$38

Tadano Carrier ATF220G-5 Operation Manual – PDF DOWNLOAD

Tadano Carrier ATF220G-5 Operation Manual - PDF DOWNLOAD

FILE DETAILS:

Tadano Carrier ATF220G-5 Operation Manual - PDF DOWNLOAD

Language : English

Pages :487

Downloadable : Yes

File Type : PDF

Model: ATF-220G5-1

Serial No.: GB0170–

TABLE OF CONTENTS:

Tadano Carrier ATF220G-5 Operation Manual - PDF DOWNLOAD

Introduction 1

Warranty 1

Qualifications Required for Driving and

Operation (Applicable in Japan) 2

Inspection and Maintenance 2

In Event of Failure 2

Exporting Abroad 2

For Safety 3

Contents 5

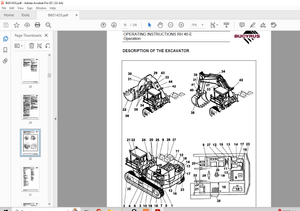

Name of Each Part 9

Contents with Illustration 10

Outrigger Control System 10

Crane Control System11

Safety Rules 15

Precautions before Starting Engine 15

Precautions for Traveling on Roads 20

Precautions during Operation 21

Warning Label 38

Label Location and Content of Warnings 39

OPERATION45

Terminology 47

Before Crane Operation 49

Pre-operational Inspection 49

Preparing for Crane Operation 49

How to Read Performance Data Plates 51

Working Range Chart 51

Rated Lifting Capacity Table 52

Working Area Diagram 59

AML (Automatic Moment Limiter) 62

Display 64

Registration of Operating Status and AML

Function Check 68

Alarm and Recovery Operation 77

Other Functions 83

Action against AML System Error 100

CGC (Cockpit Graphic Control System) 101

Main Screen Symbols 101

Adjusting Monitor Screen Contrast 107

How to Use Monitor 108

Drum Monitoring Camera (Option)111

Other Safety Devices112

Anti-two-block Device112

Over-unwinding Cutout Device113

Anemometer114

AML External Indicator Lamp (Option)115

Outriggers116

Outrigger Control Panel117

Outline of Outrigger Extending Operation 121

Outrigger Set-up 123

Extending Outriggers 124

Horizontal Set-up 128

Outline of Outrigger Stowing Operation 130

Retracting Outriggers131

Outrigger Operation While Traveling in

Work Site 134

Entering Cab 136

Opening/Closing Door 136

Opening/Closing Windshield 137

Adjusting Seat Tilt 138

Adjusting Seat 139

Adjusting Control Lever Stand 142

Sun Visor 142

Starting and Stopping Engine 14 3

How to Start Engine 146

How to Start Engine in Cold Season147

How to Stop Engine 148

Functions of Control Lever and Pedal 15 0

Hoisting 15 3

Hoisting Up/Down Operation 155

Winch Speed Changeover Operation 158

Drum Rotation Indicator 159

Lift Adjuster Operation 160

Boom Telescoping Operation 163

Outline of Telescoping System 166

Types of Telescope Mode 167

Normal Telescoping Operation 168

Maintenance Telescoping 177

Slow Telescope Mode 185

Boom Telescoping Speed Changeover

Operation 187

Elevating Boom 189

Elevating Boom 191

Slow Stop Cancel Switch 193

Changing Boom Elevating Speed 194

Slewing Operation 195

Slewing Operation 196

Slow Stop Cancel Switch 198

Slewing Free Switch 199

Slewing Lock Operation 200

Slewing Alarm Switch (Option) 201

Full Automatic Luffing Jib (FLJ) Operation 202

Full Automatic Luffing Jib Operation 205

Changing Jib Speed 209

Reeving Wire Ropes 21 0

Standard Number of Parts of Line 210

Reeving Procedure 216

Single Top 21 9

Mounting Single Top 220

Stowing Single Top 224

Accessories in Cab 22 7

Heater and Air Conditioner 228

How to Use Other Accessories 231

MOUNTING/DISMOUNTING23 5

Mounting/Dismounting Boom and Elevating

Cylinder 23 7

Mounting Boom and Elevating Cylinder 238

Dismounting Boom and Elevating Cylinder 260

Mounting/Dismounting Counterweight 281

Combinations of Counterweights 281

Mounting Counterweight 286

Dismounting Counterweight 296

Mounting/Dismounting Full Automatic

Luffing Jib (FLJ) 304

Mounting Full Automatic Luffing Jib (FLJ) 305

Dismounting Full Automatic Luffing Jib (FLJ) 323

Stowing Hydraulic Hose When Jib is

Not Used 339

INSPECTION AND MAINTENANCE 34 1

Precautions for Inspection and Maintenance 34 3

Precautions for Inspection and Maintenance 343

Inspection and Maintenance 35 1

About Inspection and Maintenance 351

Legal Inspection 351

Periodic Replacement Part 352

Inspection and Maintenance Interval 353

Pre-operational Inspection 35 8

Engine 359

Hydraulic System 364

Control System 366

Outrigger System 367

Slewing System 369

Boom, Jib System 369

Lifting Device 371

Safety Devices374

Inspection of Crane Structure 377

Greasing 379

Maintenance Table 380

Greasing Chart 381

Greasing Centralized Lubrication System 387

Gear Oil 388

Maintenance Table 388

Winch Speed Reducer

(Main/Auxiliary Winch) 389

Winch Motor Coupling 390

Slewing Speed Reducer 391

Engine 393

Maintenance Table 393

Engine Oil 394

Air Cleaner 396

Engine Cooling System 398

Maintenance Table 398

Coolant 399

Radiator 399

Fuel System 400

Maintenance Table 400

Fuel tank 401

Water Separator 401

Hydraulic System 404

Maintenance Table 405

■ Hydraulic Oil Tank 406

Line Filter 409

Slewing System 41 0

Maintenance Table410

Slewing Bearing Mounting Bolt410

Outrigger System41 2

Maintenance Table412

Chain for Telescoping412

Electrical System41 5

Maintenance Table415

Fuse Replacement415

Battery Electrolyte Inspection418

Wire Rope 42 0

Replacing Wire Ropes 420

Handling Wire Ropes 429

Action against Emergency 43 1

If Boom Cannot be Telescoped 431

Action against Abnormality (A) 436

Action against Abnormality (B) 444

Action against Abnormality (C) 451

If Error Occurs in AML System 452

If Error Occurs with AML Main Body 453

If Crane Operation Does Not Stop Even When

Control Lever is Returned to Neutral Position 454

If Weight Set Failure Warning Lamp Does Not

Go Out 455

If Engine Cannot be Started/Stopped 456

If Battery Is Exhausted 457

INFORMATION AND DATA45 9

Conversion Tables 461

The Safety Ordinance for Cranes (Japan) 462

Hand Signals 471

Major Specifications 472

Crane 472

Overall Dimensions 473

Relief Valve Set Pressure474

Wire Rope Specifications474

Hook Block Mass474

Others474

Oils and Greases 475

Oils and Greases Table 475

Recommended Oils and Greases 476

Main Transportation Component List 478

Mass Distribution List 480

IMAGES PREVIEW OF THE MANUAL: