$33

Still FXD20N Double pallet stacker with driver seated Workshop Manual 11648012111 – PDF DOWNLOAD

Still FXD20N Double pallet stacker with driver seated Workshop Manual 11648012111 – PDF DOWNLOAD

FILE DETAILS:

Still FXD20N Double pallet stacker with driver seated Workshop Manual 11648012111 – PDF DOWNLOAD

Language : English

Pages : 208

Downloadable : Yes

File Type : PDF

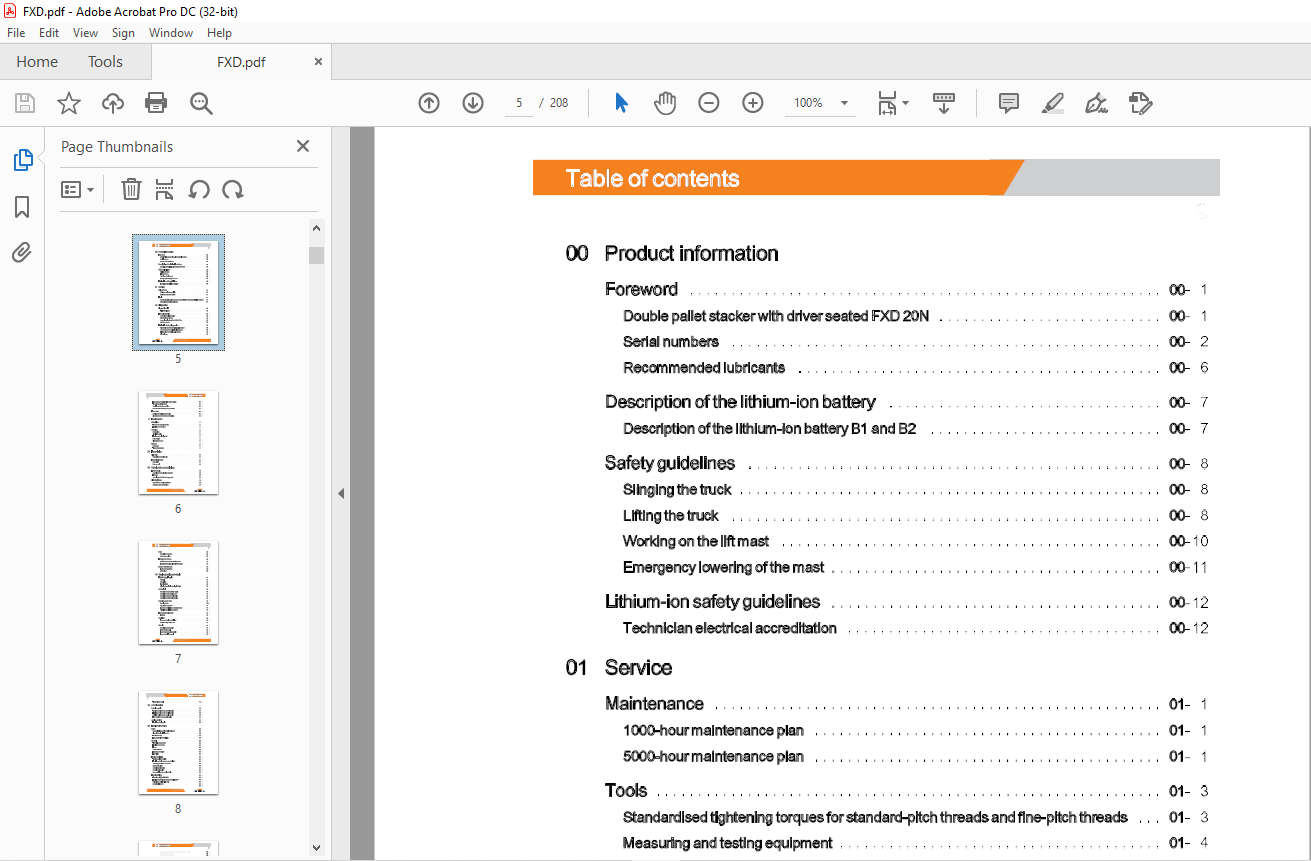

TABLE OF CONTENTS:

Still FXD20N Double pallet stacker with driver seated Workshop Manual 11648012111 – PDF DOWNLOAD

00 Product information

Double pallet stacker with driver seated FXD 20N

Serial numbers

Recommended lubricants

Description of the lithium ion battery

Description of the lithium ion battery B1 and B2

Safety guidelines

Slinging the truck

Lifting the truck

Working on the lift mast

Emergency lowering of the mast

Lithium ion safety guidelines

Technician electrical accreditation

01 Service

Maintenance

1000 hour maintenance plan

5000 hour maintenance plan

Tools 01 3

Standardised tightening torques for standard pitch threads and fine pitch threads 01 3

Measuring and testing equipment 01 4

02 Diagnostics

Diagnostic tool

ST EDS Navigator

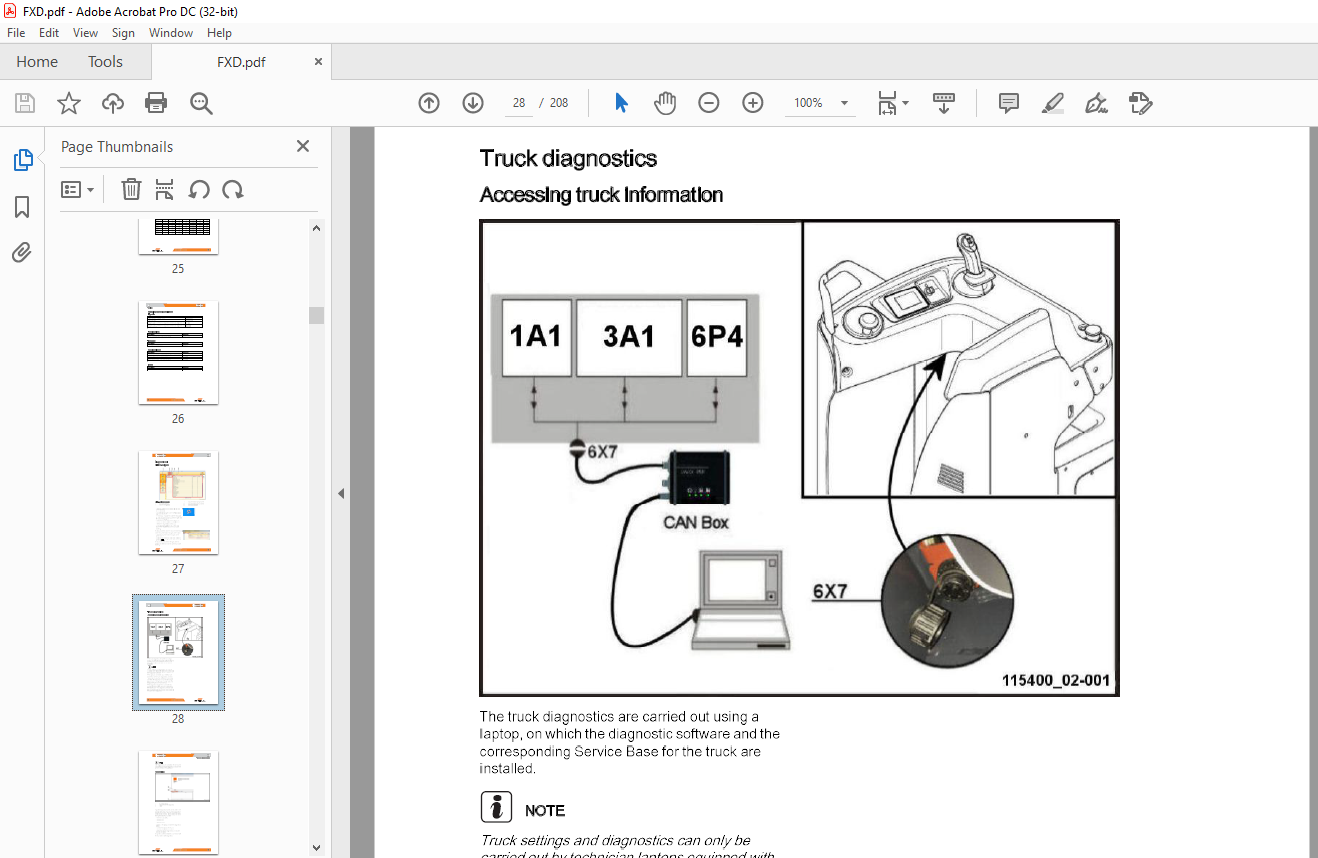

Truck diagnostics

Accessingtruckinformation

Diagnostics service box

Connecting a laptop to the USB CAN Box

CAN bus network

Lithium ion battery diagnostics

Diagnostic connector of the lithium ion battery

CAN bus network of the lithium ion battery

Indicator lightforthe lithium ion battery

Block diagram

Error codes for the lithium ion battery B1 B2 02 11

Troubleshooting flow chart 02 14

Analysing the battery condition 02 25

Questionnaire to identify battery condition 02 27

Error codes 02 28

Reading and deleting the error list 02 28

Pictograms of error codes on the display 02 30

11 Traction motor

Description 11

Features of the traction motor 11

Location of components 11 3

Checking 11 4

Preparation 11 4

Visual inspection 11 4

Traction motor winding test 11 4

Rotor testing 11 4

Cleaning the motor 11 5

Sensors 11 6

Rev sensor 11 6

Temperature sensor 11 7

23 Transmission

Drive unit 23

Description of the drive unit 23

Transmission gear 23 2

Description 23 2

Reducer unit 23 4

30 Chassis, bodywork and fittings

IV

Fixed chassis 30

Accessing the technical compartment 30

Features 30 2

Accessing the dashboard components 30 3

Driver’s platform 30 4

Description of the adjustable floor 30 4

Operator presence detection 30 5

11648012111 EN 09/2017 STILL

Table of contents

Seat 30 6

Description of the seat 30 6

Seat heater (option) 30 8

Linkage of the truck 30 9

Load lift system with level compensator 30 9

Load lift system without level compensator 30 11

Battery compartment 30 12

Types of compartment 30 12

Battery lock 30 13

42 Steering, braking and wheels

ES30 24 steering unit 42

General 42

Description 42 2

Technical data 42 3

Adjusting the electric steering ES30 24 42 4

Control unit 42 6

Description of the steering wheel 42 6

Description of the steering knob 42 7

Description of the control module 42 8

Descriptionofthejoystick(option) 42 10

Setpoint sensor 3B2 42 11

Steering centre 42 11

Description of the pivot 42 12

Features of the Hall effect setpoint sensor 42 13

Principle of the Hall effect sensor 42 14

Electromagnetic brake 42 15

Features 42 15

Stabiliser 42 16

Features of the fixed stabiliser 42 16

Stabiliser height adjustment 42 17

Wheels 42 19

Description of the wheels 42 19

Types of drive wheel 42 20

Types of wear on drive wheels 42 21

Typesofstabiliserwheels 42 22

STILL 11648012111 EN 09/2017 V

Table of contents

Typesofloadwheel 42 23

50 Control devices

Control module 50

Traction function on the control module 50

lnitial lift function on the control module 50 2

Main lift function on the control module 50 3

Horn function on the control module 50 4

Joystick (option) 50 5

Functions of the joystick 50 5

60 Electrics/electronics

VI

Safety 60

Safety guidelines for electrical equipment 60

Cleaning the electrical system 60 2

Insulation testing 60 4

Electromagnetic compatibility 60 5

General 60 6

Technical compartment 60 6

Location of connectors 60 7

Fuses 60 8

Contact switches 60 10

Emergency off switch 60 10

Horn(4H1) 60 11

Traction and lifting 60 12

Traction and lift controller 60 12

Functions of the inputs/outputs of the LAC 60 13

Activating controllers 1 A 1 and 3A 1 60 15

Speed reductions 60 17

Central negative point 60 18

Central positive point 60 20

Parameterising the control module 60 21

Electric steering 60 22

Electric steering unit ES30 24 60 22

Functions of the “inputs/outputs” of the ES30 24 60 23

Switching on the ES30 24 unit 60 24

Operational checks 60 26

Rev sensor ( 1 B2) 60 26

11648012111 EN 09/2017 STILL

Table of contents

Checking the operation of the temperature sensor (1 B6) 60 29

Electromagnetic brake (Y 1) 60 31

Operator presence detection 60 32

Fan(9M1) 60 33

Controlmodule(1B1) 60 34

Lithium ion battery B 1 and B2 60 35

Location of connectors for the lithium ion battery 60 35

Replacing the cover provided 60 36

Replacing the push button provided 60 38

Replacing the diagnostic harness 60 39

Replacingtheterminal block 60 40

Replacing the power cable 60 41

BMS 60 42

Descri ption 60 42

Replacing the BMS 60 43

Module 60 45

Lith ium ion module 60 45

Disassembling the B1 and B2 battery module 60 46

Reassembling the B1 and B2 battery module 60 49

Replacing the shunt 60 52

Power box 60 54

Overview 60 54

Replacing the contact switch 60 55

Replacing the fuse 60 57

STILL 11648012111 EN 09/2017 VII

Table of contents

Charger for lithium ion batteries (option) 60 58

Description 60 58

Installing the external charger 60 61

Hydraulic controls 60 62

Main lift operation 60 62

Display 60 66

Description of the display 60 66

Display operating unit 60 68

Operation of the display unit 60 68

Electronic key 60 73

Digicode LFM GO 60 73

FleetManager™ (option) 60 75

FleetManager description 60 75

TDU: Access control 60 76

FleetManager™ option 60 77

70 Hydraulics

Hydraulic system 70

70

70 2

Initial Lift operation flow chart

Main Lift operation flow chart

Pump motor unit 70 3

Technical features 70 3

Operating the pump motor unit 70 4

Identifying the solenoid valves 70 5

Tightening torques 70 6

Pressure sensor 70 8

Description 70 8

81 Lift mast

Main lift 81

Speed limitations (lifting/lowering) 81

Fork position detector 2B6 (0 3 m from the ground) 81 2

Forkheightmagneticdetector2B6(1 5mfromtheground) 81 3

IMAGES PREVIEW OF THE MANUAL: