$37

Tadano All Terrain Crane GA-1000N Operation Manual – PDF DOWNLOAD

Tadano All Terrain Crane GA-1000N Operation Manual – PDF DOWNLOAD

FILE DETAILS:

Tadano All Terrain Crane GA-1000N Operation Manual – PDF DOWNLOAD

Language : Japanese

Pages :257

Downloadable : Yes

File Type : PDF

Model: GA-1000N-1

Serial No.: GA5184

TABLE OF CONTENTS:

Tadano All Terrain Crane GA-1000N Operation Manual – PDF DOWNLOAD

Safety A-1

Safety Rules A-2

Before OperationA-2

Rules for Operation (Setting Outriggers) A-7

Rules for Operation (General) A-8

Rules for Operation (Weather) A-17

Rules for Operation (Power Lines, Radio

Waves) A-18

Rules for Operation (Special Operation) A-19

After Operation A-20

Rules for Road Travel A-21

Rules for Inspection and Maintenance A-22

Warning Labels A-29

Label Location and Content of Warnings A-30

Contents 1

Preface 4

Warranty 4

Maintenance and Inspection 4

Qualifications Required for Driving and

Operation 5

Servicing and Ordering Parts 6

Components 7

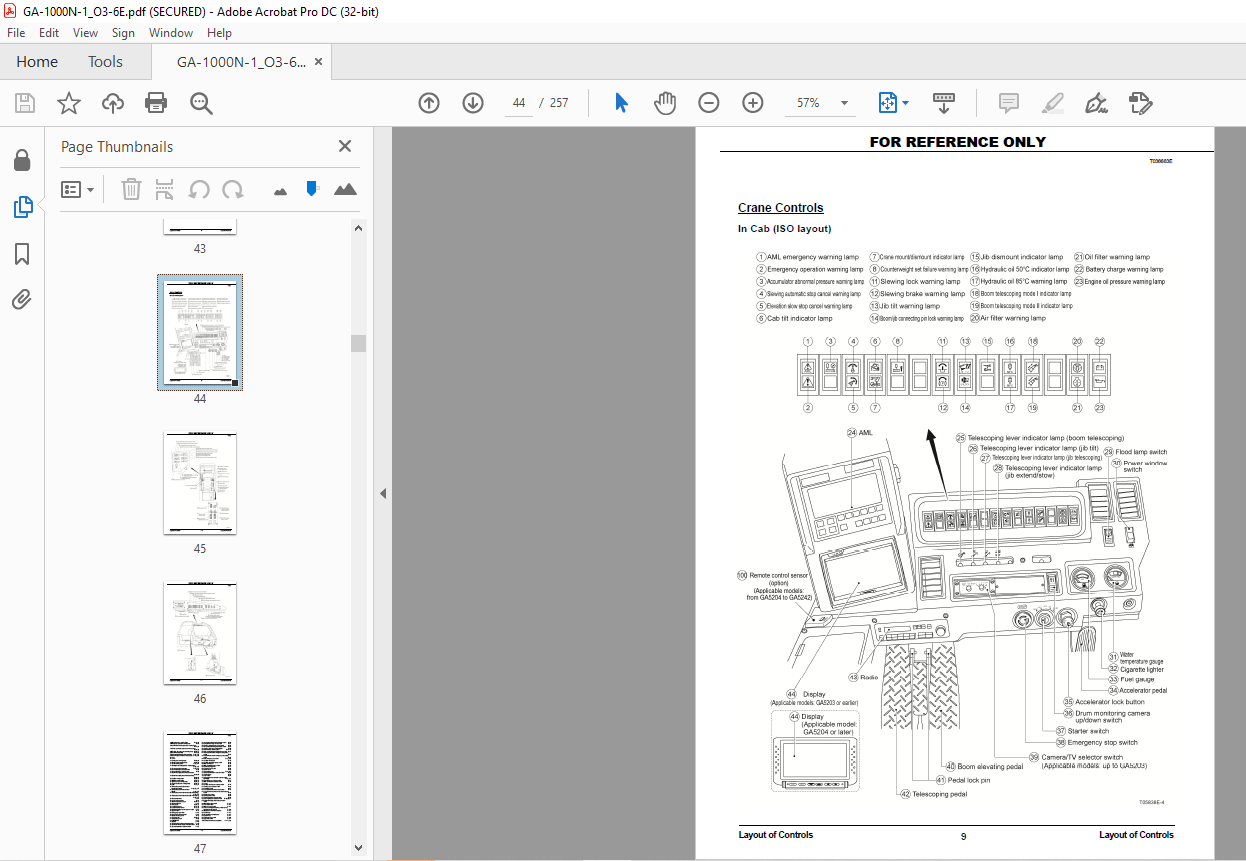

Layout of Controls 8

Outrigger Controls 8

Crane Controls 9

Terminology 15

[OPERATION]

Outline of Crane Operation Procedure 17

Work Preparation 17

During Operation 18

Procedure after Operation 18

How to Read the Performance Data Plates 19

Working Range Chart 19

Rated Lifting Capacity Table 20

How to Read the Working Area Diagram 23

AML (Load Moment Indicator) 24

Functions of AML System 25

Control Devices 28

Messages and Recovery Operations 29

In the Event of a System Failure 33

How to Use the AML Main Body 34

Names and Functions of Each Part 34

Turning ON/OFF the Power Supply 37

Registering the Operating State 38

Registering the Number of Parts of Line and

Displaying the Hook Block Travel Amount 40

Indicating the Main Hydraulic Pressure and

Accumulator Pressure 42

Pre-operational Inspection of AML 42

Using the Work Range Limit Function 43

Preset Menu 47

Adjusting Contrast of Moment Ratio Display 50

Other Safety Devices 51

Anti-Two-Block Device 51

Over-unwinding Cutout Device 52

Accumulator Low-Pressure Alarm Device 52

AML External Indicator Lamp 53

Alarm Buzzer and Voice Alarm 53

Operating the Outriggers 54

Selecting Set-Up Location 54

Control Devices 55

Outrigger Extension Width 56

Preparation for Outrigger Operation 56

How to Use Accelerator Switch 56

Extending the Outriggers 57

Level Set-up 60

Stowing the Outriggers 61

Stowing the Outriggers When Traveling in

Work Site 62

Entering Crane Cab 63

Before Entering the Crane Cab 63

Opening/Closing the Door 63

Opening/Closing the Window 64

Adjusting the Seat 65

Adjusting the Lever Stand 65

Releasing the Lever Lock 66

Cab Tilt (Inclination) Operation 67

How to Read the Meter Panel 68

Starting and Stopping the Engine 72

Control Devices 72

Inspection before Starting the Engine 73

Starting the Engine 73

Stopping the Engine 74

Accelerator Operation 75

Control Devices 75

Operating the Winch 76

Control Devices 76

Hoisting Up/Down 77

Changing the Winch Speed 78

Telescoping the Boom 80

Control Devices 80

Telescoping the Boom 83

Correcting the Boom Length 85

Changing the Telescoping Speed 86

Emergency Telescoping Operation 86

Elevating the Boom 87

Control Devices 87

Elevating the Boom 88

Changing the Elevating Speed 89

Canceling the Boom Elevation Slow Stop

Function 89

Slewing Operation 90

Control Devices 90

Slewing Operation 91

Changing the Slewing Speed 92

Slewing Lock Operation 93

Canceling the Slewing Stop Function 93

Selecting the Slewing Alarm (Option) 94

Removing and Stowing the 50 t Hook Block 95

Removing the 50 t Hook Block 95

Stowing the 50 t Hook Block 96

Reeving the Wire Rope 98

Standard Number of Parts of Line 98

Reeving Procedure 99

Single Top 101

Components 101

Single Top Operation 101

Mounting/Dismounting the Single Top 102

Stowing the Single Top 104

Jib 106

Components 106

Control Devices 107

Jib Operation 109

Mounting the Jib 111

Jib Telescoping and Tilt Operation 117

Stowing the Jib 118

Boom Lift Operation for Jib Removal 123

Mounting and Dismounting the Counterweight 124

Components 124

Combinations of Counterweights 125

Control Devices 126

Mounting and Dismounting the Counterweight 127

How to Use Counterweight Cylinder Retraction

Switch 131

Mounting and Dismounting the Crane 132

Components 132

Control Devices 133

Precautions for Mounting/Dismounting 134

Installing/Removing the Spacer of

Mounting/Dismounting Ring 135

Mounting the Superstructure 136

Removing the Superstructure 142

How to Use Equipment Inside the Cab 147

Control Devices 147

Air Conditioner 148

AM/FM Radio 151

Display Screen (Applicable up to Serial

No. GA5203) 155

Drum Monitoring Camera (Applicable up to Serial

No. GA5203) 156

How to Watch the Television (TV) (Applicable up to

Serial No. GA5203) 157

Display Screen (Applicable to Serial No. GA5204 or

later) 160

Drum Monitoring Camera (Applicable to Serial No.

GA5204 or later) 162

How to Watch the Television (TV) (Applicable to

Serial No. GA5204 to GA5242) 162

How to Use Other Equipment 163

Actions against Emergency 165

When Crane Operation Does Not Stop Even

When Control Lever is Returned to Neutral 165

When Crane Operation is Impossible Due

to AML System Failure 165

When Crane Operation is Impossible Due

to AML Main Body Failure 166

When Crane Operation is Impossible Due to

AML Automatic Stop Circuit Failure 166

[INSPECTION AND MAINTENANCE]

Inspection and Maintenance 167

Legal Inspection 167

Pre-operational Inspection 168

Periodic Replacement Parts 169

Greasing 171

Maintenance Table 171

Greasing Chart 172

Gear Oil 174

Maintenance Table 174

Winch Speed Reducer Oil Replacement 174

Slewing Speed Reducer Oil Level Check 175

Slewing Speed Reducer Oil Replacement 175

Engine 176

Maintenance Table 176

Air Cleaner Element Cleaning 177

Element Replacement 177

Engine Cooling System 178

Maintenance Table 178

Coolant Level Check 178

Fuel System 179

Maintenance Table 179

Fuel Tank Oil Level Check 179

Hydraulic System 180

Maintenance Table 180

Oil Level Check (Hydraulic Oil Tank) 181

Oil Replacement (Hydraulic Oil Tank) 181

Return Filter Replacement (Hydraulic Oil Tank) 182

Return Filter Replacement (Drain Circuit) 182

Line Filter Cleaning (ACC Circuit) 183

Line Filter Replacement (Automatic Stop Circuit)183

Air Breather Replacement (Hydraulic Oil Tank) 183

Slewing System 184

Maintenance Table 184

Slewing Bearing Mounting Bolt Check 184

Electrical System 185

Maintenance Table 185

Fuse Replacement 185

Battery Electrolyte Check 186

Air Conditioner System 187

Maintenance Table 187

Inspecting and Washing the Condenser 187

Inspecting the Refrigerant Amount 187

Inspecting the Refrigerant Piping Joint 188

Inspecting and Cleaning the Air Filter 188

Inspecting the V Belt 188

Periodic Replacement Part 189

Wire Ropes 190

Handling Wire Ropes 190

Replacing Wire Ropes 191

[INFORMATION AND DATA]

Conversion Table 195

The Safety Ordinance for Crane (Applicable in

Japan)

196

Hand Signals 202

Major Specifications 203

Crane Specifications 203

Overall Dimensions 204

Relief Valve Set Pressure 205

Wire Rope Specifications 205

Hook Block Mass 205

Other 205

Oils and Greases 206

Oils and Greases Table 206

Recommended Oils and Greases 207

Mass Distribution List 209

Traveling Configuration on General Roads 209

Traveling Configuration in Work Site 210

IMAGES PREVIEW OF THE MANUAL: