$39

Sany SY115C9/135C/155H Crawler Hydraulic Excavator Operation and Maintenance Manual – PDF DOWNLOAD

Sany SY115C9/135C/155H Crawler Hydraulic Excavator Operation and Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Sany SY115C9/135C/155H Crawler Hydraulic Excavator Operation and Maintenance Manual – PDF DOWNLOAD

Language : English

Pages :444

Downloadable : Yes

File Type : PDF

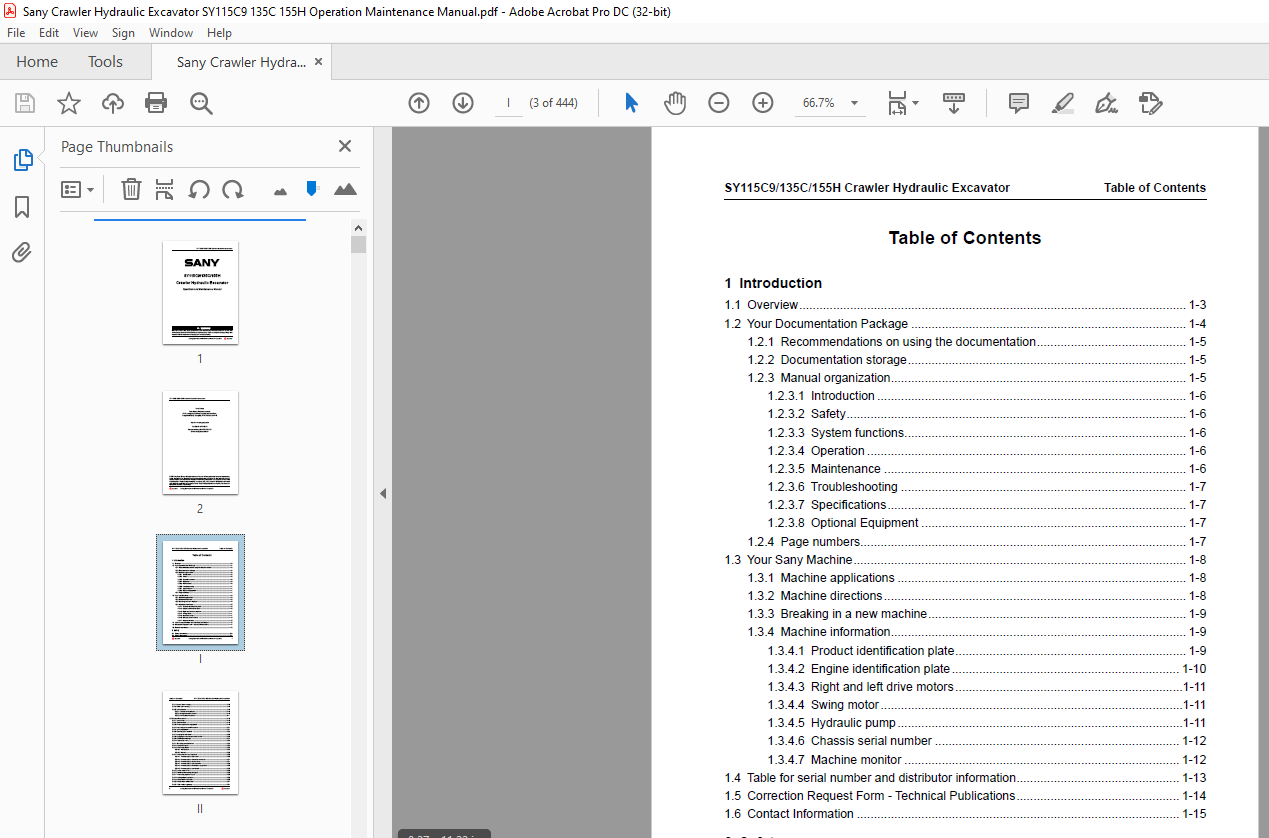

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Sany SY115C9/135C/155H Crawler Hydraulic Excavator Operation and Maintenance Manual – PDF DOWNLOAD

1 Introduction

11 Overview 1-3

12 Your Documentation Package 1-4

121 Recommendations on using the documentation 1-5

122 Documentation storage 1-5

123 Manual organization 1-5

1231 Introduction 1-6

1232 Safety 1-6

1233 System functions 1-6

1234 Operation 1-6

1235 Maintenance 1-6

1236 Troubleshooting 1-7

1237 Specifications 1-7

1238 Optional Equipment 1-7

124 Page numbers 1-7

13 Your Sany Machine 1-8

131 Machine applications 1-8

132 Machine directions 1-8

133 Breaking in a new machine 1-9

134 Machine information 1-9

1341 Product identification plate 1-9

1342 Engine identification plate 1-10

1343 Right and left drive motors 1-11

1344 Swing motor 1-11

1345 Hydraulic pump 1-11

1346 Chassis serial number 1-12

1347 Machine monitor 1-12

14 Table for serial number and distributor information 1-13

15 Correction Request Form – Technical Publications 1-14

16 Contact Information 1-15

2 Safety

21 Safety Information 2-5

22 Safety Messages 2-7

Table of Contents

Table of Contents

Safety, Operation and Maintenance II Manual – Sep 2012

SY115C9/135C/155H Crawler Hydraulic Excavator

221 Hazard alert wording 2-8

222 Other alert wording 2-9

223 Safety decals 2-9

2231 Textual safety decals 2-10

2232 Graphical safety decals 2-10

2233 Safety decal locations 2-11

23 General Precautions 2-19

231 Safety rules 2-19

232 Abnormalities 2-19

233 Personal protective equipment 2-19

234 Fire extinguisher and first aid kit 2-21

235 Safety equipment 2-21

236 Cleaning your machine 2-22

237 Keeping the cab clean 2-23

238 Engaging the hydraulic lockout control 2-23

239 Handholds and steps 2-24

2310 Overhead work 2-25

2311 No sitting on attachment 2-25

2312 Articulated parts 2-25

2313 Preventing burns 2-25

23131 Hot coolant 2-25

23132 Hot oil 2-26

2314 Preventing fire and explosion 2-26

23141 Fire caused by fuel or oils 2-26

23142 Fire caused by flammable materials 2-27

23143 Fire caused by electric lines 2-27

23144 Fire caused by hydraulic lines 2-28

23145 Fire caused by illumination equipment 2-28

23146 Fire caused by heat shield 2-28

2315 In the event of fire 2-28

2316 Windshield cleaning detergent 2-29

2317 Preventing ejection of part 2-29

2318 Falling object protection 2-30

2319 Attachment installation 2-30

2320 Attachment combination 2-31

2321 Cab windows glasses 2-31

Table of Contents

Safety, Operation and Maintenance Manual – Sep 2012 III

SY115C9/135C/155H Crawler Hydraulic Excavator

2322 Unauthorized modification 2-31

2323 Job site investigation 2-31

2324 Operation on soft ground 2-32

2325 Overhead power cables 2-33

2326 Ensuring a good visibility 2-34

2327 Ventilating enclosed area 2-35

2328 Asbestos hazard 2-35

2329 Alternate exit 2-36

24 Safe Operation Precautions 2-37

241 Safe starting 2-37

2411 Safe mounting 2-37

2412 Seat adjustment 2-38

2413 Seat belt 2-38

2414 Before starting the engine 2-38

2415 Engine starting rules 2-39

2416 Safe starting 2-39

2417 Starting engine in cold season 2-40

2418 Engine starting aid 2-40

2419 After starting the engine 2-41

242 Operation 2-42

2421 Inspection before operation 2-42

2422 Prior-operation precautions 2-42

2424 Travel directions 2-43

2423 Rules for steering safety 2-43

2425 Rules for traveling safety 2-45

2426 Safe traveling 2-46

2427 Operation on an incline 2-47

2428 Operation in snowy weather 2-48

2429 Restricted operations 2-48

243 Parking the machine 2-51

2431 Select a parking place 2-51

2432 Machine shutdown 2-51

244 Transportation 2-52

2441 Loading and unloading the machine 2-52

2442 Transporting the machine 2-53

245 Battery 2-54

Table of Contents

Safety, Operation and Maintenance IV Manual – Sep 2012

SY115C9/135C/155H Crawler Hydraulic Excavator

246 Lifting objects with the machine 2-56

25 Precautions for Maintenance 2-57

251 Prior-maintenance precautions 2-57

252 Select a working area 2-57

253 Preparing the machine 2-58

254 Preparing yourself 2-59

255 Lock-out and tag-out 2-60

256 Using proper tools 2-60

257 Maintenance with engine running 2-61

258 Working under the machine 2-61

259 Track maintenance 2-62

2510 Track tension adjustment precautions 2-63

2511 Recoil spring 2-63

2512 Welding operation 2-64

2513 High-pressure hoses 2-64

2514 Pressurized fluid 2-65

2515 Hot cooling system 2-66

2516 Air-conditioning system 2-66

2517 High voltage precautions 2-67

2518 Accumulator 2-67

2519 Avoiding fire and explosion 2-68

2520 Regular replacement of safety-related parts 2-69

2521 Maintenance operation 2-70

2522 Proper disposal of wastes 2-71

3 System Functions

31 Machine Overview 3-5

32 Machine Controls 3-6

33 Monitor 3-7

331 Monitor introduction 3-7

332 System information and operation 3-10

3321 Main Page 3-10

3322 System Information 3-12

3323 Time Setup 3-13

3324 Main Menu 3-14

3325 Engine & Throttle Signals 3-15

Table of Contents

Safety, Operation and Maintenance Manual – Sep 2012 V

SY115C9/135C/155H Crawler Hydraulic Excavator

3326 Main Pump Signals 3-15

3327 Input Switch Signals 3-16

3328 Output Switch Signals 3-16

3329 Machine Configuration 3-17

33210 Failure codes 3-17

33211 Maintenance Information 3-18

33212 Engine Speed Calibration 3-23

33213 Language Selection 3-25

33214 GPS Monitoring Information 3-26

33215 System Setup 3-27

33216 Machine configuration setup 3-28

33217 Coolant Temperature 3-29

33218 Service Call 3-30

34 Switches 3-31

3421 Start switch 3-32

3422 Fuel control dial 3-33

3423 Work lamp switch 3-33

3424 Wiper switch 3-35

3425 Washer switch 3-36

3426 Head lamp switch 3-36

3427 Horn switch 3-37

3428 Cab lamp 3-37

3429 Cigar lighter 3-37

34210 Preheat switch (only for SY135C8M) 3-38

34211 Alternator indicator 3-38

35 Control levers and pedals 3-39

351 Hydraulic lockout control 3-40

352 Travel controls 3-41

353 Joystick controls 3-42

36 Roof Hatch 3-44

361 Opening the roof hatch 3-44

362 Closing the roof hatch 3-44

37 Windshield 3-45

371 Opening the window 3-45

372 Closing the window 3-48

373 Removing the lower window 3-50

Table of Contents

Safety, Operation and Maintenance VI Manual – Sep 2012

SY115C9/135C/155H Crawler Hydraulic Excavator

38 Alternate Exit 3-51

39 Door Catch 3-52

310 Cover/cap with a Latch 3-52

3101 Opening/closing the cover with lock 3-53

3102 Opening/closing the cap with lock 3-54

311 Cup Holder 3-55

312 Storage Box 3-56

313 Literature Bag 3-56

314 Ashtray 3-57

315 Air Conditioning System 3-58

3151 Control panel 3-58

3152 Operation method 3-64

3153 A/C operation precautions 3-72

316 Radio 3-74

3161 Control panel 3-74

3162 Radio operation 3-76

317 Auxiliary Power Supply 3-80

318 Fuses 3-80

319 Fusible Link 3-81

320 Controller 3-82

321 Toolbox 3-82

322 Grease pump frame 3-82

323 Fire extinguisher 3-83

4 Operation

41 Before Starting the Engine 4-5

411 Routine checks 4-5

412 Checks before starting 4-7

4121 Fuel tank – check/drain 4-7

4122 Water separator – check/drain 4-7

4123 Drain valve – regulate 4-8

4124 Hydraulic oil – check/refill 4-9

4125 Coolant – check/refill 4-10

4126 Oil in engine oil pan – check/refill 4-11

4127 Electric wires – check 4-12

4128 Fuel tank – check/refuel 4-13

Table of Contents

Safety, Operation and Maintenance Manual – Sep 2012 VII

SY115C9/135C/155H Crawler Hydraulic Excavator

4129 Work lamp switch – check 4-14

41210 Horn – check 4-15

413 Adjustment before operation 4-15

4131 Operator seat 4-15

4132 Rear view mirrors 4-17

4133 Seat belt 4-19

414 Before Starting the Engine 4-20

42 Engine Starting 4-22

421 Engine Preheating 4-25

422 Warm-up operation 4-26

423 Selecting a working mode 4-26

43 Engine Shutdown 4-27

44 Machine Operation 4-28

441 Before moving the machine 4-28

442 Moving the machine forward 4-29

443 Moving the machine backward 4-30

444 Parking the machine 4-31

45 Steering Operation 4-32

4541 Steering with travel controls 4-32

4542 Steering with machine stopped 4-32

4543 Steering during traveling 4-33

4544 Pivot turn 4-33

451 Swing operation 4-34

46 Work Equipment Control and Operation 4-35

47 Working mode 4-37

48 Restricted Operations 4-38

481 Operation with swinging force 4-38

482 Operation with traveling force 4-38

483 Operation when hydraulic cylinder reaches its stroke end 4-39

484 Operation with bucket landing force 4-39

485 Operation with machine weight 4-40

486 Hard rocky ground 4-40

487 Sudden shift of travel speed during fast traveling 4-41

49 General Operation 4-41

491 Traveling operation 4-41

492 High-speed travel 4-41

Table of Contents

Safety, Operation and Maintenance VIII Manual – Sep 2012

SY115C9/135C/155H Crawler Hydraulic Excavator

493 Permissible depth of water 4-42

410 Traveling on Slope 4-42

4101 Traveling downhill 4-44

4102 Engine stalls on an incline 4-44

4103 Cab door on an incline 4-44

411 Removing Machine from Mud 4-44

4111 One track trapped 4-44

4112 Both tracks trapped 4-45

412 Recommended Applications 4-45

4121 Backhoe operation 4-45

4122 Trench work 4-46

4123 Loading operation 4-46

413 Parking Operation 4-47

414 Checks after Each Workday 4-49

415 Locking the Machine 4-50

416 Operation in Cold Weather 4-50

4161 Operation instruction 4-50

41611 Fuel and lubricant 4-50

41612 Battery 4-51

4162 After each workday 4-52

4163 After cold season 4-53

417 Long-Term Storage 4-54

4171 Before storage 4-54

4172 During storage 4-55

4173 After storage 4-56

4174 Starting the engine after long-term storage 4-56

418 Transportation Information 4-57

4181 Transport methods 4-57

4182 Loading/unloading machine to/from a trailer 4-57

41821 Loading the machine 4-59

41822 Securing the machine 4-61

41823 Rear view mirrors 4-62

41824 Unloading the machine 4-63

4183 Lifting the machine or its components 4-65

41831 Lifting precautions 4-65

41832 Choosing a wire rope 4-66

Table of Contents

Safety, Operation and Maintenance Manual – Sep 2012 IX

SY115C9/135C/155H Crawler Hydraulic Excavator

41833 Lifting the machine 4-67

5 Maintenance

51 Maintenance Information 5-5

52 General Service 5-9

521 Oil, fuel and coolant 5-9

5211 Oil 5-9

5212 Fuel 5-10

5213 Coolant 5-11

522 Grease 5-12

523 Oil and fuel storage 5-13

524 Filter element 5-13

525 Electrical system 5-14

526 Hydraulic system 5-14

53 Replacement Parts 5-16

54 Recommended Fluids 5-17

541 Fluid capacities 5-19

542 Recommended oils: 5-20

55 Tightening Torque Specification 5-22

56 Safety-Related Parts 5-24

57 Maintenance Schedule 5-25

571 List of maintenance schedule 5-25

572 Hydraulic Breaker Service Interval 5-27

58 Maintenance Procedures 5-28

581 Maintenance after initial 50 service hours 5-28

5811 Engine oil and filter – change/replace 5-28

5812 Fuel filter – replace 5-28

582 When Required 5-29

5821 Air cleaner – clean/replace 5-29

5822 Cooling system – clean 5-37

5823 Track shoe bolts – inspect/tighten 5-41

5824 Track tension – inspect/adjust 5-42

5825 Bucket tips (lateral pin) – replace 5-45

5826 Bucket Replacement 5-47

5827 Bucket clearance – adjust 5-49

5828 Window washer fluid – check/refill 5-51

Table of Contents

Safety, Operation and Maintenance X Manual – Sep 2012

SY115C9/135C/155H Crawler Hydraulic Excavator

5829 Air conditioner – inspect/service 5-52

58210 Gas spring – inspect 5-54

58211 Air in hydraulic system – purge 5-55

58212 Hydraulic circuit internal pressure – release 5-58

583 Checks before starting 5-59

584 Every 100 service hours 5-60

5841 Lubrication 5-60

585 Every 250 service hours 5-63

5851 Compressor belt tension – inspect/adjust 5-63

5852 Oil in engine oil pan and oil filter – change/replace 5-65

5853 Primary fuel filter – replace 5-67

5854 Secondary fuel filter – replace 5-71

586 Every 500 service hours 5-74

5861 Swing bearing – lubricate 5-74

5862 Swing pinion gear grease – check/refill 5-75

5863 Coolant tank and radiator fins – inspect/clean 5-76

5864 Air conditioner filters – clean 5-77

5865 Swing drive oil – check/refill 5-80

5866 Final drive oil – check/fill 5-81

587 Every 1000 service hours 5-82

5871 Hydraulic oil filter – replace 5-82

5872 Swing drive oil – change 5-84

5873 Engine exhaust pipe clamps – check 5-85

5874 Fan belt tension – check/replace 5-85

5875 Nitrogen pressure in accumulator (breaker) – check 5-85

588 Every 2000 service hours 5-86

5881 Final drive oil – change 5-86

5882 Hydraulic tank filter screen – clean 5-88

5883 Nitrogen pressure in accumulator (control oil circuit) – check 5-89

5884 Hydraulic circuit internal pressure – release 5-92

5885 Oil in hydraulic tank – change 5-93

5886 Alternator – inspect 5-95

5887 Engine valve clearance – check/adjust 5-95

589 Every 4000 service hours 5-95

5891 Coolant pump – inspect 5-95

5892 Start motor – check 5-95

Table of Contents

Safety, Operation and Maintenance Manual – Sep 2012 XI

SY115C9/135C/155H Crawler Hydraulic Excavator

5893 Accumulator (control oil circuit) – replace 5-96

5894 High-pressure tube clamps and rubber – check 5-97

5895 Compressor working condition – inspect 5-97

5810 Every 8000 service hours 5-98

58101 High-pressure tube clamps – replace 5-98

5811 Every 10000 service hours 5-98

6 Troubleshooting

61 Troubleshooting Preparation 6-3

611 Checks before troubleshooting 6-3

612 Troubleshooting procedure 6-4

613 Troubleshooting precautions 6-6

614 Electrical circuits troubleshooting precautions 6-9

615 Hydraulic components handling precautions 6-10

62 Pseudo Failures 6-12

63 Towing the Machine 6-13

64 Towing Hook for Light Loads 6-15

65 Severe Operating Conditions 6-15

66 Engine Failures 6-16

661 Engine troubleshooting table 6-16

662 Coolant temperature high 6-19

663 Engine oil pressure low 6-20

664 When fuel exhausts 6-22

665 When engine rotates reversely 6-24

67 Failures of the Electrical System 6-25

671 Electrical system troubleshooting table 6-25

672 Failure codes 6-28

68 Battery 6-30

681 Battery removal and installation 6-30

682 Battery charging 6-31

683 Jump-starting the engine 6-32

6831 Connecting the jumper cables 6-33

6832 Starting the engine 6-34

6833 Disconnecting the jumper cables 6-34

69 Failures of the Hydraulic System 6-35

610 Other Common Failures 6-39

Table of Contents

Safety, Operation and Maintenance XII Manual – Sep 2012

SY115C9/135C/155H Crawler Hydraulic Excavator

7 Specifications

71 Machine Dimensions 7-3

72 Working Ranges 7-4

8 Optional Equipment

81 General Safety 8-3

811 Selection precautions 8-3

812 Reading the instruction books 8-3

813 Removal and installation precautions 8-3

814 Operation precautions 8-4

82 Hydraulic Control Elements and Oil Circuit 8-6

821 Location of the components 8-6

8211 Stop valve 8-6

8212 Selector valve 8-7

8213 Control pedal 8-7

822 Hydraulic circuit 8-8

8221 Hydraulic circuit switching 8-8

8222 Shifting to breaker / general optional equipment 8-8

8223 Connecting hydraulic oil circuit 8-9

8224 Hydraulic oil passage 8-10

823 Optional equipment removal and installation 8-11

8231 Removal 8-11

8232 Optional equipment installation 8-13

824 Hydraulic oil and hydraulic tank filter – change/replace 8-15

825 Long-term storage 8-16

826 Hydraulic specifications 8-16

83 Optional equipment Guide 8-17

831 Work equipment combination 8-17

832 Bucket tips selection 8-19

8321 Rockwork bucket tips 8-19

8322 Earthwork bucket tips 8-19

84 Recommended Operations 8-20

841 Hydraulic breaker 8-20

842 Hydraulic breaker operation 8-21

85 Restricted Operations 8-22

86 Hydraulic Breaker Lubrication 8-25

Table of Contents

Safety, Operation and Maintenance Manual – Sep 2012 XIII

SY115C9/135C/155H Crawler Hydraulic Excavator

87 Quick Coupler and Control System 8-26

871 Quick coupler installation 8-26

872 Operating precautions 8-28

88 Refueling System 8-29

881 Introduction 8-29

882 Components 8-30

89 Central Lubrication System 8-31

891 Scheme and components 8-31

892 System working principle 8-33

893 Setting the lubrication time of electric grease pump 8-34

894 Technical description 8-35

895 Adding grease with electric pump 8-36