$30

Still Electric Pallet Truck EXU-5 22 EXU-5 24 Workshop Manual 50158070901 – PDF DOWNLOAD

Still Electric Pallet Truck EXU-5 22 EXU-5 24 Workshop Manual 50158070901 – PDF DOWNLOAD

IMAGES PREVIEW OF THE MANUAL:

FILE DETAILS:

Still Electric Pallet Truck EXU-5 22 EXU-5 24 Workshop Manual 50158070901 – PDF DOWNLOAD

Language : English

Pages :172

Downloadable : Yes

File Type : PDF

Size: 9.83 MB

DESCRIPTION:

Still Electric Pallet Truck EXU-5 22 EXU-5 24 Workshop Manual 50158070901 – PDF DOWNLOAD

Introduction

- Structure The manual is structured according to the same rules as the parts catalogue, ie itis divided into groups and subgroups. To simplify the marking of the treated assemblies, the number of the relevant assembly is located at the top right corner of each page.

- There are tables with technical data for mainte- nance, which must be observed. This manual contains a detailed description of the design characteristics as well as the func- tional description of individual components and assemblies. Notes and instructions and explanatory illustra- tions are inserted in the description of the tasks in this manual.

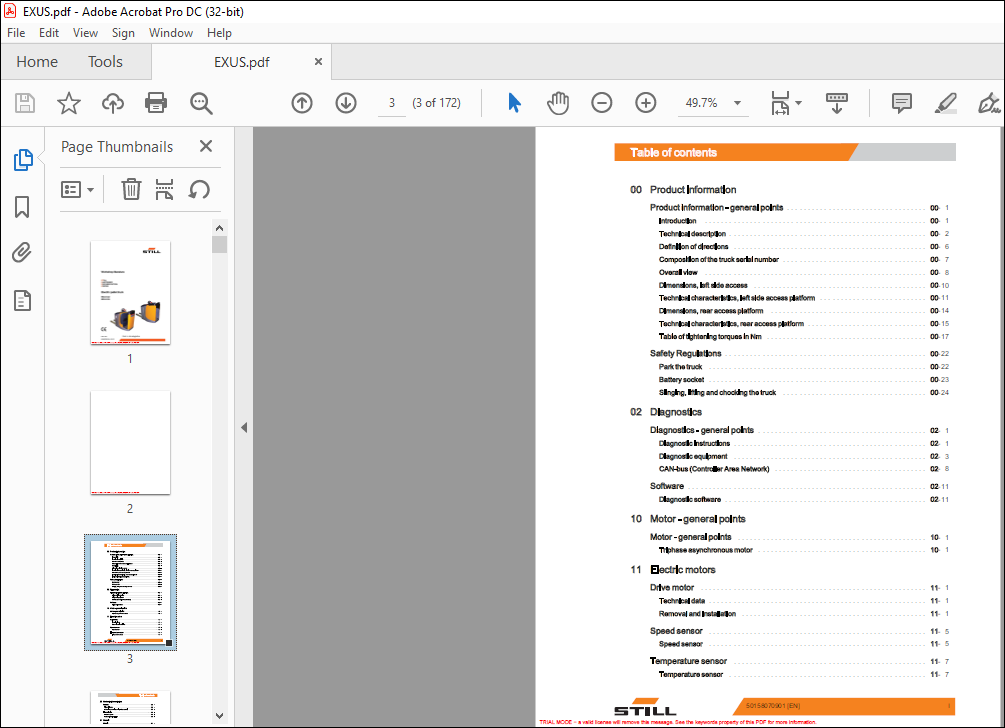

TABLE OF CONTENTS:

Still Electric Pallet Truck EXU-5 22 EXU-5 24 Workshop Manual 50158070901 – PDF DOWNLOAD

Product information – generalpoints 00- 1

Introduction LL 00- 1

Technical description 00- 2

Definition of directions 00- 6

Composition of the truck serial number 00- 7

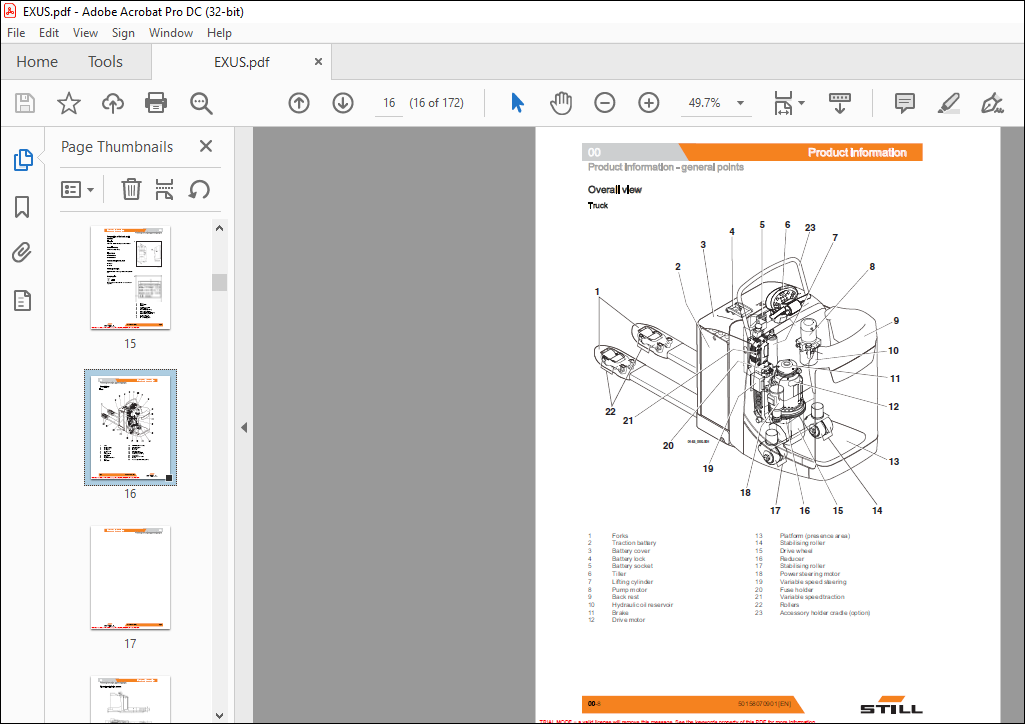

Overall view 00- 8

Dimensions, leftsideaccess 00-10

Technical characteristics, left side access platform 00-11

Dimensions, rearaccessplatform 00-14

Technical characteristics, rearaccess platform 00-15

Table of tightening torquesinNm 00-17Safety Regulations 00-22

Parkthetruck 00-22

Batterysocket 00-23

Slinging, lifting and chockingthetruck 00-2402 DiagnosticsDiagnostics -generalpoints 02- 1

Diagnosticinstructions 02- 1

Diagnosticequipment 02- 3

CAN-bus (Controller AreaNetwork) 02- 8Software 02-11

Diagnosticsoftware 02-1110 Motor – general pointsMotor-generalpoints 10- 1

Triphase asynchronous motor 10- 111 Electric motorsDrivemotor 11-1

Technicaldata 11-1

Removal andinstallation 11-1Speed Sensor 11-5

Speed SENSOr LL 11- 5Temperature SeNSOr 1-7

Temperature SeNSOT «Lo 11- 7AySTILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contents22 Mechanical transmissionReducer 22-1

Technicaldata 22-1

Reduction gear – Dismantling-Reassembly 22- 2Transmission 22-5

Traction system 22- 5

Removalandinstallation 22- 631 ChassisChassis 31-1

General points 31-1

COVES oo 31- 3

Motor Covers 31- 4

Battery cover 31- 5

Load backrest 31- 5

Instrumentpanel 31- 642 Steering systemElectrical steering 42-1

Technicaldata 42- 1

Driving behaviour depending on the steeringlockangle 42- 1

Blockdiagram 42- 2

Powersteeringmotor 42- 3

Desired value potentiometer 42- 5

Recopy potentiometer 42- 7

Description of the recopy potentiometer 42- 8

Dismantling and reassembling – recopy potentiometer 42- 8

Potentiometer pinionbearing 42-1046 Wheels and tyresWheels 46- 1

Traction Wheel 46- 1Rollers 46- 2

Stabiliserrollers 46- 2

Loadwheels 46- 5

Load wheels – Dismantlingandreassembly 46- 749 Braking systemElectrical braking system LL 49- 1

Technicaldata 49- 1

Operation 49- 2

Electricalsystem 49- 3

Removal andinstallation 49- 450 Control unitsControlconsole 50- 1

Cockpit 50- 1

Enteringtheusercode LLL 50- 2

Digicode control 50- 4

Addingthemastercode 50- 5

Deletingthemastercode 50- 6

Addingthedriver’scode 50- 8

Deletingadriverscode LL 50- 9

Electricalconnections 50-11

Check 50-11

Removal andinstallation 50-1260 Electrics / ElectronicsElectrics / electronics -general points 60- 1

Wiringdiagram 60- 1

Descriptionofcomponents 60- 2

Technicaldata 60- 4

Locationofunits 60- 5Electricalequipment 60- 6

Emergencyisolatorbutton 60- 6

FUSES 60- 7

Contactor K1 60- 7Batteryand accessories 60- 9

BatteryPzS(open-lead) 60- 9

Changingthebattery 60-10

Changing the batteryusingahoist 60-12

Battery change with aroller batteryholder 60-13

Closing the battery compartment 60-14

Dismantling – Reassembling the batteryplug 60-15Presencepedal

Presence pedal-generalpoints

Dismantling and Reassembly – Presencepedal

Heightsensor

64 Electronic controls

Varable speed traction

Generalpoints

Electricalconnections

Dismantling-Reassembly

Fans

Variable speedsteering

General

Electricalconnections

Dismantling-Reassembly

70 Hydraulics

GeneralHydraulics

Hydraulicdiagram

71 Working hydraulics

Pump

Dismantling – Reassembly ofthetank

Intakefilter

Motorand drivingplatepin

Brushes LL

Rollerbearings

76 Valves – Check valves

Distributor

Pumpunit

Lifting system -generalpoints 80- 1

Technicaldata 80- 1

Basicliftingdevice 80- 2

Litingeylinder 80- 2

84 Load holder

Forkholder 84- 1

Traction rods 84- 1

Dismantling and Reassembly – Tractionrods 84- 1

Separation of fork chassis/motor 84- 4

Lateralliftingguides 84- 5