassembly and installation 426

1166 Removing the steering main valve 427

1167 Installing the steering main valve 429

117 Checking and adjusting 430

1171 Checking and adjusting of the steering / tipping pump pressures 430

1172 Checking and adjusting steering valve pressures 433

1173 Steering cylinder bypass test 437

1174 Forced functions 443

1175 Diagnostics 446

118 VCM-System troubleshooting 449

12 BOX HYDRAULICS 453

121 Main components 454

122 Hydraulic diagram 455

123 System description 456

1231 Box control 456

1232 Ejector box control 458

124 Functional description of components 459

1241 Tipping valve 459

1242 Tipping cylinder 459

1243 Pump P201 460

1244 Return filter 460

1245 Other box hydraulic components 460

125 Box counter 461

1251 Inputs 461

1252 Outputs 461

126 Tipping cylinders 462

1261 Removing the tipping cylinder hoses 463

1262 Installing the tipping cylinder hoses 466

1263 Removing the tipping cylinder 468

1264 Installing the tipping cylinder 471

1265 Tipping cylinder disassembly 473

1266 Inspection and repair 473

1267 Reassembly and installation 474

127 Checking and adjusting 475

1271 Checking of the steering / box hydraulic pump pressures 475

1272 Checking of the box valve pressures 476

1273 Tipping cylinders leakage test 480

1274 Forced functions 487

1275 Diagnostics 489

1276 Testing the movement of the control joystick 490

1277 Control joystick calibration 491

1278 The measurement data of the modules 492

128 VCM-System troubleshooting 493

13 BRAKE SYSTEM 497

131 Main components 498

132 Hydraulic diagram 499

133 System description 500

1331 Service and parking brake inputs 502

1332 Service and parking brake outputs 502

134 Functional description of components 503

1341 Brake charging valve 503

1342 Sequence valve 504

1343 Filter unit 504

1344 Brake pedal valve 506

1345 Brake release pump unit 507

1346 Pressure accumulators 508

135 Brake flushing 509

1351 Hydraulic diagram, brake flushing 510

1352 System description 511

1353 Functional description of components 511

136 Automatic Brake Activation 512

1361 Automatic Brake Activation tests 512

1362 Transmission pressure sensor test 513

1363 Automatic parking brake engaging test (low brake charging pressure) 514

137 Neutral brake 515

1371 Inputs 515

1372 Outputs 515

138 Disassembly of brakes 516

139 Assembly of brakes 517

1310 Checking and adjusting 517

13101 Brake flushing pressure check 518

13102 Brake pump pressure check / adjustment 519

13103 Brake charging valve pressure check 522

13104 Parking brake test 524

13105 Service brake pedal test 526

13106 Accepting the brake test results 528

13107 Brake test log entries 529

13108 Aborted brake test 530

13109 Brake friction disc lining wear check procedure 531

131010 Brake Slack Adjuster Adjustment (Posi-Stop) 533

131011 Testing the brake accumulator 535

131012 Measuring the brake accumulator precharge pressure P0 536

131013 Measuring brake pressures 538

131014 Measuring brake temperatures 540

131015 Forced functions 541

131016 Diagnostics 545

1311 VCM-System troubleshooting 548

14 GENERAL ELECTRICAL SYSTEM 559

141 System description 560

142 Lights 561

1421 Front lights 561

1422 Reversing lights 562

1423 Parking lights 562

1424 Brake lights and blinkers 563

1425 Cabin corner lights 564

1426 Loading lights 564

1427 Warning light (beacon) 565

1428 Warning brake light 565

1429 Direction indicator lights 566

143 Horn signal and reversing warning 566

1431 Horn signal 566

1432 Alarm signal and lights for reversing 567

144 Emergency stop 567

1441 Inputs 567

1442 Outputs 567

145 Warning and alarm condition 568

1451 Inputs & outputs 569

146 Batteries 570

1461 Battery technical data 570

1462 Removing the batteries 574

1463 Installing the batteries 576

147 Alternator 578

1471 Removing the alternator 579

1472 Installing the alternator 581

148 Twin alternator 583

1481 Removing the twin alternator 584

1482 Installing the twin alternator 585

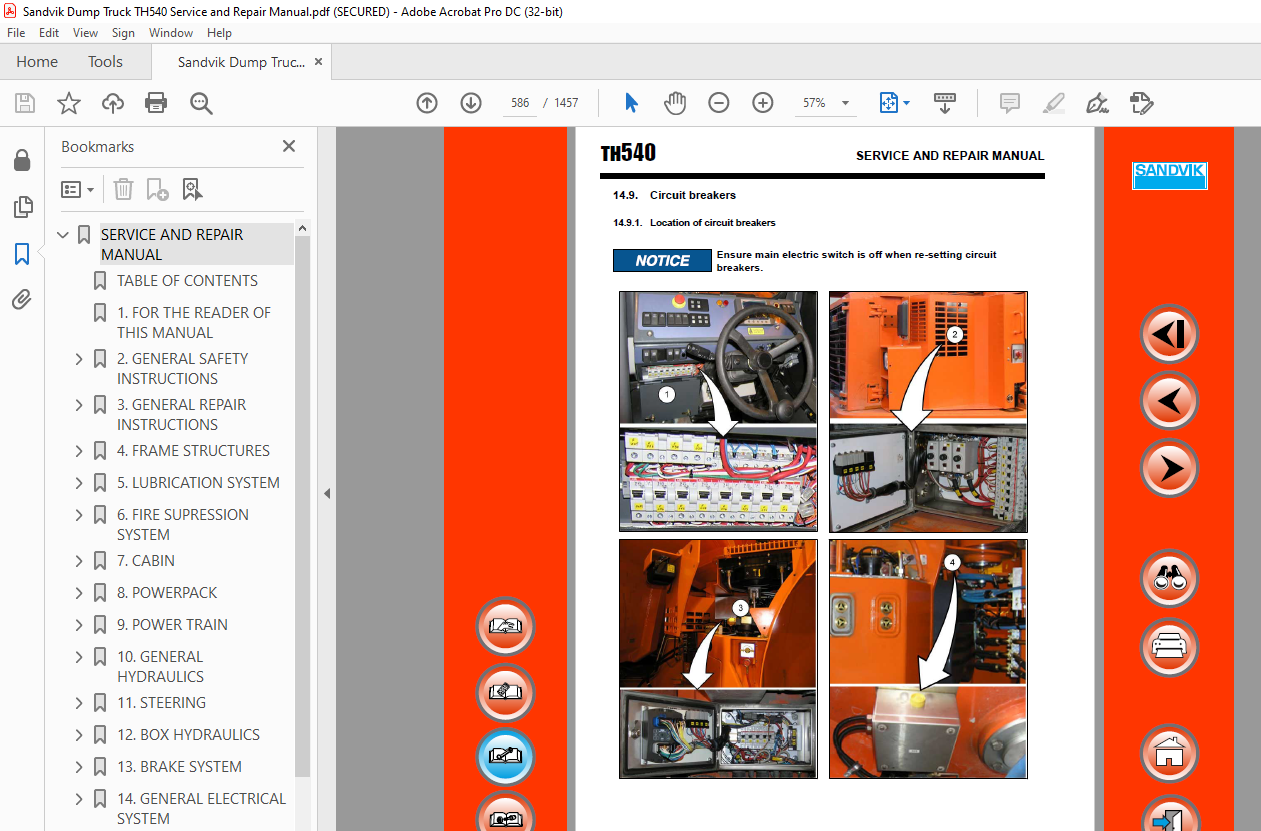

149 Circuit breakers 586

1491 Location of circuit breakers 586

1492 Circuit breakers descriptions and values 587

1410 Vehicle Control and Management system user interface 589

14101 Using the display module 589

14102 Symbols on the display windows 590

14103 Main window 596

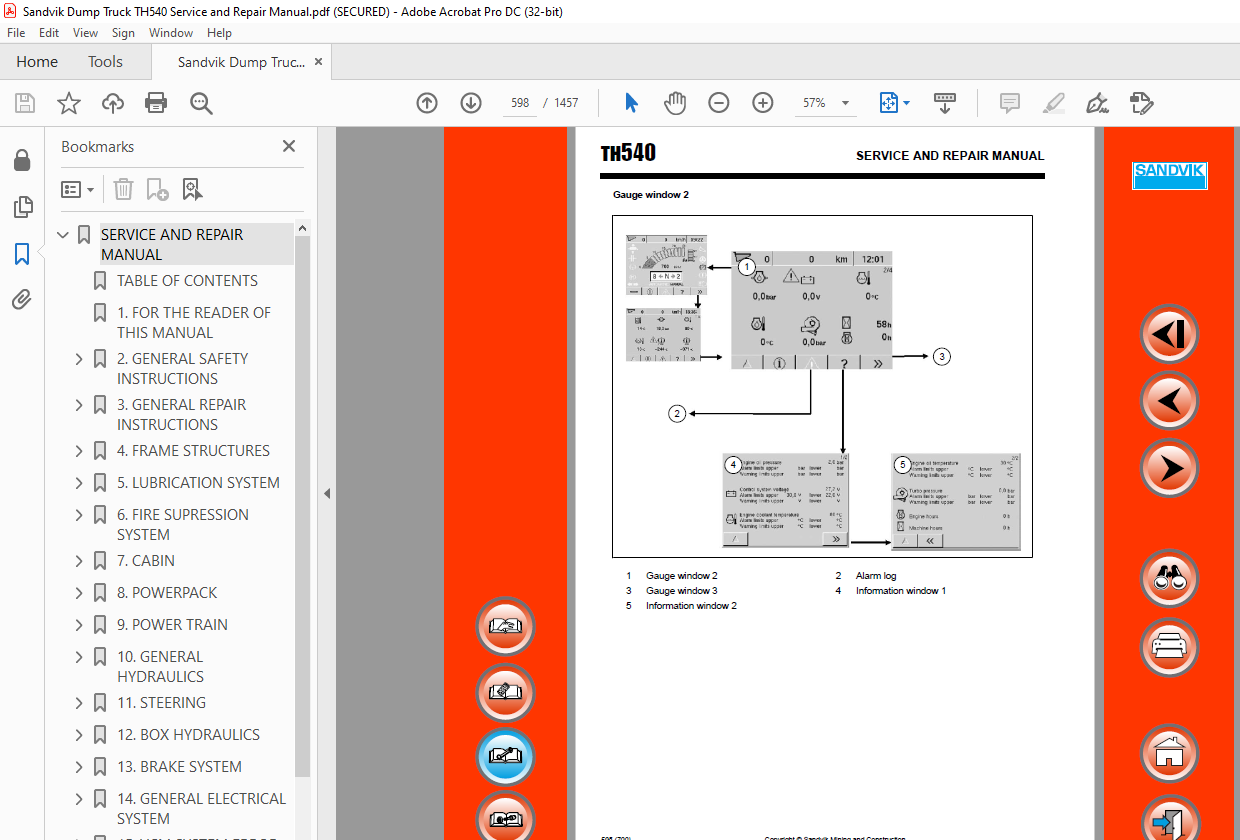

14104 Gauge windows 597

14105 Alarm log 601

14106 Service windows for the operator 602

14107 Service windows for service personnel 609

14108 Service password 630

1411 Changing the control modules 631

14111 Location of the VCM-system modules 631

14112 Changing a single I/O module 632

14113 Changing several I/O modules 634

14114 Changing the display module 634

1412 System implementation 635

1413 VCM system self test on start-up 637

14131 Conditions for starting the system (the enable) 637

14132 Alarm log 639

14133 Display information of the Main window and Gauge windows 640

14134 Driving speed and Distance driven measurement and sensor diagnostics 640

1414 Program updating of modules 641

14141 Updating manually the programs of system modules 641

14142 Program updating with PC 641

14143 Programming a new module 642

14144 How to check installation package version 644

1415 How to upload alarm log with update display 644

1416 Checking and adjusting 645

14161 Display settings 645

14162 Status data of the CAN bus 646

14163 Forced functions 647

14164 Diagnostics 652

14165 Checking emergency stop and shutdown system 654

14166 Common rules for checking cables 655

14167 Signal level and scaling of the sensors 656

1417 Controlling additional functions 659

14171 Controlling additional functions in the service window 660

1418 Parameter control 661

14181 Restoring parameters 661

14182 Saving parameters 662

1419 VCM-system troubleshooting 663

1420 How to read electric diagrams 675

14201 Marking 675

14202 Marking of the actuators 676

14203 Parts location 677

14204 The consecutive number 677

14205 Marking of cables 677

14206 Drawing sheets 678

14207 VCM-system module connections 681

1421 Electric diagrams 682

15 VCM SYSTEM ERROR CODES 683

151 Alarm log 684

1511 Error codes 685

16 APPENDICES 697

1 The tightening torques for screws and nuts 701

2 Diaphragm accumulators 703

3 Piston accumulator Operation and Service instructions 709

4 Dana transmission Maintenance / Service manual 727

5 Dana converter Service manual 793

6 Dana axle Service manual 861

61 Posi-Torq – Limited Slip Differential 959

7 Radiator Service manual 991

8 Hydraulic oil cooler Installation and Servicing manual 999

9 Heat exchanger Servicing manual1021

10 Tank breather filter1031

11 Exide battery1037

12 Dana cardan shafts1043

13 Telma1059

14 Donaldson air filter manual1075

15 Wiggins refueling system Technical manual (option)1087

16 Wiggins Installation and Operators manual (option)1103

17 Sandvik FS1000 fire suppression system manuals (option)1119

18 ANSUL fire suppression system Installation, Recharge, Inspection and Maintenance manual1175

19 Function of lubrication system1313

20 Doser groups1319

21 Air conditioner Service1327

22 Update display Operating instructions1369

23 Rexroth piston pump repair instructions1393

24 Weighing system General Workshop Maintenance instruction (option)1419

IMAGES PREVIEW OF THE MANUAL:

S.M 5/24