$24

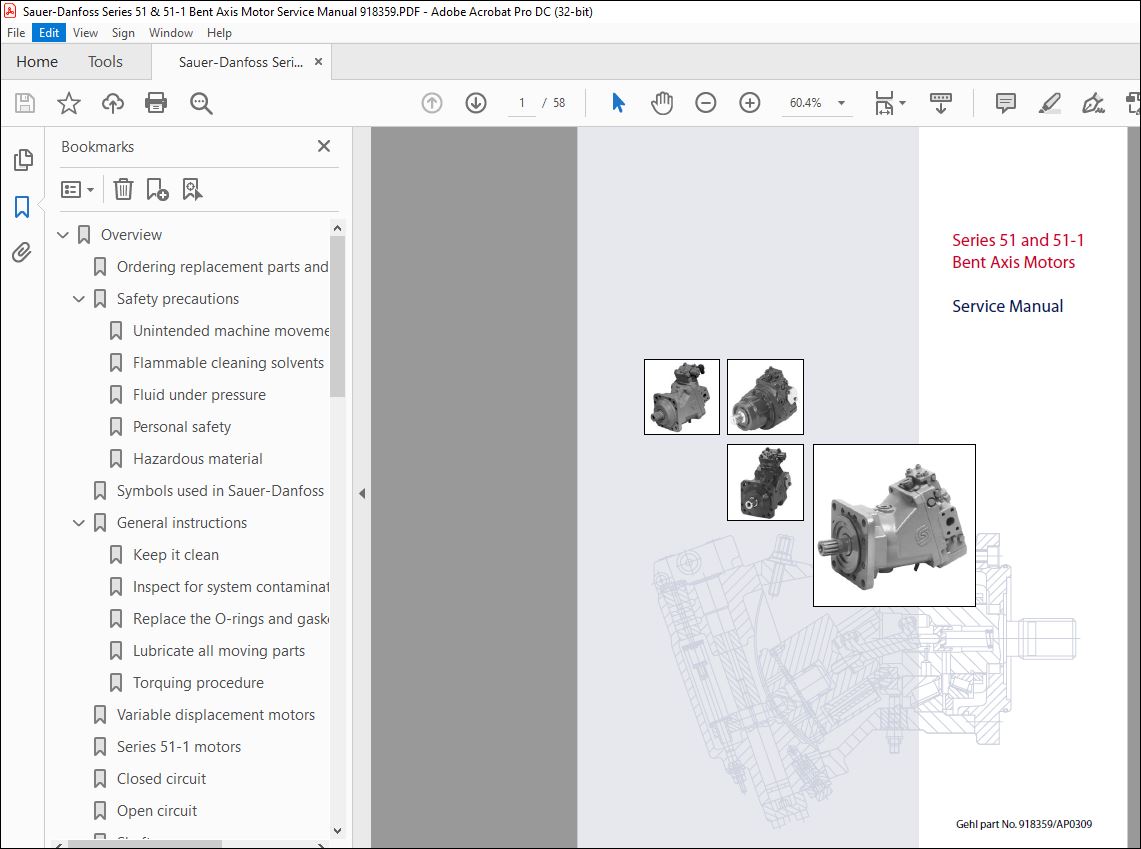

Sauer-Danfoss Series 51 & 51-1 Bent Axis Motor Service Manual 918359 – PDF DOWNLOAD

Sauer-Danfoss Series 51 & 51-1 Bent Axis Motor Service Manual 918359 – PDF DOWNLOAD

FILE DETAILS:

Sauer-Danfoss Series 51 & 51-1 Bent Axis Motor Service Manual 918359 – PDF DOWNLOAD

Language : English

Pages : 58

Downloadable : Yes

File Type : PDF

Size: 5.42 MB

IMAGES PREVIEW OF THE MANUAL:

DESCRIPTION:

Sauer-Danfoss Series 51 & 51-1 Bent Axis Motor Service Manual 918359 – PDF DOWNLOAD

INTRODUCTION:

- The complete service and repair information for Series 51 and Series 51-1 motors is in a modular format. Service information modules are available for the basic motor components, for each family of motor controls, and for major repair procedures. Each module contains information on the function, adjustment, and repair of each group of components or controls. The repair instructions module focuses on major repair procedures.

- Functional description, technical specifications, adjustment procedures, minor repair procedures, and exploded view common parts drawings for the basic Series 51 and Series 51-1 motor components comprise this manual. It discusses those minor repairs you can perform without removing the motor’s end cap. These repairs will not affect the unit’s warranty.

- Major repairs require removing the motor’s end cap. This manual does not describe them. Only Sauer-Danfoss Global Service Partners and / or original equipment manufacturers trained by Sauer-Danfoss should perform these repairs.

TABLE OF CONTENTS:

Sauer-Danfoss Series 51 & 51-1 Bent Axis Motor Service Manual 918359 – PDF DOWNLOAD

Introduction

Initial startup pr ocedures

Fluid and filter maintenance

Operation

Tech nical specifications

Pressure measurements

Overview…………………………………………………………………………………………………………………………………………5

Ordering replacement parts and service……………………………………………………………………………………5

Safety precautions…………………………………………………………………………………………………………………………6

Unintended machine movement…………………………………………………………………………………………..6

Flammable cleaning solvents………………………………………………………………………………………………….6

Fluid under pressure…………………………………………………………………………………………………………………6

Personal safety…………………………………………………………………………………………………………………………..6

Hazardous material…………………………………………………………………………………………………………………..6

Symbols used in Sauer-Danfoss literature………………………………………………………………………………….7

General instructions………………………………………………………………………………………………………………………8

Keep it clean………………………………………………………………………………………………………………………………8

Inspect for system contamination………………………………………………………………………………………….8

Replace the O-rings and gaskets…………………………………………………………………………………………….8

Lubricate all moving parts……………………………………………………………………………………………………….8

Torquing procedure………………………………………………………………………………………………………………….8

Variable displacement motors……………………………………………………………………………………………………..9

Series 51-1 motors……………………………………………………………………………………………………………………….10

Closed circuit………………………………………………………………………………………………………………………………..11

Open circuit…………………………………………………………………………………………………………………………………..11

Shafts……………………………………………………………………………………………………………………………………………..12

Loop flushing………………………………………………………………………………………………………………………………..13

Displacement limiters………………………………………………………………………………………………………………….15

Mounting configurations……………………………………………………………………………………………………………16

Speed sensors……………………………………………………………………………………………………………………………….17

Controls………………………………………………………………………………………………………………………………………….18

Two-position controls………………………………………………………………………………………………………………….18

Overview…………………………………………………………………………………………………………………………………..18

Pressure-compensator controls…………………………………………………………………………………………………19

Proportional controls…………………………………………………………………………………………………………………..20

General specifications…………………………………………………………………………………………………………………21

Technical data……………………………………………………………………………………………………………………………….21

Fluid specifications………………………………………………………………………………………………………………………22

Required tools………………………………………………………………………………………………………………………………23

Port locations and gauge installation……………………………………………………………………………………….23

Fluid and filter recommendations……………………………………………………………………………………………..25

Hazardous material…………………………………………………………………………………………………………………25

Procedure………………………………………………………………………………………………………………………………………26

oubleshooting

Sluggish system……………………………………………………………………………………………………………………………28

System operating hot………………………………………………………………………………………………………………….28

Excessive noise or vibration………………………………………………………………………………………………………..29

Motor operates normally in one direction only………………………………………………………………………29

Improper output speed………………………………………………………………………………………………………………29

Low output torque……………………………………………………………………………………………………………………….30

Overview……………………………………………………………………………………………………………………………………….31

Charge pressure relief valve…………………………………………………………………………………………………..31

Measuring charge pressure……………………………………………………………………………………………………31

Adjusting charge pressure…………………………………………………………………………………………………….32

Minimum displacement limiter………………………………………………………………………………………………….33

Adjusting minimum displacement……………………………………………………………………………………….33

Maximum displacement limiter…………………………………………………………………………………………………35

Series 51 motors ……………………………………………………………………………………………………………………..35

Series 51-1 motors ………………………………………………………………………………………………………………….35

Installation and adjustment……………………………………………………………………………………………………….37

DIN and SAE flange units ………………………………………………………………………………………………………37

Cartridge units…………………………………………………………………………………………………………………………38

Shaft seal replacement………………………………………………………………………………………………………………..39

SAE and DIN flanged motors…………………………………………………………………………………………………39

Cartridge flanged motors………………………………………………………………………………………………………41

Loop flushing shuttle valve………………………………………………………………………………………………………..42

Charge relief valve………………………………………………………………………………………………………………………..44

Overview…………………………………………………………………………………………………………………………………..44

Poppet style (older production)……………………………………………………………………………………………44

Orificed style…………………………………………………………………………………………………………………………….45

Defeat plug………………………………………………………………………………………………………………………………46

Maximum angle stop – Series 51 motors………………………………………………………………………………….47

Maximum angle stop – Series 51-1 motors………………………………………………………………………………48

Minimum angle adjustment screw……………………………………………………………………………………………50

4-Way valve and threshold springs……………………………………………………………………………………………52

Threshold adjustment screw and springs disassembly…………………………………………………….54

Housing plugs and speed sensors…………………………………………………………………………………………….60

Flange and shaft seal…………………………………………………………………………………………………………………..61

Endcap…………………………………………………………………………………………………………………………………………..62

Series 51 ramp and threshold…………………………………………………………………………………………………….64

Series 51-1 Endcap……………………………………………………………………………………………………………………….66