$33

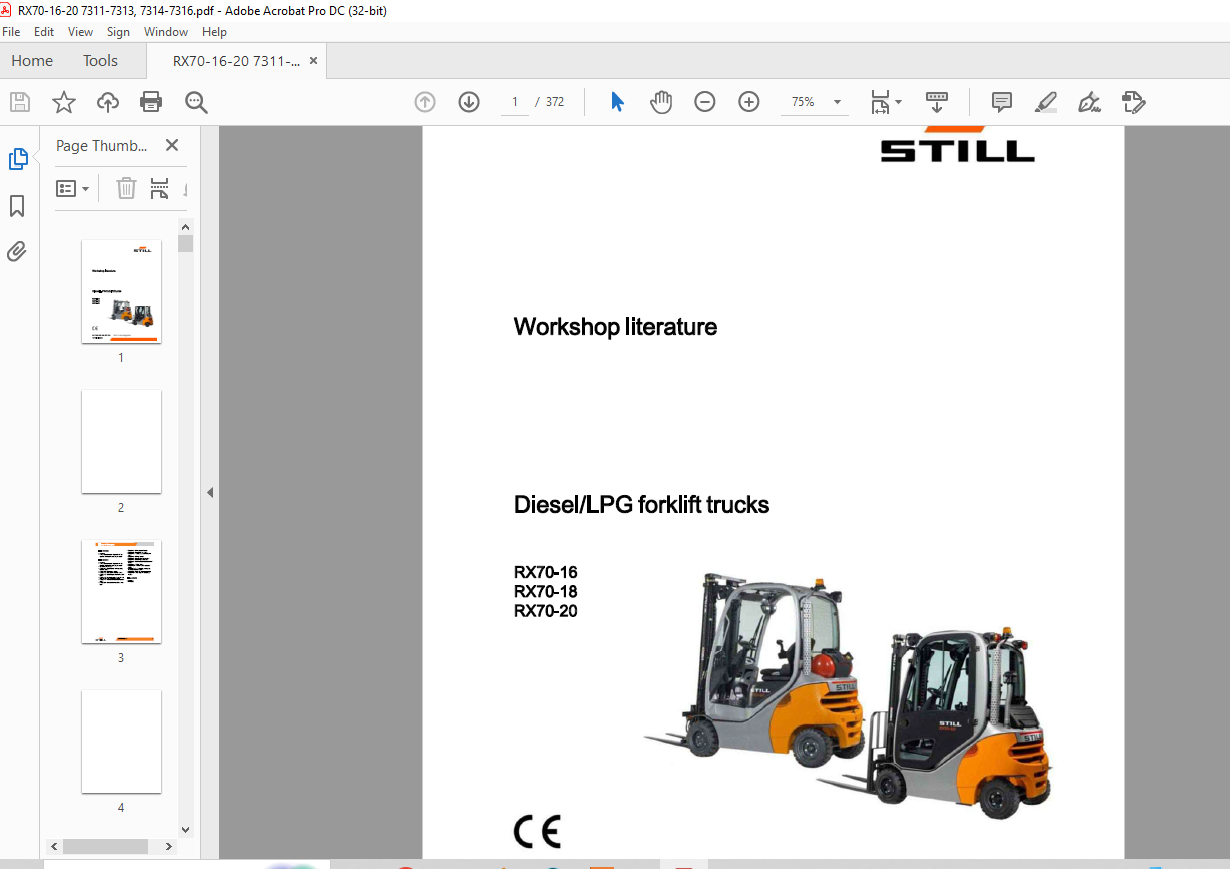

STILL STED Diesel LPG forklift trucks RX70-16 RX70-18 RX70-20 workshop Manual – PDF DOWNLOAD

STILL STED Diesel LPG forklift trucks RX70-16 RX70-18 RX70-20 workshop Manual – PDF DOWNLOAD

FILE DETAILS:

STILL STED Diesel LPG Forklift Trucks RX70-16 RX70-18 RX70-20 Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 372

Downloadable : Yes

File Type : PDF

DESCRIPTION:

STILL STED Diesel LPG Forklift Trucks RX70-16 RX70-18 RX70-20 Workshop Manual – PDF DOWNLOAD

Special featuresThe type carriers described belong to the RX series. A few units with a high proportion of common parts make up many different trucks of different versions.New in this series:• Ergonomic driver’s workplace Generation 2 mini-lever Generation 2 display operating unit• Diesel-electric drive with three-phase AC technology Closed-loop AC drive technology Intelligent drive management for very low consumption Hydraulic fans and exhaust system with new air cooling duct• Blue-Q Characteristic curve optimisation of the drive The following can be parameterised switching off auxiliary consumers and enabling the consumption display• Removable diesel tank on the counterweight Brake resistor integrated in the radiator• Air filter integrated in the inverter housing

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

STILL STED Diesel LPG Forklift Trucks RX70-16 RX70-18 RX70-20 Workshop Manual – PDF DOWNLOAD

00 Product Information

Foreword

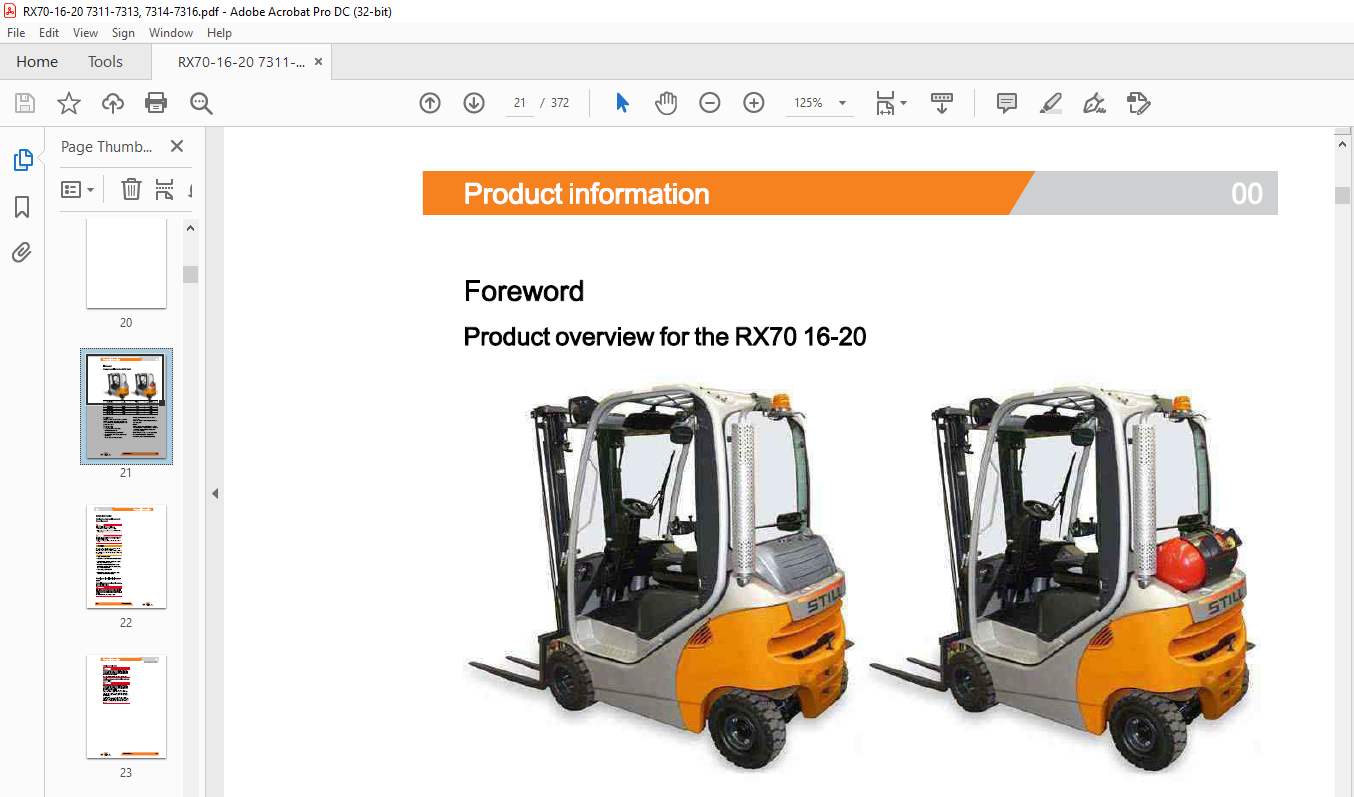

Product overview for the RX70 16-20

Safety Information

Parking the truck so is secured for service work

Working on Ive electrical components

Working on the LPG system

Securing the fork carriage

01 Service

Maintenance

Maintenance Instructions

Maintenance-1000 hours/annually

Maintenance-3000 hours/every two years

Operating materials

Measuring and testing equipment

Special tool

Hamesses and holsts

Standardised lightening torques for standard-pich threads and fine-lich threads

Standardised lightening torques for hose fittings

02 Diagnostics

Introduction to DiaMon

STEDS-Navigator

CAN box diagnostics

Diagnostic set-up

Staring DiaMon

Working with DiaMon

Reading out and clearing the erroret

Reading out access codes

Working using the ABE

Read error st Clearing orrorists

11 Electric motor

Traction motor

General techalcal data

Sectrical connections

Drive unit

Rev sensor

Pin sensor

Temperature sensor

Temperature sensor KTY84

Generator

General technical data

Generator

Removing and Instal ng the generator

12 Internal combustion engine

Internal combustion engine

Engine unk

Engine unit Removal and Installation

Starter motor

Starter ring gear

Alternator monitoring

Retrofitting the 110-Aerator for TCU 1

Diesel engine

SDI generall technical data

VW-Diesel engine

Engine control un ECU-two-part

LPG engine

LPG general technical data

VW LPG-2.0 Bre B

Engine control un ECU

13 Internal combustion engine-attachment parts

Air Intake/filer

Air Intake

Air filter

Cooling system

Cooling drou

Coolant

Checking, topping up and changing the coolant Radiator system

Radiator Removal and Installation

Fan Impeller-fan motor

Diesel fuel system

Fuel system

Fuel filter

Low fuel warning threshold

LPG system

LPG system

Impoo components

Evaporator function-gas mixer

Suction module

MAPIMAT sensor 088

Chassis module

Actuator un

Gas shut-off valve unit

Gas shut-off valve monitoring Shut-down due to lack of gas

Maintenance and test specifications

Testing for leaks in the LPG system

Testing CO level in exhaust gases

Servicing the LPG ther

Servicing the 30-bar high-pressure relief valve

Evaporator-maintenance

Safety valve-1.7 bar

LPG cylindertank

LPG cylinder

14 Internal combustion engine-exhaust system

Exhaust system-diesel

Exhaust system

Exhaust system-particle filter

Generall technical data-Eberspächer

Eberspächer particle for

7.5kW■berspächer particle fiber Regeneration

Maintenance Instructions

Exhaust system-LPG

Lambda control system

Lambda sensor

Three-way catalytic converter

22 Mechanical drive axle

Drive aude AD20-02

General technical data

Drive axde

Removal Installation of the drive ande

Drive wheel unit

Removal Installation of the drive wheel unit

Repairing the drive wheel un

Traction motor

Service brake

Gearbox o

31 Chassis

Counterweight Counterweight

34 Driver’s place

Bonnet-cover-Insulation

Bonnet

42 Steering system

Hydraulic steering

General technical data

Steering system

Steering-error detection

Steering unk

Priority valve

Steering wheel and steering column

Steering column

Steering axde

General technical data, swing ade

Swing exe

Swing axe Removal and Installation

Wheel hub

Steering angle

Tie rod

Axle stub

49 Brake system

Mechanical service brake

Brake sensor 182

Changing the brake cable Service brake

Parking brake

Changing the brake cable for the handbrake

Actuating force of the handbrake

Parking brake switch 183

50 Controls

Single pedal

Accelerator-single-pedal

Dual pedal

Accelerator-dual-pedal 2nd generaton

Controls

Joystick 4Plus

Axle assignment-Joystick 4Plus

Joystick

Joystick operation

Generation 2 minHover

Generation 2 minHoverActuation

Tip switch

Generation 1 minHover

Axle assignment

56 Display elements

Operating console

Direction Indicator module (Fall)

Display screen

Display and operating unit, generation 2 (ABE2)

ABE 2 Instalation and removal

CPP 28

Soot CPP (CPP5)

Relay Power-Port

64 Electronic controls

Traction hydraulics and working hydraulics control

Truck Control Un (TCU)

TCU, generation 2 (TCU2)

Truck Control Unit (TCU) Removal and Instalation

Inverter

Inverter

Inverter Removal and Instalation

Brake resistor

69 Battery and accessories

Starter battery Starter battery

70 Hydraulics

General

General technical data

Depressurising the hydraulics

Liting operating speeds

Ting operating speed

Lowering operating speeds

Safety check

Forward

safely beat

Lowering safety test

Safety checks of hose assembly

Basic hydraulics

Basic hydrauca

Fan motor

Steering hydraulics

Worlding hydraulics

Hydraulic pump

Hydraulic pump Removal and Installation

Hydraulico

Breather for Intake fler

High-pressure her

Conical nipplefings (CNF)

Bolted joint

71 Working hydraulics

Tcy nders

Mast

Tit cylinder Removal and Installation

Changing the set of seals (1500-2000 kg)

Auxary hydraulics

Attachments

Second operating function for attachments

76 Valves

Servo hydraulics

General technical data

Valve block components

Valve block Removal and Installation

Directional control valve block

Directional control valve function, ing Directional control valve function, lowering

80 Load Ift system

Mast bearings

Mast bearings, 1.01-201

81 Lift masts

Liftmast

General technical data

Hose safety valve of triplexx mast

Support roerplay (108/117/130) Load chains-Checking and caring Run-out barler

Worlding on it masts

Liftmast-removal

Liftmast-Installation

Telescopic lit mast

Telescopic

mast (108/117/130)

Adjusting the load chains Telescopic mast (108/117/130)

NIHot mast

Hot mast (108/117/130)

Adjusting the load chains Hot mast (108/117/130)

Triplext mast

Triplet mast (108/117/130)

Removing the support rollers In the It mast

Assembling the it mast after replacing the support rollers

Outer load chains and chain rollers

Middle load chain and chain roer

Adjusting the outer load chains Tilemast (108/117/130) Adjusting the middle load chain Triplet mast (108/117/130)

Lift cylinder

Ut jack

Working on it cyinders

Outer cylinder

Disassembling/assembling the outer cylinder

Centre cylinder

Disassembling/assembling the middle cylinder

End pollon damping of outer cylinder

Middle cylinder end dampener

84 Load support

Fork carriage

Fork canlage

Annex

X Circuit diagrams

Hydraulics

Servo hydraulics