$36

STILL STED Forklift MX-X order picker Truck Generation 4, 80V Workshop Manual – PDF DOWNLOAD

STILL STED Forklift MX-X order picker Truck Generation 4, 80V Workshop Manual – PDF DOWNLOAD

FILE DETAILS:

STILL STED Forklift MX-X order picker Truck Generation 4 ,80V Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 858

Downloadable : Yes

File Type : PDF

DESCRIPTION:

STILL STED Forklift MX-X order picker Truck Generation 4 80V Workshop Manual – PDF DOWNLOAD

Product informationGeneral product information

Speed optimisation

- Speed optimisation is a software function in the FZS that reduces the driving speed of the truck in relation to the lift height and the load itis carrying. Apart from the actual driving speed, the rate of acceleration and deceleration is reduced, as are those of the auxiliary movements.

- This means, for example, that acceleration of the shift function takes place more gently at 10m than in the lowered state. Speed optimisation comes in different versions ( 2.X,3.X,4.X)and releases (e.g. 3.0,3.1,3.2,3.3)

Since each truck can have its own (customer- specific) dimensions, a different reduction char- acteristic must be calculated for each truck. This is done with the help of a special software pro- gram (“VNAP tool”). The corner points (P1-P6) resulting from these calculations are important for the stability of the truck.

The corner points are stored in the FZS.The following factors are the basis for the calcu-lation mentioned above:= Battery type* max. load carrying capability* A-dimension of the turret head* Max. outreach* Max. lift height of main lift* Max. lift height of auxiliary lift= Overall height of truck* Width of load wheel axle«Mechanical rail guidance or inductive guide

ring= Traction drive version

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

STILL STED Forklift MX-X order picker Truck Generation 4 80V Workshop Manual – PDF DOWNLOAD

Table of contents

00 Product information

General productinformation 00-2

Speedoptimisation 00-2

GENETAl © oot 00-2

BUNCH ON 00-4

Generation 3 truck performancedata i 00-6

Fanmanagement 00-7

Fanmanagement 00-7

02 Diagnostics

Software 02-2

Winflash Vi 1X —general 02-2

DeSCIIPHiON oo 02-2

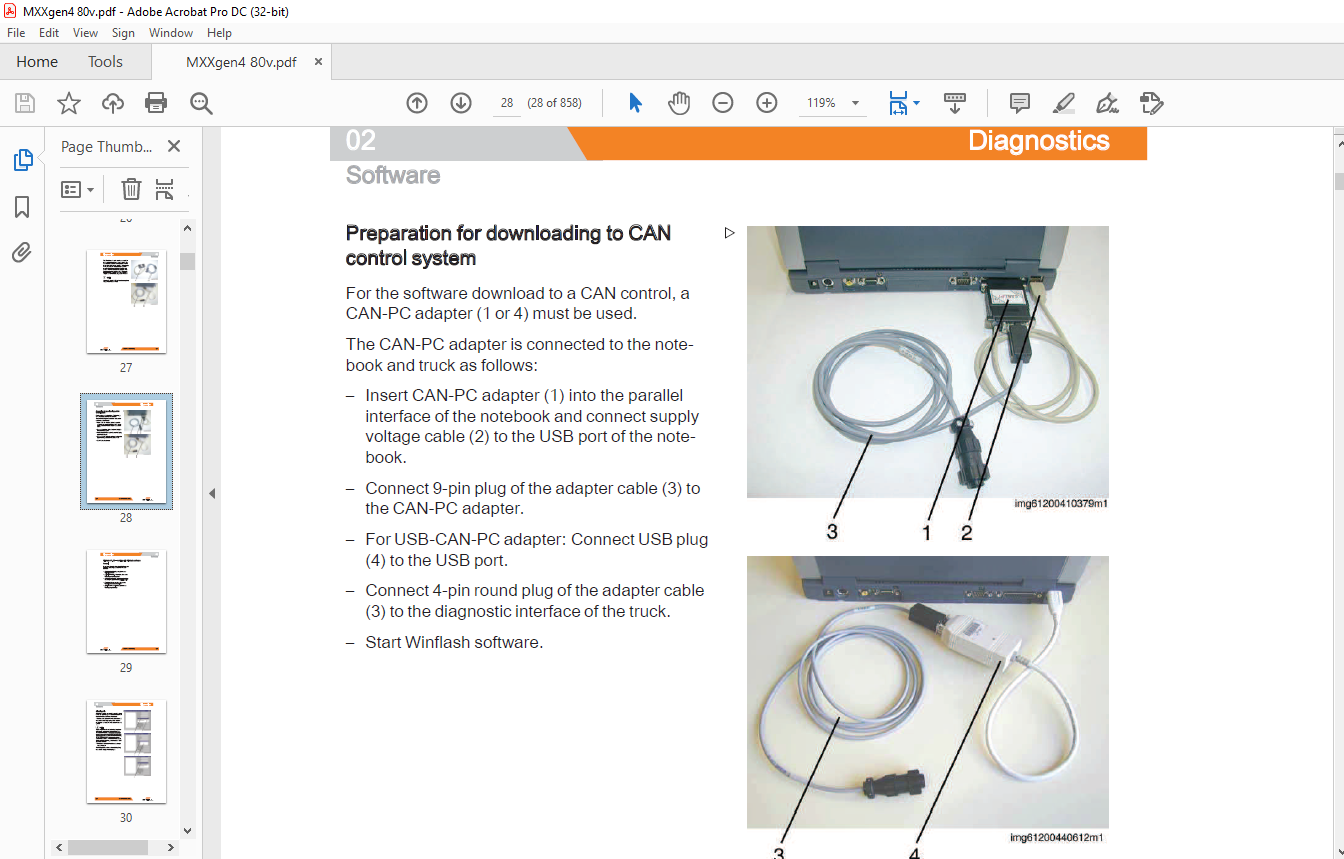

Preparation for downloading to CAN controlsystem 02-4

Winflash V1 1X —working with Winflash software 02-5

GENETAl © oot 02-5

Selectingafile 02-6

Selecting atruUCk oe 02-7

Selectinga control system 02-8

Checking the connection to the CAN control system 02-9

Start programming to CAN control systems ii 02-10

Loading VNAP identifier in truck control system 02-11

Close the Program 02-12

Errorlists 02-13

Truck central control (FZS) faultlistand information 02-13

Traction and pump controller (FPS) faultlist 02-89

Load handling controls errorlist (LHC 2) 02-110

Operating panel controller (BPS) faultlist 02-119

FleetManager Errorlist (FLM) in 02-132

Displayerrorlist 02-134

Error List Input/Output Extension Module (IOX) 02-136

Electric steering (ELK) errorlist 02-142

Inductive guidance (IZF)errorlist 02-154

Errorlistforlefthand BKS (BKS) 02-196

Errorlistforright-hand BKS(BKS) 02-203

Teach-in 02-210

Operating panel controller (BPS 2) ii 02-210

General 02-210

SEeIVICE MOTE Loo 02-211

Main lift, double liftmast 02-212

Lift mast, triplexliftmast 02-213

Auxiliary lift 02-214

Shift 02-215

SWIVEL Lo 02-216

Forkadjustment 02-217

11 Electric motor

Tractionmotor 11-2

General 11-2

Repairs 11-6

Maintenance 11-8

Speed SBNSOr 11-9

General 11-9

Repair 11-11

Temperature SBNSOT 11-12

General 11-12

LT 11-13

Repair 11-14

20 Mechanical drive axle

Frontbevelgears 20-2

General 20-2

12 20-3

REPEAT © tt 20-4

Maintenance 20-9

34 Driver’s compartment

Driverscab 34-1

Tilting order picking barrier 34-1

[MODULE] © ttt tee eee ee 34-1

42 Steering

Electricsteering 42-2

General 42-2

Emergencysteering 42-5

Steeringunit 42-6

GENEIAl oot 42-6

TES 42-8

REPaINS 42-8

Maintenance 42-11

Setpointpotentiometer 42-11

GENEIAl «oo 42-11

Test 42-12

REPaIr ot 42-13

Actual value potentiometer 42-14

GENETAl Lott 42-14

= PE 42-15

REPaIrS 42-16

Referenceswitch 42-17

GENETAl Lott 42-17

REPaIrS 42-18

43 Mechanical guidance

Guideelements 43-2

General 43-2

Test 43-3

Repairs 43-4

Aisledetection 43-7

General 43-7

Test 43-7

44 Inductive guidance

Inductiveguidance 44-2

General 44-2

Test 44-8

Repairs 44-8

Centralunit 44-12

General 44-12

Test 44-13

Repair 44-13

Periherals 44-15

Antennas LL 44-15

General «a 44-15

Testing «oo 44-16

REPaINS 44-16

GuideWire 44-17

General «a 44-17

Frequency generator otitis 44-18

General Lo 44-18

Aisledetection 44-20

General 44-20

Steering angle limiter (LWB) 44-22

General 44-22

1 44-22

Repairs 44-23

Maintenance 44-24

46 Wheels and tyres

Wheels 46-2

General 46-2

Test 46-6

Repairs 46-8

Maintenance 46-12

49 Brake system

Brakemodes 49-2

General 49-2

Hydraulicparkingbrake L 49-6

General 49-6

Test 49-10

Repairs 49-13

Maintenance 49-19

Pressure SBNSOr 49-20

GENEIAl oo 49-20

Test 49-22

REPAINS Lt 49-24

Accumulator 49-27

GENEIAl ot 49-27

Test 49-28

REPAINS Lt 49-29

Valve block 49-31

General 49-31

Electromagnetic parkingbrake ol 49-35

General 49-35

Test 49-37

REPAIrS 49-42

Maintenance 49-50

50 Operating devices

Operatingpanel 50-2

Controls and displays (BPS 2) 50-2

General 50-2

REPaIr oo 50-9

Teach-in ofthe operatinglever i 50-22

Braking deceleration values — measurementand display 50-23

Operating panel emergency lowering function 50-23

Setting the display brightness 50-24

56 Display elements

Operatingconsole 56-1

General 56-1

[MODULE] 56-1

Electrics 56-1

[MODULE] 56-1

Mechanics 56-2

General 56-2

Testing «oo 56-3

Repairing horizontal adjustment 56-4

Repairing the folding mechanism 56-6

Repairing the vertical adjustment gas compressionspring 56-7

Repairing the gas compression spring pistonrodhead 56-10

Maintenance 56-12 60-2

Distance sensormainlift 60-2

GENEIAl 60-2

REPaIr oo 60-4

Maintenance 60-15

Load detectionsensor 60-15

Load detection sensor7B40 60-15

Overhead guardswitch 60-17

General oo 60-17

Testing Le 60-18

RPA «Le 60-20

Maintenance 60-22

64 Electronic controllers

Drive and pump controller (FPS)A10 64-2

General 64-2

Test 64-7

CONVEIET 64-10

General 64-10

Test 64-19

Repair 64-20

Maintenance 64-21

Otherelectroniccontrols 64-22

Truckcontrolunit4 (FZS4)8UB0 64-22

GENEIAl oo 64-22

Testing ooo 64-24

REPAIr o 64-28

Maintenance oe 64-30

Load handling controls (LHC) 8U61 64-31

GENEIAl ot 64-31

REPAIr «ot 64-34

On-board charge confrollerBLS 64-34

GENEIAl ot 64-34

REPAIr «ot 64-43

Input/outputcontroller OX 64-44

General 64-44

RPA «oe 64-47

CANDUS 64-48

General 64-48

70 Hydraulics, general

Basichydraulics 70-2

Oiltank 70-2

GENEIAl oot 70-2

TES 70-5

REPAINS «i 70-6

Maintenance oe 70-10

Table of contents

Breatherfilter 70-11

GENEIAl «oo 70-11

Test 70-12

Maintenance 70-13

71 Working hydraulics

Pumpunits 71-2

General 71-2

Test 71-3

Repair 71-4

Maintenance 71-6

Hydraulicpump 71-7

Testing «oo 71-7

REPaINS 71-8

Pump motor 71-12

GENEIAl «oo 71-12

Test 71-15

REPaINS 71-17

Maintenance 71-21

Temperature SENSOT LL 71-22

GENEIAl «oo 71-22

Testing «oo 71-23

REPaINS 71-24

SPEEA SENSOr 71-25

GeNEIaAl 71-25

Testing 71-26

Repair 71-27

76 Valves

Pressurereliefvalve 76-2

General 76-2

Testing oo 76-3

Repairs 76-4

Proportionalvalves 76-5

Main liftlowering proportionalvalve 76-5

GENETAl «ot 76-5

REP 76-7

Shiftproportional valve 76-8

GENETAl «ot 76-8

CHECKING ttt 76-9

Repair Lo 76-10

Swivelproportionalvalve 76-12

General oo 76-12

CheCKINg «ooo 76-13

Auxiliary lift lowering proportional valve 76-14

General oo 76-14

CheCKINg «ooo 76-15

RPA «Le 76-16

Valveblock 76-18

Chassisvalveblock 76-18

GENEIAl oo 76-18

Testingand adjusting coo 76-22

REPAIr «oe 76-24

High-pressure filter 76-24

81 Lift mast

Telescopicmast 81-2

Liftmast-general 81-2

Test 81-4

REPaIrS 81-11

Maintenance 81-33

Triplemast 81-37

General 81-37

Test 81-42

REPaIrS 81-50

Maintenance 81-74

Auxiliary liftmast 81-78

Load Sensor 81-78

GENIAL oo 81-78

Testing ooo 81-79

REPAIr o 81-81

6 Attachments

Turrethead 86-3

General 86-3

Shifting 86-4

General Le 86-4

CheCKINg oo 86-7

REPAIr «oe 86-10

Maintenance ee 86-16

Shiftpotentiometer 86-17

GENETAl Lt 86-17

Test 86-18

REPaIr ot 86-19

Shiftcontourswitch 86-21

GENEIAl «oo 86-21

Checking «oo 86-22

REPaIr ot 86-23

Swivelling 86-24

GENETAl Lott 86-24

CHECKING «tt 86-26

Repair Lo 86-28

Maintenance 86-32

Swivelpotentiometer 86-33

GENETAl Lott 86-33

= PE 86-34

Repair Lo 86-35

Swivelcontourswitch 86-36

GENEIAl «oe 86-36

Checking «oo 86-37

Repair 86-38

Pullingcylinder 86-39

GENEIAl «oe 86-39

Checking «oo 86-40

RPA «oe 86-41

Maintenance 86-43

Auxiliary liftmast 86-44

GENEIAl 86-44

CHECKING «tt 86-47

Repair Lo 86-48

Maintenance 86-53

Auxiliary lifteylinder 86-54

GENETAl Lott 86-54

CHECKING «tt 86-56

Repair Lo 86-57

Maintenance 86-60

Auxiliary liftdistance sensor 86-61

GENEIAl «oo 86-61

Checking «oo 86-64

Repair 86-65

Valveblock 86-70

GENEIAl «oe 86-70

Checking «oo 86-71

Repair 86-72

Maintenance 86-74

Hydraulicmotor 86-75

General oo 86-75

CheCKINg «ooo 86-76

RPA «Le 86-77

Maintenance 86-78

Overreachfunction 86-79

OVEI-IEAaCh LL 86-79

Telescopicfork 86-81

General 86-81

Testing 86-88

Repairs 86-89

90 Special equipment/accessories

Optionalequipment 90-3

Forkeycle 90-3

GNEIAl oo 90-3

Heightpreselection 90-7

GNEIAl oo 90-7

FUNCHON 90-8

Teach-in of shelfheights (levels) iii 90-11

Loaddetection 90-12

General Le 90-12

Intelligent load capacitydiagram 90-14

GENEral 90-14

Accesschecking 90-16

GENIAL oo 90-16

“PIN code” generation and management i 90-17

Special “PIN Code” Lo 90-18

Fillingaid 90-19

GENIAL oo 90-19

FUNCHON 90-21

ZAG 90-25

Determining the braking distance 90-25

ZAGIinductive 90-28

GENEral Le 90-28

Activating the option “ZAG inductive” 90-29

Inductive proximity switches 90-30

Determining the lengths ofthe steelsheets 90-31

Mounting the steelplates i 90-32

Classification 0f Zones 90-35

Suppression of interfering metalparts 90-41

DIAGNOSIS © oo tt 90-42

ZAGmagnetic 90-43

General «a 90-43

Activating the “magnetic ZAG” option 90-44

Magneticswitches 90-46

Switching magnets 90-50

Maximumstopping distance 90-53

Switch solenoid installation positions 90-54

Classificationofzones 90-60

Diagnosis «oo 90-65

ZAGreflexdli 90-66

GENEIAl «oo 90-66

Activating the option “ZAG reflexli” 90-67

Reflector types 90-68

Mounting height of the reflectorsontherack 90-71

Arrangementofreflexsensors 90-73

Maximumstopping distance 90-75

Mounting thereflectors 90-76

Classificationofzones 90-80

Importantregulations 90-84

Diagnosis «oo 90-85

ZAG RFID 90-86

GENEIAl © oot 90-86

Activating the “ZAG RFID” option i 90-87

ZAGTunction variants LL 90-90

Displacement transducer it 90-93

RFID read/write device (LSG) «o oo it 90-96

TraNSPONAEIS «oot tet 90-100

Diagnostics «oot 90-104

COMMISSIONING © «ott ee 90-109

Devices 90-112

Dynometer 90-112

General productinformation 2

Speed optimisation 2

General oe 2

FUNCHON Lo 4

Generation truck performance data 6

Fanmanagement 7

Fan management 7