$34

Tadano GR-150XL Rough Terrain Crane Operation Manual – PDF

Tadano GR-150XL Rough Terrain Crane Operation Manual FD3574 – PDF DOWNLOAD

FILE DETAILS:

Tadano GR-150XL Rough Terrain Crane Operation Manual FD3574 – PDF DOWNLOAD

Language : English

Pages : 415

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Tadano GR-150XL Rough Terrain Crane Operation Manual FD3574 – PDF DOWNLOAD

Introduction 1

Warranty 1

In Event of Failure 2

Using Crane Out of Country of Purchase

(Including Satellite/Mobile Communication

Terminal) 2

For Safety 2

Contents 4

Name of Each Part 9

Contents with Illustrations 10

Traveling System 10

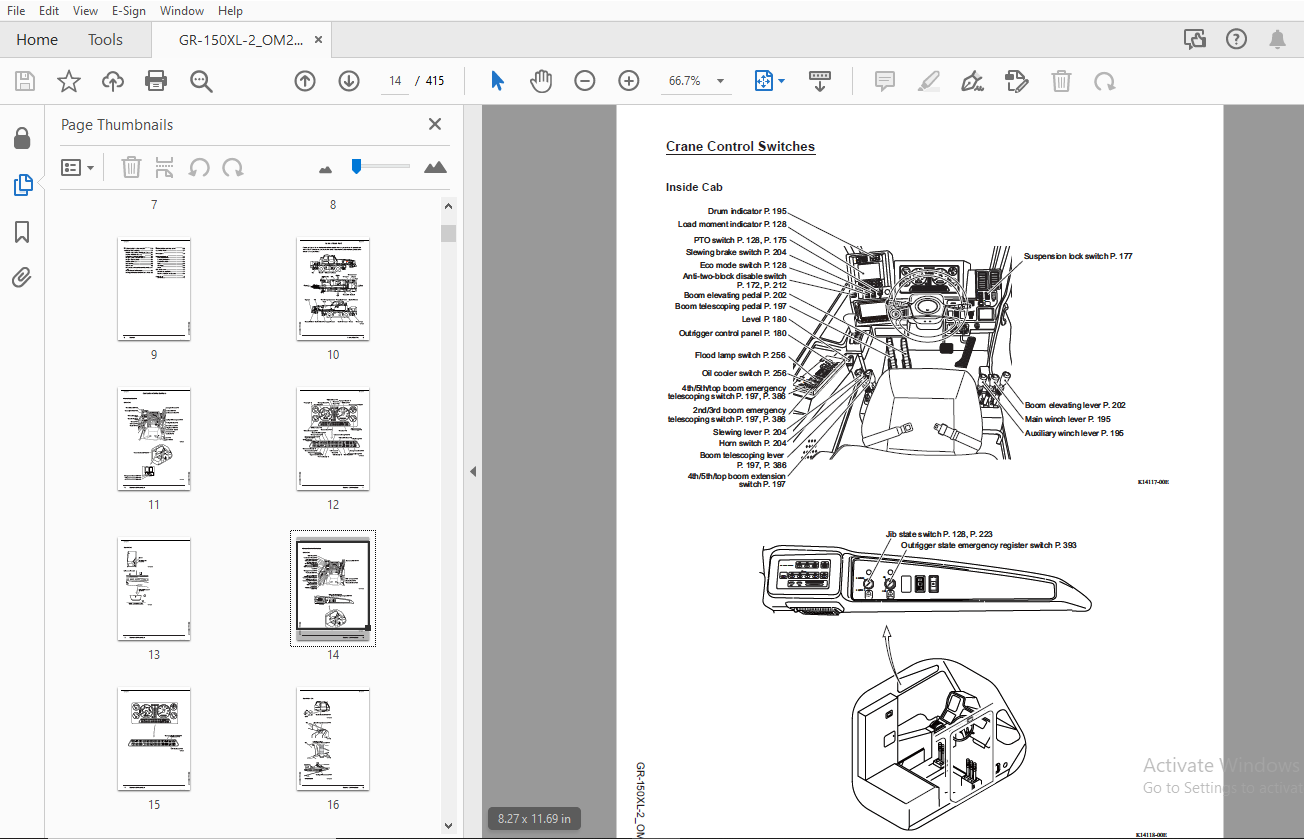

Crane Control Switches 13

Other Controls 16

Safety Precautions 19

Precautions before Starting Engine 19

Precautions for Traveling on Roads 24

Precautions during Operation 30

Warning Labels 45

Label Location and Content of Warnings 46

TRAVELING 57

Before Traveling 59

Checking Traveling Posture 59

Status of Traveling System 59

Inspection before Traveling 59

Entering Cab 60

Opening/Closing Door 60

Opening/Closing Window 62

Adjustment of Seat 63

Adjustment of Steering Wheel 64

Adjustment of Mirrors 64

Fastening/Unfastening of Seat Belt 65

Stowing Control Levers 66

Sunshade 66

Reading Instrument Panel 67

Instrument Panel and Gauges 67

Warning Lamps 70

Starting and Stopping Engine 73

Starting Engine 74

Stopping Engine 75

Transmission Operation 76

Shift Lever Operation 77

Brake Operation 80

Foot Brake Operation 82

Parking Brake Operation 83

Exhaust Brake Operation 83

Steering Operation 84

Steering Mode Selecting Operation 86

Drive Mode Selection 91

Selecting Drive Mode 92

Lighting Switch and Other Switches 93

Lighting Switch 93

Turn Signal Lever 94

Hazard Lamp Switch 95

Horn Switch 95

Wiper 95

Accessories in Cab 97

Air Conditioner 98

Fuel Consumption Monitor 103

Monitor 107

How to Use Other Accessories 110

Operation in Cold Season 11 2

Winterization 112

OPERATION 11 3

Terminology 11 5

Before Crane Operation 11 7

Pre-operational Inspection 117

Preparation for Crane Operation 117

How to Read Performance Data Plates 11 9

Working Range Chart 119

Rated Lifting Capacity Table 120

Reduced Lifting Capacity from Rated Lifting

Capacities 126

Load Moment Indicator (AML) 12 7

Display 130

Selection of Display 134

Crane State Indicator Display 135

Registration of Operating State and Load Moment

Indicator Function Check 137

Alarm and Recovery Operation 147

Other Functions 152

Action against Load Moment Indicator System

Error 171

Other Safety Devices 172

Anti-two-block device 172

External Warning Lamps (Option) 173

Load Moment Indicator External Indicator Lamp

(Option) 174

PTO 175

Engaging PTO (PTO “ON” Operation) 175

Disengaging PTO (PTO “OFF” Operation) 176

Suspension Lock 177

Suspension Lock Operation 178

Suspension Lock Release Operation 179

Outriggers 180

Outrigger Set-up 183

Outrigger Extending Operation 184

Level Set-up 188

Outrigger Stowing Operation 190

Adjustment of Control Levers 193

Adjustment of Levers 193

Hoisting 195

Hoisting Up/Down Operation 195

Drum Indicator 196

Telescoping Boom 197

Boom Extending/Retracting Operation 197

Maintenance Telescoping Operation 200

Elevating Boom 202

Boom Raising/Lowering Operation 202

Boom Elevation Slow Stop/Cancel Operation 203

Slewing Boom 204

Slewing Boom 205

On-rubber Operation 207

On-rubber Stationary Operation 208

On-rubber Creep Operation 209

Taking Out and Stowing Hook Block 21 2

Taking Out Hook Block 212

Stowing Hook Block 214

Reeving Wire Rope 21 6

Standard Number of parts of line 216

Reeving Procedure 217

Single Top 22 1

Standard Jib 22 2

Selection of Jib Mounted Condition 224

Jib Lift 225

Outline of Jib Mounting 226

Mounting Jib 227

Changing Jib Offset Angle 236

Changing Jib Length 239

Outline of Jib Stowing 247

Stowing Jib 248

Accessories in Cab 256

Flood Lamp Switch 257

Roof Washer Switch 257

Roof Wiper Switch 257

Oil Cooler Switch 258

INSPECTION AND MAINTENANCE 259

Precautions for Inspection and Maintenance 261

Precautions for Inspection and Maintenance 261

Inspection and Maintenance 271

About Inspection and Maintenance 271

Under Severe Use (Severe Condition) 272

Conditions of Severe Use 272

Periodic Replacement Part 273

Inspection and Maintenance Interval (Carrier) 276

Inspection and Maintenance Interval (Crane) 283

Inspection before Traveling 288

Abnormal Items Detected on Previous Day or

Operation 289

Inspection around Carrier 290

Inspection of Engine Room 297

Inspection at Driver’s Seat 300

Pre-operational Inspection 307

Hydraulic System 308

Operating Device 309

Outrigger System 310

Slewing System 312

Boom/Jib System 313

Lifting Device 315

Safety Devices 318

Inspection of Crane Structure 32 0

Greasing 32 2

Maintenance Table 323

Greasing Chart 324

Gear Oil 32 7

Maintenance Table 327

Winch Speed Reducer (Main/Auxiliary Winch) 328

Slewing Speed Reducer 329

Axle (Carrier) 330

Axle (Planetary Gear) 331

Engine 33 3

Maintenance Table 333

Air Cleaner 334

Engine Cooling System 33 6

Maintenance Table 336

Coolant Filter 337

Torque Converter System 33 8

Maintenance Table 338

Transmission 338

Line Filter 341

Fuel System 34 2

Maintenance Table 342

Engine Fuel Filter 343

Water Separator 343

Brake System 34 5

Maintenance Table 345

Brake Fluid Reservoir 345

Disc Brake Pad 346

Air Dryer 347

Tire, Wheel 34 8

Maintenance Table 348

Tire 348

Wheel Nut 350

Hydraulic System 351

Maintenance Table 352

Hydraulic Oil Tank 353

Return Filter 355

Line Filter

(Pump Circuit for Steering and Slewing) 356

Telescoping System 358

Maintenance Table

(for serial No FD4262 or later) 358

Wire Rope for Boom Telescoping

(for serial No FD4262 or later) 358

Slewing System 360

Maintenance Table 360

Slewing Bearing Mounting Bolt 360

Electrical System 362

Maintenance Table 362

Replacing Fuses 362

Air Conditioner System 366

Maintenance Table 366

Condenser 366

Refrigerant Level 366

Refrigerant Piping Connection 367

Inside Air Filter 367

V-belt 368

Periodic Replacement Part 368

Water Pump 368

Wire Ropes 369

Replacing Wire Ropes 369

Handling Wire Ropes 376