$37

Still Racking Truck GX-X Forklift Workshop Manual 8054478 – PDF DOWNLOAD

Still Racking Truck GX-X Forklift Workshop Manual 8054478 – PDF DOWNLOAD

FILE DETAILS:

Still Racking Truck GX-X Forklift Workshop Manual 8054478 – PDF DOWNLOAD

Language : English

Pages : 796

Downloadable : Yes

File Type : PDF

DESCRIPTION:

Still Racking Truck GX-X Forklift Workshop Manual 8054478 – PDF DOWNLOAD

Speed optimisation:

General:

Speed optimisation is a software function in the FZS that reduces the driving speed of the truck in relation to the lift height and the load it is carrying. Apart from the actual driving speed, the acceleration and delay of the driving speed are reduced , as are those of the ancillary movements.

- This means, for example, that acceleration of the reach function takes place more gently at a height of 1 Om than in the lowered state.

- Speed optimisation comes in different versions, 3.X and 4.X, and configuration levels, 3.0, 3.1, 3.2 and 3.3. Since each truck can have its own dimensions, different reduction characteristics must be calculated for each truck.

- This is done with the help of a special software program, the “VNAPtool”. The corners (P1-P6) resulting from these calculations are important for the stability of the truck.

General product infomation:

The corners are stored in the FZS.

The following factors are the basis for the calculation mentioned above:

• Battery type

• Max. load capacity

• A-dimension of the turret head

• Max. shifting depth

• Max. lift height of main lift

• Overall height of truck

• Width of the load wheel axle

• Mechanical rail guidance or inductive guidance

There are different speed optimisation variants depending on the truck’s sensor system and the options that have been activated accordingly in the FZS. This results in different truck functions.

