$38

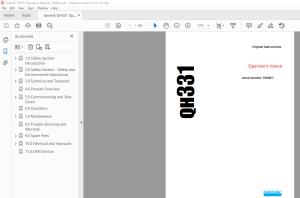

Sandvik QH331 Operators Manual_1884BG – PDF DOWNLOAD

Sandvik QH331 Operators Manual_1884BG - PDF DOWNLOAD

FILE DETAILS

Sandvik QH331 Operators Manual_1884BG - PDF DOWNLOAD

Language : English

Pages :256

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Sandvik QH331 Operators Manual_1884BG - PDF DOWNLOAD

1.0 Safety Section - Introduction............................................................................... 11

1.1 The purpose of these instructions....................................................................... 12

1.2 Identification of the product........................................................................... 12

1.2.1 Product type and serial number.................................................................... 12

1.2.2 Product manufacturer.............................................................................. 13

1.2.3 Manuals........................................................................................... 13

1.2.4 How to identify the right manual for the product.................................................. 14

1.2.5 Validity of the manuals........................................................................... 14

1.3 Copyright notice........................................................................................ 14

1.4 Definitions............................................................................................. 14

2.0 Safety Section - Safety and Environmental Instructions...................................................... 17

2.1 Safety labels and signals............................................................................... 18

2.1.1 Signal words...................................................................................... 18

2.1.2 General hazard symbol............................................................................. 18

2.1.3 Symbols for mandatory actions..................................................................... 19

2.1.4 Symbols for prohibited actions.................................................................... 20

2.1.5 Hazard symbols.................................................................................... 20

2.1.6 Labels on the product............................................................................. 22

2.1.7 Visual and audible signals........................................................................ 25

2.2 User obligations........................................................................................ 25

2.2.1 Managing work related hazards..................................................................... 26

2.2.2 Scheduled safety inspections and preventive maintenance........................................... 27

2.2.3 Personal protective equipment..................................................................... 28

2.3 Product limitations..................................................................................... 29

2.3.1 Intended use...................................................................................... 29

2.3.2 Foreseeable misuse................................................................................ 29

2.3.3 Prohibited use.................................................................................... 29

2.3.4................................................................................................... 29

2.3.5 Maximum inclination angles during tramming and parking............................................ 29

2.3.6 Maximum inclination angles during operation....................................................... 30

2.3.7 Modifications..................................................................................... 30

2.4 Hazard zones............................................................................................ 31

2.5 Safeguarding............................................................................................ 32

2.5.1 Guards............................................................................................ 32

2.5.2 Protective devices................................................................................ 34

2.6 Complementary protective measures....................................................................... 35

2.6.1 Use of Emergency stop function.................................................................... 35

2.6.2 Emergency exit.................................................................................... 37

2.6.3 Safe access to machinery and three point support.................................................. 37

2.6.4 Isolation and energy dissipation.................................................................. 38

2.6.5 Fire risk control measures........................................................................ 40

2.7 Protection against emission hazards..................................................................... 41

2.7.1 Noise............................................................................................. 41

2.7.2 Vibration......................................................................................... 42

2.7.3 Dust.............................................................................................. 42

2.8 Emergency procedures and methods for unblocking......................................................... 43

2.9 Safety considerations for maintenance................................................................... 44

2.10 Environment............................................................................................ 47

2.10.1 Decommissioning.................................................................................. 47

2.10.2 Dismantling...................................................................................... 47

2.10.3 Disposal......................................................................................... 48

2.11 Potential product related hazards identified by the user............................................... 49

2.12 Incident reporting..................................................................................... 50

3.0 Technical and Transport..................................................................................... 51

3.1 Transport............................................................................................... 52

3.1.1 Special Considerations For Transport Of The QH331................................................. 52

3.1.2 Machine Preparation for Transport................................................................. 52

3.1.3 Preparing the Feed Conveyor....................................................................... 54

3.1.4 Preparing the feed Conveyor maintenance platform.................................................. 55

3.1.5 Preparing the ladders............................................................................. 56

3.1.6 Tracking the machine onto and off the transport vehicle........................................... 58

3.2 Technical Information................................................................................... 59

3.2.1 Standard Features................................................................................. 59

3.2.2 Options........................................................................................... 59

3.2.3 Transport and Working Dimensions.................................................................. 61

3.3 Identification of Main Units............................................................................ 63

3.4 Specification of Main Units............................................................................. 64

3.4.1 Feeder Hopper..................................................................................... 64

3.4.2 Feed Conveyor..................................................................................... 64

3.4.3 Crusher........................................................................................... 64

3.4.4 Main Conveyor..................................................................................... 64

3.4.5 Tracks............................................................................................ 64

3.4.6 Power Unit........................................................................................ 64

4.1 Product Overview........................................................................................ 66

4.1.1 Major Components.................................................................................. 66

4.1.2 Identification and Operation of the QH331 Controls................................................ 67

4.1.3 Main Control Panel................................................................................ 67

4.1.4 Hydraulic Controls................................................................................ 69

4.1.5 Radio Remote Control Unit......................................................................... 70

4.1.6 Umbilical Remote Control Unit..................................................................... 71

4.0 Product Overview............................................................................................ 65

5.0 Commissioning and Shut Down................................................................................. 73

5.1 Commissioning & Shutdown Safety......................................................................... 74

5.1.1 Who is at Risk.................................................................................... 74

5.1.2 Managing Work related Hazards with a Risk Assessment.............................................. 74

5.1.3 When carrying out maintenance or adjustment....................................................... 74

5.2 Commissioning........................................................................................... 75

5.2.1 Preparation for Machine STARTUP................................................................... 75

5.2.2 Engine Start-up Sequence.......................................................................... 76

5.2.3 Setting Language of Control Panel Display......................................................... 77

5.2.4 Setting the date/time............................................................................. 78

5.2.5 Sequence For Tracking Machine..................................................................... 79

5.2.6 Initial Setup and Operation....................................................................... 82

5.2.7 Set Up ladder 1 and ladder 2...................................................................... 83

5.2.8 Preparing the feed Conveyor maintenance platform.................................................. 85

5.2.9 Restarting the Engine to activate Auxillary Controls.............................................. 86

5.2.10 Preparing the Feed Conveyor...................................................................... 86

5.2.11 Belt Tension Check during Commissioning.......................................................... 89

5.3 Machine operation....................................................................................... 92

5.4 Machine Shut Down....................................................................................... 92

5.4.1 Auto Stop Sequence................................................................................ 92

5.4.2 Preparing the machine for transport or for the machine to be moved to another location............ 93

5.4.3 Emergency Stop.................................................................................... 93

5.5 Location Of Emergency Stops On qh331.................................................................... 94

5.5.1 Preparing the machine for transport or for the machine to be moved to another location............ 95

6.1 Operation Safety........................................................................................100

6.1.1 Who is at Risk....................................................................................100

6.1.2 Managing Work related Hazards with a Risk Assessment..............................................100

6.1.3 When carrying out maintenance or adjustment.......................................................100

6.2 Loading the feeder......................................................................................101

6.2.1 Avoid damage to equipment.........................................................................101

6.3 Common Applications.....................................................................................103

6.3.1 Construction, Demolition and recycling............................................................103

6.3.2 Minerals and Quarrying............................................................................103

6.3.3 Maximum Feed size for Crusher.....................................................................103

6.4 Feed and Jams...........................................................................................104

6.5 Operating the QH331.....................................................................................105

6.5.1 Start-up Sequence For Running the Crusher.........................................................105

6.5.2 Auto Run Mode.....................................................................................107

6.5.3 Auto Start Up Sequence............................................................................108

6.5.4 Auto Stop Sequence................................................................................109

6.5.5 Manual Run Mode...................................................................................110

6.5.6 Manual Start Up...................................................................................111

6.5.7 Feed Conveyor Adjustment..........................................................................113

6.5.8 Hopper Level Adjustment...........................................................................114

6.5.9 Tail Conveyor Level Sensor........................................................................115

6.6 Machine Shut Down.......................................................................................116

6.6.1 Manual Stop Sequence..............................................................................116

6.7 Clearing Crusher Chamber Jam’s..........................................................................117

6.7.1 Managing Work Related Hazards with a Risk Assessment..............................................117

6.7.2 Auto Run Closed Side Setting (CSS) Adjustment.....................................................118

6.7.3 Main Operations Menu..............................................................................119

6.0 Operation................................................................................................... 99

7.0 Maintenance.................................................................................................121

7.1 Maintenance Safety......................................................................................122

7.1.1 Who is at Risk....................................................................................122

7.1.2 Managing Work related Hazards with a Risk Assessment..............................................122

7.1.3 When carrying out maintenance or adjustment.......................................................122

7.2 Maintenance Schedule....................................................................................123

7.2.1 Power Unit Engine and Hydraulic...................................................................123

7.2.2 Crusher & Feeder..................................................................................124

7.2.3 Testing the Emergency stop function and Battery Isolator..........................................126

7.2.4 Conveyors and General.............................................................................128

7.2.5 Belt Tension......................................................................................129

7.2.6 Engine Maintenance................................................................................132

7.2.7 Radio Remote Control battery Charging.............................................................132

7.2.8 Air Cleaner Maintenance...........................................................................133

7.2.9 Battery Maintenance...............................................................................134

7.2.10 Check / Adding Fuel..............................................................................134

7.2.11 Emptying the Fuel Filter Water Trap..............................................................135

7.2.12 Special Considerations For Maintenance Or Repair with Welding....................................136

7.3 Hydraulic System........................................................................................137

7.3.1 Hydraulic Oil.....................................................................................137

7.3.2 Hydraulic oil is added as follows:................................................................138

7.3.3 Changing The Return Line Filter...................................................................139

7.3.4 Changing The Suction Filters and the Hydraulic Oil................................................140

7.4 Lubrication System......................................................................................142

7.4.1 Lubrication Oil...................................................................................143

7.4.2 Changing the Lubrication Oil......................................................................144

7.4.3 Track Maintenance.................................................................................145

7.4.4 Checking the Track Tension........................................................................146

7.4.5 Tighten the Tracks................................................................................147

7.4.6 Loosen the Tracks.................................................................................147

7.4.7 Track Drive Units.................................................................................148

7.5 Conveyor Belt Maintenance...............................................................................149

7.5.1 Tensioning the Feed Conveyor Belt.................................................................149

7.5.2 Tensioning The Main Conveyor belt.................................................................150

7.5.3 Tracking the Belts................................................................................152

7.5.4 Maintenance Data..................................................................................154

7.5.5 Hydraulic Oil Requirements for QH331 Machines.....................................................154

7.6 Lubricants and Fluids...................................................................................157

7.6.1 Greasing Schedule.................................................................................158

7.6.2 Care of chrome....................................................................................160

8.1 Trouble Shooting Safety.................................................................................162

8.1.1 Who is at Risk....................................................................................162

8.1.2 Managing Work related Hazards with a Risk Assessment..............................................162

8.1.3 When carrying out maintenance or adjustment.......................................................162

8.1.4 Diagnostic Screen.................................................................................163

8.1.5 Engine Status.....................................................................................164

8.2 Service Log and Faults..................................................................................165

8.3 Machine Shutdown Faults.................................................................................170

8.3.1 FC 101Emergency Stop Alarm........................................................................170

8.4 Using the Proportional Spool Valve System (PSVS) controls to Diagnose Hydraulic or Electrical Faults....171

8.4.1 Service Engineer Selection for PSVS Diagnosis.....................................................171

8.4.2 PSVS Diagnosis for Hydraulic or Electrical Faults.................................................171

8.5 Commissioning and Engine Warranty.......................................................................173

8.5.1 Commissioning and Warranty Registration...........................................................173

8.6 CAT Register Instructions...............................................................................174

8.6.1 CAT C Series Warranty Statement...................................................................175

8.0 Trouble Shooting and Warranty...............................................................................161

9.0 Spare Parts.................................................................................................177

9.1 Spare Parts.............................................................................................178

9.1.1 Spare Parts illustrations.........................................................................178

9.1.2 Ordering Procedure:...............................................................................178

9.1.3 Managing Work related Hazards with a Risk Assessment..............................................179

9.1.4 When carrying out maintenance or adjustment.......................................................179

9.2 Machine Assemblies......................................................................................180

9.2.1 Top Level.........................................................................................180

9.2.2 QH331 Chassis assembly............................................................................182

9.2.3 Mid Section Walkway...............................................................................184

9.2.4 R.H.S. Maintenance Platform.......................................................................186

9.2.5 Rear Maintenance Platform.........................................................................188

9.2.6 Lubrication Tank..................................................................................189

9.2.7 Clutch Lubrication Tank...........................................................................190

9.2.8 Cone Assembly.....................................................................................192

9.2.9 Cone Discharge Chute..............................................................................194

9.2.10 Chassis Tower....................................................................................196

9.2.11 Hydraulic Tank...................................................................................198

9.2.12 Diesel Tank......................................................................................200

9.2.13 Feed Conveyor....................................................................................202

9.2.14 Feeder Support Frame.............................................................................205

9.2.15 Main Conveyor....................................................................................206

9.2.16 Main Conveyor lower section......................................................................208

9.2.17 Control Cabinet..................................................................................210

9.2.18 Power Unit.......................................................................................212

9.2.19 Flywheel guard...................................................................................217

9.2.20 Tensioning Device................................................................................218

9.2.21 Tensioning Pulley................................................................................219

9.2.22 Active Turnbuckle Assembly.......................................................................220

9.2.23 Engine Filter Kits - CAT C9 3A...................................................................221

9.2.24 Engine Filter Kits - CAT C9.3 3B.................................................................222

10.1 Electrical Schematics..................................................................................224

10.2 Hydraulic..............................................................................................246

10.2.1 Hydraulic circuit................................................................................246

10.2.2 Hydraulic hose kits..............................................................................247

10.0 Electrical and Hydraulic...................................................................................223

11.1 OEM Appendices.........................................................................................254

11.1.1 CH430 CONE Crusher Operation.....................................................................254

11.1.2 CH430 CONE Crusher maintenance Manual............................................................254

11.1.3 CH430 CONE Crusher Spare Parts...................................................................254

11.1.4 CH430 CONE Crusher Wear Parts....................................................................254

11.1.5 Crawler Tracks Operation Manual..................................................................254

11.1.6 M-PROS Control System Spare Parts................................................................254

11.1.7 Optional Extra’s.................................................................................254

11.0 OEM Section................................................................................................253

IMAGES PREVIEW OF THE MANUAL:

S.M 5/24