$34

Still EK-X 2101 EK-X10 2101 Forklift Workshop Manual 8054427 – PDF DOWNLOAD

Still EK-X 2101 EK-X10 2101 Forklift Workshop Manual 8054427 – PDF DOWNLOAD

FILE DETAILS:

Still EK-X 2101 EK-X10 2101 Forklift Workshop Manual 8054427 – PDF DOWNLOAD

Language : English

Pages : 368

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Still EK-X 2101 EK-X10 2101 Forklift Workshop Manual 8054427 – PDF DOWNLOAD

00 Product information

Safety 00-1

Safety instructions 00-1

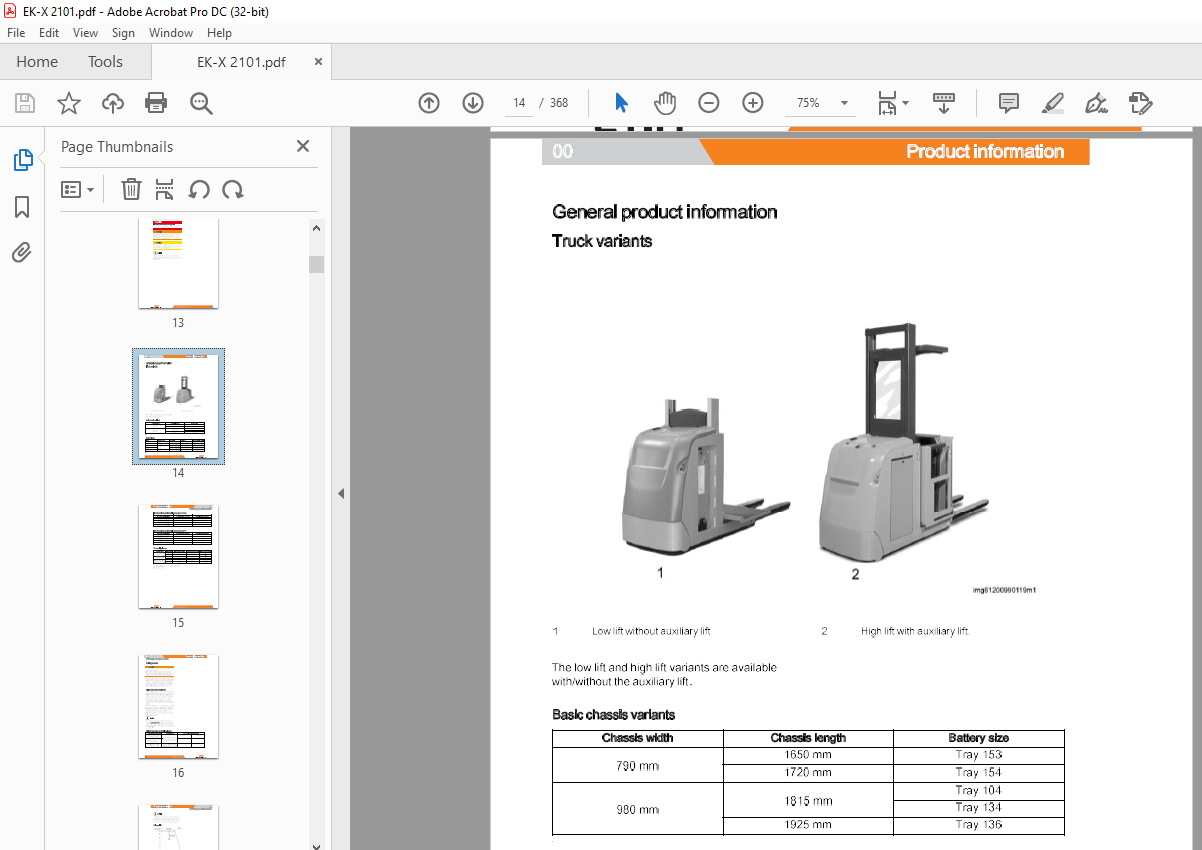

General product information 00-2

Truck variants 00-2

Driving speeds 00-4

02 Diagnostics

Software 02-1

Para Dig 02-1

General 02-1

Win Flash – General 02-7

Description 02-7

Preparation for downloading to CAN control system 02-9

Win Flash – Working with WinFlash software 02-10

General 02-10

Selecting a file 02-11

Selecting a truck 02-12

Selecting a control system 02-13

Checking the connection to the CAN control system 02-14

Start programming to CAN control systems 02-15

Close the program 02-16

Fault lists 02-11

General 02-17

Error listfor the traction controller and pump controller (FPS) A 10 02-20

Error listforoperating panel controller (BPS) 8U62, drive side (DWS) 02-41

Error listforoperating panel controller (BPS) 8U62, load side (LS) 02-43

Display error list 02-46

Error List Input/Output Extension Module (IOX) 02-48

Steering controller error list 02-54

Error listfor steering unit (ES30-24) 3M 1 02-60

Inductive guidance (IZF) error list 02-77

Error listforoperating panel controller (BPS) 8U62, drive side (DWS) 02-114

Error listforoperating panel controller (BPS) 8U62, load side (LS) 02-116

Error list IOZ1 02-119

Error list IOZ2 02-122

Teach-In 02-124

Distance sensor main lift 02-124

–·· 8 054 427 -03/2018 EN- Ill

Table of contents

11 Electric motor

Traction motor 11-1

General

Testing

11-1

11-2

Repair 11-3

Speed sensor 11-6

General

Testing

11-6

11-7

Repair 11-8

Temperature sensor 11-9

General

Testing

11-9

11-10

Repair 11-1 0

22 Mechanical drive axle

Front bevel gears 22-1

General 22-1

Test 22-2

Repair 22-3

Maintenance 22-7

34 Driver’s compartment

Driver’s cab 34-1

Tilting order picking barrier 34-1

General (for industrial trucks from 0 1/2017) 34-1

Testing 34-3

Repairs 34-4

42 Steering

IV

Electric steering (ELK) 42-1

General 42-1

Steering motor 42-2

General 42-2

Repair 42-3

Steering controller 3A20 42-4

General 42-4

Repair 42-7

Set-point potentiometer 42-8

General 42-8

8 054 427 -03/2018 EN- –··

Table of contents

Test 42-10

Repair 42-11

Actual-value potentiometer 42-12

General 42-12

Test 42-13

Repair 42-14

Reference switch 42-15

General 42-15

Test 42-15

Repair 42-16

Electric steering (ES30-24) 3M1 42-17

General

Testing

42-17

42-20

Repairs 42-21

Setpoint device 42-23

General 42-23

Testing 42-24

Repairs 42-25

Actual value transmitter 42-26

General 42-26

Reference switch 42-26

General 42-26

Testing 42-27

Repairs 42-27

–·· 8 054 427 – 03/2018 EN – V

Table of contents

43 Mechanical rail guidance

Guide elements 43-1

General 43-1

Testing 43-1

Repairs 43-2

Aisle detection 43-3

General 43-3

Testing 43-3

44 Inductive guidance

Inductive guidance 44-1

General 44-1

Test 44-8

Repair 44-9

Controller (IZF) 3A21 44-11

General 44-11

Test 44-12

Repair 44-12

Peripherals 44-14

Antennas 44-14

General 44-14

Testing 44-15

Repairs 44-15

Guide wire 44-16

General 44-16

Frequency generator 44-17

General 44-17

Aisle detection 44-19

General 44-19

46 Wheels and tyres

VI

Wheels 46-1

Traction wheel 46-1

General 46-1

Repair 46-2

Load wheel 46-3

General 46-3

Repair 46-3

8 054 427 – 03/2018 EN – –··

Table of contents

49 Brake system

Brake system 49-1

Required braking capabilities for group C industrial trucks 49-1

Electric service brake 49-3

General 49-3

Testing 49-4

Parking brake 49-6

General 49-6

Test 49-7

Repair 49-10

Maintenance 49-14

50 Controls

Operating panel 50-1

General 50-1

Display (DIS) 8A12 50-2

Standard Display 50-2

General 50-2

Repair 50-3

LCD 50-5

General 50-5

60 Electrics/electronics

Wiring – Standard design 60-1

Repair 60-1

Sensors 60-2

Distance sensor main lift 60-2

General 60-2

Repair 60-4

Overflead guard switch 60-5

General 60-5

Testing 60-5

Repair 60-7

Other Components 60-1 o

Control board 60-10

General 60-10

Plug support cabine 60-11

General 60-11

–·· 8 054 427 -03/2018 EN- VII

Table of contents

Plug support chassis 60-27

General 60-27

64 Electronic controllers

Drive/pump controller 64-1

General 64-1

Other electronic controllers 64-5

CAN-Bus 64-5

General 64-5

Test 64-6

Input/output controller (IOZ) 8U65 64-8

General 64-8

Operating panel controller(BPS) 8U62 upto 12/2016 64-11

General 64-11

Operating panel controller(BPS) 8U62from 01/2017 64-15

General 64-15

69 Batteries and accessories

Traction batteries and accessories 69-1

Replacing the battery 69-1

Maintenance 69-4

70 Hydraulics, general

Basic hydraulics 70-1

Oil tank 70-1

General 70-1

Repair 70-2

Maintenance 70-3

Breatherfilter 70-3

General 70-3

Maintenance 70-4

71 Working hydraulics

VIII

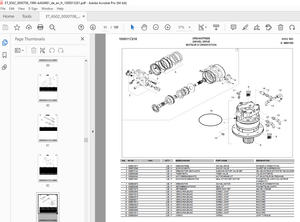

Pump unit 71-1

General 71-1

Repair 71-2

Pump motor 71-4

General 71-4

Temperature sensor 71-5

Testing 71-5

8 054 427 -03/2018 EN- –··

Table of contents

Carbon brushes 71-5

Repairs 71-5

76 Valves

Pressure relief valve 76-1

General 76-1

Control valves 76-2

General 76-2

Proportional valve 76-3

General 76-3

Testing 76-3

Repair 76-3

Valve coil 76-5

General 76-5

Testing 76-5

Repair 76-6

80 Load support device

Mast bracing 80-1

Repair 80-1

Lift mast bearing 80-2

Telescopic lift mast 80-2

Repair 80-2

81 Lift mast

Load chains 81-1

Test steps for load chains 81-1

Lift cylinder 81-6

Bleeding 81-6

Repair 81-7

Line break safety valve 81-8

General 81-8

Line break safety valve, type 1 81-9

Single mast 81-10

General 81-10

Repair 81-11

Telescopic lift mast 81-12

Repair 81-12

–·· 8 054 427 – 03/2018 EN – IX

Table of contents

Carriage support rollers 81-13

General 81-13

Testing 81-13

Repairing 81-14

90 Special equipment, accessories

Optional equipment 90-1

Access control 90-1

General 90-1

Audible and visual emergency signal 90-3

Emergency signal option 90-3

91 Special equipment, very narrow aisle trucks

End of aisle slow down and stop (ZAG) 91-1

General 91-1

ZAG universal module 91-2

Determining the braking distance 91-5

ZAG, inductive 91-7

General 91-7

Testing inductive ZAG 91-8

Inductive ZAG error list 91-9

Fitting the steel plates 91-11

Inductive proximity switches 91-12

ZAG, magnetic (bistable) 91-13

General 91-13

Testing ZAG magnetic 91-14

ZAG magnetic error list 91-15

Switching magnets 91-17

Fitting switch magnets 91-20

Bistable solenoids 91-21

92 Special equipment

Support material 92-1

Dynometer 92-1

IMAGES PREVIEW OF THE MANUAL: