$35

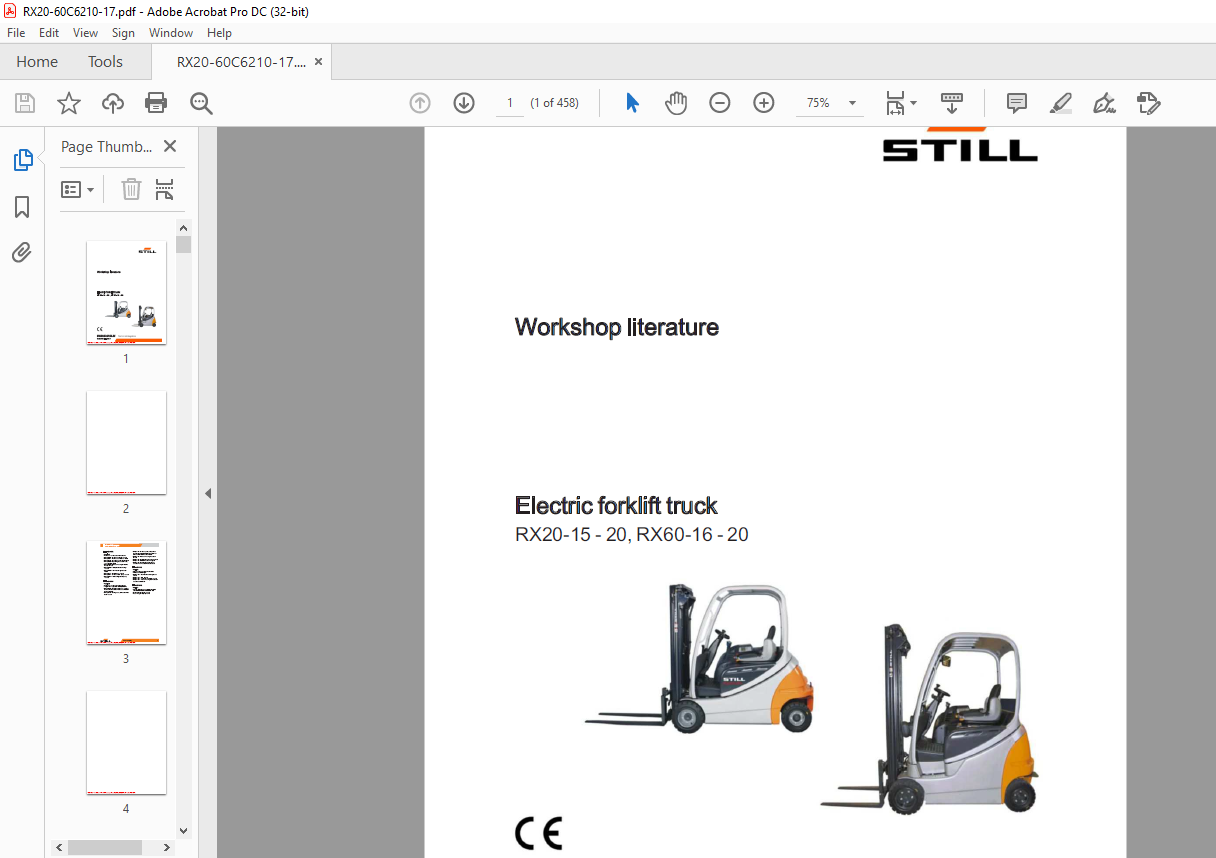

Still STED Electric forklift truck RX20-15-20, RX60-16-20 Workshop manual – PDF DOWNLOAD

STILL STED ELECTRIC FORKLIFT TRUCK RX20-15-20 RX60-16-20 WORKSHOP MANUAL – PDF DOWNLOAD

FILE DETAILS:

STILL STED Electric forklift truck RX20-15-20 RX60-16-20 Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 458

Downloadable : Yes

File Type : PDF

DESCRIPTION:

STILL STED Electric forklift truck RX20-15-20 RX60-16-20 Workshop Manual – PDF DOWNLOAD

Foreword Improved properties:

• Enhanced discharge indicator and consump tion display

- New components:

- Joystick 4Plus

- Push-up roof panel

- Metal brand emblem

- Lighting on top of the overhead guard

- • Diagnostic connector (Group connector) in the front structure

New features from 2012• New truck type RX20-14 (6209) New components:• Generation 2 MCU• Drive axle AE 18-07 New features from 2009-Facelift Step1 and Step2 Improved properties:• Ergonomic driver’s workstation• Drive mode Blue-Q New components:• Generation 2 mini-lever Generation 2 display and operating unit Electric parking brake• Load measurement• Mast vertical position• Hydraulics blocking function in accordance with EN ISO 3691-1

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

STILL STED Electric forklift truck RX20-15-20 RX60-16-20 Workshop Manual – PDF DOWNLOAD

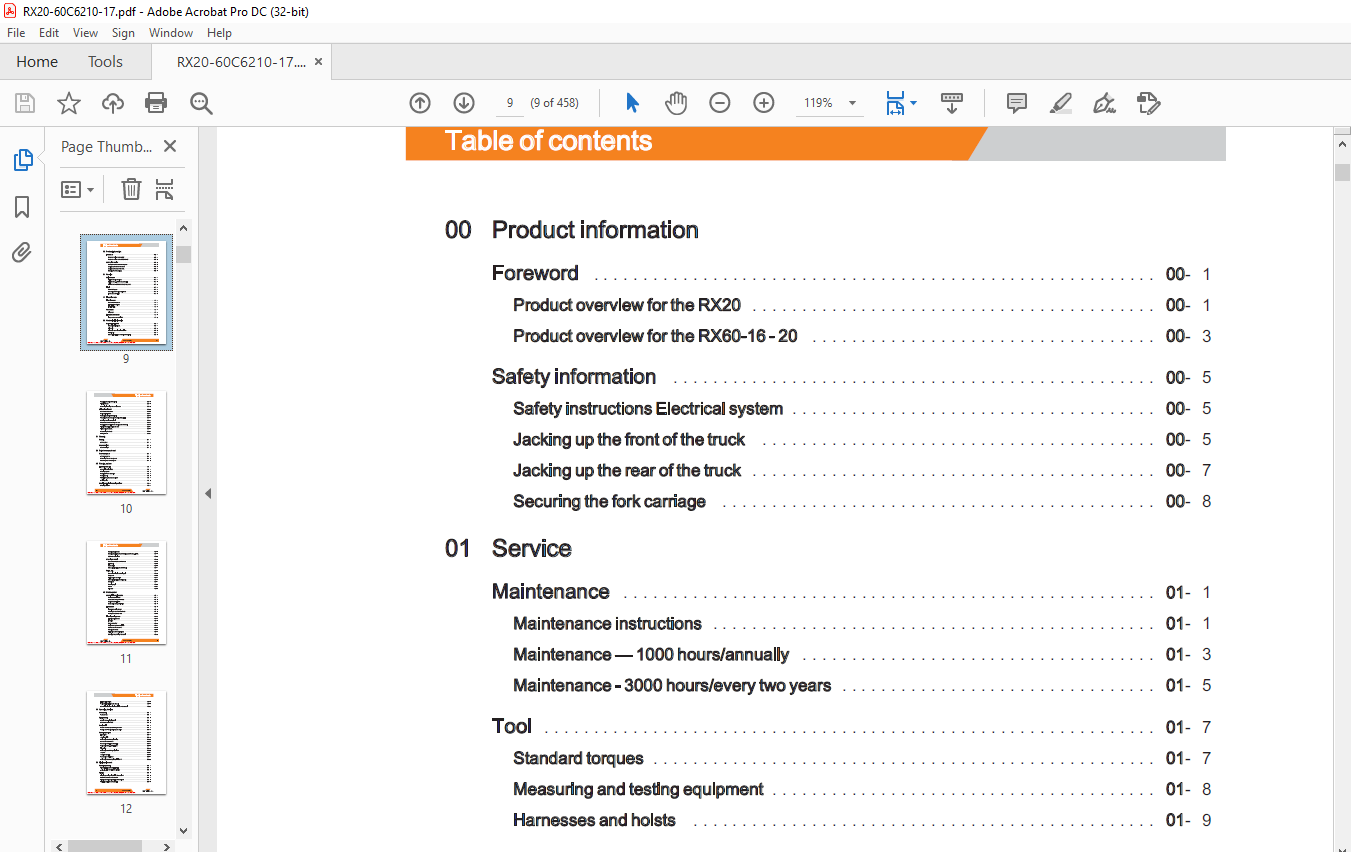

Table of contents00 Product informationForeword 00- 1

Productoverview forthe RX20 00- 1

Product overview forthe RX60-16-20 00- 3Safetyinformation 00- 5

Safety instructions Electrical system 00- 5

Jacking up the frontofthetruck LL 00- 5

Jackinguptherearofthetruck lL 00- 7

Securing theforkcarriage 00- 801 ServiceMaintenance 01- 1

Maintenance instructions LL 01-1

Maintenance — 1000 hours/annually 01- 3

Maintenance – 3000 hours/everytwoyears 01- 5Tool 01-7

Standardtorques 0-7

Measuring and testingequipment 01- 8

Harnessesandhoists 01-911 Electric motorTractionmotor 11-1

Generaltechnicaldata 11-1

Electricalconnections 11-1

Tractiondrive 11- 2RevSensor 11- 4

Pin Sensor 11- 4Temperature Sensor 11- 6

Temperature sensor KTY84 11- 622 Mechanical drive axleDriveaxle AE18-05 22-1

Generaltechnicaldata 22- 1

Drive axle 22- 2

Drive axle removal andinstallation 22- 3

Wheeldrive 22- 7

Removal/installation of the drive wheelunit 22- 8THN y

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsRepairing the drive wheelunit

TractionmotorRemoving/installing the servicebrakeDrive axle AE18-07

Generaltechnicaldata

Driveaxle AE18-07

Removingthedrivewheelunit

Changing the shaft seal on the drive wheelunit

Refitting the drivewheelunit

Traction motor — Removing therotor

Replacing the traction motor bearing and shaftseal

Traction motor – Installing therotor

Dismantlingthebrake

Assemblingthebrake iL

Filingwithoil31 ChassisChassis

BatterydoorCounterweightCounterweight34 Driver’s compartmentOverheadguard

Overheadguard

Removing the overheadguardInstallingthe overheadguard42 Steering systemHydraulicsteering

Generaltechnicaldata

Steeringsystem LL

Steering—errordetection

Steeringunit

6S3 diaphragm pressureswitch

PriorityvalveSteering wheel with steeringcolumnSteeringcolumn LLLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsSteeringangle sensor LLL 42-13

Steering angle-dependent handling performance —CSC 42-15

CSC—functionaltest 42-16

Steeringturntable 42-19

General technical dataFifthwheel 42-19

Fifthwheel 42-20

Curveswitch 42-20

Removing/installing the fifthwheel 42-21

Swingaxle 42-25

General technicaldata Swingaxle 42-25

Swingaxle 42-26

Swingaxlecurveswitch 42-27

Removing/installingthe swingaxle 42-28

Wheelhub 42-31

Steeringangle 42-33

Tierod 42-34

Axlestub 42-3549 Brake systemMechanical servicebrake 49- 1

Servicebrake AE18-05 LL 49- 1

Brake cable changer AE18-05 49- 3

Servicebrake AE18-07 LL 49- 5

Brake cable changer AE18-07 49- 6Handbrake 49- 8

Handbrake cablechanger 49- 8

Actuating force ofthehandbrake 49- 9

Parking brake switch 1S3 49-10Electricparkingbrake 49-12

Electricparkingbrake 49-12

Function 49-13

Causeandeffect 49-15

Design and systemdescription 49-17

Maintenanceinstructions LLL 49-19

Checkingthebrake 49-20

Calibration and functionaltest 49-22

Changing the parkingbrakecable 49-25oT y

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsLimitpositionswitch

Drive unit InstallationandremovalCentral lubrication device Installationand removal50 Operating devicesBrakepedalBrake sensorSinglepedal

Accelerator—single-pedal LL

Deadmanswitch7S13Dualpedal

Accelerator—dual pedal 2nd generationAccelerator —dual pedal 1stgenerationOperatingdevices

Handlever

Joystick4Plus LL

Axle assignment -Joystick4Plus

Generation2mini-lever

Generation 2 mini-leverActuation

Axle assignment-themini-lever

Tipswitch

Axle assignment -fingertipswitch

Joystick LL

Joystickoperation LL

Generation Tmini-leverAxle assignment – Joystick, minilever1 LL56 Display elementsOperatingconsole

Direction indicatormodule (Fabli)Drive direction tum indicatordisplayDisplay

Display operating unit (ABE 1) Generation1

ABE 1 Installationandremoval

Display operating unit (ABE 2) Generation2ABE 2 InstallationandremovalTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

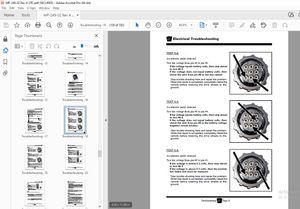

Table of contents60 Electrics / ElectronicsGeneral 60- 1

General technicaldata-48Volt 60- 1

General technicaldata-80Volt 60- 3

Overviewofthecontrollers 60- 4

Electrical system 60- 5

Electricalcomponents 60- 5

Switching on procedure for the electricalsystem 60- 7

Software compatibility 60-12

PAN DrOCESS «oo 60-13

Parametermanagement LLL 60-14

Errorring buffer 60-15

Intermediate circuit 60-16

Insulation testing forelectrictrucks 60-18

Insulation testingonthedrivebattery 60-20

Componentinsulationtesting 60-21

Temperature monitoring for the traction motor-48V 60-24

Temperature monitoring for the traction motor-80V 60-26

Temperature monitoring for the traction motor converter 60-27

Pump motor temperature monitoring 60-28

Temperature monitoring for the pump motorconverter 60-30

Available driving behaviour 60-31

Drive mode — driving behaviour Description 60-31

Blue-Q=1Q 60-33WINING 60-35

CANDus system 60-35

CANbusconnections 60-37

Powercables 60-39

Maintenance guidelines forpowercables 60-40

Repair-Contactelements 60-40Electrical system 60-42

Fuse boX 60-42

FUSES 60-42

Fuse plateUntil April2005 60-44

FusesUntil April2005 60-46

Contactor 60-47THN y

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsSensorsystem

Vertical lift mast positon

Tiltanglesensor7B46

Tiltangle sensorparameters

Installation of the vertical lift mast position

Loadmeasurement LLLoad measurementpressure Sensor LLAdditional electrical installations

7A21converterPCB

OptionBoard

CAN-Power-Port (CPP)

CPP1/CPP 3CPP2/CPP4

CPP battery carrier (CPP5)

Relay-Power-Port64 Electronic controlsTraction and working hydraulicscontrol

Main Control Unit(MCU)}

MCUwithservohydraulics

MCUgeneration2 i

Main Control Unit (MCU) Removal and installation

SupplyUnit (SU)

Supply Unit (SU) Removal and installationConverter

Inverters

Converter LAC-48/80Volt

Converter SAC-48VoltConverter-removalandinstallation69 Batteries and accessoriesBattery

Batteryplug

Maintenance guidelines for applianceplugs

Repair – Battery male connectorcontactsWorking withreducersleevesTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsDischargeindicator 69- 9

2014 dischargeindicator LL 69-1070 HydraulicsGeneral 70- 1

Generaltechnicaldata 70- 1

Depressurisingthe hydraulics 70- 2

Liftingoperatingspeeds 70- 4

Operating speeds forlowering 70- 4

Tilingoperatingspeeds 70- 5Safetycheck 70- 7

Forwardftiltsafetytest 70- 7

Loweringsafetytest 70- 7

Safety checks ofhoseassembly 70- 8Basichydraulics 70- 9

Basichydraulics 70- 9

Steering hydraulics 70-10

Working hydraulics 70-11

Hydraulictank 70-12

Hydraulicoil 70-12

Returnlinefilter 70-13

Breatherfilter 70-14

Suction filter 70-15

High-pressurefilter 70-16

Conical nipple fittings (CNF) 70-17

Boltedjoint 70-1771 Working hydraulicsPumpunit 71-1

Generaltechnicaldata 71-1

Pumpunit 71- 2

Electricalconnections LL 71- 4

Pump motorwithoutrevsensor 71- 4

Pump motorspeed sensor 71-5

Pump motor temperature sensor LLL 71- 6

Pumpmotorremoval 71- 8

Pump motorinstallation 71-10

Hydraulicpump 71-13y 4STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

76Table of contentsHydraulic pump Removal and installation 71-14

Tilteylinder 71-18

Masttilt 71-18

Tilt cylinder Removal and installation 71-18

Changing the set of seals (1500-2000kg) 71-19

Auxiliary hydraulics 71-22

Attachments 71-22

Second operating function forattachments 71-23

Clamp locking mechanism with servo hydraulics 71-23

Clamp locking mechanismforhandlevers 71-25

Accumulator 71-27

Accumulator 71-27

Checkingthe accumulator 71-28

Valves

Handlever 76- 1

Generaltechnicaldata 76- 1

Hand levervalveblock 76- 3

Emergencylowering 76- 4

Hydraulictransmitter 76- 5

Dismantling and installing valve block 76- 7

Directional control valve with blocking function (Buchholz) 76-11

Directional control valve with check valve2Y46 76-11

Discharge pressure governor (loweringbrake) 76-12

Check valve for hydraulics blocking function 76-12

Directional control valve without blocking function (Hawe) 76-14

Directional control valve -function 76-14

Directional control valve for lifting/tilting 76-15

Directional control valve -addition1and2 76-17

Pressurereliefvalve 76-18

Load holdingvalve 76-19

Loweringbrake 76-20

Servohydraulics 76-21

Generaltechnicaldata 76-21

Servo hydraulics valveblock 76-22

Manuallowering 76-23

Directional control valve block 76-24TRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contentsDirectional control valve – method of operation 76-2681 Lift mastLiftmast 81- 1

Generaltechnicaldata 81- 1

Mastbearings 81- 2

Hose safety valve of triplexmast 81- 3

Supportroller play (108/117/130) 81- 6

Load chains – Checkingandcleaning 81- 7

Run-outbarrier 81- 8

Workingonliftmasts 81-10

Liftmast—removal 81-11

Lift mast—installation 81-12Telescopicliftmast 81-15

Telescopic lift mast (108/117/130) 81-15

Adjusting the load chains Telescopic lift mast (108/117/130) 81-16NiHoliftmast 81-18

NiHoliftmast (108/117/130) 81-18

Adjusting the load chains NiHo lift mast (108/117/130) 81-20Triplexliftmast 81-22

Triple lift mast (108/117/130) 81-22

Removing the supportrollersintheliftmast 81-24

Assembling the lift mast after replacing the supportrollers 81-27

Outer load chains and chainrollers 81-29

Middle load chainand chainroller 81-31

Adjusting the outer load chains Triple lift mast (108/117/130) 81-33

Adjusting the middle load chain Triple lift mast (108/117/130) 81-34Lifteylinder 81-36

Liftjack 81-36

Workingonliftcylinders 81-37

Outercylinder 81-37

Disassembling/assembling the outercylinder 81-40

Centrecylinder 81-42

Disassembling/assembling the middle cylinder 81-44

End position damping of outercylinder 81-47

Middle cylinderenddampener 81-48oT y

STILLTRIAL MODE – a valid license will remove this message See the keywords property of this PDF for more information

Table of contents84 Load supportForkcarriage i

ForkcarriageAnnexX Circuit diagramsHydraulics

Hand lever until calendarweek 38/2009

Hand lever from calendarweek 39/2009