$30

Tadano RTF200-6 Carrier Operation Manual – PDF

Tadano RTF200-6 Carrier Operation Manual – PDF DOWNLOAD

FILE DETAILS:

Tadano RTF200-6 Carrier Operation Manual – PDF DOWNLOAD

Language : English

Pages : 121

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Tadano RTF200-6 Carrier Operation Manual – PDF DOWNLOAD

PREFACE

Operating Manual 1

Operation and Maintenance 1

Handling 2

SAFETY PROVISIONS

1 Instructions how to avoid damage 3

1 1 Applications planning 3

1 2 Instructions for mobile cranes traveling on public roads and streets 3

1 3 Steps to be taken prior to crane operation 4

1 4 Instructions for crane operation 4

1 5 Prevention of damage due to maintenance faults 5

1 6 Instructions for the crane operator 5

PART A) TECHNICAL DETAILS

1 General technical details A-1

1 1 Dimensions and weights A-1

1 2 Speeds, gradabilities and tractive efforts A-3

2 Technical details of components A-4

2 1 Engine A-4

2 2 Gearbox A-4

2 3 Axles A-s·

2 4 Axle suspension A-6

2 5 Power transmission A-6

2 6 Wheels and tires A-7

2 7 Brakes system A-7

2 8 Steering system A-8

2 9 Electrical equipment A-8

2 1 O Instruments A-9

2 11 Driver’s cab A-9

2 12 Heating system A-9

2 13 Frame A-9

2 14 Outriggers A-9

2 15 Fuel system A-1 O

2 16 Standard equipment A-1 o

PART B) OPERA TING INSTRUCTIONS

1 General Instructions concerning operation of the vehicle 8-0

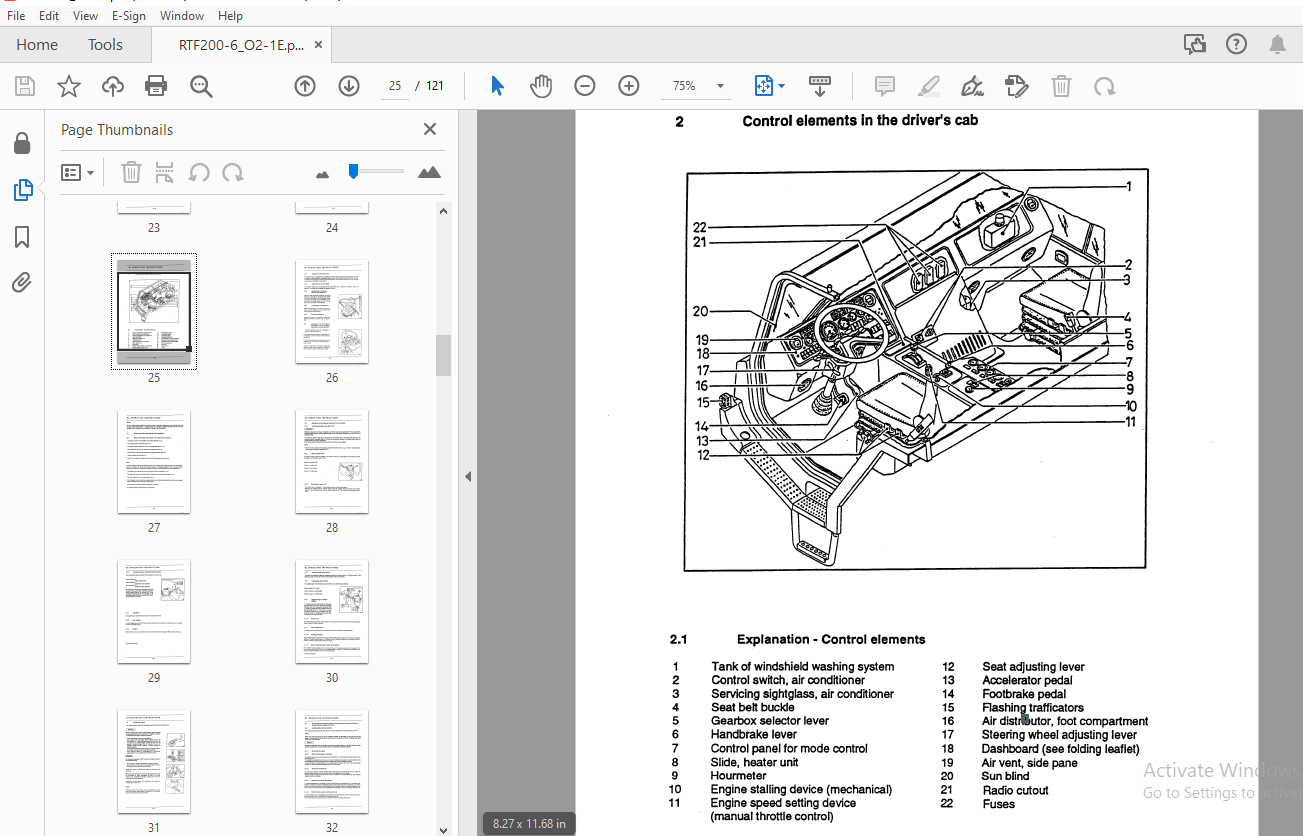

2 Control elements In th driver’s cab 8-1

2 1 Explanation – Control elements B-1

2 2 Adjustment of driver’s seat B-2

2 3 Adjustment of steering wheel’s angle of inclination and vertical position B-2

3 How to put the crane carrier Into operation 8-3

3 1 Steps to be taken and checks to be made prior to start-up B-3

3 2 Operation of the electrical equipment of the chassis B-4

3 3 Starting the engine B-7

3 4 Monitoring the indicafing, pilot and waming lamps as well as the instruments

while the engine is running B-8

3 5 Suspension B-13

4 Instructions for driving In the crane carrier 8-20

4 1 Gearshift and driving operation B-20

5 (Omitted)

6 Operation in winter 8-28

6 1 Engine B-28

6 2 Gearbox B-30

6 3 Wanning up the hydraulic oil or changing the oil type in winter B-30

6 4 Batteries B-30

6 5 Engine-fed warm water heating system B-32

6 6 Mirror heating B-32

6 7 Adjustable air vents B-32

6 8 Windshield washing system B-32

6 9 Air condition B-33

7 Dashboard 8-34

7 1 Indicating, pilot and warning lamps B-34

7 2 Miscellaneous B-34

7 3 Instruments B-34

7 4 Switches, rocker switches (WS), rocker tip switches (WT) B-34

8 Control panel for mode control

PART C) SERVICE AND MAINTENANCE

1 General Instructions concerning Service and Maintenance C-1

1 1 Instructions and steps to be taken prior to any servicing and

maintenance operation C-1

1 2 After having finished service and maintenance works C-2

1 3 Electric welding works C-2

1 4 Inspection of screw couplings C-2

1 5 Tightening torques of screws and bolts C-3

2 Engine C-4

2 1 Inspection of cooling agent in the compensating tank C-4

2 2 Air cleaner C-5

3 Allison Powershlft Gearbox, Model CLBT 755 C-8

3 1 Oil level inspection C-8

3 2 Oilchange – replacement of oil filters C-9

4 Steyr Drop Box 1600 C-12

4 1 Oil level inspection C-12

4 2 Oilchange C-12

5 Steyr Transfer Box VG 2000 C-13

5 1 Oil level inspection C-13

5 2 Oilchange C-13

6 Pump Transfer Box Technodrive AM 216 8 C-14

6 1 Oil level inspection C-14

6 2 Oilchange C-14

7 Axles (make KESSLER) C-15

7 1 Oil level inspection in the axle drive assemblies of the driven steering

axles, and in the planetary gears C-15

7 2 Oilchange in the axle drive assemblies and planetary gears C-15

7 3 Oil level inspection in inter-axle differential at the 4th axle C-16

7 4 Oilchange in inter-axle differential at the 4th axle C-16

7 5 General visual and functional check C-16

7 6 Grease filling in the wheel hubs C-17

7 7 Check axial play of steering axle bearings and planetary bearings; check

wheel bearing backlash; check spur gear supporting bolts C-17

7 8 Check screws and bolts at axles for tight fit; check axle fastening, steering

levers, thrust rod fastening etc C-17

7 9 Preservation of axle and planetary drive assemblies C-17

8 Propeller shafts C-18

8 1 Greasing of propeller shafts C-18

8 2 Inspection of backlash of propeller shafts C-18

8 3 Noise test of propeller shafts C-18

9 Cleaning and inspection of the breathers at the gearbox and the

driven steering axles C-19

10 Hydraulic system of chassis C-20

10 1 Hydraulic oil level inspection C-20

10 2 Replacement of filter cartridges C-20

10 3 Replacement of ventilation filter C-21

10 4 Oilchange in hydraulic oil tank C-21

10 5 Hydraulic system of steering assembly C-22

10 6 Hydraulic system of suspension C-23

10 7 Maintenance instructions for hydraulic cylinders or components C-24

10 8 Pressure check in hydraulic system C-24

11 Brakes system C-25

11 1 Drainage valves C-25

11 2 Air drier C-25

11 3 Pressure governor with tire inflater socket C-26

11 4 Brake cylinders C-27

11 5 Inspection of wheel brakes C-28

11 6 Wheel brakes – maintenance C-29

11 7 Test connectors for inspection of the compressed air brake system C-30

12 Electrical equipment c-31

12 1 Batteries C-31

12 2 Three-phase generator C-32

12 3 Starter C-32

12 4 Lamps and lights C-32

12 5 Fuses arrangement in the chassis C-33

12 6 Relay arrangement in the chassis C-34

13 Wheels and tires C-36

13 1 Measures to be taken to avoid accidents caused by the wheels C-36

13 2 Check wheel nuts at disc wheel for tight fit C-36

13 3 Tightening torque of wheel nuts (with thrust plate) C-36

13 4 Tire pressure C-36

13 5 Replacement of a disc wheel C-37

13 6 Change of wheels because of wear of tires

14 Fully automatic centralized grease lubricating system C-38

14 1 Method of operation of the system C-38

14 2 Pump unit with tank C-38

14 3 Setting the dead times on the control unit C-38

14 4 Malfunction indicator and functional check C-39

14 5 Maintenance C-39

15 Air condition C-40

15 1 Functional check of air condition C-40

15 2 Cleaning the air condition condenser C-40

15 3 Checking the evaporator with blower fan C-40

15 4 Checking Vee belt of air conditioner compressor C-40

16 Maintenance schedule- chassis C-41

16 1 Engine C-41

16 2 Air cleaner C-41

16 3 Allison Powershift Gearbox, Model CLBT 755 C-42

16 4 Steyr Drop Box, Model 1600 C-43

16 5 Steyr Transfer Box, Model VG 2000 C-43

16 6 Pump Transfer Box, Technodrive, Model AM 216 B C-43

16 7 Axles C-44

16 8 Propeller shafts C-45

16 9 Breathers C-45

16 1 o Hydraulic system C-45

16 11 Steering system C-46

16 12 Hydraulic system of suspension C-47

16 13 Brake system -·········· ·········· C-48

16 14 Electrical equipment C-50

16 15 Wheels and tires C-50

16 16 Fully automatic centralized lubricating system C-51

16 17 Air condition C-51

17 OIi sorts, filling capacities (recommended oil sorts) C 02

18 Lubricating greases (recommended oil sorts) C-55

18 1 Centralized lubricating system C-55

19 Inspection and cleaning diagram C-66

20 OU level Inspection and ollchange diagram C-o7

21 Lubricating schedule – Nipple greasing points C-58