$38

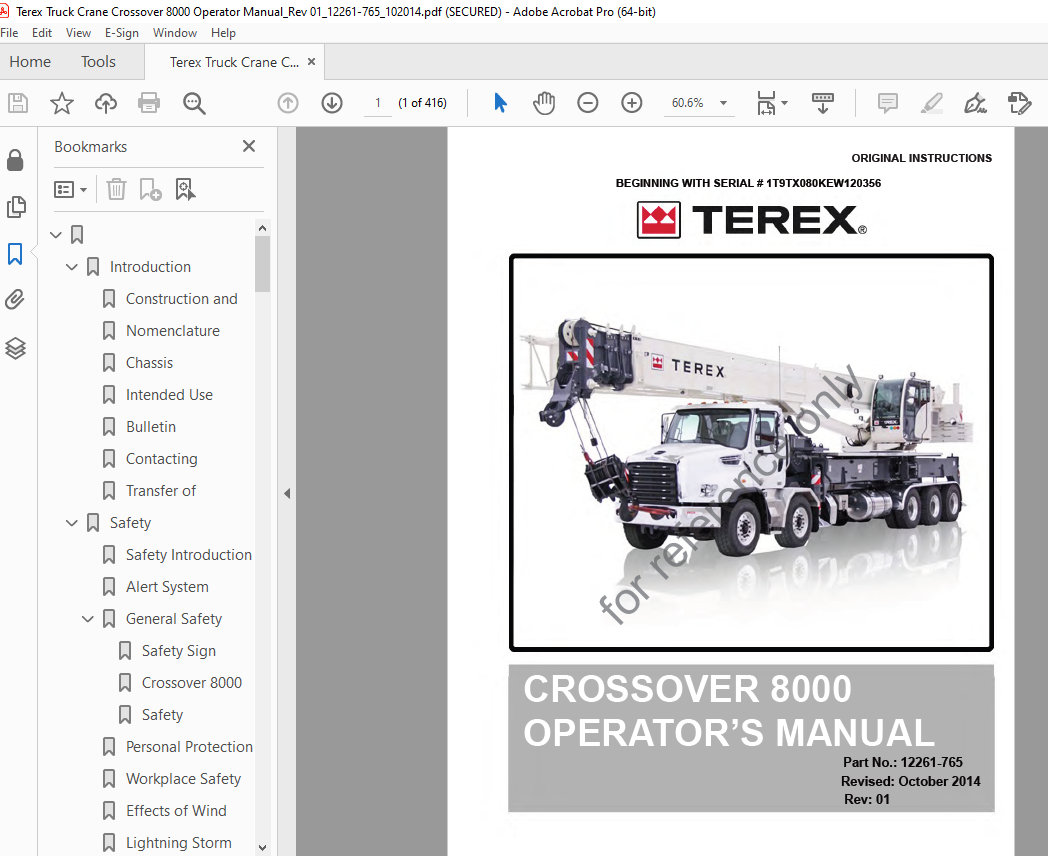

Terex Crane Crossover 8000 Operator’s Manual PN 12261-765 – PDF DOWNLOAD

Terex Crane Crossover 8000 Operator’s Manual PN 12261-765 – PDF DOWNLOAD

FILE DETAILS:

Terex Crane Crossover 8000 Operator’s Manual PN 12261-765 – PDF DOWNLOAD

Language : English

Pages : 416

Downloadable : Yes

File Type : PDF

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Crane Crossover 8000 Operator’s Manual PN 12261-765 – PDF DOWNLOAD

3

Introduction 9

Construction and Industrial Equipment Product Safety 9

Nomenclature 11

Chassis Configurations 12

Intended Use 13

Bulletin Distribution and Compliance 14

Contacting Manufacturer 15

Transfer of Machine Ownership 16

Safety 17

Safety Introduction 17

Alert System 18

General Safety 23

Safety Sign Maintenance 23

Crossover 8000 Safety Sign Locations 24

Safety Guidelines 42

Personal Protection Equipment 43

Workplace Safety 44

Effects of Wind Conditions 52

Lightning Storm 54

Temporary Interruption of Crane Operations 55

Resuming Crane Operations 58

Ending Crane Operations 59

Turning / Driving in Reverse 60

Parking the Vehicle 61

Lock Out & Tag Out 62

Access/Egress 64

Personal Safety 71

Seat Belts 72

Temperature Effects on Telescope and Boom Hoist Cylinders 73

Assembly 77

Erecting the Jib 77

Changing the Offset of the Jib 79

Spooling Wire Rope on Drums 81

Cable Sockets 85

Hoist-Line Reeving 88

Cable Reeving 91

Dead Ending Wire Rope in Socket 92

Extending and Retracting the Jib Pull-out Section 93

Counterweight Installation 95

Description Of Machine and Controls 99

Controls in the Cab 99

Upper Controls and Instruments 124

Universal Symbol Identification 131

Power Take-Off 135

Carrier Controls and Instruments 137

Side-Stow Jib 140

Rated Capacity Indicator and Anti-Two Block 142

Rated Capacity Indicator System 142

Anti-Two Block Components 143

Inspection 145

Pre-Start Inspection 145

Suggested Hydraulic Crane Inspection Checklist 147

Daily Check (8 Hours) 152

Weekly Check (40 Hours) 153

Monthly Check (80 hours) 154

Quarterly Checks (250 Hours) 155

Semiannual Checks (1000 Hours) 156

Annual Check (1500 – 2000 Hours) 157

Wire Rope Inspection 158

Wire Rope Inspection Record 160

Mobile Crane Load Test Inspection 161

Operating Instructions 165

Job-Site 165

Job Site Setup Procedure 165

Outrigger Positioning 166

Work Site Position 168

Cold Weather Operation 169

General Operational Issues 170

Ignition Switch-Carrier Cab & Upper Operator’s Cab 170

General Rules 171

Safety Devices 172

Training and Operator Qualifications 173

Operator Aids 174

Load Handling Operations 175

Max Load and Boom Angle Charts 176

Load Rating Chart Interpretation 176

Using the Maximum Load Chart 182

Operating Radius 184

Boom Angle Placards 185

Operating the Unit 186

Operator Shutoff Devices 186

Operating the Unit 189

Jump Starting an Engine- Booster Cable Instructions 190

Unusual Operating Conditions 191

Initiating Operation 195

Arm and Hand Signals 196

Lifting the Load 199

Making a Typical Lift 200

Moving the Unit 205

Removable Counterweight 205

Vehicular Operation 208

Traveling around the Jobsite 210

Roading the Unit 213

Towing or Pushing Vehicle 214

Dolly 215

Emergency Procedures 223

Emergency Procedures 223

Emergency Boom Retraction 224

Emergency Lowering of Boom 225

Emergency Rotation 226

Disassembly 227

Stowing the Jib 227

Transportation 229

Transporting the Crane 229

Instructions for Loading and Unloading 230

Maintenance 231

Maintenance Introduction 231

Cold Weather Package Specification 232

Cold Weather Package Recommendations 233

Safety Practices 237

General Work Practices 239

Storing Components 240

Cleanliness 241

Operator Observation 242

Maintenance Checks and Lubrication 243

90-Day Maintenance Items 245

Semi-Annual Maintenance Items 246

Machine Maintenance Checklist 247

Hydraulic Hoses 250

Filters and Maintenance 253

Diesel Exhaust Fluid Specification 255

TIRES 259

Tire Maintenance 261

Aluminum Decking & Fender Maintenance Procedure 264

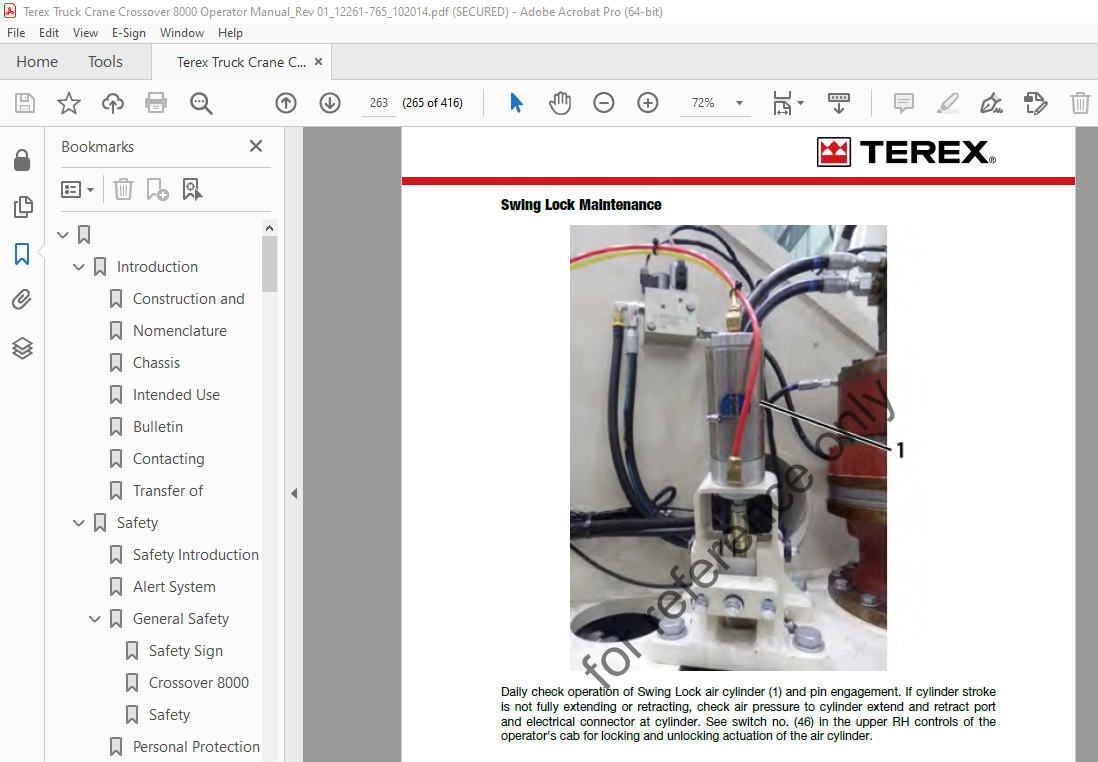

Swing Lock Maintenance 265

HVAC 266

Wire rope and reeving 270

Lubrication 272

Lubrication Introduction 272

Master Lubrication Chart 274

Grade Selection Chart 276

Hydraulic Oil Requirements 278

Koehring Spec 805 Data 281

Premium Grade Anti-Wear Hydraulic Oils 282

Turntable and Swing Pinion 285

Cable Lubrication Methods 287

Boom Lubrication 291

BOOM LUBRICATION & WEAR PADS INSPECTION RECORD 297

Swing Reducers 298

Slider Pads 299

Swing System Maintenance 300

Swing Bearing Bolting Procedure 300

Winch Lubrication 302

Wire Rope Lubrication 303

Drive Shaft Maintenance 304

Brake System Maintenance 307

Air System Maintenance 308

Engine Radiator Maintenance 309

Hydraulic System Maintenance 311

Anti-Two Block System 315

Storage 317

Storage 317

Machine Storage 319

Engine Storage 321

Transmission Storage 324

Chrome Cylinder Rod Storage 325

Restoration to Service 327

Restoring Engine to Service 328

Restoring Transmission to Service 329

Specifications 331

Wire Rope Specifications 331

Vehicle Dimensions 332

Engine Data 335

Pumps and Function Speeds 336

Troubleshooting 339

Introduction 339

General Procedure 341

Hydraulics – General 342

Operator Controls 343

Front Axles 344

Steering Circuit 346

Air Pressure 347

Swng Circuit 348

Boom Hoist Circuit 349

Telescope Circuit 350

Winch Circuit 351

Outrigger Circuit 353

Swing Pumps Circuit 354

Swing Circuit Control Valves 357

Swing Circuit Relief Valves 359

Fluid Motor 360

Cylinders 362

Cylinder Leakage 363

Excessive Heating of Oil In System 365

Electrical Controls 366

Two-Block System 367

Service / Parts 369

General Service Information 369

Outrigger Position Sensors 371

General Work Practices 239

Repairs-Adjustments-Remarks Log 374

Torque Wrench Extensions 376

Welding Instructions 378

Hydraulic System 380

Valve Adjustments 380

Pumps 386

Rotary Manifold 388

Rotation System 393

Inspection of Rotation Bearing Clearance 393

Swing Reducer 395

Electrical System 396

Fuse Block-Operator’s Cab 396

Relay & Fuse Block-Chassis 398

Electrical System Collector Ring 399

Maintenance -Free Battery Testing 401

Appendix 403

Conversion Tables 403

Average Weight of Materials 407

Torque Specs -SAE & Metric 409

California Proposition 65 Warning 411

Lead Warning – State of California 412

Greer Element VGA Operator’s Manual 413