$38

Tadano Truck Crane GS-300XL-1 Operation & Maintenance Manual – PDF DOWNLOAD

Tadano Truck Crane GS-300XL-1 Operation & Maintenance Manual – PDF DOWNLOAD

FILE DETAILS:

Tadano Truck Crane GS-300XL-1 Operation & Maintenance Manual – PDF DOWNLOAD

Language : ENHLISH

Pages :203

Downloadable : Yes

File Type : PDF

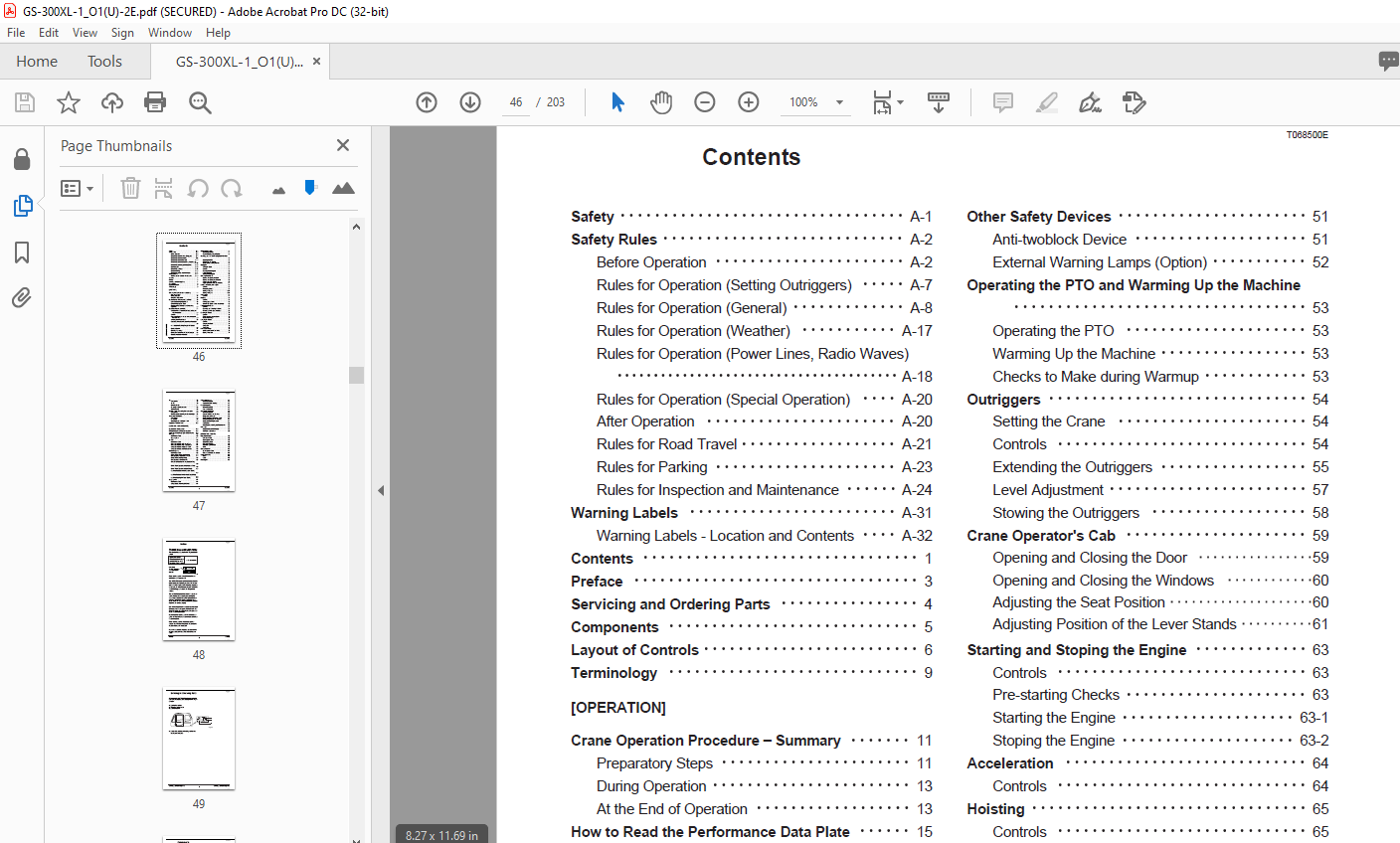

TABLE OF CONTENTS:

Tadano Truck Crane GS-300XL-1 Operation & Maintenance Manual – PDF DOWNLOAD

Safety A-1

Safety Rules A-2

Before Operation A-2

Rules for Operation (Setting Outriggers) A-7

Rules for Operation (General) A-8

Rules for Operation (Weather) A-17

Rules for Operation (Power Lines, Radio Waves)

A-18

Rules for Operation (Special Operation) A-20

After Operation A-20

Rules for Road Travel A-21

Rules for Parking A-23

Rules for Inspection and Maintenance A-24

Warning Labels A-31

Warning Labels – Location and Contents A-32

Contents 1

Preface 3

Servicing and Ordering Parts 4

Components 5

Layout of Controls 6

Terminology 9

[OPERATION]

Crane Operation Procedure – Summary 11

Preparatory Steps 11

During Operation 13

At the End of Operation 13

How to Read the Performance Data Plate 15

Load Radius/Lifting Height Chart 15

Rated Lifting Capacity Table 16

Reduced Lifting Capacity from Rated Lifting

Capacities 23

Load Moment Indicator (AML) 24

Configuration and Functions of the Load Moment

Indicator System 25

Controls 28

Names and Functions of Load Moment Indicator

Main Unit Parts 29

Selecting Operational Status 35

Load Moment Indicator Pre-operational Inspection

How to Use the Working Range Limit Function

Display Alteration 44

Recovery from a Stop 45

Display and Disposition of Failure Messages 48

Disposition of System Troubles 50

Other Safety Devices 51

Anti-twoblock Device 51

External Warning Lamps (Option) 52

Operating the PTO and Warming Up the Machine

53

Operating the PTO 53

Warming Up the Machine 53

Checks to Make during Warmup 53

Outriggers 54

Setting the Crane 54

Controls 54

Extending the Outriggers 55

Level Adjustment 57

Stowing the Outriggers 58

Crane Operator’s Cab 59

Opening and Closing the Door 59

Opening and Closing the Windows 60

Adjusting the Seat Position 60

Adjusting Position of the Lever Stands 61

Starting and Stoping the Engine 63

Controls 63

Pre-starting Checks 63

Starting the Engine 63-1

Stoping the Engine 63-2

Acceleration 64

Controls 64

Hoisting 65

Controls 65

Hoisting Up and Down 66

Other Winch-related Control and Devices 66

Telescoping the Boom 67

Controls 67

Extending and Retracting the Boom 68

Emergency Telescoping Procedure 68

Elevating the Boom 71

Controls 71

Raising and Lowering the Boom 71

Elevation Slow Stop 72

Swinging the Boom 73

Controls 73

Swinging the Boom 74

Swing Lock 75

Swing Stop 75

Reeving Wire Rope 76

Standard Number of Parts of line 76

Reeving Procedure 77

Jib 78

Components 78

Jib Lift 79

Mounting the Jib 81

Changing the Jib Offset Angle 85

Stowing the Jib 86

Mounting and Dismounting Counterweight 90

Components 90

Mounting and Dismounting the Counterweight 91

Air Conditioner (Option) 94

Components 95

How to Use 97

Error Display on the Display Panel 99

Equipment Inside the Cab 100

[INSPECTION AND MAINTENANCE]

Inspection and Maintenance 105

Pre-Operational and Periodic Inspection 106

Safety Parts Requiring Regular Replacement 109

Greasing 110

Maintenance Table 110

Greasing Chart 111

Gear Oil 113

Maintenance Table 113

Winch Speed Reducer Oil Level Check 114

Winch Speed Reducer Oil Replacement 114

Swing Speed Reducer Oil Level Check 115

Swing Speed Reducer Oil Replacement 115

Hydraulic System 116

Maintenance Table 116

Oil Level Check (Hydraulic Oil Tank) 117

Oil Replacement (Hydraulic Oil Tank) 117

Oil Level Check (Oil Reservoir) 118

Oil Replacement (Oil Reservoir) 118

Air Breather Replacement (Hydraulic Oil Tank)

Return Filter Replacement (Hydraulic Oil Tank)

Return Filter Replacement (Drain Circuit) 120

Line Filter Replacement (Winch brake Circuit)Line Filter Replacement (Automatic Stop Circuit)

Line Filter Cleaning (P4 Pump Circuit) 120

Swing System 121

Maintenance Table 121

Swing Bearing Mounting Bolt Check 121

Accelerator System 122

Maintenance Table 122

Accelerator Circuit Bleeding 122

Electrical System 123

Maintenance Table 123

Fuse Replacement 123

Air Conditioner (Option) 126

Maintenance Table 126

Condenser Check and Cleaning 126

Refrigerant Level Check 126

Refrigerant Piping Connection Check 127

Inside Air Filter Check and Cleaning 127

Outside Air Filter Replacement 127

V-belt Check 128

Parts Recommended Regular Replacement 128

Wire Ropes 129

Proper Handling of Wire Ropes 129

Wire Rope Replacement 130

[INFORMATION AND DATA]

Major Specifications 135

Conversion Table 135

Crane Specifications 137

Overall Dimensions 138

Relief Valve Pressure 139

Wire Rope Specifications 139

Other 139

Oils and Greases 140

Oil and Grease Table 140

Recommended Oils and Greases 141

Consumable Parts 142

Filters 142

Fuses 142

Hand Signals 143

IMAGES PREVIEW OF THE MANUAL: