$38

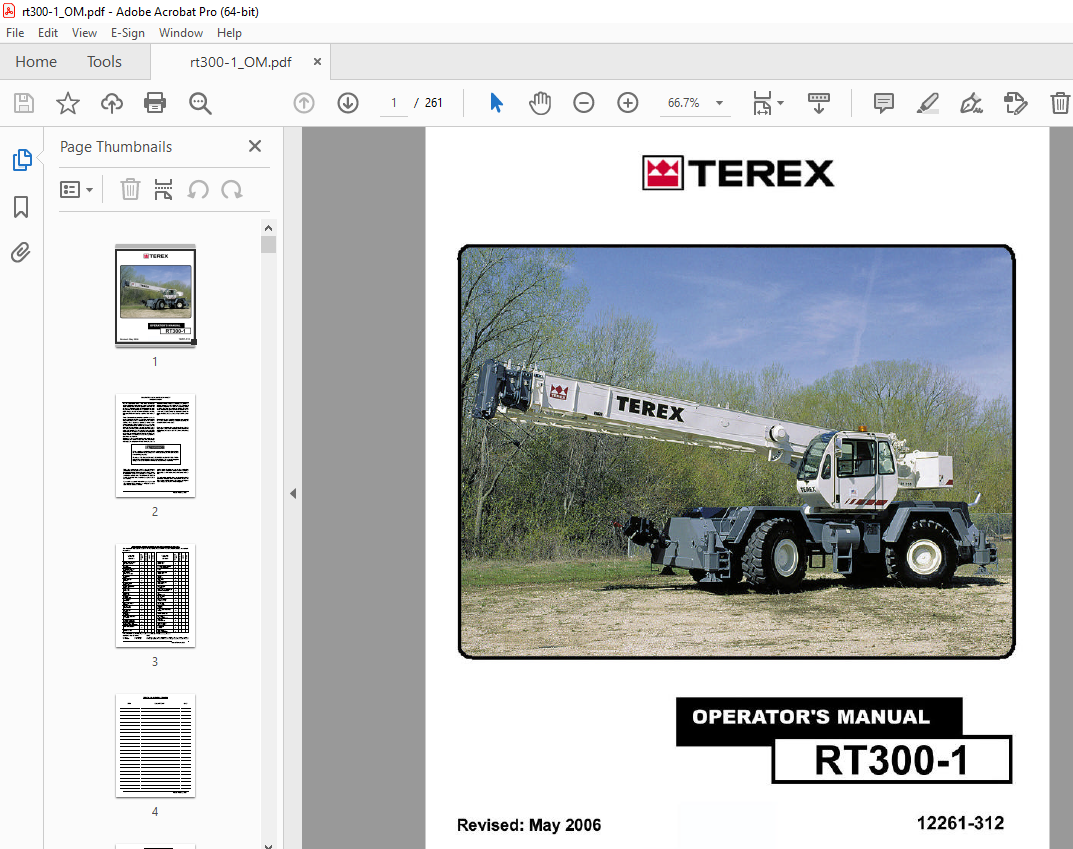

Terex Crane RT300-1 Operator’s Manual – PDF DOWNLOAD

Terex Crane RT300-1 Operator’s Manual – PDF DOWNLOAD

FILE DETAILS:

Terex Crane RT300-1 Operator’s Manual – PDF DOWNLOAD

Language : English

Pages : 261

Downloadable : Yes

File Type : PDF

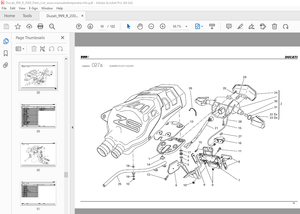

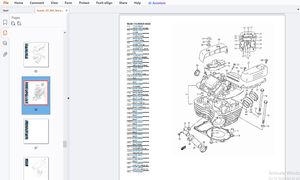

IMAGES PREVIEW OF THE MANUAL:

TABLE OF CONTENTS:

Terex Crane RT300-1 Operator’s Manual – PDF DOWNLOAD

SAFETY

INDEX

SECTION 1

SUBJECT PAGE

Introduction 1 – 1

Symbols 1 – 2

Handling Personnel 1 – 3

Training and Knowledge 1 – 3

Operator’s Responsibilities 1 – 4

Signal Person’s Responsibility 1 – 5

Responsibilities of All Crew Members 1 – 6

Management Responsibilty 1 – 6

Planning The Job 1 – 7

Operator’s Safety Check 1 – 8

Operator Aids Check 1 – 8

Operation Overload Protection 1 – 9

Operation Setup 1 – 10

Power Line Safety 1 – 10

Slip and Fall Prevention 1 – 11

Travel 1 – 11

CONTROLS AND INSTRUMENTS

Revised: April 2005

INDEX

SECTION 2

SUBJECT PAGE

Universal Symbol Identification 2 – 1

Upper Controls & Instruments 2 – 4

Upper Controls & Instruments Key 2 – 5

Upper Controls & Instruments 2 – 6

PRE-START INSPECTION 3 – 1

SAFETY EQUIPMENT 3 – 2

STARTING THE ENGINE 3 – 2

OPERATING THE ENGINE 3 – 3

COLD WEATHER STARTING 3 – 3

JUMP STARTING AN ENGINE WITH BOOSTER CABLES 3 – 4

VEHICULAR OPERATION 3 – 4

TRAVELLING AROUND THE JOBSITE 3 – 5

MAKING A TYPICAL LIFT 3 – 6

CRANE HAND SIGNALS 3 – 10

“ON TIRES” LIFTS 3 – 11

HOIST LINE REEVING 3 – 12

HOIST LINE REEVING 3 – 13

WIRE ROPE SPECIFICATIONS 3 – 13

AUXILIARY WINCH 3 – 13

TRANSPORTING THE CRANE 3 – 14

SIDE STOW OFFSET JIB 3 – 14

UNUSUAL OPERATING CONDITIONS 3 – 20

LOAD RATING CHART INTERPRETATION 3 – 23

LUBRICATION CHART 4 – 1

INTRODUCTION 4 – 2

MACHINE MAINTENANCE CHECK LIST 4 – 3

WIRE ROPE INSPECTION RECORD 4 – 6

ENGINE MAINTENANCE 4 – 7

ENGINE RADIATOR MAINTENANCE 4 – 8

TRANSMISSION MAINTENANCE 4 – 9

TRANSMISSION 4 – 10

AXLE MAINTENANCE 4 – 11

TIRES 4 – 12

AIR SYSTEM MAINTENANCE 4 – 14

BRAKE SYSTEM 4 – 15

TURNTABLE & SWING PINION 4 – 17

SWING REDUCER 4 – 18

HYDRAULIC SYSTEM MAINTENANCE 4 – 19

HYDRAULIC OIL REQUIREMENTS 4 – 21

CABLE LUBRICATION METHODS 4 – 26

ELECTRICAL SYSTEM BATTERY CHECK 4 – 27

ELECTRICAL SYSTEM COLLECTOR RING 4 – 29

CABLE REEVING 4 – 31

SPOOLING WIRE ROPE ON DRUMS 4 – 31

WIRE ROPE & REEVING 4 – 32

WIRE ROPE SPECIFICATIONS 4 – 32

CRANE BOOM 4 – 35

AIR DRYER 4 – 36

SLIDER PADS 4 – 36

General Procedure 5 – 1

Hydraulic – General 5 – 2

Operator Controls 5 – 3

Front Axle 5 – 4

Steering Circuit 5 – 6

Alternator 5 – 10

Starter 5 – 11

Brakes 5 – 12

Parking Brake 5 – 13

Air Pressure 5 – 13

Swing Circuit 5 – 14

Boom Hoist Circuit 5 – 15

Boom Telescope Circuit 5 – 16

Winch Circuit 5 – 17

Outrigger Circuit 5 – 19

Pumps 5 – 21

Control Valves 5 – 24

Relief Valves 5 – 25

Fluid Motor 5 – 26

Cylinders 5 – 28

Cylinder Leakage 5 – 29

Excessive Heating Of Oil In System 5 – 30

Electrical Controls 5 – 31

Propane Heater 5 – 32

Maintenance Free Battery Testing 5 – 35

Anti Two Block System 5 – 37

VALVE ADJUSTMENTS 6 – 1

SWING RELIEF VALVE ADJUSTMENT 6 – 3

ROTARY MANIFOLD 6 – 5

STEERING PRIORITY VALVE ADJUSTMENT 6 – 7

BOOM ALIGNMENT AND ADJUSTMENT 6 – 8

BOOM CHAIN ADJUSTMENT 6 – 10

AXLE LOCKOUT SYSTEM 6 – 12

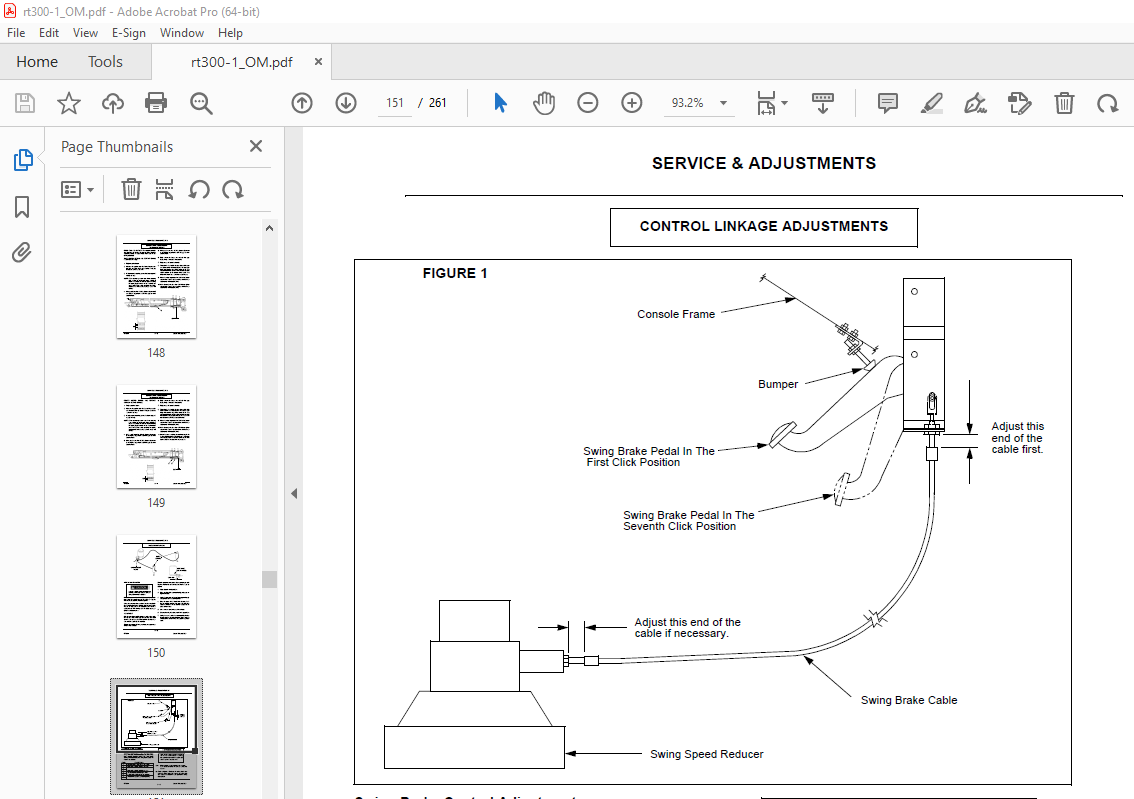

SWING BRAKE CONTROL ADJUSTMENT 6 – 13

RING GEAR BOLTING SEQUENCE 6 – 15

TORQUE WRENCH EXTENSIONS 6 – 16

WELDING INSTRUCTIONS 6 – 17

HYDRAULIC CYLINDERS 6 – 19

WIRE ROPE AND REEVING 6 – 22

SPOOLING WIRE ROPE ON DRUMS 6 – 23

CABLE SOCKETS 6 – 24

SHORT TERM STORAGE 7 – 1

LONG TERM STORAGE 7 – 1

ENGINE STORAGE 7 – 1

RESTORING ENGINE TO SERVICE 7 – 4

TRANSMISSION STORAGE 7 – 4

RESTORING TRANSMISSION TO SERVICE 7 – 5

RESTORATION TO SERVICE 7 – 5

CHROME CYLINDER ROD STORAGE 7 – 6

CONVERSION TABLES 8 – 1

AVERAGE WEIGHT OF MATERIALS 8 – 3

SUGGESTED TORQUE RATINGS 8 – 4

MACHINE SPECIFICATIONS 8 – 6

WIRE ROPE USER’S MANUAL 9-1