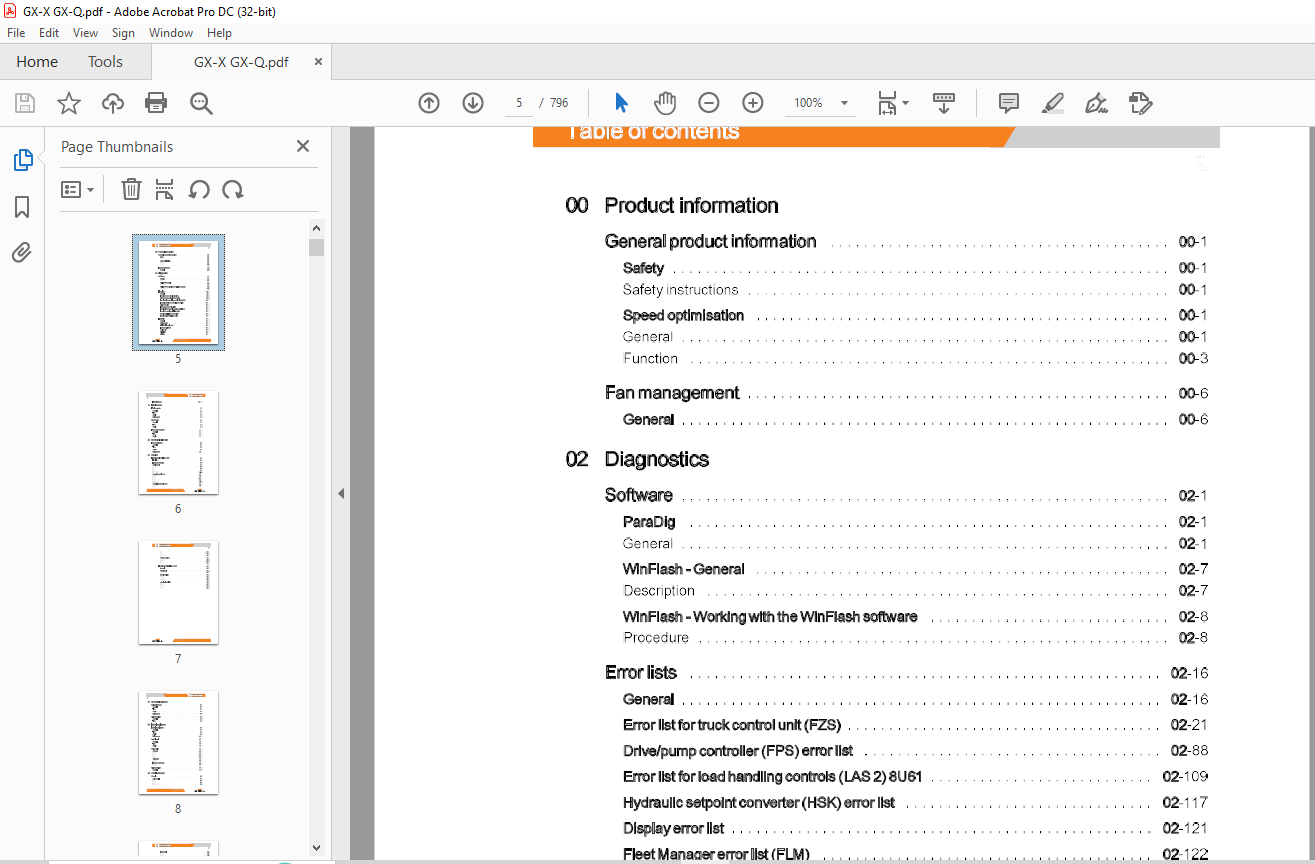

TABLE OF CONTENTS:

Still Racking Truck GX-X Forklift Workshop Manual 8054478 – PDF DOWNLOAD

00 Product information

General product information 00-1

Safety 00-1

Safety instructions 00-1

Speed optimisation 00-1

General 00-1

Function 00-3

Fan management 00-6

General 00-6

02 Diagnostics

Software 02-1

Para Dig 02-1

General 02-1

Win Flash – General 02-7

Description 02-7

Win Flash – Working with the Win Flash software 02-8

Procedure 02-8

Error lists 02-16

General 02-16

Error listfortruck control unit (FZS) 02-21

Drive/pump controller (FPS) error list 02-88

Errorlistforloadhandlingcontrols(LAS2)8U61 02-109

Hydraulic setpoint converter (HSK) error list 02-117

Display error list 02-121

FleetManagererrorlist(FLM) 02-122

Error List Input/Output Extension Module (IOX) 02-124

Errorlistforsteeringunit(ELK1)3M1 02-130

Steering unit (ELK2) 3M 1 error list 02-140

lnductiveguidance(IZF)errorlist 02-156

Teach-in 02-194

General 02-194

Service mode 02-194

Main lift, telescopic mast 02-195

Lift mast, triple mast 02-196

Auxiliary lift 02-196

Swivelling 02-197

Shifting 02-197

STILL 8 05447810/2016 EN- Ill

Table of contents

Fork adjustment 02-198

11 Electric motor

Traction motor 11-1

General 11-1

Test 11-2

Repair 11-4

Maintenance 11-6

Rev sensor 11-7

General 11-7

Test 11-8

Repair 11-9

Temperature sensor 11-10

General 11-1 0

Test 11-10

Repair 11-12

22 Mechanical drive axle

Front bevel gears 22-1

General 22-1

Test 22-2

Repair 22-4

Maintenance 22-11

42 Steering

IV

Electric steering (ELK 1) 3M 1 42-1

Function 42-1

Emergency steering 42-3

Steering unit 42-4

General 42-4

Test 42-6

Repair 42-7

Maintenance 42-10

Setpoint potentiometer 42-1 0

General 42-10

Test 42-11

Repair 42-12

Maintenance 42-14

Actual value potentiometer 42-14

General 42-14

8 05447810/2016 EN – STILL

Table of contents

Test 42-15

Repair 42-16

Maintenance 42-19

Reference switch 42-19

General 42-19

Test 42-20

Repair 42-20

Electric steering (ELK 2) 3M 1 42-22

General 42-22

Steering unit 42-22

General 42-22

Setpoint device 42-24

General 42-24

Checking 42-25

Repairs 42-26

Actual value device 42-27

General 42-27

Checking 42-28

Repairs 42-28

STILL 8 05447810/2016 EN- V

Table of contents

43 Mechanical guidance

Guide elements 43-1

General 43-1

Test 43-1

Repair 43-2

Maintenance 43-4

Aisle detection 43-5

General 43-5

Test 43-5

44 Inductive guidance

Inductive guidance 44-1

General 44-1

Test 44-6

Repair 44-7

Maintenance 44-11

Central unit 44-12

General 44-12

Test 44-13

Repair 44-13

Peripherals 44-15

Antennas 44-15

General 44-15

Test 44-15

Repair 44-16

Guide wire 44-17

General 44-17

Frequency generator 44-18

General 44-18

Aisle detection 44-20

General 44-20

46 Wheels and tyres

VI

Wheels 46-1

Drive wheel 46-1

General 46-1

Repair 46-1

Maintenance 46-3

805447810/2016 EN- STILL

Table of contents

Load wheel 46-4

General 46-4

Repair 46-5

Maintenance 46-8

49 Brake system

Brake system 49-1

Required braking capabilities for group C industrial trucks 49-1

General 49-3

Testing the brake retardation 49-4

Electric service brake 49-8

General 49-8

Hydraulic service brake 49-1 o

General 49-1 0

Test 49-13

Repair 49-14

Maintenance 49-19

Pressure sensor 49-20

General 49-20

Test 49-21

Repair 49-23

Accumulator 49-26

General 49-26

Test 49-27

Repair 49-27

Valve block 49-29

General 49-29

Repair 49-30

Parking brake 49-33

General 49-33

Test 49-35

Repair 49-38

Maintenance 49-44

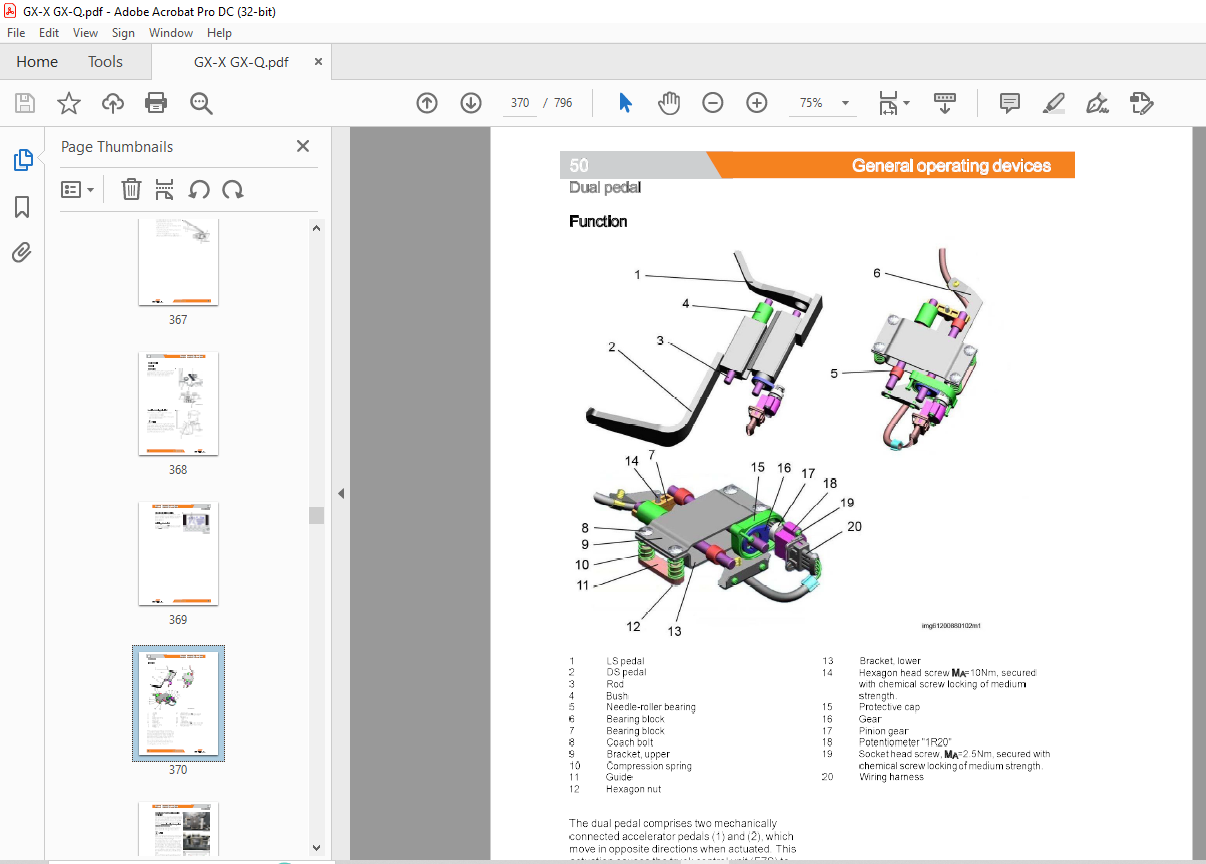

50 General operating devices

Drive and brake actuation 50-1

Accelerator pedal 50-1

General 50-1

Test 50-1

Repair 50-2

STILL 8 05447810/2016 EN- VII

Table of contents

Brake pedal 50-4

General 50-4

Test 50-5

Repair 50-6

Dual pedal 50-8

General 50-8

Function 50-1 o

Test 50-12

Repair 50-13

Maintenance 50-18

Joystick 50-19

General 50-19

Test 50-19

Repair 50-22

Maintenance 50-23

56 Display elements

Display screen 56-1

General 56-1

Test 56-4

Repair 56-5

Maintenance 56-8

60 Electrics/electronics, general

VIII

Electrical system 60-1

DC/DC converter 60-1

General 60-1

Test 60-2

Sensor system 60-5

Main lift height measurement 60-5

General 60-5

Repair 60-6

Maintenance 60-18

805447810/2016 EN- STILL

Table of contents

64 Electronic controls

Drive/pump controller (FPS) A 10 64-1

General 64-1

Test 64-4

Battery management 64-7

Repair 64-8

Maintenance 64-1 o

Converter 64-11

General 64-11

Test 64-20

Repair 64-21

Maintenance 64-22

Other electronic controls 64-23

Truck control unit (FZS) 8U60 64-23

General 64-23

Repair 64-28

Load handling controls (LHC) 8U61 64-29

General 64-29

Repair 64-31

Input/output controller (IOX) 8U65 64-32

General 64-32

Repair 64-35

Hydraulic setpointconverter(HSK)2A20 64-36

General 64-36

Test 64-39

Repair 64-41

Maintenance 64-42

CAN bus 64-42

General 64-42

Test 64-4 7

70 Hydraulics, general

Basic hydraulics 70-1

Oil tank 70-1

General 70-1

Test 70-2

Repair 70-3

Maintenance 70-5

Breather filter 70-6

General 70-6

Test 70-7

STILL 8 05447810/2016 EN- IX

Table of contents

Maintenance 70-7

71 Working hydraulics

Pump units 71-1

General 71-1

Test 71-1

Repair 71-2

Maintenance 71-5

Hydraulic pump 71-6

General 71-6

Test 71-6

Repair 71-7

Pump motor 71-11

General 71-11

Test 71-13

Repair 71-14

Maintenance 71-15

Temperature sensor 71-15

General 71-15

Test 71-15

Repair 71-17

Rev sensor 71-19

General 71-19

Test 71-21

Repair 71-22

76 Valves

X

Pressure relief valve 76-1

General 76-1

Test 76-2

Repair 76-3

Proportional valves 76-5

Main lift lowering proportional valve 76-5

General 76-5

Repair 76-6

Shift proportional valve 76-7

General 76-7

Test 76-8

Repair 76-8

Swivel proportional valve 76-1 0

General 76-10

Test 76-11

805447810/2016 EN- STILL

Table of contents

Repair 76-12

Auxiliary lift lowering proportional valve 76-14

General 76-14

Test 76-15

Repair 76-16

Valve block 76-18

Chassis valve block 76-18

General 76-18

Test 76-22

Repair 76-23

Maintenance 76-23

81 Liftmast

Load chains 81-1

Test steps for load chains 81-1

Telescopic mast 81-6

General 81-6

Test 81-9

Repair 81-12

Maintenance 81-40

Triple mast 81-44

General 81-44

Test 81-46

Repair 81-49

Maintenance 81-79

86 Attachments

Turret head 86-1

General 86-1

Shifting 86-2

General 86-2

Test 86-3

Repair 86-6

Maintenance 86-14

Shift potentiometer 86-15

General 86-15

Test 86-15

Repair 86-17

Shift position switch 86-1 9

General 86-19

STILL 8 05447810/2016 EN- XI

XII

Table of contents

Swivelling 86-20

General 86-20

Test 86-20

Repair 86-22

Maintenance 86-25

Swivel potentiometer 86-26

General 86-26

Test 86-27

Repair 86-28

Swivel position switch 86-29

General 86-29

Test 86-29

Repair 86-30

Pulling cylinder 86-31

General 86-31

Test 86-32

Repair 86-33

Maintenance 86-35

Auxiliary lift mast 86-35

General 86-35

Test 86-37

Repair 86-38

Maintenance 86-42

Auxiliary lift cylinder 86-43

General 86-43

Test 86-45

Repair 86-46

Maintenance 86-48

Auxiliary lift height measurement 86-49

General 86-49

Test 86-50

Repair 86-50

Auxiliary lift reference switch 86-54

General 86-54

Test 86-55

Repair 86-56

Valve block 86-59

General 86-59

Test 86-59

Repair 86-60

Maintenance 86-62

Hydraulicmotor 86-63

General 86-63

Checking 86-64

Repair 86-65

805447810/2016 EN- STILL

Table of contents

Maintenance 86-65

Synchronous swivel-shift movement 86-66

General 86-66

Overreach function 86-67

Overreach 86-67

Telescopic fork 86-68

General 86-68

Checking 86-73

Repair 86-75

90 Special equipment/ Accessories

Optional equipment 90-1

PIN code access control 90-1

General 90-1

“PIN code” generation and management 90-1

Special “PIN code” 90-3

Height preselection 90-4

General 90-4

Function 90-6

Teach-inofshelfheights(levels) 90-10

Load detection 90-11

General 90-11

Load sensor/weight sensor 90-13

General 90-13

Intelligent load capacity diagram 90-14

General 90-14

Fork cycle 90-16

General 90-16

91 Special equipment, very narrow aisle

End of aisle slow down and stop 91-1

ZAG braking distance 91-1

Determining the braking distance 91-1

ZAG inductive 91-3

General 91-3

Activating the “ZAG inductive” option 91-4

Inductive proximity switches 91-5

Determining the length of the steel plates 91-7

Assembly of the steel plates 91-8

Zone partitioning 91-11

Suppression of interfering metal parts 91-17

Diagnostics 91-18

STILL 8 05447810/2016 EN- XIII

Table of contents

ZAGmagnetic 91-19

General 91-19

Activating the “ZAG magnetic” option 91-20

Magnet operated switches 91-21

Magnet-operated switch 91-22

Switching magnets 91-27

Maximum braking distance 91-29

Switching magnet installation positions 91-30

Zone partitioning 91-32

Diagnostics 91-37

ZAG reflexli 91-38

General 91-38

Activating the “ZAG reflexli” option 91-39

Maximum braking distance 91-40

Reflectortypes 91-41

Arrangement of reflective light barriers 91-43

Fitting the reflectors 91-45

Mounting height of the reflectors on the rack 91-49

Zone partitioning 91-51

Important rules 91-55

Diagnostics 91-56

ZAG RFID 91-57

General 91-57

Activating the “ZAG RFI D” option 91-58

ZAG RFI D functions 91-61

Displacement transducer 91-64

RFID reader/writer(LSG) 91-67

Transponders 91-71

Diagnostics 91-76

Commissioning 91-81

92 Other accessories

XIV

Devices 92-1

Dynometer 92-1

Dynometer 92-1

Web belt 92-2

Belt 92-2

Torque table 92-3

Tightening torque in accordance with works standard 14029 92-3

Measurements drawing 92-6

Measurements drawing 92-6

IMAGES PREVIEW OF THE MANUAL: