$39

Sany SY50U Crawler Hydraulic Excavator Service Manual – PDF DOWNLOAD

Sany SY50U Crawler Hydraulic Excavator Service Manual – PDF DOWNLOAD

FILE DETAILS:

Sany SY50U Crawler Hydraulic Excavator Service Manual – PDF DOWNLOAD

Language : English

Pages : 452

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Sany SY50U Crawler Hydraulic Excavator Service Manual – PDF DOWNLOAD

1 Introduction

1 1 How to Read the Manual 1-3

1 1 1 Shop manual organization 1-3

1 1 2 Revision and distribution 1-4

1 1 3 Symbols 1-5

1 1 4 Units 1-5

1 2 Technical Terms 1-6

1 2 1 Standard size and tolerance 1-6

1 2 2 Standard clearance and value 1-7

1 2 3 Standard interference 1-7

1 2 4 Repair limit and allowable value 1-8

1 2 5 Clearance limit 1-8

1 2 6 Interference limit 1-8

1 3 Handling Electrical and Hydraulic Components 1-9

1 3 1 Points to remember when handling electric components 1-9

1 3 1 1 Handling wiring harnesses and connectors 1-9

1 3 1 2 Main failures occurring in wiring harness 1-10

1 3 1 3 Removing, installing, and drying connectors and wiring harnesses 1-12

1 3 1 4 Handling the integrated control monitor 1-16

1 3 1 5 Electric circuits troubleshooting precautions 1-17

1 3 2 Points to remember when handling hydraulic equipment 1-18

1 3 2 1 Be careful of the operating environment 1-18

1 3 2 2 Disassembly and maintenance work in the f eld 1-18

1 3 2 3 Sealing openings 1-18

1 3 2 4 Do not let any dirt or dust get in during ref lling operations 1-19

1 3 2 5 Change hydraulic oil when the temperature is high 1-19

1 3 2 6 Flushing operations 1-19

1 3 2 7 Cleaning operations 1-20

1 4 Hose Connector 1-20

1 4 1 Type of hose connector 1-21

1 4 2 Hose connector tightening torque table 1-21

1 4 3 Connection of O-rings 1-22

1 5 Table of Standard Tightening Torques 1-23

1 6 Type of Bolts 1-24

1 7 Tightening Sequence 1-24

1 8 Maintenance of Half Flanges 1-25

1 8 1 Table of tightening torques for half f ange bolts 1-25

1 8 2 Temperature 1-31

2 Shop Safety

2 1 Hazard Alert Information 2-3

2 2 General Shop Safety 2-5

2 2 1 Rules and shop behavior 2-6

2 2 2 Housekeeping 2-6

2 2 3 Shop Liquids Storage 2-7

2 2 4 Cleaning the Parts 2-7

2 2 5 Cleaning the Machine 2-8

2 2 6 Appropriate Working Apparel 2-8

2 2 7 Personal Protective Equipment 2-8

2 2 8 Using the Correct Tools 2-9

2 2 9 Fire Extinguisher and Emergency Exits 2-9

2 2 10 Electrical Dangers 2-10

2 2 11 Hoisting a Load 2-10

2 3 Before Repair 2-11

2 3 1 Safe Work Preparations 2-11

2 3 2 Preparing yourself 2-12

2 3 3 Lockout/Tagout 2-13

2 3 4 Two people when engine running 2-15

2 3 5 Safety Partners 2-15

2 4 Repair Precautions 2-16

2 4 1 Running the Machine 2-16

2 4 2 Mounting and Dismounting 2-17

2 4 3 Removing Attachments 2-18

2 4 4 Jacking Up the Machine 2-18

2 4 5 Adding Fluids to a System 2-18

2 4 6 Aligning Parts or Components 2-19

2 4 7 Driving Pins 2-19

2 4 8 When compressed air is used 2-19

2 4 9 Welding operation 2-20

2 4 10 Track Recoil Springs 2-20

2 4 11 High-Pressure Fluid Lines 2-21

2 4 12 Air-conditioning system maintenance 2-22

2 4 13 High voltage precautions 2-22

2 4 14 Disconnecting the System Power 2-23

2 4 15 Accumulator 2-23

2 4 17 Battery Hazards 2-24

2 4 18 Jump-Start Safety 2-25

2 4 19 Avoiding f re and explosion 2-26

2 4 20 Chemical hazard 2-27

2 4 21 Material Safety Data Sheets (MSDS) 2-27

2 4 22 Proper disposal of wastes 2-28

2 5 Other Precautions 2-29

2 5 1 Sling work and giving signals 2-29

2 5 2 Using mobile crane 2-31

2 5 3 Using overhead hoist crane 2-31

2 5 4 Selecting wire ropes 2-33

3 Specif cations

3 1 Dimension Drawing 3-3

3 2 Working Ranges 3-4

3 3 Technical Specif cations 3-5

3 4 Weight Table 3-7

3 5 Capacity Table 3-8

3 6 Fuel and Coolant Capacities 3-9

3 7 Engine Performance Curve 3-10

4 Structure and Functions

4 1 Engine and Cooling System 4-3

4 1 1 Water cooler and oil cooler 4-3

4 1 2 Engine control device 4-5

4 2 Power Train 4-7

4 2 1 Power transmission system 4-7

4 2 2 Swing bearing 4-8

4 2 3 Swing motor 4-9

4 3 Undercarriage 4-10

4 3 1 Track frame 4-10

4 3 2 Tensioning device 4-11

4 3 3 Tensioning device 4-12

4 4 Hydraulic System 4-13

4 4 1 Hydraulic lines 4-13

4 4 2 Hydraulic tank 4-14

4 4 3 Hydraulic pump 4-15

4 4 4 Control valve 4-17

4 4 5 Swing motor 4-22

4 4 6 Safety valve 4-26

4 4 7 Central swivel joint 4-28

4 4 8 Travel motor 4-29

4 4 8 1 Working process of parking brake 4-32

4 4 8 2 Working process of brake valve 4-33

4 4 9 Control system 4-35

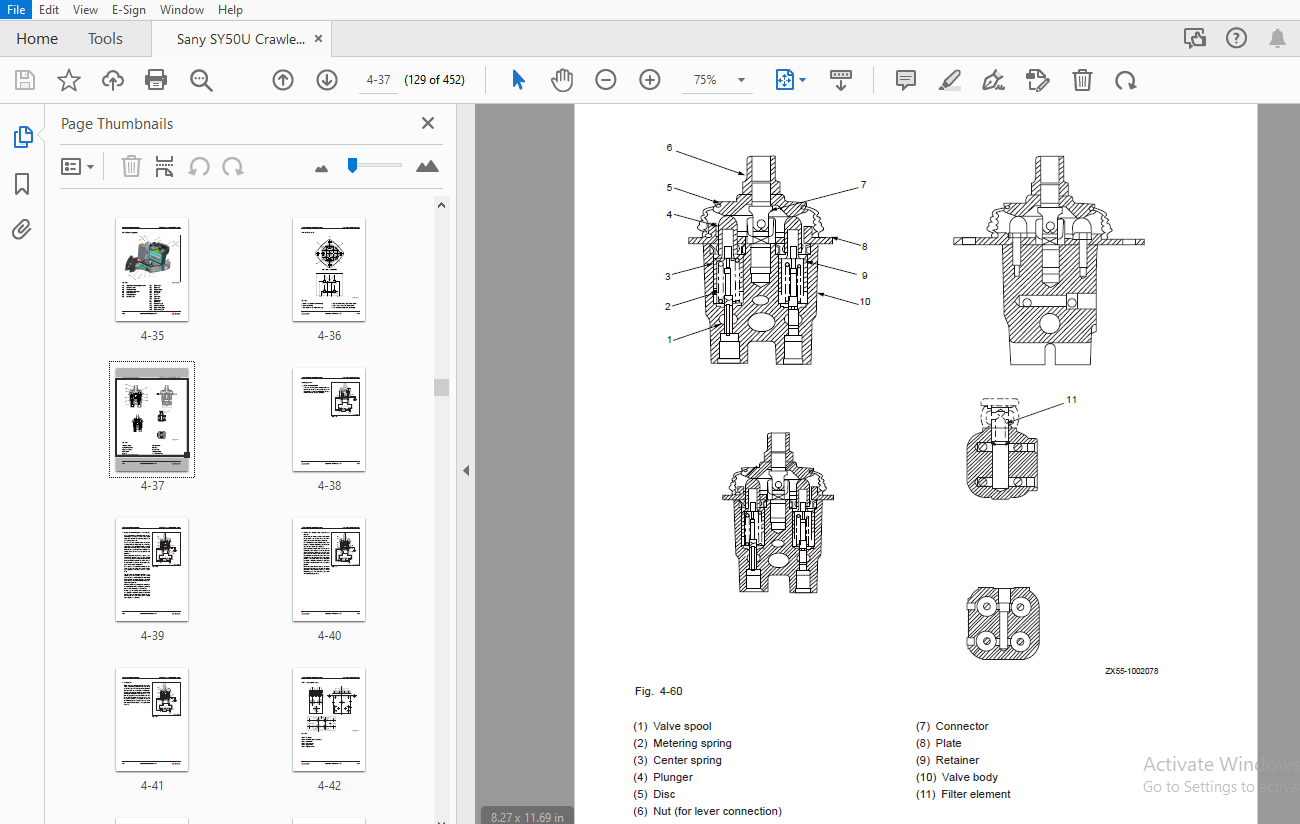

4 4 10 Pilot valve 4-36

4 4 11 Travel pilot valve 4-42

4 4 12 Oil source control valve 4-46

4 4 13 Backup pilot valve 4-47

4 4 14 Hydraulic cylinders 4-51

4 5 Air Conditioner System 4-52

4 5 1 Electric circuit 4-52

4 5 2 Component locations 4-53

4 5 3 Checking condenser f ns 4-55

4 5 4 Refrigerant-f lling operation 4-56

4 5 5 Troubleshooting with a manifold pressure gauge 4-57

4 6 Electrical System 4-66

4 6 1 Electrical circuit diagram 4-67

4 7 Electronic Control System 4-68

4 7 1 General view 4-68

4 7 2 Functional overview of electrical control system 4-69

4 7 3 Valve control function 4-71

4 7 4 preheating and overheating protection function 4-73

4 7 5 Travel speed selection 4-74

4 7 6 Machine monitoring system 4-75

4 8 Integrated-controlled Monitor System 4-77

4 8 1 Monitor 4-77

4 8 2 Page introduction and operation 4-80

4 8 2 1 Main menu 4-80

4 8 2 2 Alert information 4-81

4 8 2 3 History fault information 4-82

4 8 2 4 System information 4-82

4 8 2 5 Maintenance information 4-83

4 8 2 6 GPS monitoring and rpm calibration 4-83

4 8 2 7 Machine conf guration setup 4-84

4 8 2 8 System lockout 4-85

4 8 2 9 Password entry 4-86

4 8 2 10 System lockout 4-87

4 8 2 11 One-key call 4-88

5 Standard Values

5 1 Standard Values for Engine-Related Parts 5-3

5 2 Standard Values for Chassis-Related Parts 5-4

5 3 Standard Values for Electrical Parts 5-11

6 Testing and Adjusting

6 1 Engine Speed – Test 6-4

6 2 Exhaust Gas Color – Test 6-5

6 2 1 Using a hand tester 6-5

6 2 2 Using an instrument 6-6

6 3 Valve Clearance – Adjust 6-7

6 4 Compression Pressure – Test 6-8

6 5 Injection Timing – Test and Adjust 6-9

6 5 1 Checking injection timing 6-9

6 5 2 Adjusting the injection timing 6-12

6 6 Engine Oil Pressure – Test 6-13

6 7 Alternator Belt Tension – Test and Adjust 6-13

6 8 Hydraulic Pressure in Oil Circuits – Test and Adjust 6-14

6 9 LS Differential Pressure and LS Valve – Test/Adjust 6-16

6 9 1 Testing LS differential pressure 6-16

6 9 2 Adjusting LS valve 6-17

6 10 Hydraulic Pressure in Control Circuit – Test 6-18

6 11 Pilot Valve Output Pressure – Test 6-19

6 12 Work Equipment and Swing Pilot Valve – Adjust 6-20

6 13 Travel Deviation – Test 6-21

6 14 Oil Leakage – Test 6-22

6 14 1 Work equipment cylinder 6-22

6 14 2 Swing motor 6-24

6 14 3 Travel motor 6-25

6 15 Residual Pressure in Hydraulic Circuit – Release 6-26

6 16 Swing Bearing Clearance – Check 6-27

6 17 Track Tension – Check and Adjust 6-28

6 17 1 Checking track tension 6-28

6 17 2 Adjusting track tension 6-28

6 17 2 1 When the tension is high 6-28

6 17 2 2 When the tension is low 6-29

6 18 Air Purging 6-30

6 18 1 Purging air from hydraulic pump 6-30

6 18 2 Purging air from hydraulic cylinder 6-31

6 18 3 Purging air from swing motor 6-31

6 18 4 Purging air from travel motor 6-31

7 Troubleshooting

7 1 Troubleshooting Precautions 7-3

7 2 Checks Before Troubleshooting 7-5

7 3 Connector Locations and System Diagrams 7-6

7 4 Number of Pins Required for Connection 7-9

7 5 Electric Wire Specif cations 7-16

7 6 How to Use the Judgement Chart 7-18

7 7 How to Use a Schematic Diagram for Troubleshooting 7-20

7 8 Troubleshooting the Electrical System 7-21

7 9 Troubleshooting the Engine 7-28

7 10 Troubleshooting the Hydraulic and Mechanical System 7-53

8 Disassembly and Assembly

8 1 Operating Precautions 8-6

8 2 Engine and Main Pump AS 8-9

8 2 1 Removal 8-10

8 2 2 Installation 8-14

8 3 Central Swivel Joint AS 8-15

8 3 1 Removal 8-15

8 3 2 Installation 8-16

8 3 3 Disassembly 8-17

8 3 4 Assembly 8-17

8 4 Sprocket 8-18

8 4 1 Removal 8-18

8 4 2 Installation 8-18

8 5 Travel Motor AS 8-19

8 5 1 Removal 8-19

8 5 2 Installation 8-20

8 5 3 Disassembly 8-21

8 5 3 1 Preparatory work 8-21

8 5 3 2 General precautions for disassembling 8-21

8 5 3 3 Disassembling procedure 8-22

8 5 4 Table of maintenance standard 8-32

8 5 5 Assembly 8-35

8 5 5 1 Preparatory work 8-35

8 5 5 2 General precautions 8-35

8 5 5 3 Assembly procedure 8-36

8 5 5 4 Performance test 8-50

8 6 Swing Motor and Swing Mechanism AS 8-51

8 6 1 Removal 8-51

8 6 2 Installation 8-52

8 7 Swing Motor AS 8-53

8 7 1 Disassembly 8-53

8 7 1 1 Separate the motor from the reducer 8-53

8 7 1 2 Disassemble the motor 8-53

8 7 1 3 Disassembling the reducer 8-59

8 7 1 4 Assembling the motor 8-62

8 7 1 5 Assemble the reducer 8-70

8 7 1 6 Assembling the swing motor assembly 8-74

8 8 Swing Mechanism AS 8-75

8 8 1 Disassembly 8-75

8 8 2 Assembly 8-78

8 9 Swing Platform AS 8-82

8 9 1 Removal 8-82

8 9 2 Installation 8-84

8 10 Swing Bearing AS 8-85

8 10 1 Removal 8-85

8 10 2 Installation 8-85

8 11 Idler and Tension Spring AS 8-86

8 11 1 Removal 8-86

8 11 2 Installation 8-86

8 12 Tension Spring AS 8-87

8 12 1 Disassembly 8-87

8 12 2 Assembly 8-88

8 13 Idler AS 8-89

8 13 1 Disassembly 8-89

8 13 2 Assembly 8-89

8 14 Track Roller AS 8-90

8 14 1 Removal 8-90

8 14 2 Installation 8-90

8 15 Track Roller AS 8-91

8 15 1 Disassembly 8-91

8 15 2 Assembly 8-91

8 16 Carrier Roller AS 8-92

8 16 1 Removal 8-92

8 16 2 Installation 8-92

8 17 Track AS 8-93

8 17 1 Removal 8-93

8 17 2 Installation 8-93

8 18 Hydraulic Tank AS 8-94

8 18 1 Removal 8-94

8 18 2 Installation 8-94

8 19 Main Pump AS 8-95

8 19 1 Removal 8-95

8 18 2 Installation 8-95

8 20 Control Valve AS 8-96

8 21 1 Removal 8-96

8 21 2 Installation 8-96

8 21 Oil Source Control Valve AS 8-97

8 22 1 Removal 8-97

8 22 2 Installation 8-97

8 22 Left Pilot Valve AS (Arm and Swing Control) 8-98

8 22 1 Removal 8-98

8 22 2 Installation 8-98

8 23 Right Pilot Valve (Boom and Bucket Control) 8-99

8 23 1 Removal 8-99

8 23 2 Installation 8-99

8 24 Work Equipment Pilot Valve AS 8-100

8 24 1 Disassembly 8-100

8 24 2 Assembly 8-101

8 25 Travel Pilot Valve AS 8-102

8 25 1 Removal 8-102

8 25 2 Installation 8-102

8 26 Travel Pilot Valve AS 8-103

8 26 1 Disassembly 8-103

8 26 2 Assembly 8-103

8 27 Boom Cylinder AS 8-104

8 27 1 Removal 8-104

8 27 2 Installation 8-105

8 28 Arm Cylinder AS 8-106

8 28 1 Removal 8-106

8 28 2 Installation 8-107

8 29 Bucket Cylinder AS 8-108

8 29 1 Removal 8-108

8 29 2 Installation 8-109

8 30 Def ection Cylinder AS 8-110

8 30 1 Removal 8-110

8 30 2 Installation 8-110

8 31 Dozer Blade Cylinder AS 8-111

8 31 1 Removal 8-111

8 31 2 Installation 8-112

8 32 Hydraulic Cylinder AS 8-113

8 32 1 Disassembly 8-113

8 32 2 Assembly 8-116

8 33 Work Equipment AS 8-119

8 33 1 Removal 8-119

8 33 2 Installation 8-120

8 34 Bucket-Arm AS 8-121

8 34 1 Removal 8-121

8 34 2 Installation 8-122

8 35 Bucket AS 8-123

8 35 1 Removal 8-123

8 35 2 Installation 8-124

8 36 Arm AS 8-125

8 36 1 Removal 8-125

8 36 2 Installation 8-126

8 37 Boom AS 8-127

8 37 1 Removal 8-127

8 37 2 Installation 8-128

8 38 1 Removal 8-129

8 38 2 Installation 8-129

8 38 3 Installation 8-130

8 39 Dozer Blade AS 8-131

8 39 1 Removal 8-131

8 39 2 Installation 8-131

8 40 Cab AS 8-132

8 40 1 Removal 8-132

8 41 2 Installation 8-133

8 42 Monitor AS 8-134

8 42 1 Removal 8-134

8 42 2 Installation 8-134

9 Maintenance Standard

9 1 Swing Mechanism 9-3

9 2 Swing Bearing 9-4

9 3 Track Frame 9-5

9 4 Idler 9-6

9 5 Track Roller 9-7

9 6 Rubber track 9-8

9 7 Work Equipment 9-9

9 8 Arm Dimensions 9-11

9 9 Bucket Dimensions 9-12

9 10 Hydraulic Cylinder 9-13

10 System Schematics

10 1 Hydraulic Circuit Diagram 10-3

10 2 General System Diagram (1/5) 10-4

10 3 General System Diagram (2/5) 10-5

10 4 General System Diagram (3/5) 10-6

10 5 General System Diagram (4/5) 10-7

10 6 General System Diagram (5/5) 10-8

10 7 Electrical Circuit Diagram 10-9