$33

Tadano Forklift TG-500E-3 Truck Crane Operation and Maintenance Manual PDF

Tadano Forklift TG-500E-3 Truck Crane Operation and Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Tadano Forklift TG-500E-3 Truck Crane Operation and Maintenance Manual – PDF DOWNLOAD

Language : English,French

Pages :304

Downloadable : Yes

File Type : PDF

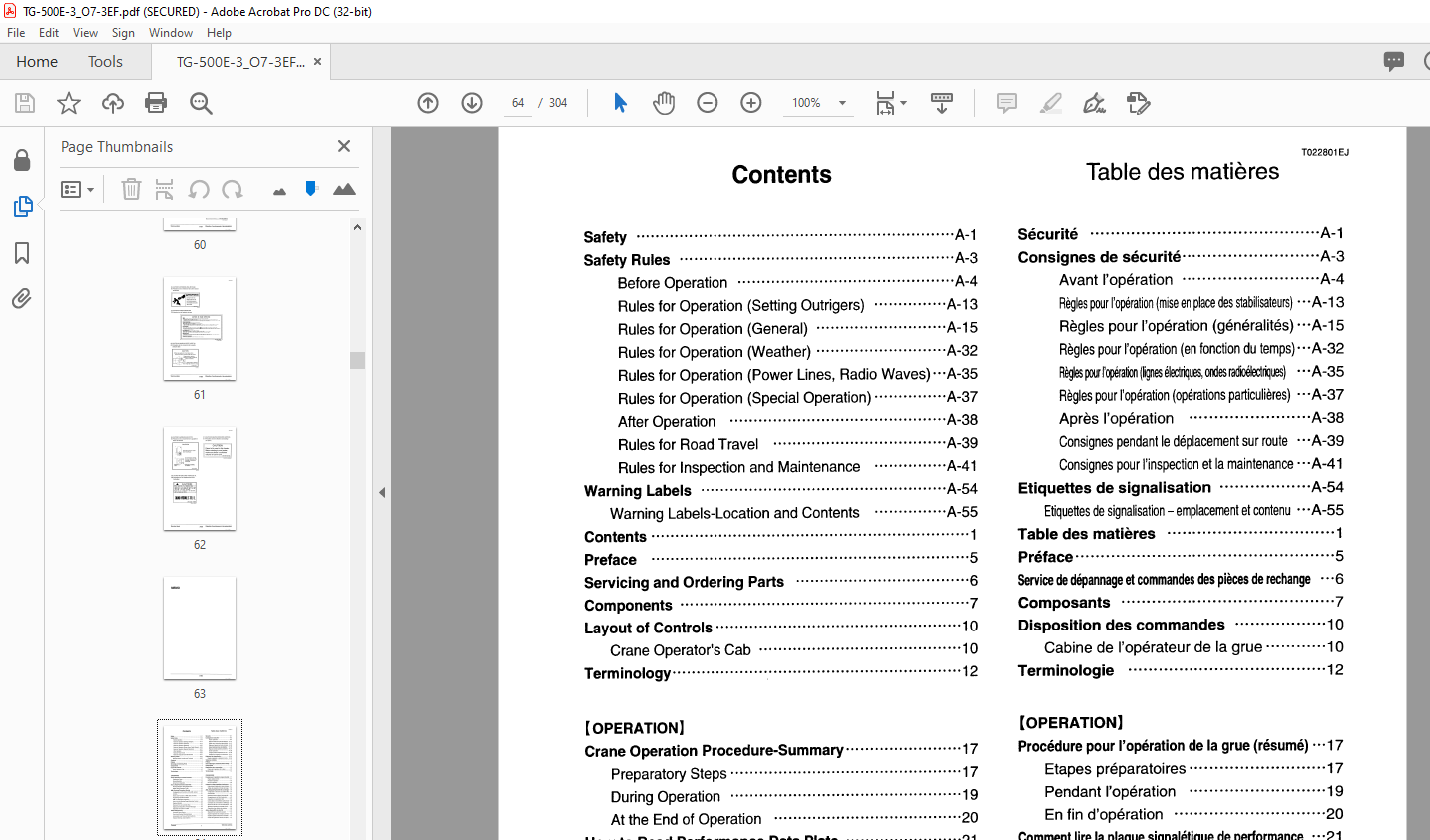

TABLE OF CONTENTS:

Tadano Forklift TG-500E-3 Truck Crane Operation and Maintenance Manual – PDF DOWNLOAD

Safety A-1

Safety Rules A-3 Before Operation

A-4 Rules for Operation (Setting Outrigers)

A-13 Rules for Operation (General) A-15 Rules for

Operation (Weather) A-32 Rules for Operation (Power Lines, Radio Waves)

A-35 Rules for Operation (Special Operation) A-37 After Operation

A-38 Rules for Road Travel

A-39 Rules for Inspection and Maintenance A-41

Warning Labels A-54 Warning Labels-Location and

Contents A-55 Contents

Preface 5

Servicing and Ordering Parts 6

Components 7

Layout of Controls 1O

Crane Operator’s Cab 1O

Terminology:12

[ OPERATION]

Crane Operation Procedure-Summary17

Preparatory Steps 17

During Operation 19

At the End of Operation 20

How to Read Performance Data Plate 21 C

Working Range & Lifting Height Chart 21

Rated Lifting Capacities Table 23

AML (Overload Prevention Device} 34 ‘ Configuration and

Functions of the AML System37

Controls 41

Names and Functions of AML Main Unit Parts 42

Registering Operational Status 49

AML Pre-operational Inspection 54

How to Use the Working Range Restricting Function 58

Display Alteration 62

Recovery from an Automatic Stop 63

Display and Disposition of Failure Messages 65

Disposition of System Troubles 69

Other Safety Devices70 ‘ Overwind Cutout

Device 70

Front Jack Overload Warning Device 72

Accumulator Low Pressure Warning Device 73

External Warning Lamps (Option) 74Starting and Stopping the Engine 75

Control75

Pre-starting Checks 75

Starting the Engine 76

Stopping the Engine 78

Operating the PTO and Warming Up the Machine 79

Operating the PTO 79

Warming Up the Machine 80

Checks to Make during Warmup 80

Outriggers 81

Setting the Crane 81

Controls 82

Extending the Outriggers 83

Level Adjustments88

Front Jack 90

Stowing the Outriggers91

Crane Operator’s Cab 93

Opening and Closing the Door 93

Adjusting Seat Position 94

Adjusting Length of Control Levers 95

Acceleration96

Controls 96

Hoisting 98

Controls 98

Hoisting Up and Down 99

Free Fall Operation103

Other Winch-related Controls and Devices 105

Telescoping the Boom 107

Controls 107

Extending and Retracting the Boom 107

Correcting Boom Length 112

Emergency Telescoping Procedure113

Elevating the Boom 114

Control 114

Raising and Lowering the Boom 114

Swinging the Boom 116

Controls 116

Swinging the Boom117

Taking Out and Stowing the Main Hook Block 120

Taking Out Main Hook Block120

Stowing Main Hook Block 122

Reeving Wire Rope 124

Standard Number of Parts of Line 124

Reeving Procedure 126

Single Top 129

Components129

Single Top Lift 129

Mounting the Single Top 130

Stowing the Single Top 133

Jib 136

Components136

Jib Lift 137

Mounting the Jib 139

Changing the Jib Offset Angle 147

Changing the Jib Length 150

Stowing the Jib 156

Equipment Inside the Cab 164

Heater (option)164

Cooler (option) 166

Other Equipment Inside the Cab 168

Equipment Outside the Cab 172

Oil Cooler 172

Winch drum monitor mirror (option) 173

[ INSPECTION AND MAINTENANCE]

Inspection and Maintenance175

Pre-Operational and Periodic Inspection 176

Safety Parts Requiring Regular Replacement 181

Greasing 182

Maintenance Table 183

Greasing Chart 184

Gear Oil 186

Maintenance Table 186

Winch Speed Reducer Oil Level Check 187

Winch Speed Reducer Oil Replacement187

Swing Speed Reducer Oil Level Check 188

Swing Speed Reducer Oil Replacement188

Hydraulic System 190 Maintenance Table

191

Oil Level Check (Hydraulic Oil Tank) 192

Oil Replacement (Hydraulic Oil Tank) 192

Oil Level Check (Oil Reservoir) 195

Oil Replacement (Oil Reservoir) 195

Return Filter (Hydraulic Oil Tank) 196

Air Breather (Hydraulic Oil Tank) 196

Line Filter (Winch Clutch Circuit) 197

Line Filter (Winch Brake Circuit) 197

Line Filter (Automatic Stop Circuit) 197

Line Filter (Accumulator Circuit) 197Swing System 198 Maintenance TableSwing Brake Bleeding 198

Swing Bearing Mounting Bolt Check 199

Winch System 200

Maintenance Table 200

Winch Brake for Wear Check 201

Winch Brake Adjustment 201

Brake Cylinder (1) Bleeding 204

Brake Cylinder (2) Bleeding 205

Winch Clutch Circuit Bleeding 207

Winch Clutch Adjustment 209

Accelerator System 211

Maintenance Table 211

Accelerator Circuit Bleeding 211

Electrical System 213

Maintenance Table 213

Fuses Replacement 213

Wire Ropes 215

Proper Handling of Wire Ropes 215

Wire Rope Replacement 217

[INFORMATION AND DATA]

Conversion 225

Major Specifications 226

Crane Specifications 226

Overall Dimensions227

Mass 228

Relief Valve Pressure228

Wire Rope Specifications 229

Other 229

Oils and Greases 230

Oil and Grease Table 230

Recommended Oils and Greases 232

Consumable Parts 234

Filters 234

Fuses 234

IMAGES PREVIEW OF THE MANUAL: