$33

STILL STED Forklift Electric Pallet Track EXU-SF-20 Workshop Manual – PDF DOWNLOAD

STILL STED Forklift Electric Pallet Track EXU-SF-20 Workshop Manual – PDF DOWNLOAD

FILE DETAILS:

STILL STED Forklift Electric Pallet Track EXU-SF-20 Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 188

Downloadable : Yes

File Type : PDF

DESCRIPTION:

STILL STED Forklift Electric Pallet Track EXU-SF-20 Workshop Manual – PDF DOWNLOAD

Description

Introduction

Layout

This workshop manual essentially has 2 parts, namely:

• General information on the product, diagnosis of breakdowns and specific tools: Group 0• Repair instructions: Groups 1 to 9

- Each part of the current manual is composed of asd of separate sheets that are fledina STILL binder according to their group number. The manual is organised according to the same rules used for the spare parts catalogue, whichis divided into sub-groups (assemblies or construc tion groups).

- To make it as simple as possible to identity the assemblies presented in this manual, the number of each assembly is printed in the upper right-hand comer of each page. Where necessary, we have included tables to provide the maintenance department with relevant technical data.

- These tables must also be consulted by experienced mechanics. The manual contains a detailed description of truck design characteristics as well as component and assembly operating characteristics. To supplement the operations described in this manual, notes, instructions and explanatory diagrams have been provided.

IMAGES PREVIEW OF THE MANUAL:

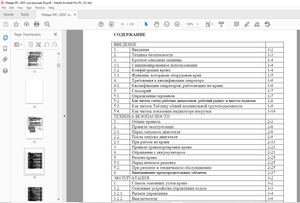

TABLE OF CONTENTS:

STILL STED Electric Pallet Track EXU-SF-20 Workshop Manual – PDF DOWNLOAD

00 Product Information

Description

Introduction

Technical descrip on

Overview

Composition of the truck serial number

Dimensions

Technical data (VDI)

Defining directions

Table of lightening torques In Nm

Safety Instructions

Parking the truck.

Battery connector

Singing and jacking the truck

02 Diagnostics

General

Diagnostic Instructions

Accessing truck Information

CAN-bus (Controller Area Network)

Error codes

Error codes

11 Motor

Traction motor

Technical data

Overview

Claassembly

Speed sensor

Speed sensor

Temperature sensor

Temperature sensor

22 Drive-Transmission

Reducer

Technical data

Disassembly

23 Drive unit

Drive unk

Description

Drive unit support

Proportional spring

30 Truck structure

Covers

Access to the technical compartment

34 Operator’s seat

Platform

Poking platform

Side protection

Side protection

42 Steering system

Ter

General

“Cold store” resistorsTM

Removing theer head

Removing the er

Bectrical steering

Steering controer

Steering motor

Recopy potentiometer Potentiometer pinion bearing

46 Wheels

Wheels

Drive wheel Stab ser rollers Support roers

49 Brake system

Bectromagnetic brake

Technical data

Checking the a gap and the braking power

Disassembly

56 Display

Display

Display

Disassembly

Digicode

Digibode option (LFM Go)

Disassembly

60 Electrical equipment

General

ectric Circuit Diagram

Overview

Connectors

Bectrical equipment

Description of the electrical panel

Disassembly

Emergency stop

Fuses

Key switch

Diagnostic connector

Signa ng equipment

Hom

Battery and accessories

Battery PzS (open-Head)

Battery change

Battery connector

Charging the battery using an external charger

On-board charger

On-board charger

64 Electronic controls

Traction controler

Technical data

Traction controlor wiring

Disassembly

70 Hydraulics

General General

71 Hydraulic control unit

Pump unit

Technical data

Disassembly

Serviding the hydraulic system

81 Lifting system

Unkage

Disassembly

Lift cylinder

Disassembly

Annex

100 Diagrams

Wring diagram

Circuit diagrams

Hydraulic diagram

Hydraulic circuit diagram