$34

Still RX70-22 RX70-25 RX70-30 RX70-35 Diesel LPG Forklift Trucks Workshop Manual 171866 – PDF DOWNLO

Still RX70-22 RX70-25 RX70-30 RX70-35 Diesel LPG Forklift Trucks Workshop Manual 171866 – PDF DOWNLOAD

FILE DETAILS:

Still RX70-22 RX70-25 RX70-30 RX70-35 Diesel LPG Forklift Trucks Workshop Manual 171866 – PDF DOWNLOAD

Language : English

Pages : 418

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Still RX70-22 RX70-25 RX70-30 RX70-35 Diesel LPG Forklift Trucks Workshop Manual 171866 – PDF DOWNLOAD

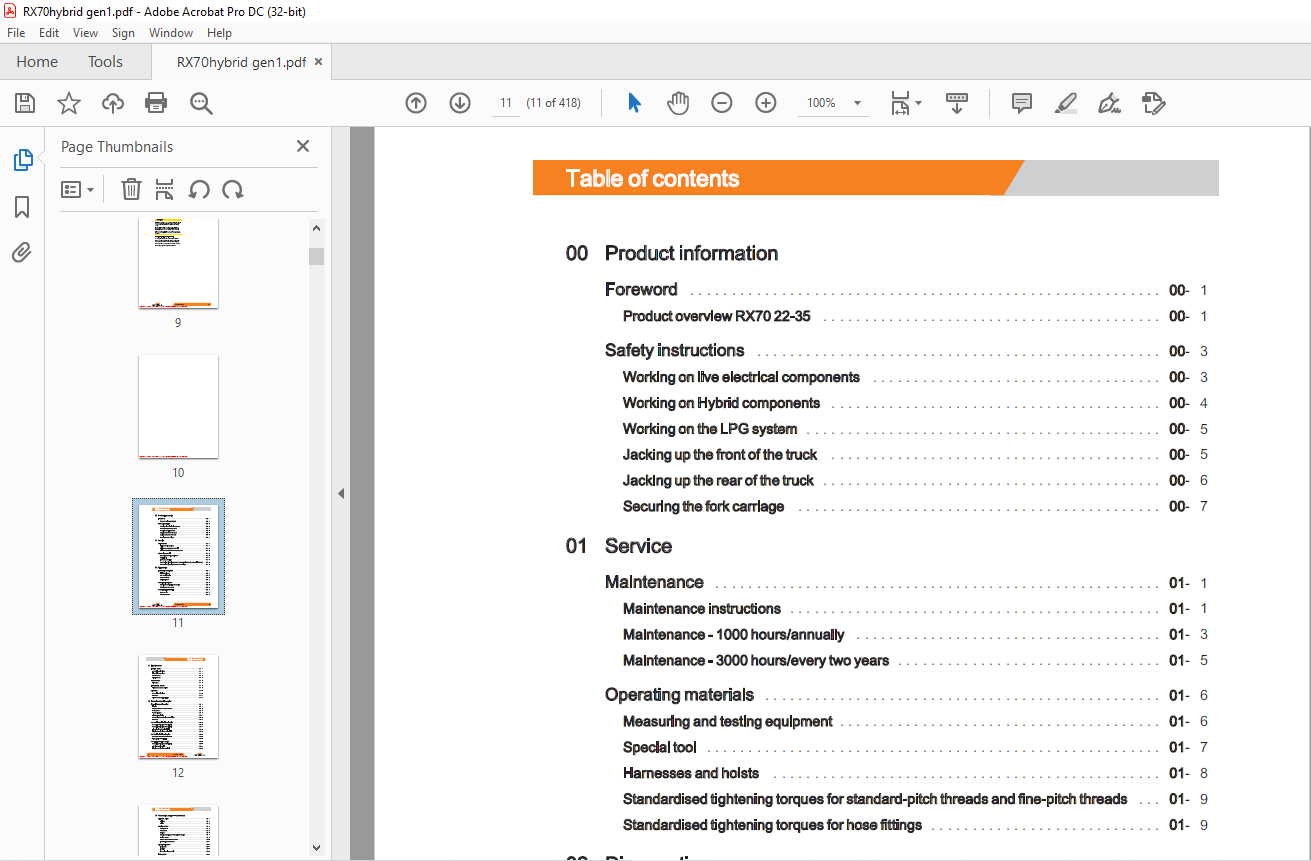

00 Product informationForeword 00- 1

Productoverview RX7022-35 00- 1

Safetyinstructions 00- 3

Working on live electricalcomponents LL 00- 3

WorkingonHybridcomponents 00- 4

Workingonthe LPGsystem 00- 5

Jackingupthe frontofthetruck iL 00- 5

Jackinguptherearofthetruck iL 00- 6

Securing theforkcarriage 00- 7

01 Service

Maintenance 01- 1

Maintenanceinstructions 01-1

Maintenance-1000 hours/annually 01- 3

Maintenance – 3000 hours/everytwoyears 01- 5

Operatingmaterials 01- 6

Measuring and testingequipment 01- 6

Specialtool 0-7

Harnessesandhoists LL 01- 8

Standardised tightening torques for standard-pitch threads and fine-pitch threads 01- 9

Standardised tightening torques for hose fittings 01- 902 DiagnosticsIntroductiontoDiaMon 02- 1

STEDS-Navigator 02- 1

CANboxdiagnostics 02- 2

Diagnosticset-up 02- 3

Starting DiaMon 02- 4WorkingwithDiaMon 02- 5

Reading outandclearingtheerrorlist 02- 5

Readingoutaccesscodes 02- 6Workingusingthe ABE 02-7

Readerrorlist 02- 7

Clearingerrorlists 02- 9oT AR

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

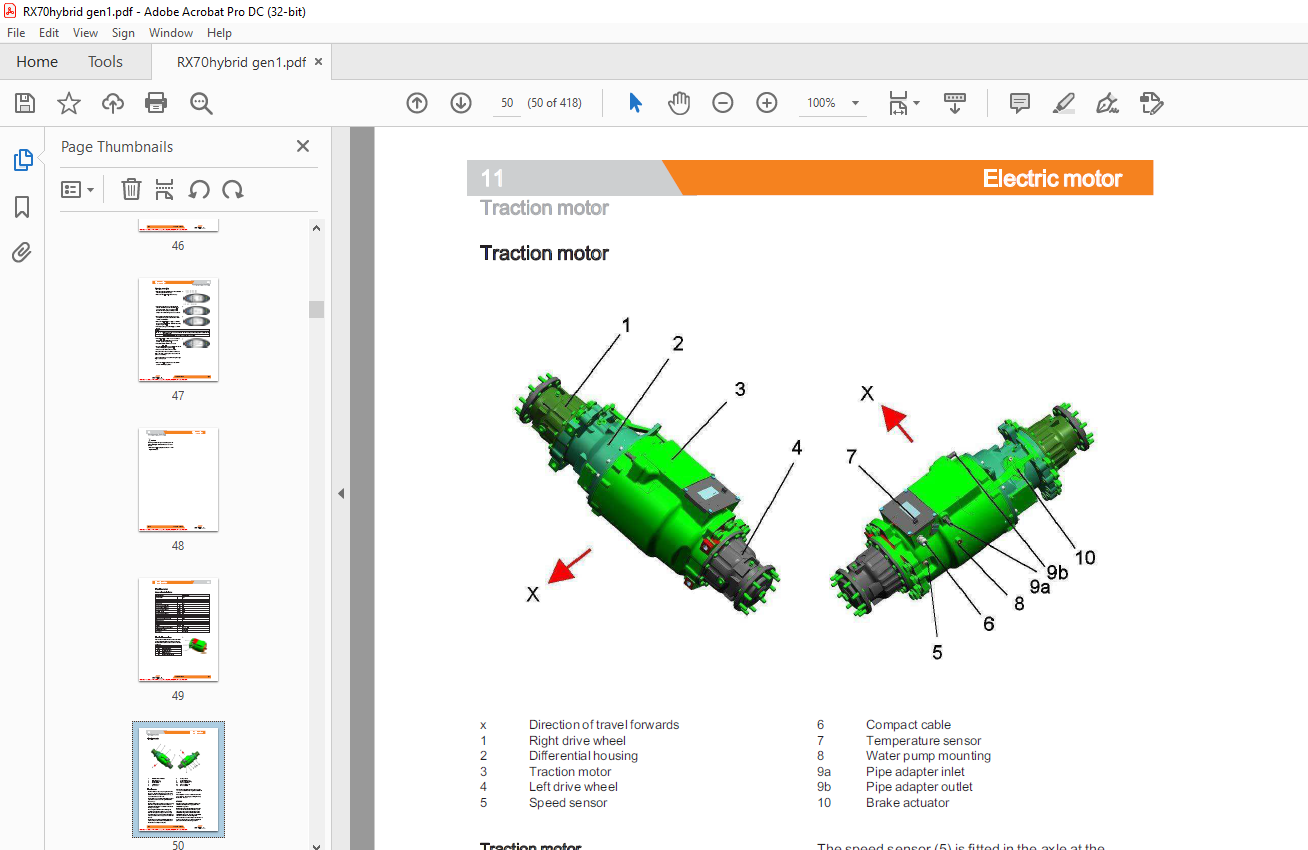

Table of contents11 Electric motorTractionmotor 11-1

Generaltechnicaldata 11-1

Electricalconnections 11-1

Traction motor 1- 2

Tractionmotor 11-3Speed sensor 11- 6

Pin Sensor 11- 6Temperature SEeNSOr ii 11- 8

Temperature sensor KTY84 11- 8Alternator 11-10

Generaltechnicaldata 11-10

Alternator 11-11

Alternator removal-installation 11-1212 Internal combustion engineInternal combustionengine 12-1

Engine 12- 1

Engine unitRemoval and installation 12- 3

Startermotor 12- 8

Starterringgear 12- 9

Alternatormonitoring 12-11

Retrofitting the 110-A alternatorfor TCU1 12-13

Alternator 12-14VW 1 9-litre SDI/TDI dieselengine 12-16

General technicaldataVW 1 91SDI 12-16

General technicaldata VW 1 91TDI 12-17

Dieselengine VW 1 QISDI/TDI 12-18

Engine control unit VW 1 9ISDI/TDI 12-19VW 2 0-litre TDI dieselengine 12-22

General technical data VW 2 01 TDI 12-22

Dieselengine VW 2 01 TDI 12-23VW 2 0-litre SPILPGengine 12-25

General technicaldata VW 2 01SPI 12-25

VWLPG-20Iitre BEF 12-27

Engine controlunitVW 2 01SPI 12-28\ THN

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contents13 Combustion engine — attachmentsAirintake /filter 13- 1

Airintake LLL 13- 1

Airfilter 13- 2Coolingsystem 13- 4

Coolingcircuit 13- 4

Waterpump 13- 5

Coolant 13- 6

Checking, topping up and changingthecoolant 13- 7

Radiatorsystem 13- 9

Radiator Removal and installation 13-10

Fanwheelrotor-fanmotor 13-11Diesel fuel system 13-14

Fuelsystem 13-14

Fuelfilter 13-15

Low fuelwarningthreshold 13-15LPG system 13-17

LPG system 13-17

IMPCOCOMPONENtS 13-18

Evaporator function-gasmixer 13-19

Suctionmodule 13-21

MAP/MAT sensor0B6 13-23

Chassismodule 13-23

Actuatorunit 13-25

Gasshut-offvalveunit 13-26

Gas shut-offvalve monitoring 13-26

Shut-downduetolackofgas i 13-27

Maintenance and test specifications iL 13-28

Testing forleaksinthe LPGsystem 13-29

Testing CO levelinexhaustgases 13-30

Servicingthe LPGfilter 13-32

Servicing the 30-bar high-pressure reliefvalve 13-33

Evaporator-maintenance LL 13-34

Safetyvalve-1 7bar 13-37LPGecylinderftank 13-39

LPGeylinder 13-39THN AR

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contents14 Combustion engine — exhaust systemExhaustsystem-diesel iL 14- 1

Exhaustsystem 14- 1

Exhaust system – particlefilter 14- 2

General technical data-Eberspacher 14- 2

Structure of the Eberspécher particlefilter 14- 3

7 5 kW Eberspacher particlefilter 14- 3

Regeneration LL 14- 6

Maintenance instructions 14- 8

Exhaustsystem —LPG 14- 9

Lambdacontrolsystem 14- 9

Lambdasensor 14-10

Three-way catalyticconverter LL 14-1222 Mechanical drive axleDriveaxle 8 30 22-1

General technical data, Carraro 8 30 i 22- 1

Drive axle 22- 3

Wheeldrive 22- 4

Removal and installation of thedriveaxle 22- 6

Servicebrake 22-9

Differential gearbox 22-1231 ChassisChassis 31-1

Floorplate 31-1

Counterweight 31- 2

Counterweight 31- 234 Driver’s compartmentHood —covering—insulation 34- 1

Motorhood 34- 142 Steering systemHydraulicsteering iL 42-1

Generaltechnicaldata 42-1

Steering system 42- 2

Steering—errordetection LL 42- 3_ THN

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsSteeringunit 42- 3

Priority valve 42- 6

Steering wheel and steeringcolumn 42- 7

Steering column LLL 42- 7

Steeringaxle 42-11

Generaltechnicaldata 42-11

Swing axle 42-12

Swing axle Removal and installation 42-13

Wheelhub 42-15

Steeringangle LL 42-17

Tierod 42-18

Axlestub 42-1949 Brake systemHydraulicservicebrake 49- 1

Brakesensor1B2 LLL 49- 1

Parkingbrake 49- 2

Replacingthebrakecable 49- 2

Actuating force ofthe handbrake 49- 2

Parkingbrake switch 183 49- 350 Operating devicesSinglepedal 50- 1

Accelerator—single-pedal 50- 1

Dualpedal 50- 4

Accelerator—dualpedal 50- 4

Operatingdevices 50- 7

Handlever 50- 7

Joystick oo 50- 8

Joystickoperation LLL 50-10

Generation2mini-lever LL 50-12

Generation 2mini-leverActuation 50-14

Tipswitch Lo 50-16

Generation Tmini-lever 50-18

Axleassignment LLL 50-19

Joystick4Plus 50-23

Axle assignment -Joystick4Plus 50-24oT y

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contents56 Display elementsOperatingconsole

Direction indicatormodule (Fabli)Display

Display and operating unit, generation2(ABE2)

ABE 2 Installationandremoval

Display operating unit (ABE 1) Generation1

ABE 1 Installationand removalDrive direction tum indicatordisplay60 Electrics/ElectronicsGeneral

Generaltechnicaldata

Overviewofthecontrollers

Overview of electricalcomponents

Software compatibility

PANDProcess

Parametermanagement

Errorringbuffer

Intermediatecircuit

Insulation measurement LL

Hybrid component insulation measurements

Traction motor temperature monitoring

Temperature monitoring, traction inverter with aircooling

Drive mode — driving behaviour Availability

Driving mode — driving behaviour Description

Blue-Q=1QWiring

CANbussystem i

CANbusconnections

Powercables

Maintenance guidelines forpowercablesRepair-ContactelementsElectrical system L

FuseboxTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more informationon

@

© © oO bw Ww

Table of contentsSensorsystem 60-30

Vertical lift mast position 60-30

Titanglesensor7B46 LL 60-31

Tiltangle sensorparameters 60-33

Installation of the vertical lift mast position 60-34

Load measurement LL 60-37

Load measurement pressure SENSOr o oo 60-39Additional electrical installation 60-40

OptionBoard 60-40

CAN-Power-Port (CPP) 60-42

CPP CPP 3 60-42

CPP 2/CPP 4 60-43

CPP 2B 60-45

Soot CPP (CPPS) 60-46

Relay-Power-Port 60-4664 Electronic controllersTruckcontrolunit LL 64- 1

Truck Control Unit (TCU) 64- 1

TCU, generation2(TCU2) i 64- 2

Truck Controll Unit (TCU) Removal and installation 64- 2Converters 64- 5

Inverter 64- 5

Hybrid converter 64- 6

ConvertersRemoval andinstallation 64- 8

Brakeresistor LL 64-11Hybridcomponents 64-13

Hybrid function 64-13

DC/DC converter 64-14

DC/DC converter Removal and installation 64-15

Storage module —energy accumulators 64-18

Storage module Removal andinstallation 64-20

Forced ventilation 64-2169 Batteries and accessoriesStarterbattery 69- 1

Starterbattery 69- 1oT A

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

70 HydraulicsTable of contentsGeneral 70- 1

Generaltechnicaldata 70- 1

Depressurisingthe hydraulics 70- 3

Liftingoperatingspeeds 70- 3

Tilting operatingspeeds LL 70- 4

Lowering operatingspeeds LL 70- 5Safetycheck 70- 6

Forwardftiltsafetytest 70- 6

Lowering safetytest LL 70- 6

Safety checksofhoseassembly lL 70- 7Basichydraulics 70- 8

Basichydraulics 70- 8

Fanmotorcontrolunit 70-10

Fancontrolvalve 70-11

Steering hydraulics 70-13

Operatinghydraulics 70-14

Variable displacementpump 70-16

Hybrid variable displacementpump 70-18

Pumpregulator 70-19

Variable pumpRemoval and installation 70-20

Hydraulictank 70-22

Hydraulicoil 70-23

Returnfilter 70-24

Breather 70-25

Suction filter 70-26

High-pressurefilter 70-27

Conical nipple fittings (CNF) 70-28

Bolted joint 70-2871 Operating hydraulicsTilteylinder 71-1

Masttilt 71-1

Tilt cylinder Removal and installation 71- 2

Changing the set of seals2200-5000kg-LSP 500 71- 3Additional hydraulics 71- 6

Attachments 71- 6N Ti

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsSecond operating function forattachments 71- 8

Clamp locking mechanism forhandlevers 71- 8

76 Valves

Hand lever 76- 1

Generaltechnicaldata 76- 1

Hand levervalveblock 76- 2

Valve block Removal /installation 76- 3

Directional control valve block 76- 5

Check valve for hydraulics blocking function 76- 7

Hydraulictransmitter 76- 9

Servohydraulics 76-11

Generaltechnicaldata 76-11

Servo hydraulics valveblock 76-12

Directional control valve block 76-13

Directional control valve function Lifting 76-16

Directional control valve function Lowering 76-1881 Lift mastLiftmast 81- 1

Generaltechnicaldata 81- 1

Carraro 8 30 mastbearing 81-1

Hose safety valve of triplexmast 81- 3

Supportroller play (108/117/130) 81- 6

Load chains – Checkingandcleaning 81- 7

Run-outbarrier 81- 8

Workingonliftmasts 81-10

Lift mast—removal 81-11

Lift mast—installation 81-12Telescopicliftmast 81-15

Telescopic lift mast (108/117/130) i 81-15

Adjusting the load chains Telescopic lift mast (108/117/130) 81-16NiHoliftmast 81-18

NiHoliftmast (108/117/130) 81-18

Adjusting the load chains NiHo lift mast (108/117/130) 81-20Triplex liftmast 81-22

Triple lift mast (108/117/130) 81-22oT AR

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsRemoving the support rollersintheliftmast

Assembling the lift mast after replacing the supportrollers

Outer load chains and chainrollers

Middle load chainand chainroller

Adjusting the outer load chains Triple lift mast (108/117/130)

Adjusting the middle load chain Triple lift mast (108/117/130)Lifteylinders

Liftjack

Working onliftcylinders

Outercylinder

Disassembling/assembling the outercylinder

Centrecylinder

Disassembling/assembling the middle cylinder

End position damping ofoutercylinderMiddle cylinderenddampener84 Load supportForkcarriage

ForkcarriageAnnexX Circuit diagramsHydraulics i

Hand leveruntil 12/2009

Hand lever from 01/2010

IMAGES PREVIEW OF THE MANUAL: