$34

STILL Electric Forklift Truck Rx50-10 RX50-13 RX50-15 RX50-16 Workshop Manual – PDF DOWNLOAD

STILL Electric Forklift Truck Rx50-10 RX50-13 RX50-15 RX50-16 Workshop Manual – PDF DOWNLOAD

FILE DETAILS:

STILL Electric Forklift Truck Rx50-10 RX50-13 RX50-15 RX50-16 Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 274

Downloadable : Yes

File Type : PDF

DESCRIPTION:

STILL Electric Forklift Truck Rx50-10 RX50-13 RX50-15 RX50-16 Workshop Manual – PDF DOWNLOAD

Safety Instructions

Safety Instructions

Electrical system

Work on the Inverters

- Due to the Internal energy accumulator In the Inverters and control units, In the event of a fault there can be dangerously high voltages at the electrical connections, even after the battery plug has been disconnected

- Do not touch energised contact points such as the positive and negative connections of the power control unit! Before working on electrical power connections, always check the voltage between all contacts and between the contact and the truck chassis using a suitable measuring device (capable of measuring up to 1000V DC). Discharge the intermediate circuit.

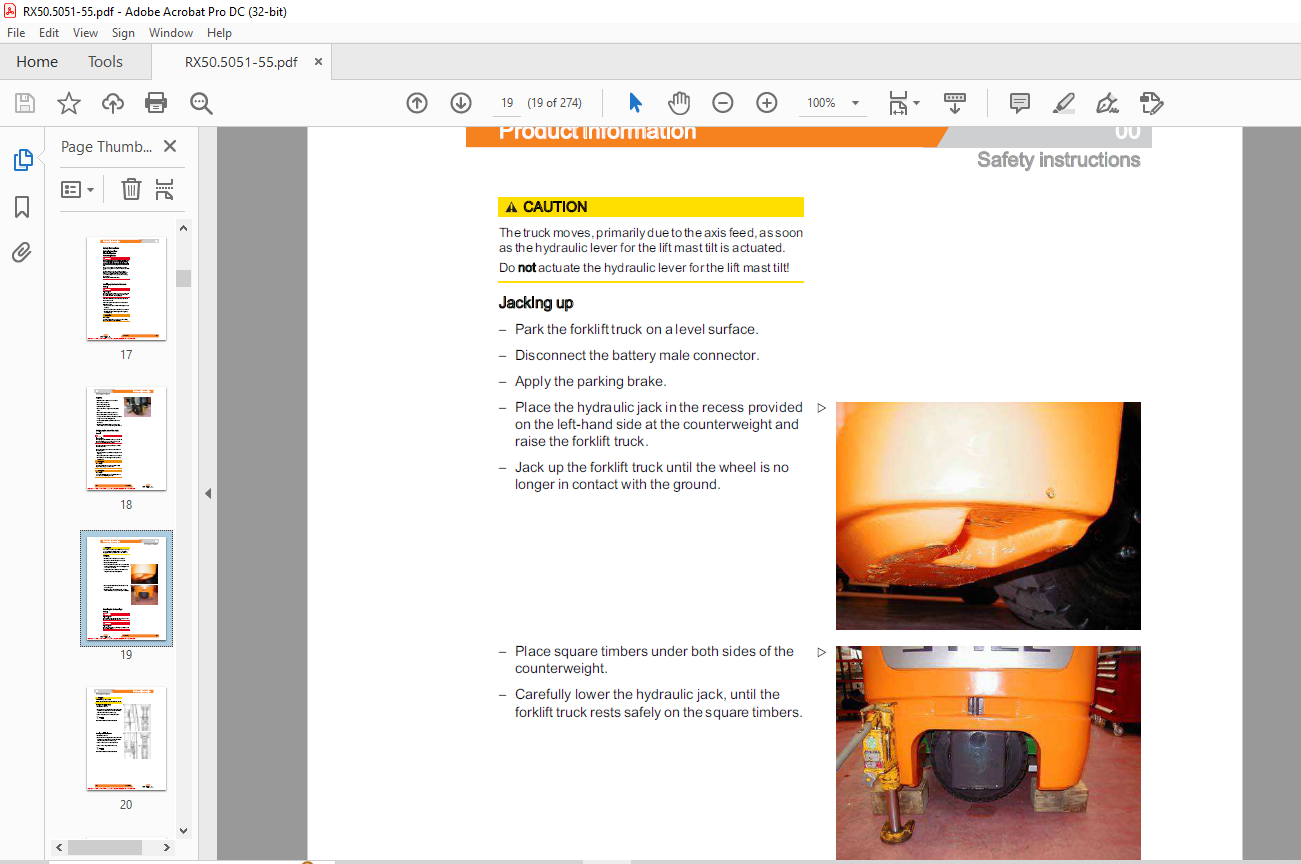

Jacking up the front of the truck

GeneralRisk of acddent When jacking up the forklift truck, always secure it with the appropriate means (chocks, wooden blocks) to prevent the truck from slipping or tipping.The forklift truck has to be jacked up for various maintenance tasks. The following must be taken into consideration when doing this:

- • Only use hydraulic jacks with an adequate load capacity Only jack up the forklift truck on a level surface

- • Secure the forklift truck against rolling away and dropping.

IMAGES PREVIEW OF THE MANUAL:

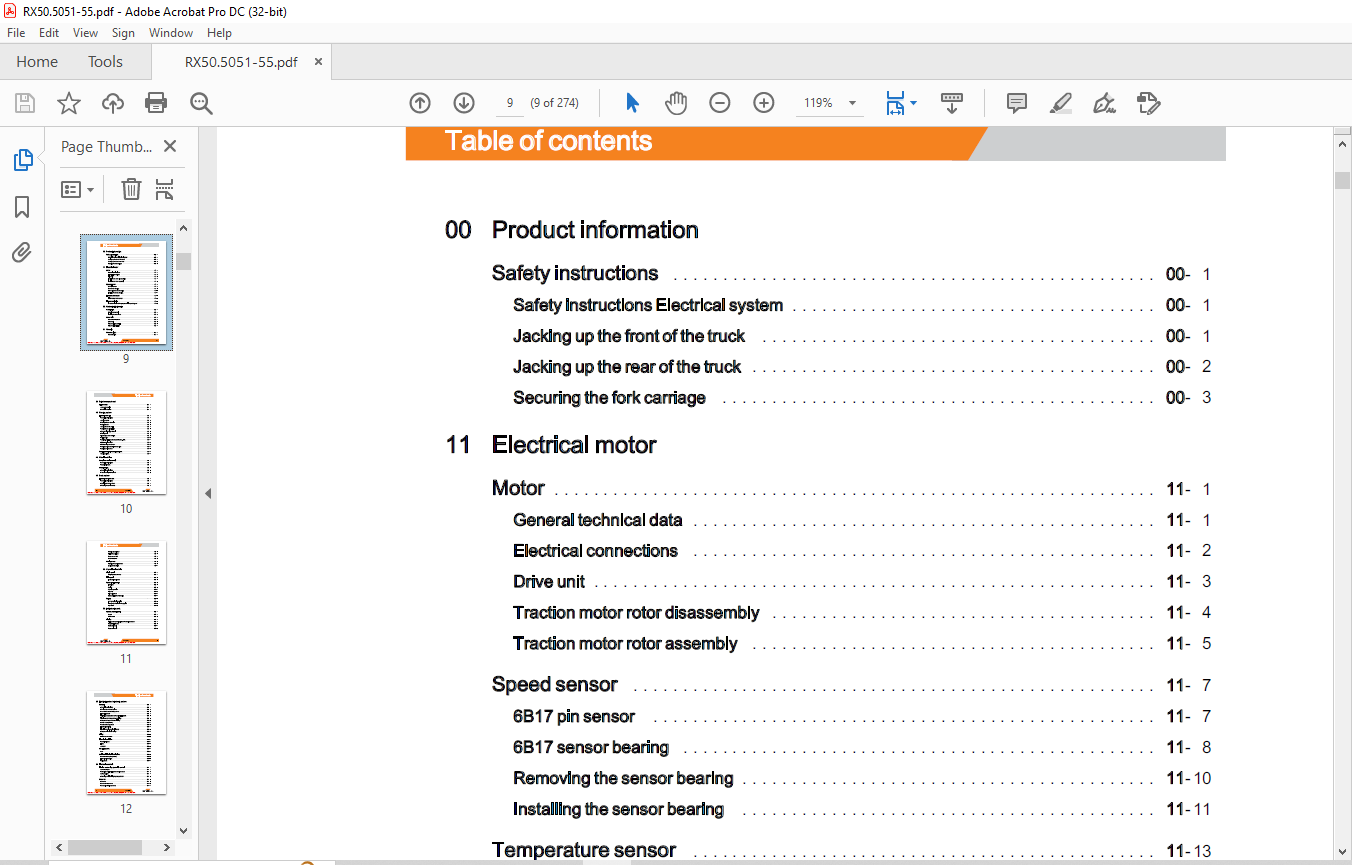

TABLE OF CONTENTS:

STILL Electric Forklift Truck Rx50-10 RX50-13 RX50-15 RX50-16 Workshop Manual – PDF DOWNLOAD

00 Product Information

Safety Instructions

Safety Instructions ectrical system

Jacking up the front of the truck

Jacking up the rear of the truck

Securing the fork carriage

11 Electrical motor

Motor

General technical data

ectrical connections

Drive un

Traction motor rotor disassembly

Traction motor rotor assembly

Speed sensor

6817 pin sensor

6817 sensor bearing

Removing the sensor bearing

Installing the sensor bearing

Temperature sensor

KTY84 temperature sensor

Forced ventilation

Forced venton at the pump motor Heavydust guard

22 Mechanical drive axle

Wheel drive

Wheel hub removal

Insta■ng the wheel hub

Power un

General technical data

power un

Power unit disassembly

Power unit Installation

31 Chassis

Counterweight

Counterweight

34 Driver’s compartment

Driver’s seat

seat contact swtich

Seatbelt lock switch

42 Steering system

Hydraulic steering

General technical data

stooring system

Steering-error detection

Steering motor

steering motor removal

Steering motor Instalation

Sprocket with trigger whool

Stooring unit

diaphragm pressure switch

Priority valve

Steering-angle-dependent performance-CSC

CSC-functional test

3828 steering zero sensor

Stearing angle sensor with sensor disc

Stooring angle sensor

Steering wheel with steering column

steering column

46 Wheels and tires

Complete wheel assembly

General technical data

Superelastic tyres

Wheel bearing

General technical data

Whool bearing-whool hub

49 Brake system

Hydraulic service brake

General technical data

Replacing the brake shoes

Checking the service brake

Wheel brake cylinder Main brake cylinder Brake sensor 182 Brakefuld switch

Parking brake

Adjusting the parking brake

parking brake swich

50 Operational controls

Single pedal

Single-pedal accelerator

Twth-pedal

Two-pedal accelerator

Operational controls

Hand lover

joystick

Joystick operation

Fingerp

Axle assignment

Depressuring the hydrau

Switch

emergency stor switch

Emergency off switch in the joystick

Key switch

56 Indicator elements

operator control panel

keypad

mini console

Display

Display and operating element-control processor

Programming mode

Password level 1

60 Bectrical system/electronic system

General

General technical data

Device code and read options

Overview of electrical components

Bectrical system

Switching on procedure for the electrical system

Traction motor temperature monitoring

Pump motor temperature monitoring

Software compat by

Parameter management

Intermediate drcult

Insulation testing for electric trucks

Component Insulation testing

Wiring

CAN bus connections

Bectrical Instalation

Control un (vo)

Fuses

contactor

Warning system

hom

Additional electrical installations

Rear distributor plate (add-on) Front distributor plate

Relay board

64 Bectronic controls

Traction and working hydraules control

control computer

Removing and Installing the control processor pump regulator60 Bectrical system/electronic system

General

General technical data

Device code and read options

Overview of electrical components

Bectrical system

Switching on procedure for the electrical system

Traction motor temperature monitoring

Pump motor temperature monitoring

Software compaty

Parameter management

Intermediate circult

Insulation testing for electric trucks

Component Insulation testing

Wing

CAN bus connections

Bectrical Installation

Control un (vo)

Fuses

contactor

Warning system

hom

Additional electrical Installations Rear distributor plate (add-on)

Front distributor plate

Relay board

64 Bectronic controls

Traction and working hydraulics control

control computer

Removing and Installing the controll processor pump regulator

Removing and Insta■ng the pump actuator

Converter

Converter

Generation 3 converter

Generation 5 drive converter

Removing and Insta■ng the pump actuator

Converter

Converter

Generation 3 converter

Generation 5 drive converter

Removing and Insta■ng the converter

Hydraulic controller

Hydraccontrou

69 Batteries and accessories

Traction battery

battery

Battery connector

battery discharge Indicator

roller platform

70 Hydraulics

General

General technical dete

Operating speeds for g

Operating speeds

Operating speeds for lowering

Forward safety test

Lowering safety test

Safety checks of hose assembly

Base hydraulics

HydraulInstalation

hydral bank

Hydraco

Intake filter

breather for

High-pressure for

Conical nipple fittings (CNP)

Boled joint

71 Working hydraulics

Pump assembly

General technical data

Pumpun

electrical connections

Pump motor-speed sensor

Temperature sensor pump motor motor brush monitor

brushes

Pump motor removal

Pump motor nation

hydre pump

Hydraulic pump Removal and Instalation

Tcy nder

Mast

Ttcy¶nder Removal and Installation

Changing the set of seals

Connection screw joints

Additional hydrau.cs

Attachments

Clamp locking mechanism for handlevers Hose ne on mast

76 Valves

Hand lever

General technical data

Hand lever valve block

Removing and Installing the valve block

Directional control valve-arrangement

Directional control valve-function

Hydraulic sensor

pressure regulator

Servo hydraulics

General technical data

Servo hydraus valve block

Manual lowering

Directional control valve block

81 Mast

Mast

General technical data

Telescopic mast

Nhom mast

triplex mast

Mast removal

MastInstalation

Chains

Load chains Checking, cleaning

Adjusting the load chains Telescopic mast

Adjusting the load chains NHot mast

Outer load chain Titple mast

Middle load chain Temast

End position damping

End pollon damping of outer cylinder

Middle cylinder end dampener

Hose safety valve

Hose safety valve of triplex mast

Shock valve Instalation posons

Lift cylinder

Utjack

Centre cylinder

Outer cynder

Rollers/supporting rollers

Removing and Instang the support roars

84 Load carrier

Fork carriage

Fork carriage

Roer

Annex

X Circuit diagrams

Hydraulics

Hand lover

Servo hydraulics