$31

Tadano GR-500EX Rough Terrain Crane Operation Manual – PDF

Tadano GR-500EX Rough Terrain Crane Operation Manual 540791–549999 RA0001 – PDF DOWNLOAD

FILE DETAILS:

Tadano GR-500EX Rough Terrain Crane Operation Manual 540791–549999 RA0001 – PDF DOWNLOAD

Language : English

Pages : 443

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Tadano GR-500EX Rough Terrain Crane Operation Manual 540791–549999 RA0001 – PDF DOWNLOAD

EC Declaration of Conformity 1

Appendix 2

Introduction 5

Using Crane Out of Country of Purchase

(Including Satellite/Mobile Communication

Terminal) 6

For Safety 6

Contents 8

Name of Each Part 13

Contents with Illustrations 14

Traveling System 14

Crane Control System 18

Other Controls 22

Safety Precaution 25

Precautions before Starting Engine 25

Precautions for Traveling on Roads 30

Precautions during Operation 35

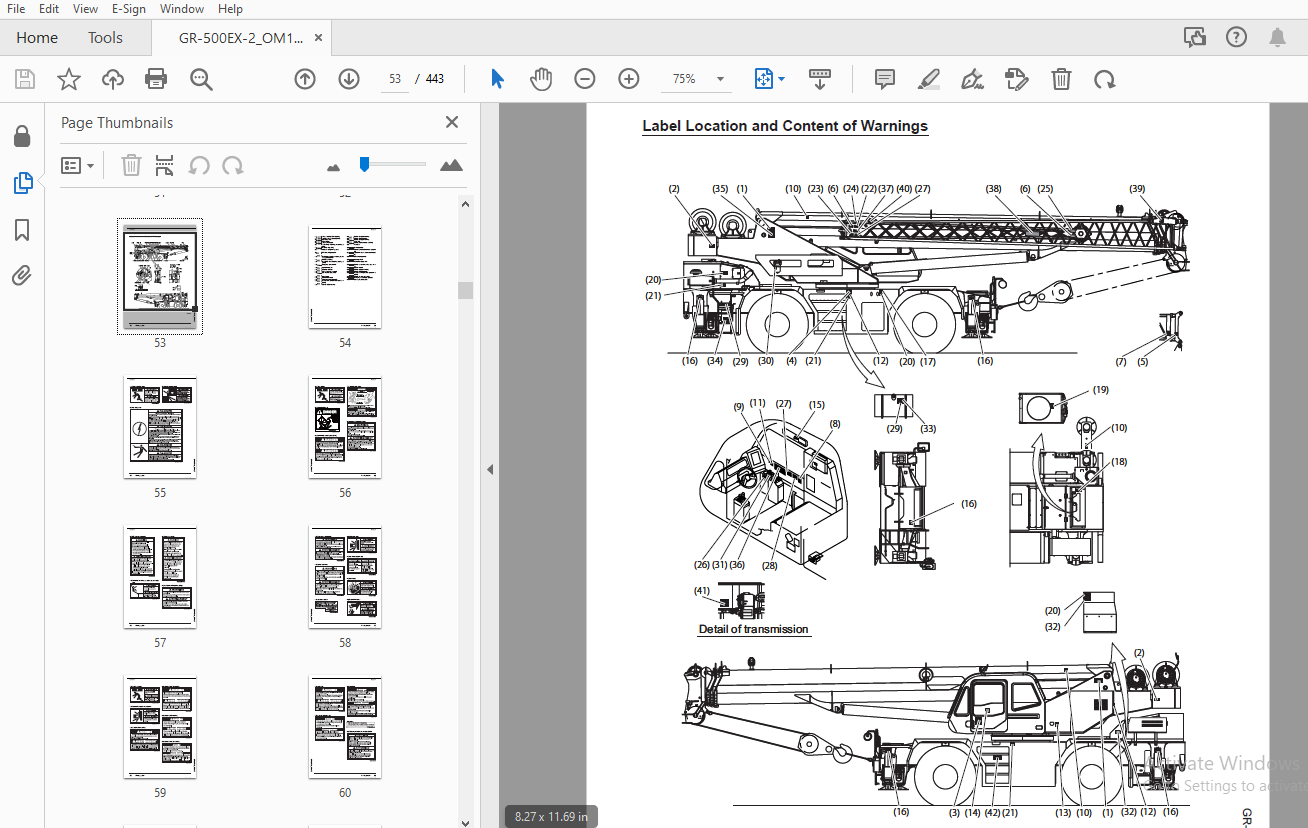

Warning Labels 51

Label Location and Content of Warnings 52

TRAVELING 65

Before Traveling 67

Check of Traveling Configuration 67

Status of Traveling Controls 67

Inspection before Traveling 67

Entering Cab 68

Opening/Closing Door 68

Opening/Closing Window 70

Adjustment of Seat 71

Adjustment of Steering Wheel 72

Adjustment of Mirrors 72

Fastening/Unfastening of Seat Belt 73

Adjustment of Control Lever Stand 74

Sunshade 74

Reading Instrument Panel 75

Meters and Gauges 75

DPF (Diesel Particulate Filter) Indicator 79

Warning lamp 81

Starting and Stopping Engine 84

How to Start Engine 85

How to Stop Engine 86

DPF regeneration 87

Transmission Operation 89

Shift Lever Operation 90

Brake Operation 92

Foot Brake Operation 94

Parking Brake Operation 95

Exhaust Brake Operation 95

Steering Operation 96

Selecting Steering Mode 98

Drive Mode Selection 102

Drive Mode Selection 103

Lighting Switch and Other Switches 104

Lighting Switch 104

Turn Signal Lever 105

Hazard Lamp Switch 106

Horn Switch 106

Wiper 107

Accessories in Cab 108

Fuel Consumption Monitor 109

Air Conditioner 112

Cab Lamp 117

Cigarette Lighter 117

Handling Tires 11 8

Tire Air Pressure 118

Restriction of Continuous Traveling 118

Operation in Cold Season 11 9

Winterization 119

OPERATION 12 1

Terminology 12 3

Before Crane Operation 12 5

Pre-operational Inspection 125

Preparing for Crane Operation 125

How to Read Performance Data Plates 12 7

Working Range Chart 127

Rated Lifting Capacity Table 128

Boom LiftSingle Top Lift 132

Reduction of Rated Lifting Capacity 134

Automatic Moment Limiter (AML) 13 5

How to Read Indication 138

Selecting Display 142

Crane Status Indicator 143

Registration of Operating Status and AML

Function Check 145

Alarm and Recovery Operation 155

Other Functions 159

Action against AML system errors 181

Other Safety Devices 18 2

Overwind Cutout Device 182

AML External Warning Lamps 184

External Warning Buzzer 184

Emergency Stop Switch 185

Over-unwinding Cutout Function (Option) 186

Digital Anemometer (Option)

(For Serial No 541011 or later) 189

PTO 192

PTO “ON” Operation 192

PTO “OFF” Operation 193

Suspension Lock 194

Locking Suspension 195

Releasing Suspension Lock 196

Outriggers 197

Outrigger Set-up 200

Extending Outriggers 202

Horizontal Set-up 206

Stowing Outriggers 208

Hoisting 21 1

Hoisting Up/Down 212

Drum Indicator (visual type) 214

Drum Indicator (vibration type) (optional) 214

Boom Telescoping Control 21 5

Boom Telescoping Control 215

Elevating Boom 21 8

Boom Raising/Lowering Operation 218

Elevation Slow Stop Function 219

Swinging Boom 22 0

Swinging Boom 221

Swing Free/Lock Selector Switch 223

Automatic Swing Stop Function 223

On-rubber Operation 22 4

On-rubber Stationary Operation 225

On-rubber Creep Operation 226

Taking Out and Stowing Hook Block 22 8

Taking Out Main Hook Block 228

Stowing Main Hook Block 229

Reeving Wire Ropes 23 0

Standard number of parts of line 230

Reeving Procedure 233

Single Top 23 8

Mounting Single Top 239

Stowing Single Top 243

Jib 24 7

Registration of Jib status 249

Jib Lift 250

Outline of Jib Mounting 251

Mounting of Base Jib 252

Mounting of Base Jib + Top Jib 262

Changing Jib Offset Angle 272

Outline of Jib Stowing 275

Stowing of Base Jib 276

Stowing of Base Jib + Top Jib 284

Dismounting Jib 290

Mounting Jib 292

Accessories in Cab 294

Flood Lamp Switch 295

Roof Washer Switch 295

Roof Wiper Switch 295

ECO Mode Switch 296

Accessories Outside of Cab 297

Winch Drum Monitoring Mirror 297

Boom Top Flood Lamp (Option) 298

INSPECTION AND MAINTENANCE 299

Precautions for Inspection and Maintenance 301

Precautions for Inspection and Maintenance 301

Inspection and Maintenance 309

About Inspection and Maintenance 309

Under Severe Use (Severe Condition) 310

Conditions of Severe Use 310

Periodic Replacement Part 311

Inspection and Maintenance Interval (Carrier) 314

Inspection and Maintenance Interval (Crane) 320

Inspection before Traveling 32 5

Abnormal items detected on previous day or travel

326

Inspection around Carrier 327

Inspection of Engine Room 334

Inspection at Driver’s Seat 337

Pre-operational Inspection 34 3

Hydraulic System 345

Control System 346

Outrigger system 347

Swing system 349

Boom, Jib System 350

Lifting Device 352

Safety Devices 355

Inspection of Crane Structure 357

Greasing 359

Maintenance Table 360

Greasing Chart 361

Gear oil 36 4

Maintenance Table 364

Winch Speed Reducer (Main/Auxiliary Winch) 365

Swing Speed Reducer 366

Axle (Carrier) 368

Axle (Planetary Gear) 369

Engine 37 1

Maintenance Table 371

Radiator Fin 371

Engine Cooling System 37 2

Maintenance Table 372

Coolant Filter 373

Transmission System 37 4

Maintenance Table 374

Transmission 374

Line filter 377

Fuel System 37 8

Maintenance Table 378

Draining Water from Water Separator 379

Brake system 38 0

Maintenance Table 380

Brake Fluid Reservoir 380

Disc Brake Pad 381

Air Dryer 382

Parking Brake Pad 383

Tire, Wheel 38 5

Maintenance Table 385

Tire 385

Wheel Nut 387

Hydraulic system 38 8

Maintenance Table 389

Hydraulic oil tank 390

Return Filter (Front of Hydraulic Tank) 392

Line Filter (Pump Circuit for Steering/Swing) 392

Swing System 394

Maintenance Table 394

Swing Bearing Mounting Bolt 394

Electrical System 397

Maintenance Table 397

Replacing Fuses 397

Air Conditioner System 399

Maintenance Table 399

Condenser 399

Refrigerant level 399

Refrigerant Piping Connection 400

Inside Air Filter 400

Outside Air Filter 400

V-belt 401

Periodic Replacement Part 401

Wire Rope 402

Replacing Wire Ropes 402

Handling Wire Ropes 409

Eliminating Excessive Twisting of Wire Rope 410

EMERGENCY OPERATIONS 41 1

Action against Emergency 41 4

If Failure Occurs during Traveling on Road 414

If Stalled at Railroad Crossing 414

To Interrupt DPF Regeneration 415

If Transmission Cannot Be Operated 416

If Engine Speed Does Not Increase 419

If Engine Does Not Stop 419

If Overheated 420

When Towed 421

If Crane Does Not Operate toward Non-critical

Sides 423

If Boom Raising Is Not Possible 424

If Error Occurs in AML System 425

If Boom Telescoping is Not Possible 426

If Outrigger Status is Not Detected 427

INFORMATION AND DATA 42 9

Conversion Tables 43 1

Major Specifications 43 2

Crane Specifications 432

Carrier Specifications 432

Overall Dimensions 433

Mass 434

Wire Rope 434

Other 434

Oils and Greases 43 5

Oils and Greases Table 435

Recommended Oils and Greases 436

Service Data 43 9

Service Data 439