$38

Tadano All Terrain Crane ATF100G-4 Operation Manual – PDF DOWNLOAD

Tadano All Terrain Crane ATF100G-4 Operation Manual – PDF DOWNLOAD

FILE DETAILS:

Tadano All Terrain Crane ATF100G-4 Operation Manual – PDF DOWNLOAD

Language : English

Pages :455

Downloadable : Yes

File Type : PDF

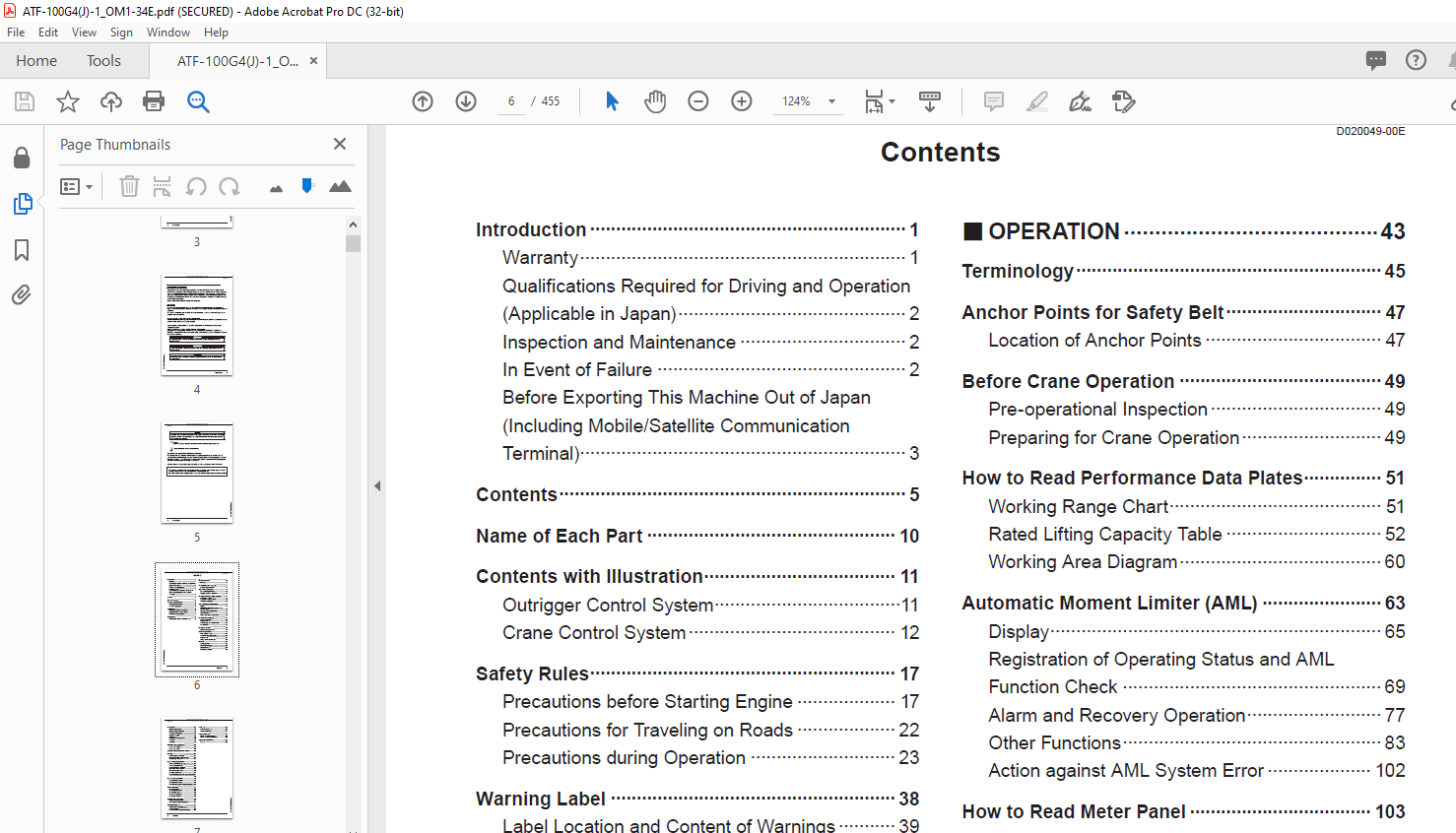

TABLE OF CONTENTS:

Tadano All Terrain Crane ATF100G-4 Operation Manual – PDF DOWNLOAD

Introduction 1

Warranty 1

Qualifications Required for Driving and Operation

(Applicable in Japan) 2

Inspection and Maintenance 2

In Event of Failure 2

Before Exporting This Machine Out of Japan

(Including Mobile/Satellite Communication

Terminal) 3

Contents 5

Name of Each Part 10

Contents with Illustration 11

Outrigger Control System11

Crane Control System 12

Safety Rules 17

Precautions before Starting Engine 17

Precautions for Traveling on Roads 22

Precautions during Operation 23

Warning Label 38

Label Location and Content of Warnings 39

OPERATION43

Terminology 45

Anchor Points for Safety Belt 47

Location of Anchor Points 47

Before Crane Operation 49

Pre-operational Inspection 49

Preparing for Crane Operation 49

How to Read Performance Data Plates 51

Working Range Chart 51

Rated Lifting Capacity Table 52

Working Area Diagram 60

Automatic Moment Limiter (AML) 63

Display 65

Registration of Operating Status and AML

Function Check 69

Alarm and Recovery Operation 77

Other Functions 83

Action against AML System Error 102

How to Read Meter Panel 103

Meters and Gauges 104

Alarm Buzzer 105

Warning Lamp and Indicator Lamp 106

Monitor (AML) 108

How to Use Monitor 109

Drum Monitoring Camera111

Other Safety Devices11 2

Anti-two-block Device112

Over-unwinding cutout device113

Anemometer114

AML external indicator lamp116

Outriggers11 7

Outrigger Set-up 121

Extending Outriggers 122

Horizontal Set-up 126

Retracting Outriggers 128

Entering Cab 13 2

Opening/Closing Door 132

Opening/Closing Windshield 133

Extending/Stowing Step 134

Adjusting Seat Tilt 135

Adjusting Seat 136

Adjusting Control Lever Stand 139

Sun Visor 139

Sunshade 139

Starting and Stopping Engine 14 0

How to Start Engine 142

How to Stop Engine 144

Functions of Control Lever and Pedal 14 6

Hoisting 14 9

Hoisting Up/Down Operation151

Winch Speed Changeover Operation 153

Drum Rotation Indicator 154

Boom Telescoping Operation 15 5

Outline of Telescoping System 158

Types of Telescope Mode 159

Normal Telescoping Operation 160

Telescoping with Load Lifted 168

Maintenance Telescoping 169

Slow Telescope Mode174

Boom Telescoping Speed Changeover Operation

176

Boom Elevating Operation 177

Boom Elevating Operation 179

Slow Stop Cancel Switch 181

Boom Elevating Speed Changeover Operation 182

Slewing Operation 183

Slewing Operation 184

Slewing Release Switch 186

Slewing Brake Pedal 186

Slewing Lock Operation 187

Slewing Alarm Switch 188

Hydraulic Tilt Jib Operation 189

Hydraulic Tilt Jib Operation 191

Jib Tilt Speed Changeover Operation 193

Reeving Wire Ropes 194

Standard Number of Parts of Line 194

Reeving Procedure 205

Stowing Procedure for Main Wire Rope 208

Single Top 209

Mounting Single Top 210

Stowing Single Top 214

Accessories in Cab 21 7

Heater and Air Conditioner 218

How to Use Other Accessories 222

Accessories outside Cab 22 6

Ladders 226

MOUNTING/DISMOUNTING22 7

Mounting/Dismounting Counterweight 22 9

Combinations of Counterweights 229

Counterweight Operation 234

Mounting Counterweight 236

Dismounting Counterweight 251

Mounting/dismounting of Hydraulic Tilt Jib 264

Mounting Hydraulic Tilt Jib 265

Dismounting Hydraulic Tilt Jib 284

Mounting/Dismounting of Auxiliary Winch 285

Mounting Auxiliary Winch 285

Dismounting Auxiliary Winch 291

■ INSPECTION AND MAINTENANCE293

Precautions for Inspection and Maintenance 295

Precautions for Inspection and Maintenance 295

Inspection and Maintenance 305

About Inspection and Maintenance 305

Legal Inspection 305

Periodic Replacement Part 306

Inspection and Maintenance Interval 309

Pre-operational Inspection 31 5

Engine 316

Hydraulic System 321

Control System 322

Outrigger System 323

Slewing System 325

Boom, Jib System 325

Lifting Device 327

Safety Devices 330

Inspection of Crane Structure 33 3

Greasing 33 6

Maintenance Table 336

Greasing Chart 337

Greasing Centralized Lubrication Device 341

Gear Oil 34 2

Maintenance Table 342

Winch Speed Reducer (Main/Auxiliary Winch) 343

Slewing Speed Reducer344

Engine 34 6

Maintenance Table 346

Engine Oil 347

Air Cleaner 349

Engine Cooling System 35 0

Maintenance Table 350

Coolant 351

Radiator 351

Fuel System 35 2

Maintenance Table 352

Fuel Tank 353

AdBlue® Tank 354

Water Separator 355

Hydraulic System 35 8

Maintenance Table 358

Hydraulic Oil Tank 360

Line Filter 363

Slewing System 364

Maintenance Table 364

Slewing Bearing Mounting Bolt 364

Outrigger System 366

Maintenance Table 366

Outrigger Beam 366

Electrical System 367

Maintenance Table 367

Replacing Fuse 367

Battery Electrolyte Inspection 368

Air Conditioner System 370

Maintenance Table 370

Checking Refrigerant Level 370

Checking and Cleaning Condenser 372

Cleaning and Replacing Air Filter 372

Checking Refrigerant Hose 372

Checking V belt 372

Wire Rope 373

Replacing Wire Ropes 373

Handling Wire Ropes 382

Action against Emergency 385

If Boom Cannot be Telescoped 385

Monitor Screen During Emergency Telescoping

Operation 388

Action against Abnormality (A) 389

Action against Abnormality (B) 401

Action against Abnormality (C)410

If Error Occurs in AML System412

If Error Occurs with AML Main Body413

If Crane Operation Does Not Stop Even When

Control Lever is Returned to Neutral Position414

If Weight Set Failure Warning Lamp Does Not Go

Out416

If Engine Cannot be Started/Stopped417

If Battery Is Exhausted418

INFORMATION AND DATA 42 1

Conversion Tables 42 3

The Safety Ordinance for Cranes (Japan) 42 4

Hand Signals 43 3

Major Specifications 43 4

Crane 434

Overall Dimensions 435

Oils and Greases 43 6

Oil and Grease Table 436

Main Transportation Component List 43 7

Mass Distribution List 43 9

Mounting Counterweights with Traveling

Configuration in Work Site with

Boom Mounted 440

Stowing/Taking Out Hook Block 443

Traveling Configuration in the Work Site 446

IMAGES PREVIEW OF THE MANUAL: