$37

Sany SRT55D Off-Highway Trucks Safety, Operation and Maintenance Manual – PDF DOWNLOAD

Sany SRT55D Off-Highway Trucks Safety, Operation and Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Sany SRT55D Off-Highway Trucks Safety, Operation and Maintenance Manual – PDF DOWNLOAD

Language : English

Pages : 268

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Sany SRT55D Off-Highway Trucks Safety, Operation and Maintenance Manual – PDF DOWNLOAD

1 Foreword

1 1 Overview 1-1

1 2 Safety Information 1-3

1 3 Your Documentation Package 1-5

1 3 1 Recommendations on using the documentation 1-5

1 3 2 Documentation storage 1-5

1 4 Page Numbers 1-6

1 5 Regulation of Use 1-6

1 5 1 Machine applications 1-6

1 5 2 Directions of machine 1-6

1 6 Breaking in a New Machine 1-6

1 7 Visibility from Operator’s Seat 1-7

1 8 Machine Information 1-9

1 8 1 Product identification plate 1-9

1 8 2 Engine identification plate 1-10

1 8 3 Display screen 1-11

1 8 4 Table for serial number and distributor information 1-11

2 Safety

2 1 Safety Labels 2-1

2 1 1 Position for attaching safety labels 2-1

2 1 2 Safety labels 2-2

2 2 General Precautions 2-8

2 2 1 Safety rules 2-8

2 2 2 Abnormalities 2-8

2 2 3 Personal protective equipment 2-8

2 2 4 Fire extinguisher and first aid kit 2-9

2 2 5 Safety equipment 2-10

2 2 6 Cleaning your machine 2-10

2 2 7 Keeping the cab clean 2-11

2 2 8 Precautions when leaving the machine 2-11

2 2 9 Handholds and steps 2-12

2 2 10 Preventing burns 2-13

2 2 10 1 Hot coolant 2-13

2 2 10 2 Hot oil 2-13

2 2 11 Preventing fire and explosion 2-14

2 2 11 1 Fire caused by fuel or oils 2-14

2 2 11 2 Fire caused by flammable materials 2-15

2 2 11 3 Fire caused by electric lines 2-15

2 2 11 4 Fire caused by hydraulic lines 2-15

2 2 11 5 Fire caused by illumination equipment 2-16

2 2 12 In the event of fire 2-16

2 2 13 Windshield cleaning detergent 2-16

2 2 14 Precautions when using ROPS(Roll over protective structure) 2-17

2 2 15 Attachment installation 2-17

2 2 16 Cab windows glasses 2-18

2 2 17 Unauthorized modification 2-18

2 2 18 Examination and confirmation of worksite 2-18

2 2 19 Operation on soft ground 2-19

2 2 20 Overhead power cables 2-20

2 2 21 Alternate exit 2-21

2 2 22 Ensure good visibilty 2-21

2 2 23 Asbestos hazard 2-22

2 3 Safe Operation Precautions 2-23

2 3 1 Safe starting 2-23

2 3 1 1 Safe mounting 2-23

2 3 1 2 Seat adjustment 2-23

2 3 1 3 Seat belt 2-24

2 3 1 4 Before starting the engine 2-24

2 3 1 5 Engine starting rules 2-25

2 3 1 6 Starting engine in cold season 2-25

2 3 1 7 Engine starting aid 2-26

2 3 1 8 After starting the engine 2-27

2 3 2 Operation 2-27

2 3 2 1 Inspection before operation 2-27

2 3 2 2 Prior-operation precautions 2-27

2 3 2 3 Precautions when traveling 2-28

2 3 2 4 Precautions when traveling on slopes 2-30

2 3 2 5 Precautions when operating 2-30

2 3 2 6 Precautions for accumulated snow, and ice 2-30

2 3 2 7 Parking the machine 2-31

2 3 2 8 Preparing the machine 2-32

2 3 3 Transportation 2-33

2 3 3 1 Loading and unloading the machine 2-33

2 3 3 2 Transporting the machine 2-34

2 3 4 Battery 2-35

2 3 5 Towing 2-37

2 4 Precautions for Maintenance 2-38

2 4 1 Lock-out and tag-out 2-38

2 4 2 Select a working area 2-38

2 4 3 Prior-maintenance precautions 2-38

2 4 4 Preparing yourself 2-39

2 4 5 Stop engine before carrying out maintenance 2-40

2 4 6 Maintenance with engine running 2-41

2 4 7 Using proper tools 2-42

2 4 8 Handling suspension cylinder 2-42

2 4 9 Working under the machine 2-42

2 4 10 Work in loud noise 2-43

2 4 11 Use compressed air 2-43

2 4 12 Use a hammer 2-43

2 4 13 Welding operation 2-43

2 4 14 Precautions with high-pressure oil 2-44

2 4 15 High-pressure hoses 2-45

2 4 16 Hot cooling system 2-45

2 4 17 Air-conditioning system 2-46

2 4 18 High voltage precautions 2-46

2 4 19 Accumulator 2-47

2 4 20 Avoiding fire and explosion 2-47

2 4 21 Regular replacement of safetyrelated parts 2-48

2 4 22 Maintenance operation 2-48

2 4 23 Proper disposal of wastes 2-49

2 5 Precautions With Tires 2-50

2 5 1 Handling tires 2-50

2 5 2 Precautions when storing tire 2-51

3 Controls and Operating

3 1 Controls and Instruments 3-1

3 2 Indicator 3-2

3 3 Instruments 3-4

3 4 Reversing Monitoring System 3-6

3 5 Switches 3-7

3 6 Combined Switch 3-9

3 7 Air Conditioner Control Panel 3-9

3 8 Driver Seat 3-11

3 9 Seat Belt 3-12

3 10 Truck Controls 3-13

3 10 1 Braking 3-13

3 10 2 Service Brake 3-13

3 10 3 Parking Brake 3-14

3 10 4 Emergency brake 3-14

3 10 5 Retarder 3-14

3 11 Engine 3-16

3 11 1 Electronic Foot Pedal 3-16

3 11 2 Quantum electronic fuel system 3-17

3 11 3 Quantum electronic fuel system – description 3-18

3 11 4 Quantum electronic fuel system – operation 3-19

3 11 5 Electronic fuel system diagnostic codes 3-20

3 12 Steering 3-23

3 13 Transmission 3-24

3 13 1 CEC2 shift system 3-24

3 13 2 Introduction and operation 3-27

3 13 3 General transmission operation 3-31

3 13 4 Retrieving diagnostic codes 3-32

3 13 5 Clearing diagnostic codes 3-33

3 14 Body Control 3-36

4 Operating the Truck

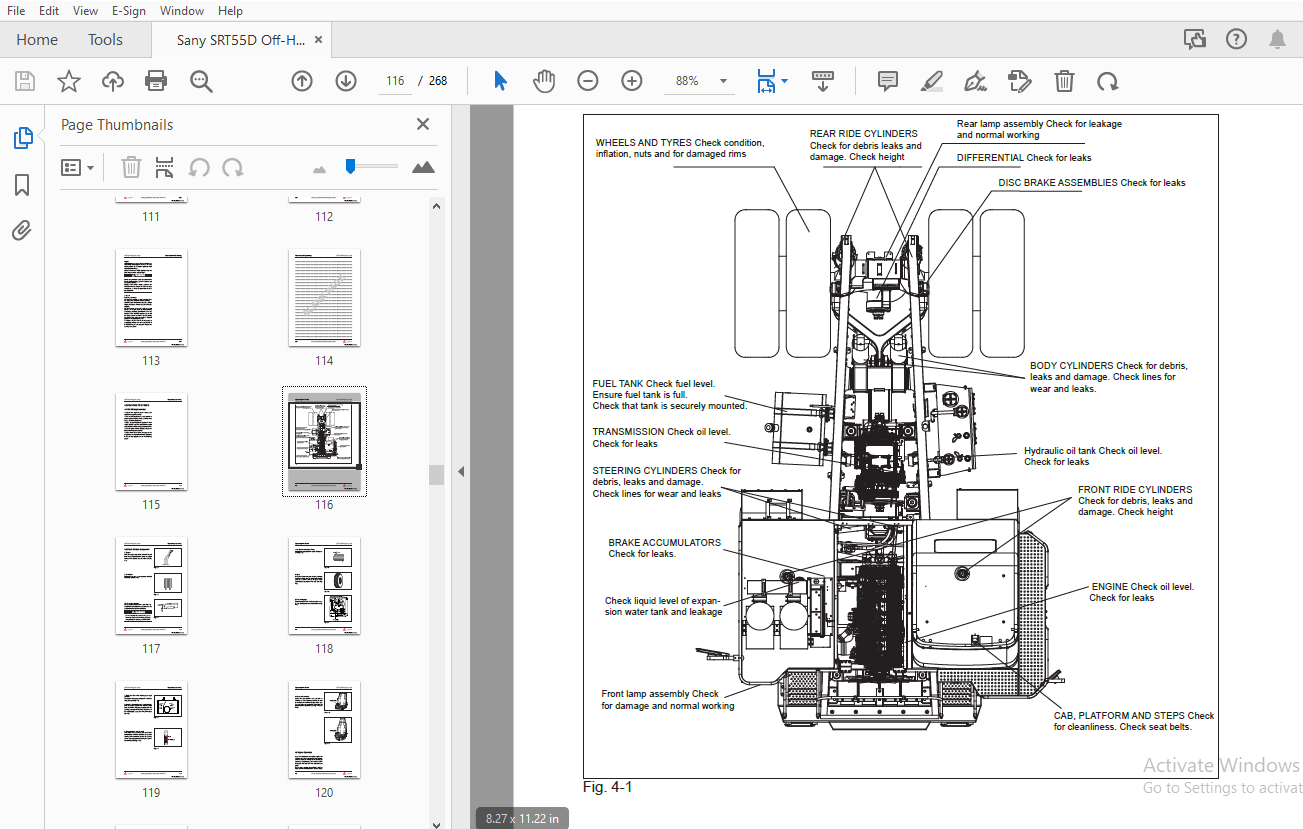

4 1 Pre-Starting Inspection 4-1

4 2 Check Of Each Component 4-3

4 3 Engine Operation 4-6

4 4 Start the Engine 4-8

4 5 Starting the Engine with Jumper Cables 4-10

4 6 Check Before Driving 4-11

4 7 Braking Function Check 4-12

4 8 Service Brake Performance Check 4-12

4 9 Emergency Brake Performance Check 4-13

4 10 Driving and Stopping 4-13

4 11 Stopping the Engine 4-14

4 12 Parking 4-16

4 13 Prolonged Storage 4-16

5 Working the Truck

5 1 Working the Truck 5-1

5 2 Loading 5-1

5 3 Hauling 5-3

5 4 Dumping 5-4

5 5 Empty Return 5-6

6 Roading

6 1 General 6-1

6 2 Preparation Prior to Roading 6-2

6 3 In Case of Trouble 6-3

7 Moving Disabled Truck

7 1 Moving Disabled Truck 7-1

8 Lubrication and Servicing

8 1 Safety Precautions 8-1

8 2 Lubrication and Maintenance 8-2

8 3 Other Maintenance 8-8

8 4 Service Capacity 8-12

8 5 Recommended Lubricants 8-13

8 6 Maintenance Procedures 8-19

8 6 1 Daily (10hrs) maintenance inspection form 8-19

8 6 2 Maintenance inspection form for 150hrs 8-23

8 6 3 Maintenance inspection form for 250hrs 8-25

8 6 4 Maintenance inspection form for 300hrs 8-27

8 6 5 Maintenance inspection form for 450hrs 8-29

8 6 6 Maintenance inspection form for 500hrs 8-31

8 6 7 Maintenance inspection form for 600hrs 8-33

8 6 8 Maintenance inspection form for 750hrs 8-35

8 6 9 Maintenance inspection form for 900hrs 8-37

8 6 10 Maintenance inspection form for 1000hrs 8-39

8 6 11 Maintenance inspection form for 1050hrs 8-43

8 6 12 Maintenance inspection form for 1200hrs 8-45

8 6 13 Maintenance inspection form for 1250hrs 8-47

8 6 14 Maintenance inspection form for 1350hrs 8-49

8 6 15 Maintenance inspection form for 1500hrs 8-51

8 6 16 Maintenance inspection form for 1650hrs 8-55

8 6 17 Maintenance inspection form for 1750hrs 8-57

8 6 18 Maintenance inspection form for 1800hrs 8-59

8 6 19 Maintenance inspection form for 1950hrs 8-61

8 6 20 Maintenance inspection form for 2000hrs 8-63

8 6 21 Maintenance inspection form for 2100hrs 8-67

8 6 22 Maintenance inspection form for 2250hrs 8-69

8 6 23 Maintenance inspection form for 2400hrs 8-71

8 6 24 Maintenance inspection form for 2500hrs 8-73

8 6 25 Maintenance inspection form for 2550hrs 8-75

8 6 26 Maintenance inspection form for 2700hrs 8-77

8 6 27 Maintenance inspection form for 2750hrs 8-79

8 6 28 Maintenance inspection form for 2850hrs 8-81

8 6 29 Maintenance inspection form for 3000hrs 8-83

8 6 30 Maintenance inspection form for 3150hrs 8-87

8 6 31 Maintenance inspection form for 3250hrs 8-89

8 6 32 Maintenance inspection form for 3300hrs 8-91

8 6 33 Maintenance inspection form for 3450hrs 8-93

8 6 34 Maintenance inspection form for 3500hrs 8-95

8 6 35 Maintenance inspection form for 3550hrs 8-97

8 6 36 Maintenance inspection form for 3600hrs 8-99

8 6 37 Maintenance inspection form for 3750hrs 8-101

8 6 38 Maintenance inspection form for 3900hrs 8-105

8 6 39 Maintenance inspection form for 4000hrs 8-107

8 6 40 Maintenance inspection form for 4050hrs 8-111

8 6 41 Maintenance inspection form for 4200hrs 8-113

8 6 42 Maintenance inspection form for 6000hrs 8-115

8 6 43 Maintenance inspection form for 10000hrs 8-119