$30

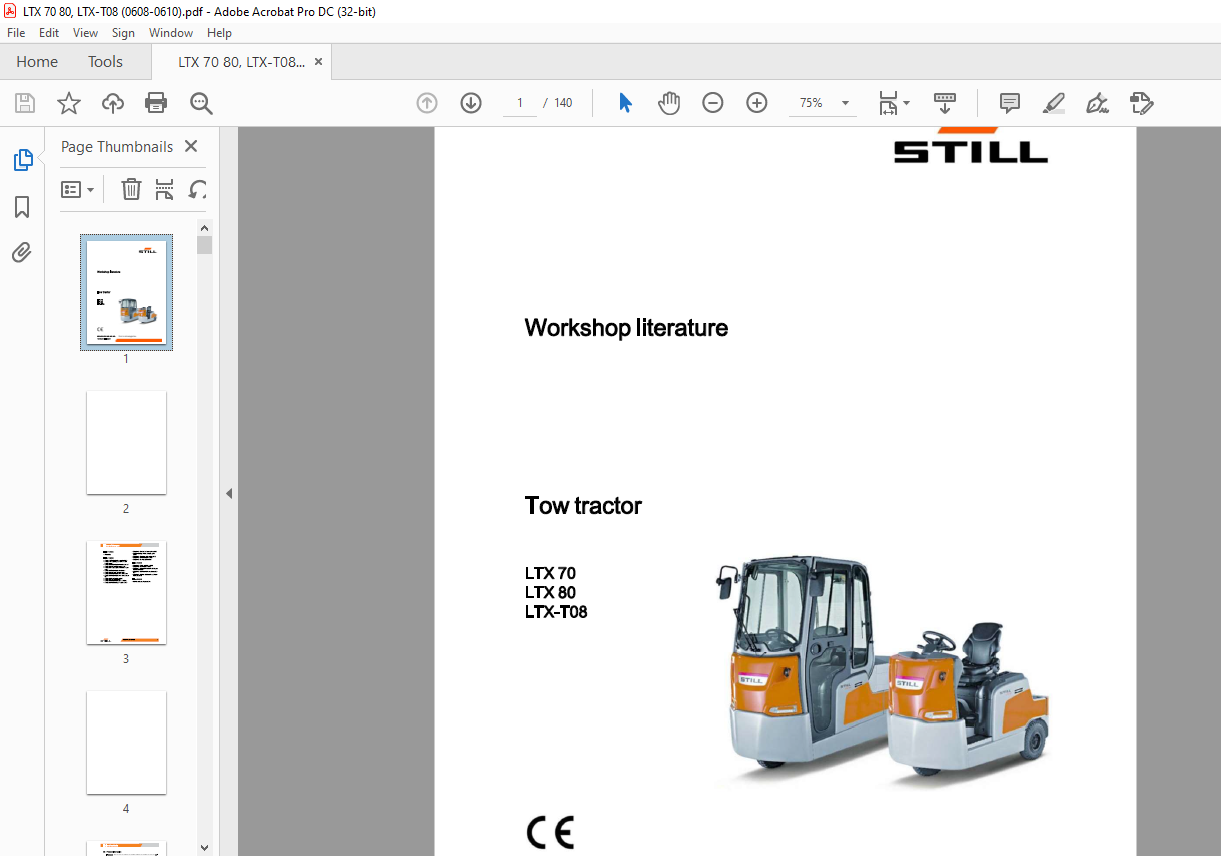

Still STED forklift Tow tractor LTX70 LTX80 LTX-T08 Workshop Manual – PDF DOWNLOAD

Still STED forklift Tow tractor LTX70 LTX80 LTX-T08 Workshop Manual – PDF DOWNLOAD

FILE DETAILS:

Still STED forklift Tow tractor LTX70 LTX80 LTX-T08 Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 140

Downloadable : Yes

File Type : PDF

DESCRIPTION:

Still STED forklift Tow tractor LTX70 LTX80 LTX-T08 Workshop Manual – PDF DOWNLOAD

Foreword

Technical description

Introduction

The tow tractor and the carrier have been developed to meet the most arduous application requirements. They comply with all current European directives. The tow tractor and the carrier have a nominal towing capacity of 6.2 to 8 tonnes and an unladen traction speed of up to 20 km/h.

There are three different models:

The 7-tonne model

The 8-tonne model

The carrier model

Driver’s compartment and controls

For optimal ergonomics, a low step facilitates access to the driver’s compartment. Adjusting all the controls and the seat contributes to optimum driver comfort and efciency. The arrangement of the pedals, controls and steering wheel (automotive), together with the electronic control, provides smooth handling.

The accurate recording of the tow tractor’s shift

time, the hour meter and battery discharge

indicator allow:

Better management of maintenance intervals

Minimised risk of battery damage. The truck

can be equipped with an electrolyte level

sensor

Chassis

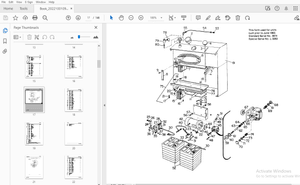

The chassis is designed for maximum strength and rigidity. A low centre of gravity ensures safe road handling, and its compact size ensures excellent manoeuvrability. The traction motor and electronic control are protected within the chassis but remain easily accessible for servicing. The battery is located between the two axles to obtain maximum stability and to allow quick and easy removal

Drive and transmission

A powerful 4.5-kW traction motor (AC technology) is mounted transversely on the drive axle. Power is transmitted to the rear wheels through a reduction gearbox as well as a differential

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Still STED forklift Tow tractor LTX70 LTX80 LTX-T08 Workshop Manual – PDF DOWNLOAD

00 Product information

Foreword 00

Technical description 00

Safety guidelines 00

Slinging the tow tractor 00

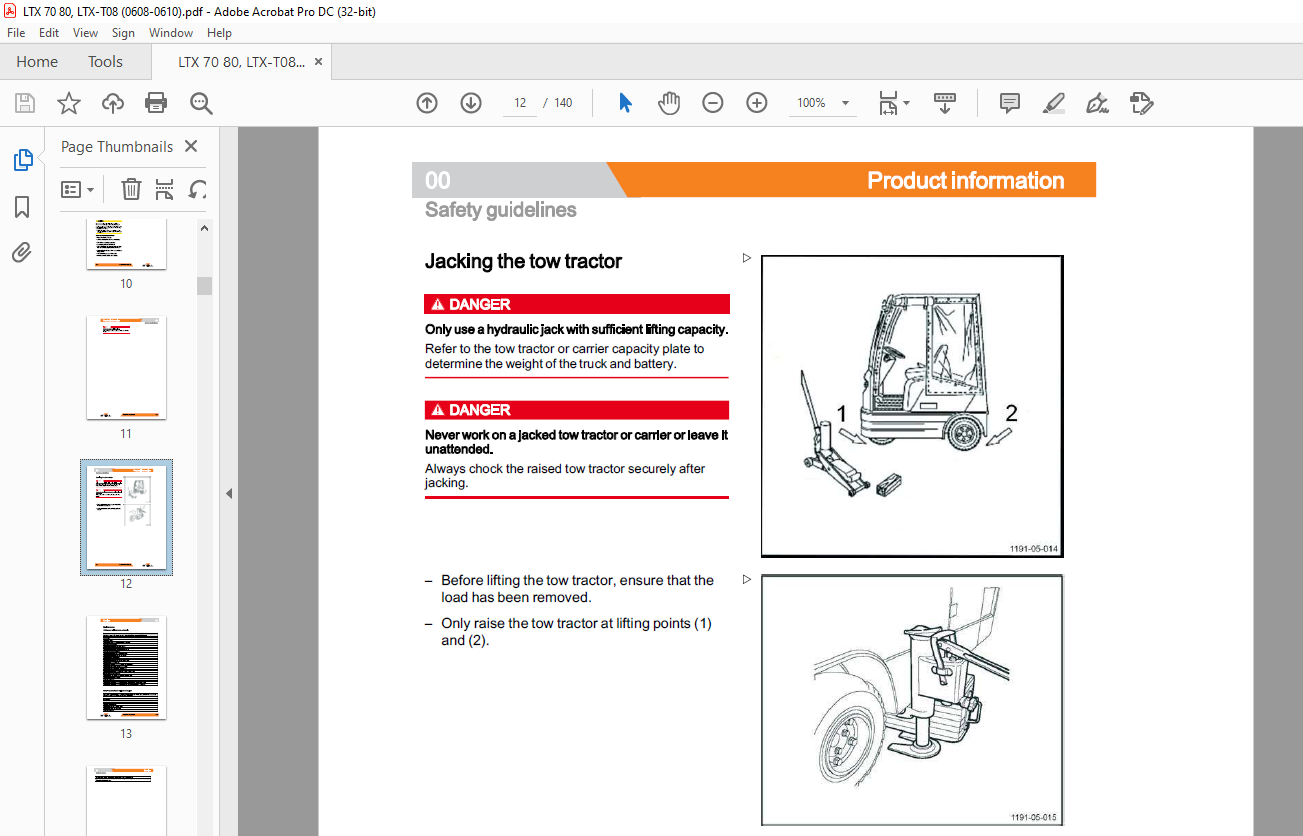

Jacking the tow tractor 00

01 Service

Maintenance 01

1000-hour maintenance schedule 01

3000-hour/two-year maintenance plan 01

Tools 01

Standardised tightening torques for standard-pitch threads and fine-pitch threads 01

Measuring and testing equipment 01

02 Diagnostic

Diagnostic tool 02

STEDS-Navigator 02

Truck diagnostics 02

Overview 02

CAN box diagnostics 02

Connecting a laptop to the USB CAN Box 02

CAN bus network 02

Error codes 02

Reading and deleting the error list 02

TRACTION fault codes 02

11 Motor

Rear axle 11

Overview 11

Shock absorbers 11

Cleaning and checking the gearbox breather 11

Replacing the rear axle 11

Traction motor 11

Technical data 11

Replacing the bearing

Checking the motor 11

Preparation 11

Visual inspection 11

Traction motor winding test 11

Rotor testing 11

Cleaning the motor 11

Motor connections 11

Location of motor cables 11

Power module connections 11

Motor sensors 11

Rev sensor 11

Temperature sensor 11

23 Transmission

Transmission 23

Replacing the transmission seal 23

30 Chassis, bodywork and fittings

Driver’s seat 30

Changing the seat contact 30

Driver’s cab 30

Replacing the windscreen wiper motor 30

Replacing the windscreen 30

Battery compartment 30

Installing and adjusting the battery door 30

42 Steering, braking and wheels

Steering system 42

Steering angle sensor 42

Steering column 42

Braking 42

Functional diagram of the brake circuit 42

50 Control devices

Accelerator 50

Function 50

Changing the accelerator

Braking 50

General 50

Electrical braking 50

Blue-Qmode 50

Energy-saving mode 50

Parameterising Blue-Q mode 50

60 Electrics/electronics

General 60

Safety guidelines for electrical equipment 60

Cleaning the electrical system 60

Insulation testing 60

Electromagnetic compatibility 60

Traction controller 1 A 1 60

LAC traction controller (1A 1) 60

Functions of the “Inputs/Outputs” of the LAC 60

Fan 60

Fan 60

Changing the fan 60

Electric components 60

Emergency off switch 60

Voltage converter U1 (75 W) 60

Voltage converter U2 (500 W) 60

Main fuses 60

Line switch 1 KO 60

ABE2 display 60

Symbols 60

Display 60

Replacing the ABE 2 display 60

Maintenance interval indicator 60

Display of the remaining travel time 60

STILL

VI 11918012101 EN – 09/2019

Table of contents

Discharge indicator 60

CPP control box 60

Functions of CPP (Can Power Port) control boxes 60

CPP 1 (front lighting) 60

CPP 2 (rear lighting) 60

CPP 3 (cab option) 60

CPP 4 (electric hook and additional hydraulics) 60

CPP 6 (top rear lighting) 60

FleetManager (option) 60

FleetManager description 60

Access control 60

FleetManager options 60

On-board charger (option) 60

Description 60

Charger operation 60

Parameterising the charger 60

Opportunity charging (option) 60

Description of opportunity charging 60

Electric coupling (option) 60

Description of the coupling 60

Liftrunner (option) 60

Features 60

Location of components 60

Description 60

90 Special equipment

Battery holders 90

Changing the battery with the Fork Off tool 90

Changing the battery with the Roll Off tool 90

Heating system 90

Electric heating