$31

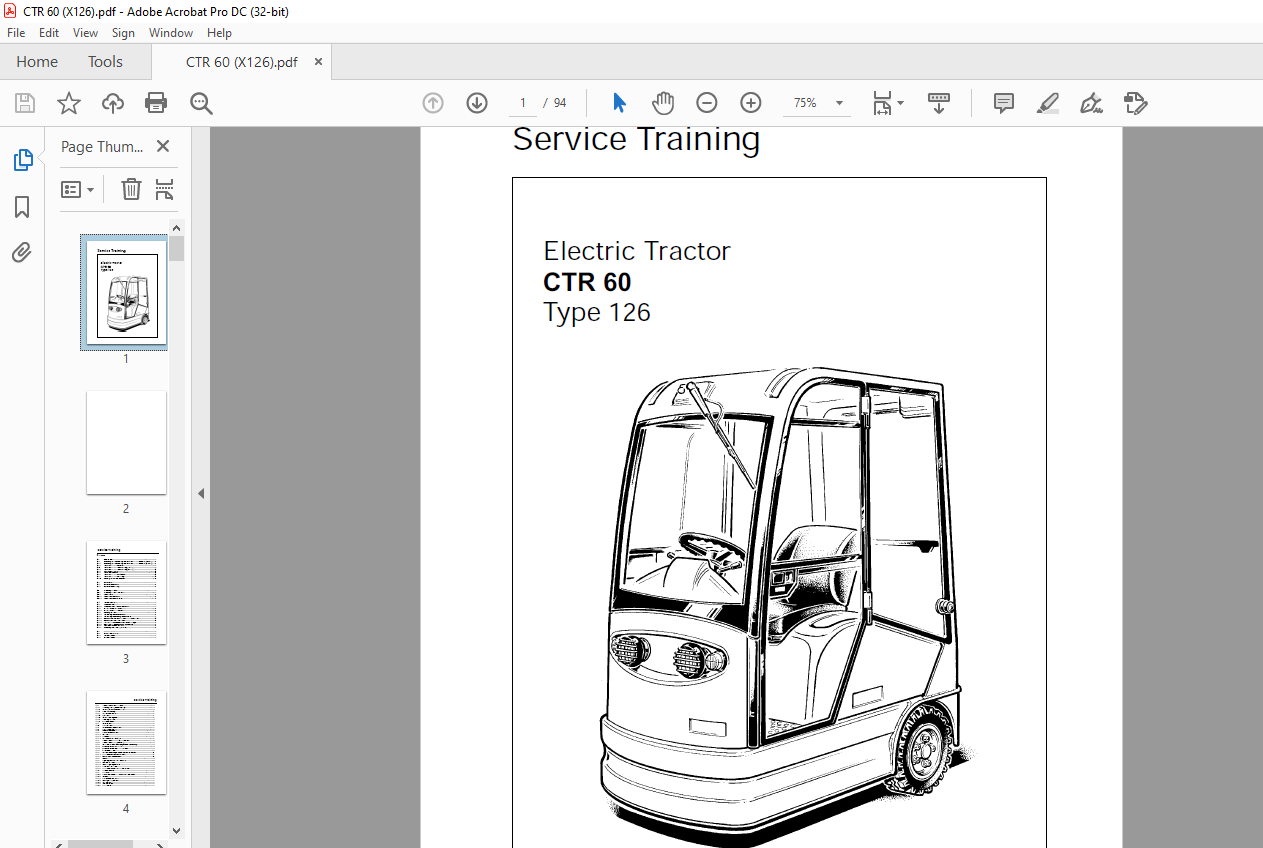

STILL STED Electric Pallet Truck EXU-16 EXU-18 EXU-20 EXU-22 Workshop Manual – PDF DOWNLOAD FILE DET

STILL STED Electric tractor CTR 60 Type 126 Service Training Manual – PDF DOWNLOAD

FILE DETAILS:

STILL STED Electric tractor CTR 60 Type 126 Service Training Manual – PDF DOWNLOAD

Language : English

Pages : 94

Downloadable : Yes

File Type : PDF

DESCRIPTION:

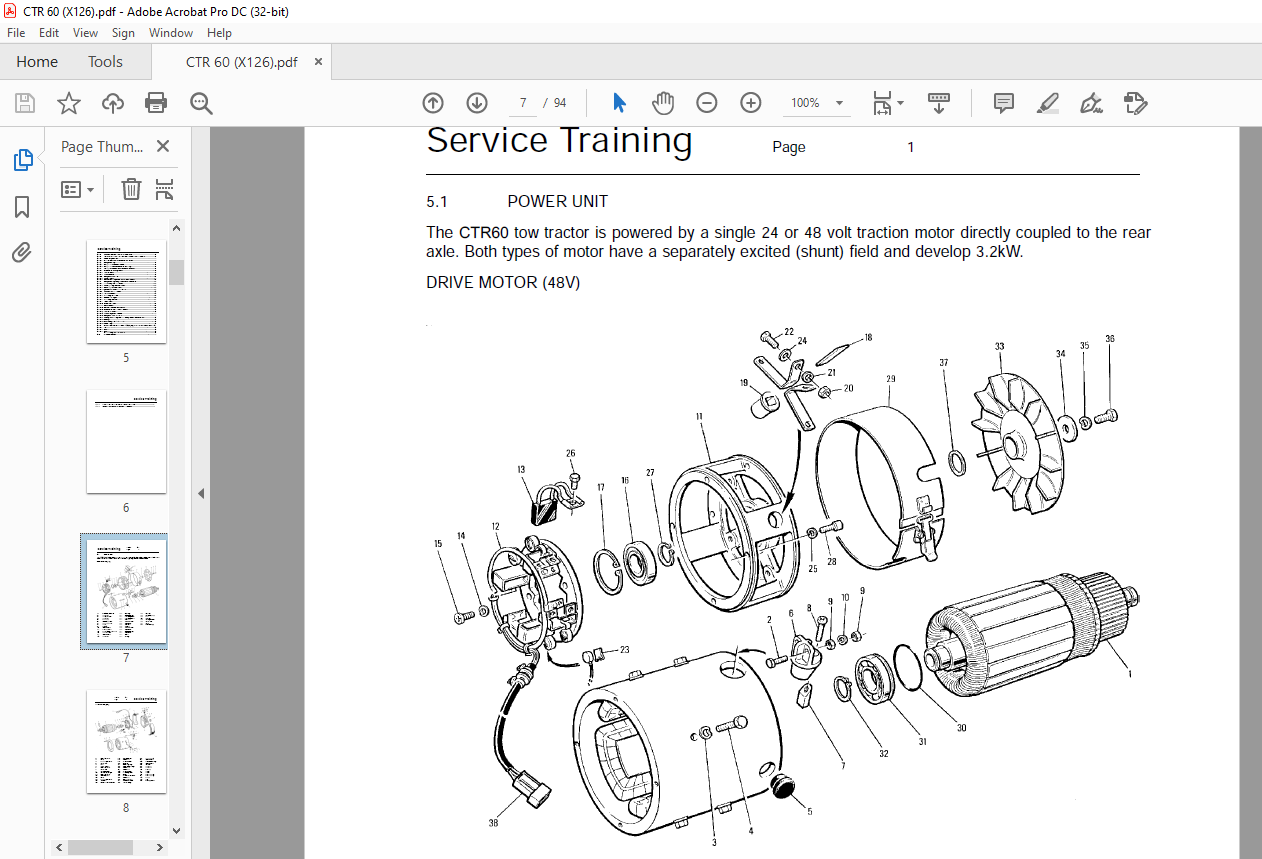

STILL STED Electric tractor CTR 60 Type 126 Service Training Manual – PDF DOWNLOAD

Service Training5.1.1 CHECKING AND REPLACING THE TRACTION MOTOR BRUSHES– Turn the keyswitch off and apply the parking brake.

– Open the battery cover and disconnect the battery.

– Release the toggle catch on the brush cover band. Slide the brushwear cable with rubber grommet

out of slot in the cover. Move the cover towards the field terminals (taking care not to damage the

brushwear cable). Remove the cover by feeding between armature and field terminals.

– At this point, in order to gain easier access to the rear brushes, the three M8 bolts securing the motor

to the gearbox can be removed thus allowing the motor to be rotated on its bearing.

– Pull back brush springs to relieve tension.

– Withdraw the brushes from their holders and check (Minimum length 15mm).

– Replace or, if necessary renew the brushes.

NOTE: Always replace brushes as a complete set.

– Release brush springs and check the brushes are seated firmly.

– Ensure that the flexible brush leads are completely free and not distorted or fouled in such a way as

to prevent the brush spring from keeping the brush in firm contact with the commutator.

– Replace the motor securing bolts if they have been removed.

– Replace the brush cover band.

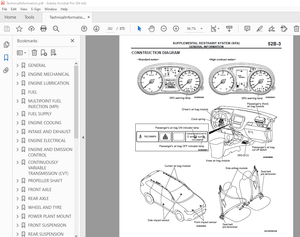

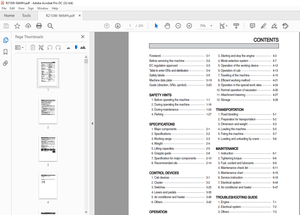

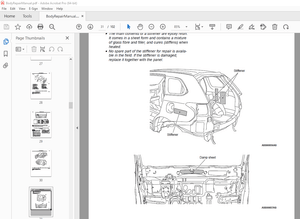

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

STILL STED Electric tractor CTR 60 Type 126 Service Training Manual – PDF DOWNLOAD

5 1 POWER UNIT 1

5 1 1 CHECKING AND REPLACING THE TRACTION MOTOR BRUSHES (48VOLT) 3

5 1 2 CHECKING AND REPLACING THE TRACTION MOTOR BRUSHES (24VOLT) 3

5 1 3 TRACTION MOTOR REMOVAL 4

5 1 4 TRACTION MOTOR – DISMANTLING (48 VOLT) 4

5 1 5 TRACTION MOTOR – DISMANTLING (24 VOLT) 5

5 1 6 COMPONENT INSPECTION 5

5 1 7 ARMATURE CHECKS 5

5 1 8 TRACTION MOTOR RE-ASSEMBLY 5

5 1 9 TRACTION MOTOR REFITTING 5

5 1 10 BEDDING OF MOTOR BRUSHES 6

5 2 REAR AXLE 1

5 2 1 REAR AXLE REMOVAL 2

5 2 2 REAR AXLE REFITTING 3

5 4 STEERING COLUMN 1

5 4 1 STEERING COLUMN REMOVAL 1

5 4 2 FRONT AXLE 2

5 4 2 1 FRONT AXLE REMOVAL 3

5 4 2 2 FRONT AXLE REPLACEMENT 3

5 5 TRAVEL CONTROL 1

5 5 1 ACCELERATOR UNIT 1

5 5 1 1 ACCELERATOR ASSEMBLY REMOVAL 1

5 5 2 DIRECTION SELECTION SWITCH 2

5 5 2 1 DIRECTION SWITCH REMOVAL 2

5 5 3 BRAKING SYSTEM 3

5 5 3 1 ADJUSTING THE BRAKE SHOES 3

5 5 3 2 ADJUSTING THE PARKING BRAKE CABLE 4

5 5 3 3 REMOVAL OF THE FRONT BRAKE DRUM AND WHEEL 5

5 5 3 4 REMOVAL OF THE REAR BRAKE DRUMS 6

5 5 3 5 INSPECTION AND RENEWAL OF BRAKE LININGS 7

5 5 3 6 REFITTING THE BRAKE SHOES AND DRUMS 7

5 5 3 7 MASTER CYLINDER REMOVAL 8

5 5 3 8 BLEEDING THE BRAKING SYSTEM 8

5 6 INTRODUCTION 1

5 6 1 ELECTRICAL SYSTEM 1

5 6 2 48 VOLT TRUCKS 1

5 6 3 24 VOLT TRUCKS 1

Service Training

5 6 4 SPEED & DIRECTION CONTROL 2

5 6 4 1 STANDING FIELD (field nom current) 2

5 6 4 2 INITIAL GENTLE ACCELERATION 3

5 6 4 3 FIELD WEAKENING 4

5 6 4 4 RAPID ACCELERATION 4

5 6 4 5 GRADIENTS 4

5 6 4 6 INITIAL SLOWING DOWN 4

5 6 4 7 SLOWING TO STOP 6

5 6 4 8 ANTI-ROLL BACK 7

5 6 5 INTERLOCKS 7

5 6 6 SEAT SWITCH 7

5 6 7 HANDBRAKE MICROSWITCH 8

5 6 8 MOTOR MONITORING 9

5 6 9 THERMAL SENSOR 10

5 6 10 DIRECTION SELECTION 11

5 6 10 1 FORWARD 11

5 6 10 2 REVERSE 11

5 6 10 3 RAPID DIRECTION CHANGES 11

5 6 11 SPEED REDUCTION – FULL TIME OPTION 12

5 6 12 SPEED REDUCTION – (switchable) 12

5 6 13 FOOT BRAKE ELECTRICAL REGENERATIVE BRAKING 12

5 6 14 ALTERNATIVE KEY SWITCHES 12

5 6 15 ALTERNATIVE BATTERY CONNECTORS 12

5 6 16 ACCELERATOR UNIT 13

5 6 17 BATTERY DISCHARGE INDICATOR AND INTERLOCK 14

5 6 17 1 BDI INTERLOCK AND ADJUSTMENT 14

5 6 17 2 ADJUSTMENT PROCEDURE 14

5 6 18 FUSES 15

5 6 19 LIGHTING AND AUXILIARY CIRCUITS 16

5 6 19 1 TRAILER SOCKETS 16

5 6 19 2 FRONT LIGHTING CLUSTER 16

5 6 19 3 REAR LAMP CLUSTER 16

5 6 19 4 HORN PUSH AND DIRECTION INDICATOR 16

5 6 20 DRIVERS DISPLAY 18

5 6 21 OPTIONS 19

5 6 21 1 DIRECTION INDICATORS AND HAZARD FLASHERS 19

5 6 21 2 LEVERS 19

5 6 21 3 HEATED DRIVERS SEAT 19

5 6 21 4 FULL LIGHTING OPTION 19

5 6 21 5 CAB OPTION 19

5 6 21 6 CAB DEMISTER 19

5 6 21 7 HOUR METER 19

Service Training

5 6 22 CONNECTOR AND STAR POINT POSITIONS 22

5 6 23 126 MAIN HARNESS – CONNECTOR PINS, DUTIES AND ROUTE 23

5 6 24 BASIC DIAGNOSTICS 31

5 6 24 1 DISPLAYED ALARMS AND POSSIBLE CAUSE 31

5 6 25 PROGRAMMING 32

5 6 25 1 DIAGNOSTIC CONNECTOR 6X7 32

5 6 25 2 DIAGNOSTIC AND PARAMETER SETTING 32

5 6 26 USING THE DEDICATED HAND HELD TERMINAL 32

5 6 26 1 PARAMETER CHANGE MENU 34

5 6 26 2 TESTER MENU 36

5 6 26 3 ALARMS MENU 38

5 6 26 4 PROGRAM VACC MENU 40

5 6 26 5 CONFIG MENU 41

5 6 26 6 SPECIAL SETTINGS AND ADJUSTMENTS MENU 42

5 6 27 PROGRAMMING USING A PERSONAL COMPUTER 44

5 6 27 1 INSTALLING THE SOFTWARE 44

5 6 27 2 CONFIGURING THE SOFTWARE 44

5 6 27 3 RUNNING THE SOFTWARE 44

5 6 27 3 1 GENERAL WINDOW PROPERTIES 44

5 6 27 4 CONNECTION TO TRUCK 45

5 6 27 5 INITIAL SCREEN 45

5 6 27 6 WORKING “OFF LINE” 46

5 6 27 7 ERROR MESSAGES 46

5 6 27 8 WORKING “ON LINE” 47

5 6 27 9 THE MENUS 47

5 6 27 10 SHORT-CUT KEYS 48

5 6 27 11 PASSWORDS 48

5 6 27 12 DEFAULT PARAMETER ACCESS 49

5 6 27 13 PARAMETER ADJUSTMENT WINDOW 50

5 6 27 14 TESTER WINDOW 50

5 6 27 15 ALARM LOGBOOK WINDOW 51

5 6 27 16 PROGRAM VACC WINDOW 51

5 6 27 17 SAVING, RESTORING AND BROWSING TRUCK INFORMATION 52

5 6 27 17 1SAVING 52

5 6 27 17 2RESTORING – “Protected menu” 52

5 6 27 17 3BROWSING 52

5 6 29 ELECTRICAL SAFETY CHECKS – (126) WITH SEM2L LTM CONTROL 54

5 6 29 1 INTRODUCTION 54

5 6 29 2 PART I 54

5 6 29 3 PART II 54

CIRCUIT DIAGRAM 126 802 01 00 58

5 10 MISCELLANEOUS 1

Service Training

5 10 1 RECOMMENDED LUBRICANTS – SPECIFICATIONS 1

5 10 2 INSPECTION AND MAINTENANCE SCHEDULE 2