$38

Tadano AR-5500M All Terrain Crane Operation Manual – PDF DOWNLOAD

Tadano AR-5500M All Terrain Crane Operation Manual – PDF DOWNLOAD

FILE DETAILS:

Tadano AR-5500M All Terrain Crane Operation Manual – PDF DOWNLOAD

Language : English

Pages :292

Downloadable : Yes

File Type : PDF

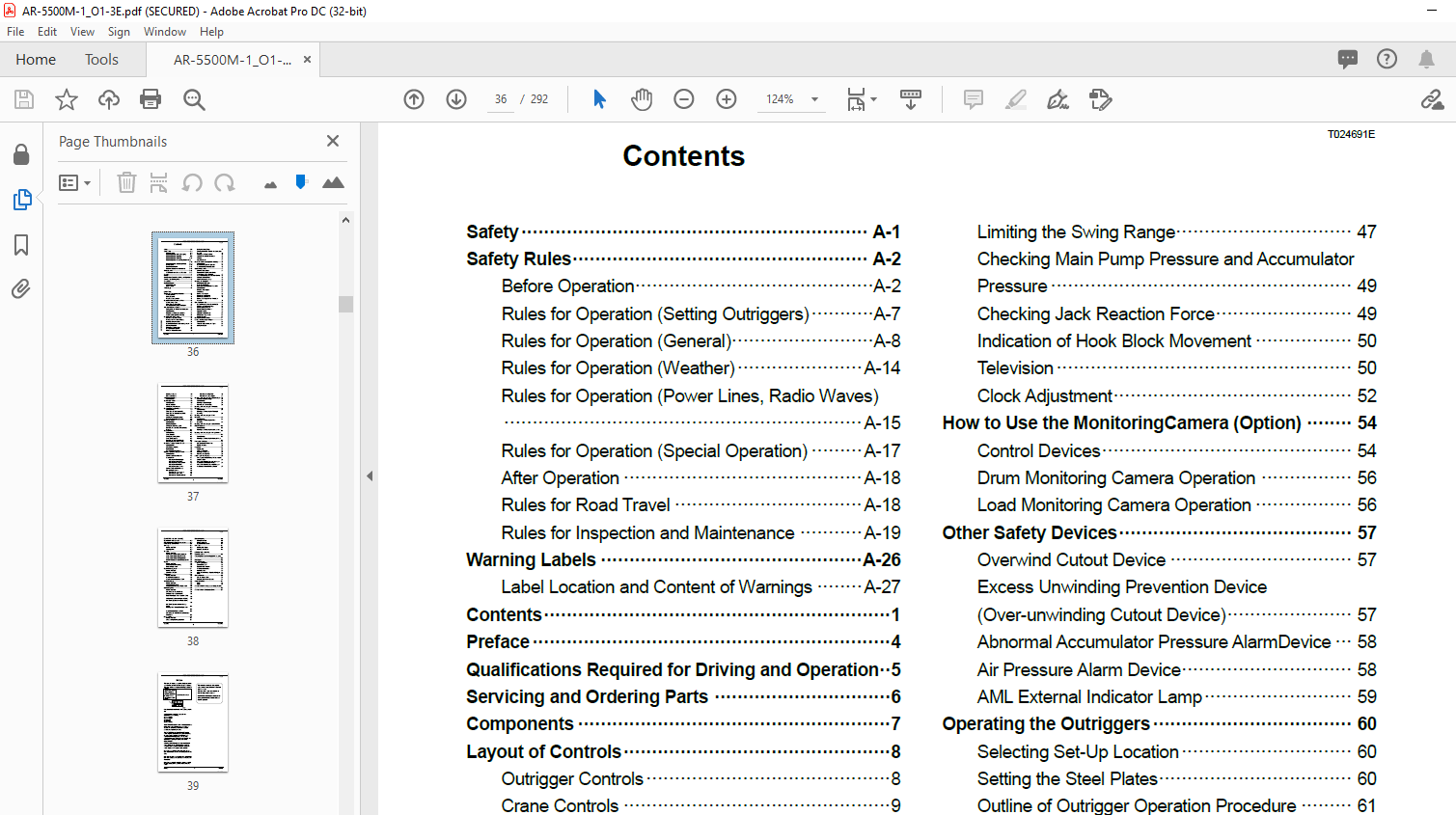

TABLE OF CONTENTS:

Tadano AR-5500M All Terrain Crane Operation Manual – PDF DOWNLOAD

Safety A-1

Safety Rules A-2

Before OperationA-2

Rules for Operation (Setting Outriggers)A-7

Rules for Operation (General)A-8

Rules for Operation (Weather) A-14

Rules for Operation (Power Lines, Radio Waves)

A-15

Rules for Operation (Special Operation) A-17

After Operation A-18

Rules for Road Travel A-18

Rules for Inspection and Maintenance A-19

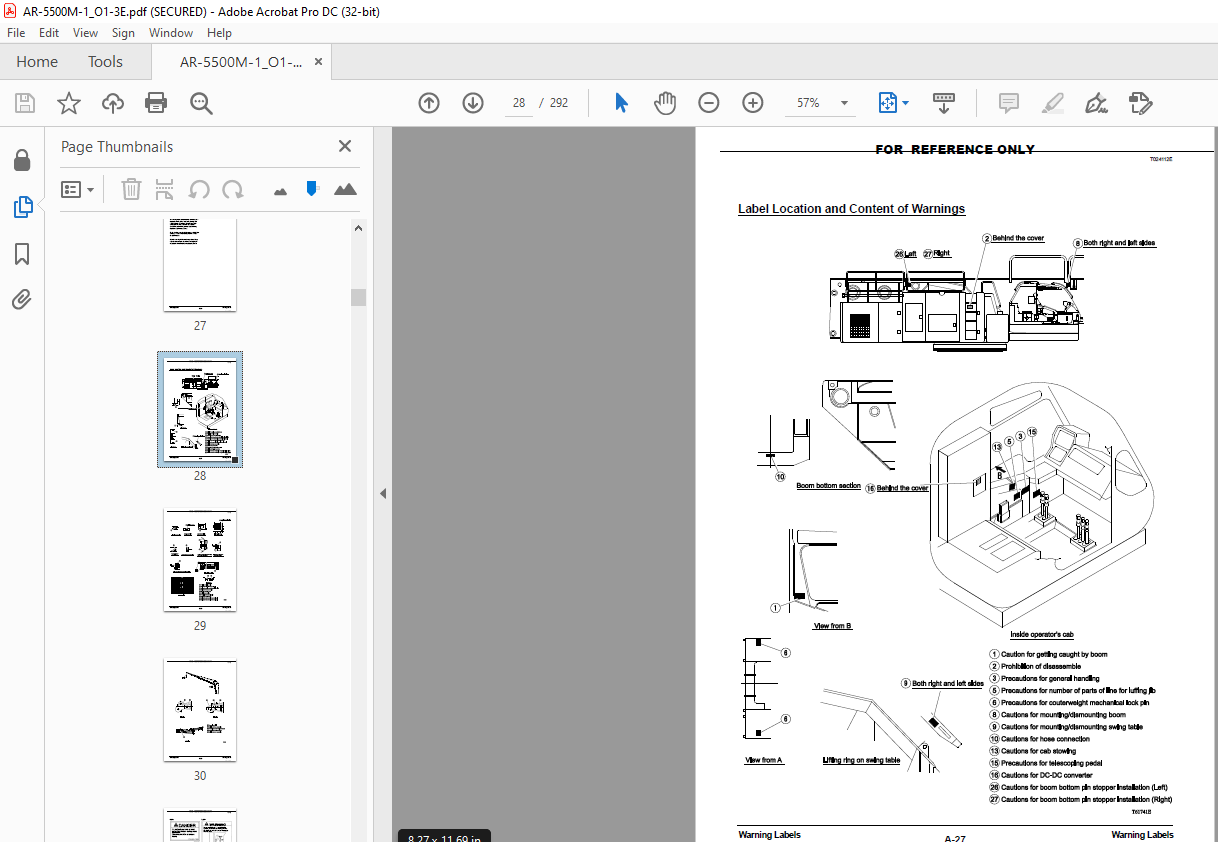

Warning Labels A-26

Label Location and Content of Warnings A-27

Contents 1

Preface 4

Qualifications Required for Driving and Operation 5

Servicing and Ordering Parts 6

Components 7

Layout of Controls 8

Outrigger Controls 8

Crane Controls 9

Terminology15

[OPERATION]

Outline of Crane OperationProcedure 17

Work Preparation 17

During Operation18

Procedure after Operation 18

How to Read Performance DataPlates 19

Working Range Chart 19

Rated Lifting Capacity Table20

How to Read the Working AreaDiagram 23

AML (Load Moment Indicator)25

Configuration and Functions of AML System 26

Control Devices 27

Messages and Recovery Operations 28

Actions against System Abnormality 31

How to Use the Multi-Display32

Names and Functions of Keys32

Turning ON/OFF the Power Supply 34

Before Operating the Crane 34

Screen Brightness and Brightness Adjustment 36

Selecting the Screen36

Registering Operating State 37

Pre-Operational Inspection 42

Functions of Standard Screen 45

Limiting the Swing Range 47

Checking Main Pump Pressure and Accumulator

Pressure 49

Checking Jack Reaction Force 49

Indication of Hook Block Movement 50

Television 50

Clock Adjustment 52

How to Use the MonitoringCamera (Option) 54

Control Devices 54

Drum Monitoring Camera Operation 56

Load Monitoring Camera Operation 56

Other Safety Devices 57

Overwind Cutout Device 57

Excess Unwinding Prevention Device

(Over-unwinding Cutout Device) 57

Abnormal Accumulator Pressure AlarmDevice 58

Air Pressure Alarm Device 58

AML External Indicator Lamp 59

Operating the Outriggers 60

Selecting Set-Up Location 60

Setting the Steel Plates 60

Outline of Outrigger Operation Procedure 61

Control Devices 62

Extending the Outriggers 63

Level Set-up 67

Stowing the Outriggers 68

Operating the Assist Jacks 69

Operating the Center Jack 72

Stowing the Outriggers When Traveling in

Work Site 75

Crane Operator’s Cab 76

Before Entering the Crane Operator’s Cab 76

Extending and Stowing the Steps 76

Opening/Closing the Door 78

Opening/Closing the Window 79

Adjusting the Seat 79

Adjusting the Control Lever 80

Extending/Stowing the Cab 81

Cab Tilt Operation 83

How to Read the Meter Panel 84

Starting and Stopping the Engine 88

Control Devices 88

Inspection before Starting the Engine 88

Starting the Engine 89

Stopping the Engine89

Bleeding the Engine90

Accelerator Operation 91

Control Devices91

Operating the Winch 92

Control Devices92

Hoisting Up/Down 93

Changing the Winch Speed 94

Boom Telescoping Operation 95

Control Devices95

Telescoping the Main Boom (MB)96

Telescoping the Telescopic Boom (TB) 98

Fixing the Boom 100

Changing the Telescoping Speed101

Emergency Telescoping Operation102

Elevating the Boom103

Control Devices103

Elevating the Boom104

Changing the Elevating Speed 104

Canceling the Boom Elevation Slow Stop

Function 105

Swing Operation106

Control Devices106

Swing Operation107

Changing the Swing Speed108

Swing Lock Operation109

Canceling the Swing Stop Function109

Selecting the Swing Alarm (Option) 110

How to Use Equipment Inside the Cab 111

Control Devices 111

Air Conditioner (Option) 112

Radio (Option) 113

How to Use Other Equipment 116

Mounting and Dismounting the Crane 118

Control Devices 119

Outline of Assembly Procedure120

Assembly Work 121

Mounting the Rear Outrigger121

Mounting the Swing Table 124

Mounting the Elevating Cylinder 126

Mounting the Main Boom127

Mounting the Standard Head 131

Outline of Disassembly Procedure 134

Disassembly Procedure136

Removing the Standard Head136

Removing the Main Boom138

Removing the Elevating Cylinder143

Removing the Swing Table 145

Removing the Rear Outrigger 147

Mounting and Dismounting the Counterweight 150

Combination of Counterweight 150

Control Devices 152

Mounting the Counterweight 154

Removing the Counterweight 158

Mounting and Dismounting the Telescopic

Boom (TB) 160

Control Devices 160

Mounting and Dismounting the Telescopic

Boom (TB) 160

Mounting and Dismounting the Fixed

Boom (FB) 165

Control Devices 165

Mounting and Dismounting the Fixed

Boom (FB) 165

Mounting and Dismounting the Standard Head

(With FB Mounted) 170

Control Devices 170

Mounting and Dismounting the Standard Head

170

Mounting and Dismounting the Heavy-Lift Head

175

Control Devices 175

Mounting and Dismounting the Heavy-Lift Head

175

Reeving the Wire Rope 181

Standard Number of Part Lines 181

Reeving Procedure 192

Single Top 193

Components 193

Single Top Operation 193

Mounting the Single Top 194

Removing the Single Top 195

Actions against Emergency 196

When Operation of Connecting Pin Becomes No

Longer Possible 196

When Crane Operation Becomes No Longer

Possible Due to AML System Failure 196

When Crane Operation Becomes No Longer

Possible Due to AML Main Body Failure 197

INSPECTION AND MAINTENANCE]

Inspection and Maintenance 199

Pre-operational and Periodic Inspections 200

Periodic Replacement Parts204

Greasing205

Maintenance Table205

Greasing Chart206

Gear Oil209

Maintenance Table209

Winch Speed Reducer Oil Replacement 209

Swing Speed Reducer Oil Level Check 210

Swing Speed Reducer Oil Replacement210

Mini Winch Speed Reducer Oil Replacement 211

Engine212

Maintenance Table212

Air Cleaner Element Cleaning212

Element Replacement 213

Engine Cooling System214

Maintenance Table214

Coolant Level Check214

Fuel System 215

Maintenance Table215

Fuel Tank Oil Level Check215

Water Separator Water Level Check215

Air Circuit System216

Maintenance Table216

Air Dryer Function Check 216

Air Dryer Desiccating Agent Replacement216

Hydraulic System217

Maintenance Table217

Oil Level Check (Hydraulic Tank)218

Oil Replacement (Hydraulic tank) 218

Return Filter Replacement (Hydraulic Tank)

219

Air Breather Replacement (Hydraulic Tank)219

Line Filter Replacement (4th Pump Circuit)

219

Line Filter Replacement (Automatic Stop

Circuit)220

Reducing Valve Primary Filter Replacement

220

Accumulator Gas Pressure Check 220

Oil Level Check of Tank for Atmospheric Open

Check Valve220

Swing System 221

Maintenance Table221

Swing Bearing Mounting Bolt Check 221

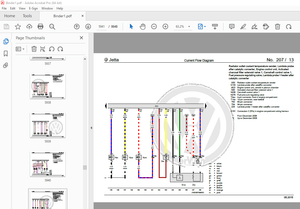

Electrical System 222

Maintenance Table 222

Fuse Replacement 222

Battery Electrolyte Check 223

Wire Ropes 224

Handling Wire Ropes 224

Replacing Wire Ropes 225

[INFORMATION AND DATA]

Conversion Table 229

The Safety Rules for Crane (Applicable in Japan)

230

Hand Signals 236

Major Specifications 237

Crane Specifications 237

Overall Dimensions 238

Relief Valve Set Pressure 239

Wire Rope Specifications 239

Hook Block Mass 239

Maximum Vertical Load Capacity of Outrigger 239

Other 239

Oils and Greases 240

Oils and Greases Table 240

Recommended Oils and Greases 241

Consumable Parts 243

Filters 243

Fuses 243

AR-5500M-1 Main Transportation Component List

245

AR-5500M-1 Mass Distribution Chart 247

IMAGES PREVIEW OF THE MANUAL: