$36

STILL Wagner STED Forklift EK 10 Workshop Manual – PDF DOWNLOAD

STILL Wagner STED Forklift EK 10 Workshop Manual - PDF DOWNLOAD

FILE DETAILS:

STILL Wagner STED Forklift EK 10 Workshop Manual - PDF DOWNLOAD

Language : English

Pages : 196

Downloadable : Yes

File Type : PDF

DESCRIPTION:

STILL Wagner STED Forklift EK 10 Workshop Manual - PDF DOWNLOAD

Foreword

This workshop manual provides specifications and describes functional characteristics of the standard truck. This provides you with a comprehensive documentation to ensure better understanding of the vehicle technology and so permit correct maintenance and repair work to be carried out. The workshop manual is always updated by supplementary sheets.

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

STILL Wagner EK 10 Workshop Manual - PDF DOWNLOAD

Additional lift NM/HM

Additional load carriage

Adjustment of steering controller

Adaption, option

Bleeding the lift cylinder

Block diagram ting/lowering

Block diagram steering

Block diagram of steering system

Block diagram of travel

Block diagram of hydraulic system

Bogle bearing

Brake deceleration

Brake function

Brake rotor

Brake system

Bubble reservoir

Carbon brushes, pump motor

Carbon brushes, servo unit

Carbon brushes, travel motor

Changing the battery

Changing the gear oil

Changing the hydraulic oil

Cylinder support

Direction of rotation

Discharge indicator Curtis

Distributor block NM/HM

Drive wheel

Driver cab, removal

Electrical steering system

Electrical system

Electromagnetic spring brake

Electromagnetic spring brake, adjustment

Electromagnetic spring brake, brake clearance C6

Electromagnetic spring brake, braking force C7

Electromagnetic spring brake, dismantling C5

Electromagnetic spring brake, removal

Error code, evaluation logic

Evaluation logic

Evaluation logic, displays

Final discharge voltage

Flashing error code

Flyer chains

G

Gear

Gear oil amount

Gear oil, classes

H

Highpuls

Hydraulic pressures

Hydraulic circuit plan

Hydraulic hoses

Hydraulic oil amount

Hydraulic oil, classes

Hydraulic pump unit

Hydraulic system

Idling wheel

Idling wheels, removal Impressum

Insulation resistance

L

Line break protection

Lifting device

Lifting function

Lift chain

Lowering function

Lubrication plan HO

Lubrication plan HO

Lubrication plan NM

Lubrication plan NO

Lubricants

M

Main lift cylinder HO/HM Main lift cylinder NO/NM

Maintenance, lift chain

Maintenance, travel motor

Module 3U50

Modules

Maximum pressure valve

Operating hours counter

P

Parameters, setting

Potentiometers and LEDs

Programming unit PMC

Pulley

Pump unit, general

Pump unit, removal

S

Safety test of steering system Series-wound motor

Sections

Service switch

Service switch, adjustement

Servo unit, installation

Servo unit, removal

Servo unit, steering system

Setpoint potentiometer 1gear

Setpoint potentiometer 5 gear

Setpoint potentiometer Side carriage

Special tool

Steering chain, installation

Steering chain, removal

Steering controler, adjustment

Steering controler, description

Steering gear

Support carriage

Support rollers

Support rollers

T

Table of parameter settings for travel Terminal board

Travel control, adjustment

Travel control, error display

Travel control, flashing code

Travel control, general

Travel control, id Nos

Travel control, input and output signals Travel control, safety monitoring

Travel control, switchboard

Travel control, terminals

Travel drive

Travel motor, general

Travel motor, installation Travel motor, Maintenance Travel motor, remove

Travel, parameters Travel, setpoint Troubleshooting

Updating the manual

U51

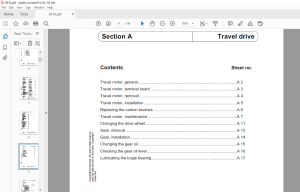

Contents

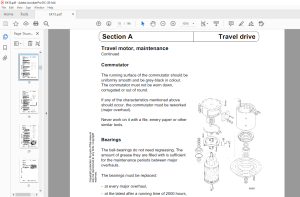

Travel motor, general

Travel motor, terminal board

Travel motor, removal

Travel motor, installation Replacing the carbon brushes

Travel motor, maintenance

Changing the drive wheel

Gear, removal

Gear, installation

Changing the gear oil

Checking the gear oil level

Lubricating the bogie bearing