$34

Tadano TR-600EXL-3 Rough Terrain Crane Operation & Maintenance Manual – PDF

Tadano TR-600EXL-3 Rough Terrain Crane Operation & Maintenance Manual 545366 – PDF DOWNLOAD

FILE DETAILS:

Tadano TR-600EXL-3 Rough Terrain Crane Operation & Maintenance Manual 545366 – PDF DOWNLOAD

Language : English & Japanese

Pages : 409

Downloadable : Yes

File Type : PDF

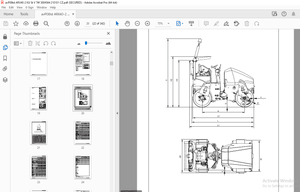

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Tadano TR-600EXL-3 Rough Terrain Crane Operation & Maintenance Manual 545366 – PDF DOWNLOAD

Safety A-1

Safety Rules A-3

Before Operation A-4

Rules for Operation (Setting Outriggers) A-15

Rules for Operation (General) A-17

Rules for Operation (Weather) A-34

Rules for Operation (Power Lines, Radio Waves) A-37

Rules for Operation (Operation without Extending

Outriggers) A-39

Rules for Operation (Special Operation) A-41

After Operation A-43

Rules for Road Travel A-44

Rules for Transportation and Towing A-49

Rules for Parking A-52

Rules for Inspection and Maintenance A-54

Warning Labels A-67

Warning Labels – Location and Contents A-68

Contents 1

Preface 7

Servicing and Ordering Parts 8

Directional Terms 9

Components 10

Layout of Controls 11

Travel Operation Controls 11

Crane Operation Controls 13

Others 15

Terminology 16

[TRAVELING]

Traveling Procedure 21

Preparatory Steps 21

Starting 25

Traveling 26

Stopping 27

Parking 28

Crane Operator’s Cab 29

Opening and Closing the Door 29

Opening and Closing the Windows 31

Adjusting the Seat Position 32

Control Levers Stowing 33

Adjusting the Steering Wheel 34

How to Read the Instrument Panel 35

Meters and Gauges 35

Indicator Lamps 39

Starting and Stopping the Engine 44

Controls 44

How to Use the Starter Switch 44

Pre-starting Checks 45

Starting the Engine 46

Stopping the Engine 48

Changing Drive Mode 49

Controls 49

Changing Drive Mode 49

Changing Speed Range 52

Controls 52

Changing Speed Range 52

Brakes 56

Controls 56

Foot Brake 56

Parking Brake 57

Exhaust Brake 58

Steering 59

Controls 59

Changing Steering Mode 59

Lighting and Other Switches 62

Controls 62

Tires 66

Air pressure 66

Restriction on Continuous Driving 66

Equipment Inside the Cab 67

Control 67

Air Conditioner (Option) 68

Equipment Inside the Cab 69

Equipment Outside the Cab 72

How to Use the Air Inflator (Option) 72

Tire Chain (Option) 74

Emergency Procedures 75

If Trouble Occurs 75

If the Engine Stops while Traveling 76

When Engine Stops Due to Fuel Shortage 76

If Shifting Gears is Impossible 77

Towing the Crane 81

[CRANE OPERATION]

Crane Operation Procedure – Summary 85

On-outrigger Operation 85

How to Read the Performance Data Plate 90

Load Radius/Lifting Height Chart 90

Rated Lifting Capacity Table 92

AML (Overload prevention device) 99

Configuration and Functions of the AML System 102

Controls 106

Names and Functions of AML Main Unit Parts 108

Selecting Operational Status 116

AML Pre-operational Inspection 121

How to Use the Working Range Limit Function 125

Display Alteration 131

Recovery from a Stop 132

Display and Disposition of Failure Messages 135

Disposition of System Trouble 138

Other Safety Devices 140

Overwind Cutout Device 140

Gate Switch 141

External Warning Lamps (Option) 142

Emergency Engine Stop Switch 143

Over-Unwinding Cutout Device 144

Operating the PTO and Warming Up the Machine 145

Operating the PTO 145

Warming Up the Machine 146

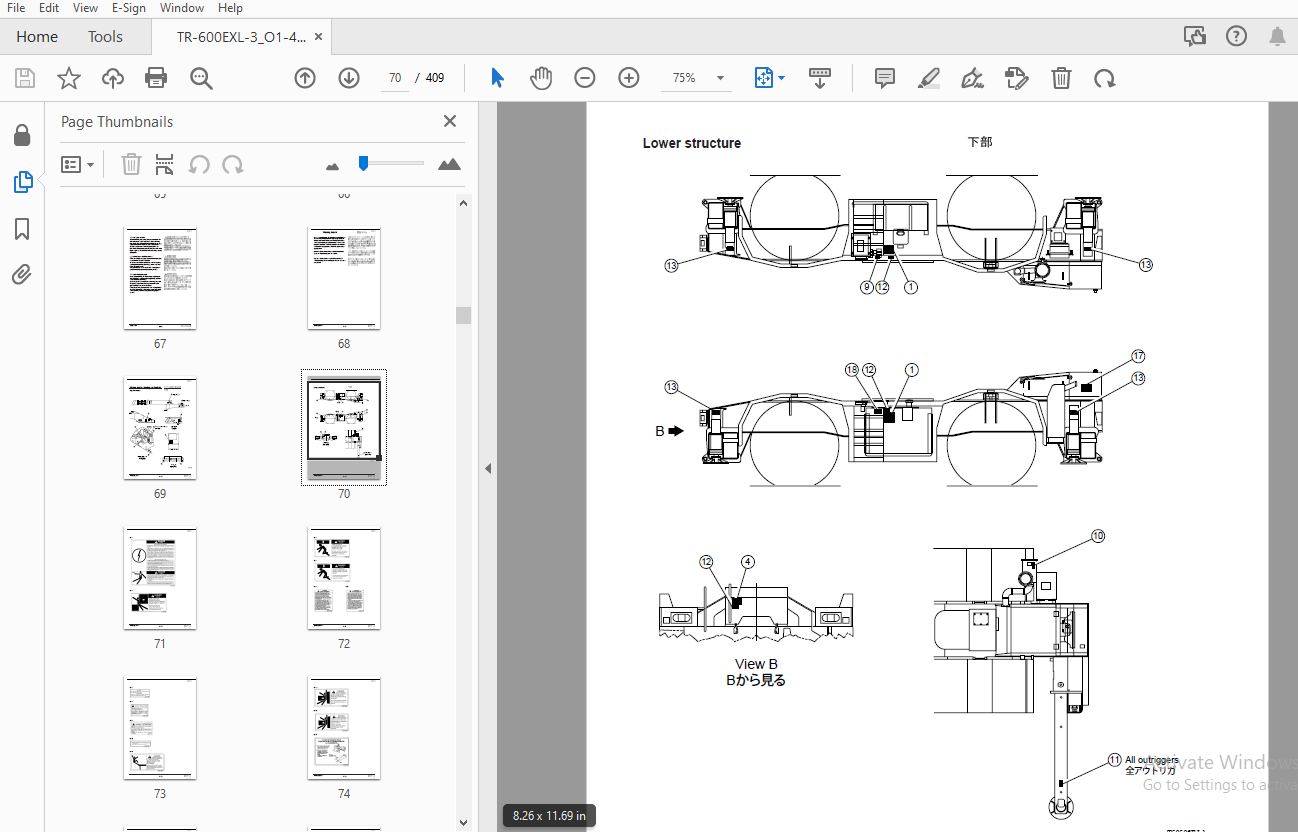

Outriggers 147

Setting the Crane 147

Controls 148

Extending the Outriggers 150

Level Adjustment 154

Stowing the Outriggers 156

Adjusting Control Levers 158

Adjusting Neutral Position of Levers 158

Adjusting Length of Control Levers 160

Hoisting 161

Controls (ISO recommended layout) 161

Hoisting Up and Down 161

Other Winch -related Control and Devices 163

Telescoping the Boom 164

Controls (ISO recommended layout) 164

Extending and Retracting the Boom 165

Emergency Telescoping Procedure 168

Elevating the Boom 170

Controls (ISO recommended layout) 170

Raising and Lowering the Boom 171

Swinging the Boom 173

Controls (ISO recommended layout) 173

Swinging the Boom 174

On-rubber Operation

177

Stationary 177

Traveling with a Load Lifted 179

Removing and Stowing the Main Hook Block 180

Removing the Main Hook Block 180

Stowing the Main Hook Block 182

Reeving Wire Rope 183

Standard Number of Parts of line 182

Reeving Procedure 186

Single Top 189

Components 189

Single Top Lift 190

Mounting the Single Top 191

Stowing the Single Top 194

Jib 197

Components 197

Jib Lift 198

Mounting the jib 200

Changing the jib Offset Angle 207

Changing the Jib Length 209

Stowing the Jib 215

Mounting and Dismounting Counterweight 221

Components 221

Mass of Removable Counterweight 221

Mounting and Dismounting Counterweight 222

Equipment Inside the Cab 225

Equipment Outside the Cab 227

Oil Cooler 227

Winch Drum Monitor Mirror (Option) 227

[INSPECTION AND MAINTENANCE]

Inspection and Maintenance 229

Pre-Operational and Periodic Inspection 230

Safety Parts Requiring Regular Replacement 230

Greasing 241

Maintenance Table 242

Greasing Chart 244

Gear Oil 246

Maintenance Table 246

Winch Speed Reducer Oil Level Check 247

Winch Speed Reducer Oil Replacement 247

Swing Speed Reducer Oil Level Check 249

Swing Speed Reducer Oil Replacement 249

Axle (Carrier Axle) Oil Level Check 251

Axle (Carrier Axle) Oil Replacement 251

Axle (Planetary Gear) Oil Level Check 253

Axle (Planetary Gear) Oil Replacement 253

Engine 255

Maintenance Table 255

Air Cleaner Check 256

Element Cleaning 257

Element Replacement 259

Engine Cooling System 260

Maintenance Table 261

Cooling Water Level Check 261

Torque Converter System 262

Maintenance Table 262

Oil Level Check 263

Oil Replacement 263

Strainer Cleaning 266

Line filter Element Replacement 267

Fuel System 268

Maintenance Table 269

Fuel Tank Level Check 269

Water Separator Water Level Check 270

Brake System 271

Maintenance Table 271

Brake Fluid Level Check 272

Brake Fluid Replacement 272

Disc Brake Pad Wear Check 273

Air Dryer Function Check 275

Air Dryer Desiccating Agent Replacement 275

Parking Brake Pad Clearance Adjustment 276

Axle system 278

Maintenance Table 278

Suspension Lock cylinder Bleeding

278

Tires and Wheels 280

Maintenance Table 280

Tire Wear Check 280

Tire Replacement 281

Loose Wheel Lug Nut Check 283

Hydraulic System 284

Maintenance Table 285

Oil Level Check (Hydraulic Oil Tank) 286

Oil Replacement (Hydraulic Oil Tank) 286

Return Filter (Hydraulic Oil Tank) 289

Air Breather (Hydraulic Oil Tank) 290

Line Filter (Automatic Stop Circuit) 290

Line Filter (Steering Circuit) 291

Line Filter (Winch Brake Circuit) 291

Swing System 292

Maintenance Table 292

Swing Bearing Mounting Bolt Check 292

Electrical System 293

Maintenance Table 293

Fuse Replacement 293

Battery Electrolyte Check 296

Boom Telescoping System 297

Maintenance Table 297

Stretch Check and Tension Adjustment of Wire Rope for

Boom Telescoping and Oil Feed Hose for Boom

Telescoping Cylinder 297

Wire Ropes 298

Proper Handling of Wire Ropes 298

Wire Rope Replacement 300

[INFORMATION AND DATA]

Conversion 307

Major Specifications 308

Crane Specifications 308

Carrier Specifications 309

Overall Dimensions 310

Mass 31

Relief Valve Pressure 311

Wire Rope Specifications 312

Others 312

Oils and Greases 313

Table 313

Recommended Oils and Greases 315

Consumable Parts 320

Filters 320

Fuses 321