$38

Tadano Crane TR-250M-s Rough Terrain Crane Operation & Maintenance Manual - PDF DOWNLOAD

Tadano Crane TR-250M-s Rough Terrain Crane Operation & Maintenance Manual - PDF DOWNLOAD

FILE DETAILS:

Tadano Crane TR-250M-s Rough Terrain Crane Operation & Maintenance Manual - PDF DOWNLOAD

Language : English

Pages :469

Downloadable : Yes

File Type : PDF

TABLE OF CONTENTS:

Tadano Crane TR-250M-s Rough Terrain Crane Operation & Maintenance Manual - PDF DOWNLOAD

Safety 1

Safety Rules 3

Before Operation 4

Rules for Operation (Setting Outriggers) 15

Rules for Operation (General) 17

Rules for Operation (Weather) 34

Rules for Operation (Power Lines, Radio Waves) 37

Rules for Operation (Operation without Extending Outriggers)

Rules for Operation (Special Operation) 41

After Operation 43

Rules for Road Travel 44

Rules for Transportation and Towing 49

Rules for Parking 52

Rules for Inspection and Maintenance 54

Contents 69

Preface 76

Servicing and Ordering Parts 77

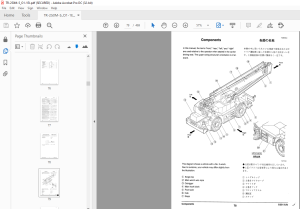

Components 78

Layout of Controls 80

Travel Operation Controls 80

Crane Operation Controls 84

Others 87

Terminology 88

[TRAVELING]

Traveling Procedure 93

Preparatory Steps 93

Starting 96

Traveling 97

Stopping 98

Parking 99

Crane Operator's Cab 101

Opening and Closing the Door 101

Opening and Closing the Windows 103

Adjusting the Seat Position 104

Adjusting the Control Levers 105

Adjusting the Steering Wheel 106

How to Read the Instrument Panel 107

Meters and Gauges 107

Indicator Lamps 111

Starting and Stopping the Engine 117

Controls 117

How to Use the Starter Switch 117

Pre-starting Checks 118

Starting the Engine 119

Stopping the Engine 121Changing Drive Mode 122

Controls 122

Changing Drive Mode 122

Gearshift Lever Operation 125

Controls 125

Gearshift Lever Operation 125

Brakes 128

Controls 128

Foot Brake 128

Parking Brake 129

Exhaust Brake 130

Auxiliary Operating Brake 131

Retarder 132

Steering 133

Controls 133

Changing Steering Mode 133

Reverse Steering 137

Spring Lock 139

Controls 139

Spring Lock Operation 139

Lighting and Other Switches 141

Controls 141

Equipment Inside the Cab 145

Controls 145

Air Conditioner (Option) 146

Radio (Option) 148

Other Equipment Inside the Cab 151

Equipment Outside the Cab 156

How to Use the Air lnflator (Option) 156

Engine Cover 158

Emergency Procedures 159

Using Emergency Flares 160

If Shifting Gears is Impossible 161

Towing the Crane 164

If the Engine Stops during Travel 167

If the Engine Does Not Stop 167

[CRANE OPERATION]

Crane Operation Procedure - Summary 169

On-outrigger Operation 169

How to Read the Performance Data Plate 174

Working Radius/Lifting Height Chart 174

Total Rated Load Table 176AML (Overload Protection Device) 185

Configuration and Functions of the AML System 188

Controls 189

Messages and Recovery Operations 190

In the Event of AML Failure 192

Using the Multi-Display 193

Names and Functions of Keys 193

Switching Power On and Off 196

Before Cnane Operation 197

Adjusting Brightness 200

Picture Selection 201

Pre-Operational Checks 203

Setting Operating Configuration 206

Main Picture 211

Setting Operating Range Limits 216

Checking Working Range Limits 219

Checking Pump and Accumalator Pressures 221

Travel 222

The "Camera" Picture 224

The "Travel Mode" Picture 226

Displaying the Total Rated Load 227

Calculation of Outrigger Vertical Load Capacity 234

Television (Option) 240

Adjusting the Clock 244

Checking the Multi-Display Operating Instructions 246

Other Safety Devices 247

Overwind Cutout Device 247

Accumulator Pressure Gauge 249

AML External Indicator Lamps(Option) 250

Operating the PTO and Warming Up the Machine· 251

Operating the PTO 251

Warming Up the Machine 254

Outriggers 255

Setting the Crane 255

Controls 256

Extending the Outriggers 257

Level Adjustment 261

Stowing the Outriggers 263

Adjusting the Control Levers 265

Adjusting the Control Levers Stand Operating Positions

Adjusting the Control Lever Length 266

Hoisting 267

Controls(Tadano Layout) 267

Hoisting Up and Down 268

Free fall Operations 273

Other Winch-related Devices 277Telescoping the Boom 278

Controls 278

Extending and Retracting the Boom 278

Emergency Telescoping Procedure 282

Elevating the Boom 284

Controls (Tadano Layout) 284

Raising and Lowering the Boom • 284

Swinging the Boom 286

Controls 286

Swinging the Boom • • 286

Other Controls • 289

On-Rubber Crane Operation 290

With the Vehicles Stationary • • 291Traveling with Load on Hook

Removing and Stowing the Main Hook Block 294

Removing the Main Hook Block 294

Stowing the Main Hook Block • • 296

Reeving Wire Rope 297

Standard Number of Parts of Line 297

Reeving Procedure 299

Single Top 302

Components 302

Single Top Lift 303

Mounting the Single Top 304

Stowing the Single Top 307

Jib 310

Componenres 310

Controls 311

Jib lift 311

Mounting the jib 313

Changing the Jib Length 327

Changing the jib Offset Angle 336

Stowing the Jib 341

Equipment Inside the Cab 354

Equipment Outside the Cab 356

[INSPECTION AND MAINTENANCE]

Inspection and Maintenance 357

Pre-Operational and Periodic Inspection 358

Crane 358

Chassis 361

Periodic Replacement of Safety Critical Parts 374

Greasing 375

Maintenance Table • 376

Greasing Chart 378Greasing (Central Grease Supply Unit) 380

Using the Central Grease Supply Unit 380

Greasing Intervals 381

Greasing Locations 381

Adding Grease 382

Gear Oil 383

Maintenance Table 383

Winch Speed Reducer Oil Level Check 384

Winch Speed Reducer Oil Replacement 384

Swiig Speed Reducer Oil Level Check 386

Swinging Speed Reducer Oil Replacement 386

Axle (Carrier Axle) Oil level Check 388

Axle (Carrier Axle) Oil Replacement 388

Axle (Planetary Gear) Oil Level Check 389

Axle (Planetary Gear) Oil Replacement 389

Engine 391

Maintenance Table 391

Retarder Oil Level Check 392

Retarder Oil Replacement 392

Air Filter Cleaning 395

Air Cleaner Check 396

Element Cleaning 396

Element Replacement 397

Engine Cooling System 398

Maintenance Table 399

Cooling Water Level Check 399

Torgue Converter System 400

MaintenanceTable 400

Oil Level Check 401

Oil Replacement 401

Strainer Cleaning 403

Line Filter Element Replacement 404

Fuel System 405

Maintenance Table 405

Fuel Tank Oil Check 405

Brake System 406

Maintenance Table 406

Brake Fluid Level Check 407

Brake Fluid Replacement 407

Disc Brake Pad Wear Check 408

Air Drier Function Check 409

Air Drier Desiccating Agent Replacement 409Tires and Wheels 411

Maintenance Table 411

Tire Pressure Check 412

Tire Wear Check 412

Tire Rotation 412

Loose Wheel Log Nut Check 414

Hydraulic System 415

Maintenance Table 416

Oil Level Check (Hydraulic Oil Tank) 417

Oil Replacement (Hydraulic Oil Tank) 417

Oil Level Check (Oil Reservoir) 419

Oil Replacement (Oil Reservoir) 419

Return Filter (Hydraulic tank) Replacement 419

Air Breather (Hydraulic Oil Tank) Replacement 420

Line Filter (Automatic Stop Circuit) Replacement 420

Swing System • 421

Maintenance Table 421

Bleeding Swing Brake 421

Swing Bearing Mounting Bolt Check 423

Winch System 424

Maintenance Table 424

Winch Brake Lining Wear 425

Winch Erake Adjustment 426

Bleeding Brake CylindeN) 429

Bleeding Brake Cylinder@ 430

Bleeding Winch Clutch Circuit 431

Winch Clutch Adjustment 432

Top Boom Section Wear Check 434

Electric System 435

Maintenance Table 435

Replacing Fuses 435

Battery Electrolyte Check 436

Wire Rope 438

Proper Handling of Wire Ropes 438

Wire Rope Replacement 440

Criteria for Replacing Wire Ropes 440

Removing Wire Rope 442

Installing Wire Rope 444Tires and Wheels 411

Maintenance Table 411

Tire Pressure Check 412

Tire Wear Check 412

Tire Rotation 412

Loose Wheel Log Nut Check 414

Hydraulic System 415

Maintenance Table 416

Oil Level Check (Hydraulic Oil Tank) 417

Oil Replacement (Hydraulic Oil Tank) 417

Oil Level Check (Oil Reservoir) 419

Oil Replacement (Oil Reservoir) 419

Return Filter (Hydraulic tank) Replacement 419

Air Breather (Hydraulic Oil Tank) Replacement 420

Line Filter (Automatic Stop Circuit) Replacement 420

Swing System • 421

Maintenance Table 421

Bleeding Swing Brake 421

Swing Bearing Mounting Bolt Check 423

Winch System 424

Maintenance Table 424

Winch Brake Lining Wear 425

Winch Erake Adjustment 426

Bleeding Brake CylindeN) 429

Bleeding Brake Cylinder@ 430

Bleeding Winch Clutch Circuit 431

Winch Clutch Adjustment 432

Top Boom Section Wear Check 434

Electric System 435

Maintenance Table 435

Replacing Fuses 435

Battery Electrolyte Check 436

Wire Rope 438

Proper Handling of Wire Ropes 438

Wire Rope Replacement 440

Criteria for Replacing Wire Ropes 440

Removing Wire Rope 442

Installing Wire Rope 444[INFORMATION AND DATA]

Major Specifications 447

Crane Specifications 447

Carrier Specifications 447

Overall Dimensions 448

Weight 450

Relief Valve Pressure 450

Wire Rope Specifications 451

Other 451

Olis and Greases 452

Table 452

Recommended Oils and Greases 454

Consumable Parts 459

Filters 459

Fuses 459

IMAGES PREVIEW OF THE MANUAL:

S.M 07/