$20

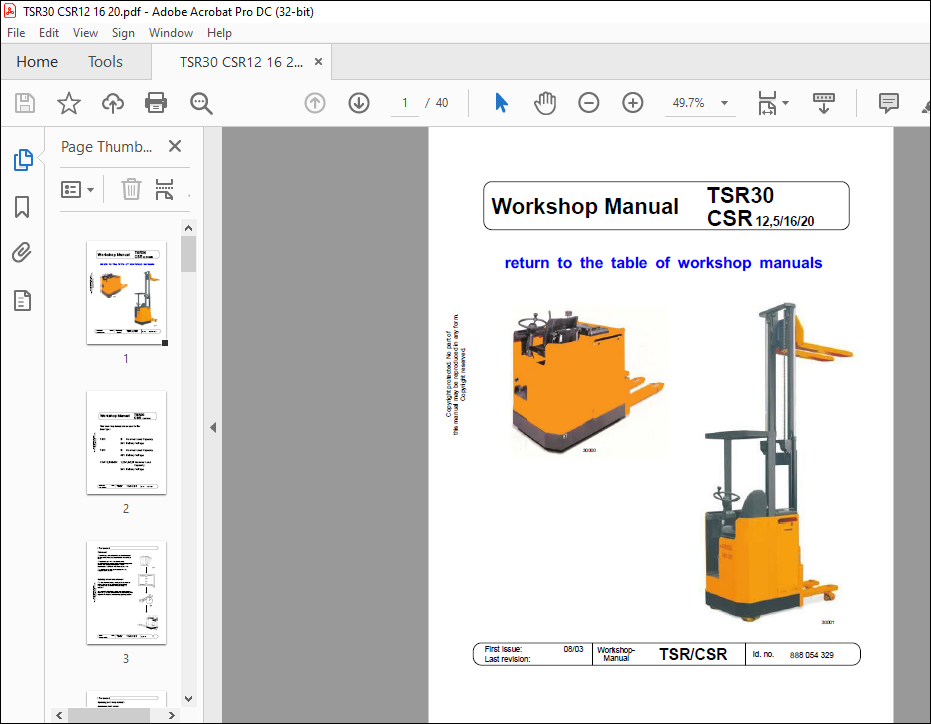

STILL STED Forklift TSR30 CSR 12,5 16 20 Workshop Manual – PDF DOWNLOAD

STILL STED Forklift TSR30 CSR 12,5 16 20 Workshop Manual – PDF DOWNLOAD

FILE DETAILS:

STILL STED Forklift TSR30 CSR 12 5 16 20 Workshop Manual – PDF DOWNLOAD

Language : English

Pages : 40

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

STILL STED Forklift TSR30 CSR 12 5 16 20 Workshop Manual – PDF DOWNLOAD

Section Contents Sheet

Foreword 1

Updating of workshop manuals 1

Exchanging faulty sheets 2

Insertion of supplementary sheets 2

Remarks, imprint 3

Sections 4

Contents 5

1 Vehicle data

Identification 1-01

Signs on the vehicle 1-02

2 Travel motor

General 2-01

Technical Data 2-02

Terminals 2-02

Removing the drive motor 2-03

Replacing the carbon brushes 2-04

Maintenance 2-05

General 2-05

Cleaning 2-05

Visual inspection, replacing damaged parts 2-06

Checking the brush unit,

replacing the carbon brushes 2-07

Commutator 2-08

Bearings 2-08

3 Drive wheel

Replacing 3-01

Removal 3-01

4 Gear

Removing 4-01

Lubricating the bogie bearing 4-02

Changing the gear oil 4-02

Oil change 4-03

Oil change procedure 4-03

5 Brake

Function 5-01

Service brake (brake pedal) 5-01

Parking brake (handbrake) 5-01

Guide to components 5-02

Installing/removing the drive motor brake 5-03

Removal 5-03

Installation 5-03

Adjusting the brake clearance 5-04

Checking the brake lining thickness 5-04

Adjusting the brakes 5-04

Adjusting the handbrake 5-05

Checking the setting 5-05

Adjusting the brake pedal 5-06

Measuring the brake deceleration 5-07

General 5-07

Preparations for measurement 5-07

Measuring the brake deceleration 5-08

Evaluating the measurement 5-08

Main brake cylinder 5-09

Bleeding / filling the brake system 5-10

Filling the brake system 5-10

Bleeding the brake system 5-10

6 Steering

General 6-01

Structure of the steering system 6-02

Steering sensor 6-03

General 6-03

Slipring system 6-04

Adjusting the steering sensor 6-05

General 6-05

Adjustment when installed 6-05

Adjustment when not installed 6-07

Servo unit 6-08

General 6-08

Terminal markings on terminal board 6-08

Exchanging the carbon brushes 6-09

Specifications 6-09

Steering controler 6-10

General 6-10

Function 6-10

Safety monitoring 6-11

Adjusting the current limitation 6-12

7 BDI/HM

Curtis Combi-Controller 803 7-01

General 7-01

Pin assignment 7-02

Setting the final discharge voltage 7-03

Technical data 7-04

Accumeter EL-AC5 (up to 6/93) 7-05

Battery discharge indicator 7-05

Hour meter 7-06

Accumeter EL-AC5 (from 7/93) 7-07

General 7-07

Installation 7-07

Electrical connection 7-08

Specifications 7-09

Adjusting accumeter EL-AC 7-10

8 Circuit board

Circuit board A1with adapter card A8 8-01

Components 8-01

Fuses 8-02

Testing the fuses 8-03

Components 8-04

Rating plate 8-04

Contactor clearance 8-04

Contact pressure 8-04

9 Travel control

General 9-01

Functional characteristics 9-01

Cycle ratio and current profile 9-01

Setpoint value current, frequency characteristic 9-02

Primary current circuit 9-03

Ignition process 9-03

Thyristors 9-04

Function 9-04

Thyristors 9-05

Installation 9-05

Installation instructions 9-05

Thyristor power block 9-06

General 9-06

Diodes 9-07

Functional characteristics 9-07

Layout, installation 9-07

Section Contents Sheet

9 Travel control

Diodes 9-08

Testing the diodes 9-08

Diode power block 9-09

General 9-09

Testing 9-09

Terminal 9-09

Functional Characteristics 9-10

Testing the primary current 9-11

Test procedure 9-12

Current actual value sensor n35 9-13

Functional characteristics 9-13

Control circuit board u200 9-14

Functional characteristics 9-14

Checking the safety circuit 9-14

Removing 9-15

Settings 9-15

Speed restriction GB (from 12/90) 9-15

Ramp-up time HZ 9-15

Reversing current RS 9-16

Drive current FS 9-16

Drive reduction 2,5kph 9-17

Adjustment of drive current 9-18

Current setting 9-18

Adapter card A8 9-20

General 9-20

Settings 9-21

Default factory settings 9-21

LED display 9-22

Measured signals 9-23

Block circuit diagram 9-24

Wiring diagram 9-25

Circuit board A1 with adapter card A8 9-25

10 Accelerator pedal

General 10-01

Functional characteristics of the magnetoresistor 10-01

11 Hydraulics

Block diagram 11-01

Hydraulic circuit diagram 11-01

Pump assembly 11-02

General 11-02

Function LIFTING 11-03

Function LOWERING 11-04

Electrically pilot controlled non-return valve 11-05

Replacing the carbon brushes 11-06

Removal / Installation 11-06

Removal 11-07

Installation 11-07

Removing the pump motor 11-08

Hydraulic pump 11-09

General 11-09

Removing the hydraulic pump 11-10

Setting the maximum pressure 11-12

Recommended values for pressure adjustment: 11-12

Hydraulic oil change 11-13

Bleeding the lifting cylinder and hydraulic system of air 11-14

Procedure 11-14

12 Hydraulic system

Diagram of the hydraulic system 12-01

Pump unit 12-02

Removal 12-02

Carbon brushes 12-02

Directional slide valve block 12-02

Adjusting the maximum pressure valve 12-03

13 Lifting device

Function of the angled lever 13-01

Adjustment 13-01

Drawbar adjuster 13-01

End stops at bottom 13-01

End stops at top 13-02

Lift stop 13-02

Angled lever – pressure rods 13-03

Lifting cylinder, low lift 13-04

Guide to parts 13-04

Adjusting the tension springs 13-04

Copyright protected No part of

this manual may be reproduced in any form

Copyright reserved Issue: 08/03 Workshop-

Replaces issue: Manual TSR/CSR Sheet no

Section Contents Sheet

14 Mast

Basic lift 14-01

General 14-01

Setting the height when lowered 14-01

General 14-02

Load carriage, concealed cylinder version 14-02

Load carriage, exposed cylinder version 14-02

Function 14-03

Removing the telscopic load carriage 14-04

Mounting 14-04

Removing the lift cylinder 14-05

Support rollers – outer mast 14-06

Lift bracket 14-07

General 14-07

Removing 14-07

Lift bracket 14-08

Setting the adjusting screws 14-08

Chains 14-09

General 14-09

Setting the control chains 14-10

Setting the clearance lift chain 14-11

Chain setting at the triplex load carriage 14-12

Testing with/without rated load 14-12

99 Maintenance

General 99-01

Safety instructions 99-02

Handling fuels and lubricants 99-02

Brake 99-03

Testing the function of the service brake 99-03

Testing the function of the parking brake 99-03

Testing the function of the reversing brake 99-03

Wear limit for the brake lining 99-03

Battery 99-04

Checking the electrolyte level 99-04

Checking the electrolyte density 99-04

Cleaning the battery 99-04

Battery lock 99-05

Battery charger 99-05

Operating elements 99-06

Ease of movement 99-06

Steering 99-07

Ease of movement 99-07

Cut-out in the event of error 99-07

Steering chain 99-07

Reverse steering 99-07

Table of Contents

10

Copyright protected No part of

this manual may be reproduced in any form

Copyright reserved Issue: 08/03 Workshop-

Replaces issue: Manual TSR/CSR Sheet no

Section Contents Sheet

99 Maintenance

Lifting chains 99-08

General 99-08

Checking the lifting chains for damage 99-09

Checking the lifting chains for damage 99-12

Checking the chain elongation 99-13

Replacing the lifting chains 99-14

Lubricating the lifting chains 99-15

Cleaning the chains 99-16

Hydraulic tank 99-17

Volume 99-17

Seals 99-17

Soiled oil 99-17

Wheels 99-18

Wear 99-18

Wheel bearings 99-18

Load wheels 99-18

Motor 99-19

Carbon brushes 99-19

Checking the brush springs 99-19

Other maintenance work 99-19

Gear 99-20

Changing the gear oil 99-20

Noises 99-20

Leaks 99-20

Mast 99-21

Mast rollers 99-21

Guide rollers of the fork holder 99-21

Windscreen 99-21

Lifting cylinder 99-21

Guides, surfaces 99-21

Forks 99-21

Chain adjustment 99-21

Pump assembly 99-22

Carbon brushes 99-22

Oil level 99-22

Noises 99-22

Soiling 99-22

Lubrication plan 99-23

Lubricants 99-23

Disposal 99-23

Lubrication plan 99-24

IMAGES PREVIEW OF THE MANUAL: